Conducting Polyaniline Nanowire and Its Applications in Chemiresistive Sensing

Abstract

:1. Introduction

2. Polyaniline Nanowires: An Overview

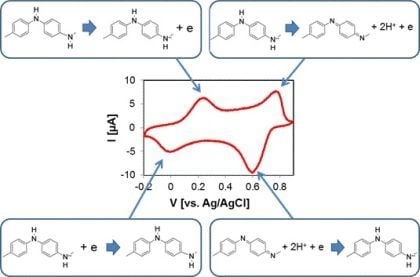

2.1. Chemical Structure and Electrochemical Properties

2.2. Electronic Conduction

3. Synthesis of Polyaniline Nanowires

3.1. Chemical Synthesis

3.2. Electrochemical Synthesis

3.2.1. Potentiostatic Growth

3.2.2. Galvanostatic Growth

3.2.3. Potentiodynamic Growth

3.2.4. Other Growth Methods

4. Polyaniline Nanowire-Based Chemiresistive Sensors

4.1. Potentiometric, Amperometric, and Conductometric Sensors

4.2. Gas Sensors

| Sensor Type | Sensing Material | Diameter (nm) | Analyte | Detection Limit (LOD) | Response Time | References |

|---|---|---|---|---|---|---|

| Surface acoustic wave | Polyaniline/In2O3 | 90 | H2, NO2, CO | ~ 2 ppm | ~ 30 s | [107] |

| Surface acoustic wave | Polyaniline | 30–50 | H2 | 0.06% | ~ 100 s | [108,109] |

| Amperometric | Polyaniline | 60–80 | nitrite | 5 × 10−8 M | ~ 5 s | [110] |

| Amperometric | Polyaniline/Au nanoparticles | 30–50 | glucose | 5 × 10−7 M | ~ 5 s | [111] |

| Chemiresistive | Polyaniline/CSA | ~100 | H2 | <1% | - | [15] |

| Chemiresistive | Polyaniline | 40–80 | NH3, HCl, EtOH | ~0.5 ppm | ~100 s | [17] |

| Chemiresistive | Polyaniline/Au nanoparticles | 80 | H2S, CH3SH | ~1 ppm | ~20 s | [101] |

| Chemiresistive | Polyaniline | 30–40 | CO | ~1 ppm | ~100 s | [100] |

| Chemiresistive | Polyaniline | 335 | NH3 | 0.5 ppm | ~75 s | [99] |

| Chemiresistive | Polyaniline | 30–120 | HCl, NH3, N2H4, CHCl3, CH3OH | 100 ppm | 2~200 s | [3] |

| Chemiresistive | SWCNT/Polyaniline | 15 | NO2, H2S | 500 ppb | ~10 min | [104] |

| Chemiresistive | Graphene/Polyaniline | 25–50 | H2 | - | ~1 min | [105] |

| Chemiresistive | Polyaniline/Au nanoparticles | 250–320 | H2S | 0.1 ppb | <2 min | [106] |

| Chemiresistive | polyaniline | 100 | humidity | - | ~1 min | [102] |

| Chemiresistive | Polyaniline/PVB/PEO | 100 | humidity | - | ~50 s | [103] |

| Target-guided formation method | Polyaniline | - | microRNA | 5 fM | 30–60 min | [94] |

| Labeled direct charge transfer | polyaniline | ~200 | Bacillus cereus | ~10 CFU/mL | - | [112] |

4.3. Biosensors

5. Current Limitations of Polyaniline-Based Sensors

6. Conclusions

Conflict of Interest

References

- Patolsky, F.; Zheng, G.; Lieber, C.M. Nanowire-based biosensors. Anal. Chem. 2006, 78, 4260–4269. [Google Scholar] [CrossRef]

- Bangar, M.A.; Shirale, D.J.; Purohit, H.J.; Chen, W.; Myung, N.V.; Mulchandani, A. Single conducting polymer nanowire chemiresistive label-free immunosensor for cancer biomarker. Anal. Chem. 2009, 81, 2168–2175. [Google Scholar]

- Virji, S.; Huang, J.; Kaner, R.B.; Weiller, B.H. Polyaniline nanofiber gas sensors: Examination of response mechanisms. Nano Lett. 2004, 4, 491–496. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, Y. Synthesis and applications of one-dimensional nano-structured polyaniline: An overview. Mater. Sci. Eng. B 2006, 134, 9–19. [Google Scholar] [CrossRef]

- Mulchandani, A.; Myung, N.V. Conducting polymer nanowires-based label-free biosensors. Curr. Opin. Biotechnol. 2011, 22, 502–508. [Google Scholar] [CrossRef]

- Ramgir, N.S.; Yang, Y.; Zacharias, M. Nanowire-based sensors. Small 2010, 6, 1705–1722. [Google Scholar] [CrossRef]

- Matlock-Colangelo, L.; Baeumner, A.J. Recent progress in the design of nanofiber-based biosensing devices. Lab. Chip 2012, 12, 2612–2620. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Wang, J. Carbon-nanotube based electrochemical biosensors: A review. Electroanalysis 2005, 17, 7–14. [Google Scholar] [CrossRef]

- Jacobs, C.B.; Peairs, M.J.; Venton, B.J. Review: Carbon nanotube based electrochemical sensors for biomolecules. Anal. Chim. Acta 2010, 662, 105–127. [Google Scholar] [CrossRef]

- Cui, Y.; Wei, Q.; Park, H.; Lieber, C.M. Nanowire nanosensors for highly sensitive and selective detection of biological and chemical species. Science 2001, 293, 1289–1292. [Google Scholar] [CrossRef]

- Patolsky, F.; Lieber, C.M. Nanowire nanosensors. Mater. Today 2005, 8, 20–28. [Google Scholar] [CrossRef]

- Yogeswaran, U.; Chen, S.-M. A review on the electrochemical sensors and biosensors composed of nanowires as sensing material. Sensors 2008, 8, 290–313. [Google Scholar] [CrossRef]

- Sunkara, M.K.; Sharma, S.; Miranda, R.; Lian, G.; Dickey, E.C. Bulk synthesis of silicon nanowires using a low-temperature vapor–liquid–solid method. Appl. Phys. Lett. 2001, 79, 1546–1548. [Google Scholar] [CrossRef]

- Virji, S.; Kaner, R.B.; Weiller, B.H. Hydrogen sensors based on conductivity changes in polyaniline nanofibers. J. Phys. Chem. B 2006, 110, 22266–22270. [Google Scholar] [CrossRef]

- Wang, J.; Bunimovich, Y.L.; Sui, G.; Savvas, S.; Wang, J.; Guo, Y.; Heath, J.R.; Tseng, H.-R. Electrochemical fabrication of conducting polymer nanowires in an integrated microfluidic system. Chem. Commun. 2006, 29, 3075–3077. [Google Scholar]

- Wang, J.; Chan, S.; Carlson, R.R.; Luo, Y.; Ge, G.; Ries, R.S.; Heath, J.R.; Tseng, H.-R. Electrochemically fabricated polyaniline nanoframework electrode junctions that function as resistive sensors. Nano Lett. 2004, 4, 1693–1697. [Google Scholar] [CrossRef]

- Kuhn, P.; Puigmartí-Luis, J.; Imaz, I.; Maspoch, D.; Dittrich, P.S. Controlling the length and location of in situ formed nanowires by means of microfluidic tools. Lab Chip 2011, 11, 753–757. [Google Scholar] [CrossRef]

- Hou, S.; Wang, S.; Yu, Z.T.F.; Zhu, N.Q.M.; Liu, K.; Sun, J.; Lin, W.-Y.; Shen, C.K.-F.; Fang, X.; Tseng, H.-R. A hydrodynamically focused stream as a dynamic template for site-specific electrochemical micropatterning of conducting polymers. Angew. Chem. 2008, 120, 1088–1091. [Google Scholar] [CrossRef]

- Puigmartí-Luis, J.; Schaffhauser, D.; Burg, B.R.; Dittrich, P.S. A microfluidic approach for the formation of conductive nanowires and hollow hybrid structures. Adv. Mater. 2010, 22, 2255–2259. [Google Scholar] [CrossRef]

- Shirakawa, H.; Louis, E.J.; MacDiarmid, A.G.; Chiang, C.K.; Heeger, A.J. Synthesis of electrically conducting organic polymers: Halogen derivatives of polyacetylene, (CH)x. J. Chem. Soc. Chem. Commun. 1977, 1977, 578–580. [Google Scholar]

- Macdiarmid, A.G.; Chiang, J.C.; Richter, A.F.; Epstein, A.J. Polyaniline: A new concept in conducting polymers. Synth. Met. 1987, 18, 285–290. [Google Scholar] [CrossRef]

- Sergeyeva, T.A.; Lavrik, N.V.; Piletsky, S.A.; Rachkov, A.E.; El’skaya, A.V. Polyaniline label-based conductometric sensor for IgG detection. Sens. Actuators B 1996, 34, 283–288. [Google Scholar]

- Gerard, M.; Chaubey, A.; Malhotra, B.D. Application of conducting polymers to biosensors. Biosens. Bioelectron. 2002, 17, 345–359. [Google Scholar]

- Dhand, C.; Das, M.; Datta, M.; Malhotra, B.D. Recent advances in polyaniline based biosensors. Biosens. Bioelectron. 2011, 26, 2811–2821. [Google Scholar] [CrossRef]

- Lange, U.; Roznyatovskaya, N.V.; Mirsky, V.M. Conducting polymers in chemical sensors and arrays. Anal. Chim. Acta 2008, 614, 1–26. [Google Scholar] [CrossRef]

- Reddinger, J.; Reynolds, J. Molecular Engineering of π-Conjugated Polymers. In Advances in Polymer Science; Springer: Berlin, Heidelberg, Germany, 1999; Volume 145, pp. 57–122. [Google Scholar]

- MacDiarmid, A.G.; Epstein, A.J. Polyanilines: A novel class of conducting polymers. Faraday Discuss. Chem. Soc. 1989, 88, 317–332. [Google Scholar] [CrossRef]

- Syed, A.A.; Dinesan, M.K. Review: Polyaniline—A novel polymeric material. Talanta 1991, 38, 815–837. [Google Scholar] [CrossRef]

- Geniès, E.M.; Boyle, A.; Lapkowski, M.; Tsintavis, C. Polyaniline: A historical survey. Synth. Met. 1990, 36, 139–182. [Google Scholar] [CrossRef]

- Huang, W.-S.; Humphrey, B.D.; MacDiarmid, A.G. Polyaniline, a novel conducting polymer. Morphology and chemistry of its oxidation and reduction in aqueous electrolytes. J. Chem. Soc. Faraday Trans. 1 1986, 82, 2385–2400. [Google Scholar] [CrossRef]

- Bhadra, S.; Khastgir, D.; Singha, N.K.; Lee, J.H. Progress in preparation, processing and applications of polyaniline. Prog. Polym. Sci. 2009, 34, 783–810. [Google Scholar] [CrossRef]

- Stejskal, J.; Sapurina, I.; Trchová, M. Polyaniline nanostructures and the role of aniline oligomers in their formation. Prog. Polym. Sci. 2010, 35, 1420–1481. [Google Scholar]

- Tran, H.D.; Wang, Y.; D’Arcy, J.M.; Kaner, R.B. Toward an understanding of the formation of conducting polymer nanofibers. ACS Nano 2008, 2, 1841–1848. [Google Scholar] [CrossRef]

- Gupta, V.; Miura, N. Large-area network of polyaniline nanowires prepared by potentiostatic deposition process. Electrochem. Commun. 2005, 7, 995–999. [Google Scholar]

- Macdiarmid, A.G.; Mu, S.-L.; Somasiri, N.L.D.; Wu, W. Electrochemical characteristics of “polyaniline” cathodes and anodes in aqueous electrolytes. Mol. Cryst. Liq. Cryst. 1985, 121, 187–190. [Google Scholar] [CrossRef]

- Gupta, V.; Miura, N. High performance electrochemical supercapacitor from electrochemically synthesized nanostructured polyaniline. Mater. Lett. 2006, 60, 1466–1469. [Google Scholar] [CrossRef]

- Zhiani, M.; Gharibi, H.; Kakaei, K. Performing of novel nanostructure MEA based on polyaniline modified anode in direct methanol fuel cell. J. Power Sources 2012, 210, 42–46. [Google Scholar] [CrossRef]

- Kelly, F.M.; Meunier, L.; Cochrane, C.; Koncar, V. Polyaniline: Application as solid state electrochromic in a flexible textile display. Displays 2013, 34, 1–7. [Google Scholar] [CrossRef]

- Anderson, M.R.; Mattes, B.R.; Reiss, H.; Kaner, R.B. Conjugated polymer films for gas separations. Science 1991, 252, 1412–1415. [Google Scholar]

- Chang, C.-H.; Huang, T.-C.; Peng, C.-W.; Yeh, T.-C.; Lu, H.-I.; Hung, W.-I.; Weng, C.-J.; Yang, T.-I.; Yeh, J.-M. Novel anticorrosion coatings prepared from polyaniline/graphene composites. Carbon 2012, 50, 5044–5051. [Google Scholar] [CrossRef]

- Focke, W.W.; Wnek, G.E.; Wei, Y. Influence of oxidation state, pH, and counterion on the conductivity of polyaniline. J. Phys. Chem. 1987, 91, 5813–5818. [Google Scholar] [CrossRef]

- Zhang, X.; Goux, W.J.; Manohar, S.K. Synthesis of polyaniline nanofibers by “nanofiber seeding”. J. Am. Chem. Soc. 2004, 126, 4502–4503. [Google Scholar] [CrossRef]

- Stafström, S.; Brédas, J.L.; Epstein, A.J.; Woo, H.S.; Tanner, D.B.; Huang, W.S.; MacDiarmid, A.G. Polaron lattice in highly conducting polyaniline: Theoretical and optical studies. Phys. Rev. Lett. 1987, 59, 1464–1467. [Google Scholar]

- Heeger, A.J. Semiconducting and metallic polymers: The fourth generation of polymeric materials. J. Phys. Chem. B 2001, 105, 8475–8491. [Google Scholar] [CrossRef]

- Ray, A.; Richter, A.F.; MacDiarmid, A.G.; Epstein, A.J. Polyaniline: Protonation/deprotonation of amine and imine sites. Synth. Met. 1989, 29, 151–156. [Google Scholar]

- Nechtschein, M.; Genoud, F.; Menardo, C.; Mizoguchi, K.; Travers, J.P.; Villeret, B. On the nature of the conducting state of polyaniline. Synth. Met. 1989, 29, 211–218. [Google Scholar]

- McManus, P.M.; Cushman, R.J.; Yang, S.C. Influence of oxidation and protonation on the electrical conductivity of polyaniline. J. Phys. Chem. 1987, 91, 744–747. [Google Scholar] [CrossRef]

- Genies, E.M.; Tsintavis, C. Redox mechanism and electrochemical behaviour or polyaniline deposits. J. Electroanal. Chem. Interfacial Electrochem. 1985, 195, 109–128. [Google Scholar]

- Geniès, E.M.; Lapkowski, M.; Penneau, J.F. Cyclic voltammetry of polyaniline: Interpretation of the middle peak. J. Electroanal. Chem. Interfacial Electrochem. 1988, 249, 97–107. [Google Scholar] [CrossRef]

- Nunziante, P.; Pistoia, G. Factors affecting the growth of thick polyaniline films by the cyclic voltammetry technique. Electrochim. Acta 1989, 34, 223–228. [Google Scholar] [CrossRef]

- MacDiarmid, A.G. “Synthetic metals”: A novel role for organic polymers (Nobel lecture). Angew. Chem. Int. Ed. 2001, 40, 2581–2590. [Google Scholar] [CrossRef]

- Focke, W.W.; Wnek, G.E. Conduction mechanisms in polyaniline (emeraldine salt). J. Electroanal. Chem. Interfacial Electrochem. 1988, 256, 343–352. [Google Scholar] [CrossRef]

- Saheb, A.H.; Seo, S.S. UV-vis and Raman spectral analysis of polyaniline/gold thin films as a function of applied potential. Anal. Lett. 2011, 44, 1206–1216. [Google Scholar] [CrossRef]

- Kobayashi, T.; Yoneyama, H.; Tamura, H. Electrochemical reactions concerned with electrochromism of polyaniline film-coated electrodes. J. Electroanal. Chem. Interfacial Electrochem. 1984, 177, 281–291. [Google Scholar]

- Li, Q.; Cruz, L.; Phillips, P. Granular-rod model for electronic conduction in polyaniline. Phys. Rev. B 1993, 47, 1840–1845. [Google Scholar] [CrossRef]

- Li, W.; Wan, M. Porous polyaniline films with high conductivity. Synth. Met. 1998, 92, 121–126. [Google Scholar] [CrossRef]

- Mott, N.F.; Davis, E.A. Electronic Processes in Non-Crystalline Materials; Oxford University Press: Oxford, UK, 2012. [Google Scholar]

- Joo, J.; Long, S.M.; Pouget, J.P.; Oh, E.J.; MacDiarmid, A.G.; Epstein, A.J. Charge transport of the mesoscopic metallic state in partially crystalline polyanilines. Phys. Rev. B 1998, 57, 9567–9580. [Google Scholar] [CrossRef]

- Ghosh, M.; Barman, A.; De, S.K.; Chatterjee, S. Crossover from Mott to Efros-Shklovskii variable-range-hopping conductivity in conducting polyaniline. Synth. Met. 1998, 97, 23–29. [Google Scholar] [CrossRef]

- Sheng, P.; Abeles, B.; Arie, Y. Hopping conductivity in granular metals. Phys. Rev. Lett. 1973, 31, 44–47. [Google Scholar] [CrossRef]

- Lin, Y.-F.; Chen, C.-H.; Xie, W.-J.; Yang, S.-H.; Hsu, C.-S.; Lin, M.-T.; Jian, W.-B. Nano approach investigation of the conduction mechanism in polyaniline nanofibers. ACS Nano 2011, 5, 1541–1548. [Google Scholar] [CrossRef]

- Zhou, Y.; Freitag, M.; Hone, J.; Staii, C.; Johnson, A.T.; Pinto, N.J.; MacDiarmid, A.G. Fabrication and electrical characterization of polyaniline-based nanofibers with diameter below 30 nm. Appl. Phys. Lett. 2003, 83, 3800–3802. [Google Scholar]

- Liu, W.; Kumar, J.; Tripathy, S.; Senecal, K.J.; Samuelson, L. Enzymatically synthesized conducting polyaniline. J. Am. Chem. Soc. 1999, 121, 71–78. [Google Scholar]

- Ma, Y.; Zhang, J.; Zhang, G.; He, H. Polyaniline nanowires on Si surfaces fabricated with DNA templates. J. Am. Chem. Soc. 2004, 126, 7097–7101. [Google Scholar]

- Trchová, M.; Šeděnková, I.; Konyushenko, E.N.; Stejskal, J.; Holler, P.; Ćirić-Marjanović, G. Evolution of polyaniline nanotubes: The oxidation of aniline in water. J. Phys. Chem. B 2006, 110, 9461–9468. [Google Scholar]

- Zhang, L.; Zujovic, Z.D.; Peng, H.; Bowmaker, G.A.; Kilmartin, P.A.; Travas-Sejdic, J. Structural characteristics of polyaniline nanotubes synthesized from different buffer solutions. Macromolecules 2008, 41, 8877–8884. [Google Scholar] [CrossRef]

- Chiou, N.-R.; Epstein, A.J. Polyaniline nanofibers prepared by dilute polymerization. Adv. Mater. 2005, 17, 1679–1683. [Google Scholar] [CrossRef]

- Wei, Y.; Tang, X.; Sun, Y.; Focke, W.W. A study of the mechanism of aniline polymerization. J. Polym. Sci. Part Polym. Chem. 1989, 27, 2385–2396. [Google Scholar]

- Yang, H.; Bard, A.J. The application of fast scan cyclic voltammetry. Mechanistic study of the initial stage of electropolymerization of aniline in aqueous solutions. J. Electroanal. Chem. 1992, 339, 423–449. [Google Scholar] [CrossRef]

- Li, D.; Huang, J.; Kaner, R.B. Polyaniline nanofibers: A unique polymer nanostructure for versatile applications. Acc. Chem. Res. 2009, 42, 135–145. [Google Scholar] [CrossRef]

- Huang, J.; Kaner, R.B. Nanofiber formation in the chemical polymerization of aniline: A mechanistic study. Angew. Chem. 2004, 116, 5941–5945. [Google Scholar] [CrossRef]

- Dias, H.V.R.; Wang, X.; Rajapakse, R.M.G.; Elsenbaumer, R.L. A mild, copper catalyzed route to conducting polyaniline. Chem. Commun. 2006, 976–978. [Google Scholar]

- Huang, J.; Kaner, R.B. A general chemical route to polyaniline nanofibers. J. Am. Chem. Soc. 2004, 126, 851–855. [Google Scholar] [CrossRef]

- Huang, J.; Virji, S.; Weiller, B.H.; Kaner, R.B. Polyaniline nanofibers: Facile synthesis and chemical sensors. J. Am. Chem. Soc. 2003, 125, 314–315. [Google Scholar] [CrossRef]

- Qiang, J.; Yu, Z.; Wu, H.; Yun, D. Polyaniline nanofibers synthesized by rapid mixing polymerization. Synth. Met. 2008, 158, 544–547. [Google Scholar] [CrossRef]

- Martin, C.R. Template synthesis of electronically conductive polymer nanostructures. Acc. Chem. Res. 1995, 28, 61–68. [Google Scholar] [CrossRef]

- Martin, C.R. Nanomaterials: A membrane-based synthetic approach. Science 1994, 266, 1961–1966. [Google Scholar]

- Li, G.; Zhang, C.; Li, Y.; Peng, H.; Chen, K. Rapid polymerization initiated by redox initiator for the synthesis of polyaniline nanofibers. Polymer 2010, 51, 1934–1939. [Google Scholar] [CrossRef]

- Kitani, A.; Kaya, M.; Yano, J.; Yoshikawa, K.; Sasaki, K. “Polyaniline”: Formation reaction and structure. Synth. Met. 1987, 18, 341–346. [Google Scholar] [CrossRef]

- Liang, L.; Liu, J.; Windisch, C.F., Jr.; Exarhos, G.J.; Lin, Y. Direct assembly of large arrays of oriented conducting polymer nanowires. Angew. Chem. Int. Ed. 2002, 41, 3665–3668. [Google Scholar] [CrossRef]

- Choi, S.-J.; Park, S.-M. Electrochemical growth of nanosized conducting polymer wires on gold using molecular templates. Adv. Mater. 2000, 12, 1547–1549. [Google Scholar] [CrossRef]

- Stilwell, D.E.; Park, S.-M. Electrochemistry of conductive polymers IV electrochemical studies on polyaniline degradation—Product identification and coulometric studies. J. Electrochem. Soc. 1988, 135, 2497–2502. [Google Scholar] [CrossRef]

- Huang, L.; Wang, Z.; Wang, H.; Cheng, X.; Mitra, A.; Yan, Y. Polyaniline nanowires by electropolymerization from liquid crystalline phases. J. Mater. Chem. 2002, 12, 388–391. [Google Scholar] [CrossRef]

- Mu, S.; Yang, Y. Spectral characteristics of polyaniline nanostructures synthesized by using cyclic voltammetry at different scan rates. J. Phys. Chem. B 2008, 112, 11558–11563. [Google Scholar] [CrossRef]

- Diaz, A.F.; Logan, J.A. Electroactive polyaniline films. J. Electroanal. Chem. Interfacial Electrochem. 1980, 111, 111–114. [Google Scholar] [CrossRef]

- Huang, Z.-M.; Zhang, Y.-Z.; Kotaki, M.; Ramakrishna, S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos. Sci. Technol. 2003, 63, 2223–2253. [Google Scholar]

- Reneker, D.H.; Chun, I. Nanometre diameter fibres of polymer, produced by electrospinning. Nanotechnology 1996, 7, 216–223. [Google Scholar] [CrossRef]

- Van Dyke, L.S.; Martin, C.R. Electrochemical investigations of electronically conductive polymers. 4. Controlling the supermolecular structure allows charge transport rates to be enhanced. Langmuir 1990, 6, 1118–1123. [Google Scholar]

- Martin, C.R. Membrane-based synthesis of nanomaterials. Chem. Mater. 1996, 8, 1739–1746. [Google Scholar] [CrossRef]

- Parthasarathy, R.V.; Martin, C.R. Template-synthesized polyaniline microtubules. Chem. Mater. 1994, 6, 1627–1632. [Google Scholar] [CrossRef]

- Jackowska, K.; Bieguński, A.; Tagowska, M. Hard template synthesis of conducting polymers: A route to achieve nanostructures. J. Solid State Electrochem. 2008, 12, 437–443. [Google Scholar] [CrossRef]

- Xiao, Y.; Kharitonov, A.B.; Patolsky, F.; Weizmann, Y.; Willner, I. Electrocatalytic intercalator-induced winding of double-stranded DNA with polyaniline. Chem. Commun. 2003, 2003, 1540–1541. [Google Scholar]

- Fan, Y.; Chen, X.; Trigg, A.D.; Tung, C.; Kong, J.; Gao, Z. Detection of microRNAs using target-guided formation of conducting polymer nanowires in nanogaps. J. Am. Chem. Soc. 2007, 129, 5437–5443. [Google Scholar] [CrossRef]

- Liu, W.; Anagnostopoulos, A.; Bruno, F.F.; Senecal, K.; Kumar, J.; Tripathy, S.; Samuelson, L. Biologically derived water soluble conducting polyaniline. Synth. Met. 1999, 101, 738–741. [Google Scholar] [CrossRef]

- Bergveld, P. Development of an ion-sensitive solid-state device for neurophysiological measurements. IEEE Trans. Biomed. Eng. 1970, BME-17, 70–71. [Google Scholar] [CrossRef]

- Bergveld, P. Thirty years of ISFETOLOGY: What happened in the past 30 years and what may happen in the next 30 years. Sens. Actuators B 2003, 88, 1–20. [Google Scholar] [CrossRef]

- Bergveld, P. Development, operation, and application of the ion-sensitive field-effect transistor as a tool for electrophysiology. IEEE Trans. Biomed. Eng. 1972, BME-19, 342–351. [Google Scholar] [CrossRef]

- Liu, H.; Kameoka, J.; Czaplewski, D.A.; Craighead, H.G. Polymeric nanowire chemical sensor. Nano Lett. 2004, 4, 671–675. [Google Scholar] [CrossRef]

- Liu, C.; Noda, Z.; Sasaki, K.; Hayashi, K. Development of a polyaniline nanofiber-based carbon monoxide sensor for hydrogen fuel cell application. Int. J. Hydrog. Energy 2012, 37, 13529–13535. [Google Scholar] [CrossRef]

- Liu, C.; Hayashi, K.; Toko, K. Au nanoparticles decorated polyaniline nanofiber sensor for detecting volatile sulfur compounds in expired breath. Sens. Actuators B 2012, 161, 504–509. [Google Scholar] [CrossRef]

- Zeng, F.-W.; Liu, X.-X.; Diamond, D.; Lau, K.T. Humidity sensors based on polyaniline nanofibres. Sens. Actuators B 2010, 143, 530–534. [Google Scholar] [CrossRef]

- Lin, Q.; Li, Y.; Yang, M. Polyaniline nanofiber humidity sensor prepared by electrospinning. Sens. Actuators B 2012, 161, 967–972. [Google Scholar] [CrossRef]

- Lim, J.-H.; Phiboolsirichit, N.; Mubeen, S.; Deshusses, M.A.; Mulchandani, A.; Myung, N.V. Electrical and gas sensing properties of polyaniline functionalized single-walled carbon nanotubes. Nanotechnology 2010, 21, 075502:1–075502:7. [Google Scholar]

- Al-Mashat, L.; Shin, K.; Kalantar-zadeh, K.; Plessis, J.D.; Han, S.H.; Kojima, R.W.; Kaner, R.B.; Li, D.; Gou, X.; Ippolito, S.J.; et al. Graphene/polyaniline nanocomposite for hydrogen sensing. J. Phys. Chem. C 2010, 114, 16168–16173. [Google Scholar] [CrossRef]

- Shirsat, M.D.; Bangar, M.A.; Deshusses, M.A.; Myung, N.V.; Mulchandani, A. Polyaniline nanowires-gold nanoparticles hybrid network based chemiresistive hydrogen sulfide sensor. Appl. Phys. Lett. 2009, 94, 083502:1–083502:3. [Google Scholar]

- Sadek, A.Z.; Wlodarski, W.; Shin, K.; Kaner, R.B.; Kalantar-zadeh, K. A layered surface acoustic wave gas sensor based on a polyaniline/In2O3 nanofibre composite. Nanotechnology 2006, 17, 4488–4492. [Google Scholar] [CrossRef]

- Sadek, A.Z.; Baker, C.O.; Powell, D.A.; Wlodarski, W.; Kaner, R.B.; Kalantar-zadeh, K. Polyaniline nanofiber based surface acoustic wave gas sensors-effect of nanofiber diameter on H2 response. IEEE Sens. J. 2007, 7, 213–218. [Google Scholar] [CrossRef]

- Arsat, R.; Yu, X.F.; Li, Y.X.; Wlodarski, W.; Kalantar-zadeh, K. Hydrogen gas sensor based on highly ordered polyaniline nanofibers. Sens. Actuators B 2009, 137, 529–532. [Google Scholar] [CrossRef]

- Wang, H.; Yang, P.-H.; Cai, H.-H.; Cai, J. Constructions of polyaniline nanofiber-based electrochemical sensor for specific detection of nitrite and sensitive monitoring of ascorbic acid scavenging nitrite. Synth. Met. 2012, 162, 326–331. [Google Scholar] [CrossRef]

- Xian, Y.; Hu, Y.; Liu, F.; Xian, Y.; Wang, H.; Jin, L. Glucose biosensor based on Au nanoparticles–conductive polyaniline nanocomposite. Biosens. Bioelectron. 2006, 21, 1996–2000. [Google Scholar] [CrossRef]

- Pal, S.; Alocilja, E.C.; Downes, F.P. Nanowire labeled direct-charge transfer biosensor for detecting Bacillus species. Biosens. Bioelectron. 2007, 22, 2329–2336. [Google Scholar] [CrossRef]

- Li, G.; Martinez, C.; Janata, J.; Smith, J.A.; Josowicz, M.; Semancik, S. Effect of morphology on the response of polyaniline-based conductometric gas sensors: Nanofibers vs. thin films. Electrochem. Solid-State Lett. 2004, 7, H44–H47. [Google Scholar] [CrossRef]

- Nicolas-Debarnot, D.; Poncin-Epaillard, F. Polyaniline as a new sensitive layer for gas sensors. Anal. Chim. Acta 2003, 475, 1–15. [Google Scholar] [CrossRef]

- Huang, J.; Virji, S.; Weiller, B.H.; Kaner, R.B. Nanostructured polyaniline sensors. Chem. Eur. J. 2004, 10, 1314–1319. [Google Scholar] [CrossRef]

- Sadek, A.Z.; Wlodarski, W.; Kalantar-Zadeh, K.; Baker, C.; Kaner, R.B. Doped and dedoped polyaniline nanofiber based conductometric hydrogen gas sensors. Sens. Actuators A 2007, 139, 53–57. [Google Scholar] [CrossRef]

- Liao, Y.; Zhang, C.; Zhang, Y.; Strong, V.; Tang, J.; Li, X.-G.; Kalantar-zadeh, K.; Hoek, E.M.V.; Wang, K.L.; Kaner, R.B. Carbon nanotube/polyaniline composite nanofibers: Facile synthesis and chemosensors. Nano Lett. 2011, 11, 954–959. [Google Scholar] [CrossRef]

- Liao, Y.; Zhang, C.; Wang, X.; Li, X.-G.; Ippolito, S.J.; Kalantar-zadeh, K.; Kaner, R.B. Carrier mobility of single-walled carbon nanotube-reinforced polyaniline nanofibers. J. Phys. Chem. C 2011, 115, 16187–16192. [Google Scholar]

- Kaner, R.B. Gas, liquid and enantiomeric separations using polyaniline. Synth. Met. 2001, 125, 65–71. [Google Scholar] [CrossRef]

- Liao, Y.; Yu, D.-G.; Wang, X.; Chain, W.; Li, X.-G.; Hoek, E.M.V.; Kaner, R.B. Carbon nanotube-templated polyaniline nanofibers: Synthesis, flash welding and ultrafiltration membranes. Nanoscale 2013, 5, 3856–3862. [Google Scholar] [CrossRef]

- Guillen, G.R.; Farrell, T.P.; Kaner, R.B.; Hoek, E.M.V. Pore-structure, hydrophilicity, and particle filtration characteristics of polyaniline–polysulfone ultrafiltration membranes. J. Mater. Chem. 2010, 20, 4621–4628. [Google Scholar] [CrossRef]

- Blinova, N.V.; Svec, F. Functionalized polyaniline-based composite membranes with vastly improved performance for separation of carbon dioxide from methane. J. Membr. Sci. 2012, 423–424, 514–521. [Google Scholar] [CrossRef]

- Clark, L.C.; Lyons, C. Electrode systems for continuous monitoring in cardiovascular surgery. Ann. N. Y. Acad. Sci. 1962, 102, 29–45. [Google Scholar] [CrossRef]

- Wang, J. Electrochemical glucose biosensors. Chem. Rev. 2008, 108, 814–825. [Google Scholar] [CrossRef]

- Bartlett, P.N.; Astier, Y. Microelectrochemical enzyme transistors. Chem. Commun. 2000, 2000, 105–112. [Google Scholar] [CrossRef]

- White, H.S.; Kittlesen, G.P.; Wrighton, M.S. Chemical derivatization of an array of three gold microelectrodes with polypyrrole: Fabrication of a molecule-based transistor. J. Am. Chem. Soc. 1984, 106, 5375–5377. [Google Scholar] [CrossRef]

- Ofer, D.; Crooks, R.M.; Wrighton, M.S. Potential dependence of the conductivity of highly oxidized polythiophenes, polypyrroles, and polyaniline: Finite windows of high conductivity. J. Am. Chem. Soc. 1990, 112, 7869–7879. [Google Scholar] [CrossRef]

- Bartlett, P.N.; Birkin, P.R. A microelectrochemical enzyme transistor responsive to glucose. Anal. Chem. 1994, 66, 1552–1559. [Google Scholar] [CrossRef]

- Bartlett, P.N.; Birkin, P.R.; Wang, J.H.; Palmisano, F.; De Benedetto, G. An enzyme switch employing direct electrochemical communication between horseradish peroxidase and a poly(aniline) film. Anal. Chem. 1998, 70, 3685–3694. [Google Scholar] [CrossRef]

- Battaglini, F.; Bartlett, P.N.; Wang, J.H. Covalent attachment of osmium complexes to glucose oxidase and the application of the resulting modified enzyme in an enzyme switch responsive to glucose. Anal. Chem. 2000, 72, 502–509. [Google Scholar] [CrossRef]

- Forzani, E.S.; Zhang, H.; Nagahara, L.A.; Amlani, I.; Tsui, R.; Tao, N. A conducting polymer nanojunction sensor for glucose detection. Nano Lett. 2004, 4, 1785–1788. [Google Scholar] [CrossRef]

- Yuk, J.S.; Jin, J.-H.; Alocilja, E.C.; Rose, J.B. Performance enhancement of polyaniline-based polymeric wire biosensor. Biosens. Bioelectron. 2009, 24, 1348–1352. [Google Scholar] [CrossRef]

- Muhammad-Tahir, Z.; Alocilja, E.C. A conductometric biosensor for biosecurity. Biosens. Bioelectron. 2003, 18, 813–819. [Google Scholar] [CrossRef]

- Tahir, Z.M.; Alocilja, E.C.; Grooms, D.L. Polyaniline synthesis and its biosensor application. Biosens. Bioelectron. 2005, 20, 1690–1695. [Google Scholar] [CrossRef]

- Forzani, E.S.; Li, X.; Tao, N. Hybrid amperometric and conductometric chemical sensor based on conducting polymer nanojunctions. Anal. Chem. 2007, 79, 5217–5224. [Google Scholar] [CrossRef]

- Gao, Z.Q.; Rafea, S.; Lim, L.H. Detection of nucleic acids using enzyme-catalyzed template-guided deposition of polyaniline. Adv. Mater. 2007, 19, 602–606. [Google Scholar] [CrossRef]

- Chang, H.; Yuan, Y.; Shi, N.; Guan, Y. Electrochemical DNA biosensor based on conducting polyaniline nanotube array. Anal. Chem. 2007, 79, 5111–5115. [Google Scholar] [CrossRef]

- Castillo-Ortega, M.M.; Rodriguez, D.E.; Encinas, J.C.; Plascencia, M.; Méndez-Velarde, F.A.; Olayo, R. Conductometric uric acid and urea biosensor prepared from electroconductive polyaniline–poly(n-butyl methacrylate) composites. Sens. Actuators B 2002, 85, 19–25. [Google Scholar] [CrossRef]

- Sangodkar, H.; Sukeerthi, S.; Srinivasa, R.S.; Lal, R.; Contractor, A.Q. A biosensor array based on polyaniline. Anal. Chem. 1996, 68, 779–783. [Google Scholar] [CrossRef]

- Muhammad-Tahir, Z.; Alocilja, E.C. Fabrication of a disposable biosensor for Escherichia coli O157:H7 detection. IEEE Sens. J. 2003, 3, 345–351. [Google Scholar] [CrossRef]

- Raffa, D.; Leung, K.T.; Battaglini, F. A microelectrochemical enzyme transistor based on an n-alkylated poly(aniline) and its application to determine hydrogen peroxide at neutral pH. Anal. Chem. 2003, 75, 4983–4987. [Google Scholar]

- Yue, J.; Epstein, A.J. Synthesis of self-doped conducting polyaniline. J. Am. Chem. Soc. 1990, 112, 2800–2801. [Google Scholar] [CrossRef]

- Yue, J.; Epstein, A.J.; Macdiarmid, A.G. Sulfonic acid ring-substituted polyaniline, a self-doped conducting polymer. Mol. Cryst. Liq. Cryst. Inc. Nonlinear Opt. 1990, 189, 255–261. [Google Scholar] [CrossRef]

- Ghenaatian, H.R.; Mousavi, M.F.; Kazemi, S.H.; Shamsipur, M. Electrochemical investigations of self-doped polyaniline nanofibers as a new electroactive material for high performance redox supercapacitor. Synth. Met. 2009, 159, 1717–1722. [Google Scholar] [CrossRef]

- Thiemann, C.; Brett, C.M. Electropolymerisation and properties of conducting polymers derived from aminobenzenesulphonic acids and from mixtures with aniline. Synth. Met. 2001, 125, 445–451. [Google Scholar] [CrossRef]

- Kamaraj, K.; Karpakam, V.; Sathiyanarayanan, S.; Venkatachari, G. Electrosysnthesis of poly(aniline-co-m-amino benzoic acid) for corrosion protection of steel. Mater. Chem. Phys. 2010, 122, 123–128. [Google Scholar] [CrossRef]

- Lukachova, L.V.; Shkerin, E.A.; Puganova, E.A.; Karyakina, E.E.; Kiseleva, S.G.; Orlov, A.V.; Karpacheva, G.P.; Karyakin, A.A. Electroactivity of chemically synthesized polyaniline in neutral and alkaline aqueous solutions: Role of self-doping and external doping. J. Electroanal. Chem. 2003, 544, 59–63. [Google Scholar] [CrossRef]

- Zhang, L.; Dong, S. The electrocatalytic oxidation of ascorbic acid on polyaniline film synthesized in the presence of camphorsulfonic acid. J. Electroanal. Chem. 2004, 568, 189–194. [Google Scholar] [CrossRef]

- Lee, K.-H.; Park, B.J.; Song, D.H.; Chin, I.-J.; Choi, H.J. The role of acidic m-cresol in polyaniline doped by camphorsulfonic acid. Polymer 2009, 50, 4372–4377. [Google Scholar] [CrossRef]

- Del Castillo-Castro, T.; Castillo-Ortega, M.M.; Villarreal, I.; Brown, F.; Grijalva, H.; Pérez-Tello, M.; Nuño-Donlucas, S.M.; Puig, J.E. Synthesis and characterization of composites of DBSA-doped polyaniline and polystyrene-based ionomers. Compos. Part Appl. Sci. Manuf. 2007, 38, 639–645. [Google Scholar] [CrossRef]

- Haberko, J.; Bernasik, A.; Łużny, W.; Hasik, M.; Raczkowska, J.; Rysz, J.; Budkowski, A. Humidity and wetting effects in spin-cast blends of insulating polymers and conducting polyaniline doped with DBSA. J. Appl. Polym. Sci. 2012, 127, 2354–2361. [Google Scholar]

- Lyutov, V.V.; Ivanov, S.D.; Mirsky, V.M.; Tsakova, V.T. Polyaniline doped with poly(acrylamidomethylpropanesulphonic acid): Electrochemical behaviour and conductive properties in neutral solutions. Chem. Pap. 2013, 67, 1002–1011. [Google Scholar] [CrossRef]

- Tarver, J.; Yoo, J.E.; Dennes, T.J.; Schwartz, J.; Loo, Y.-L. Polymer acid doped polyaniline is electrochemically stable beyond pH 9. Chem. Mater. 2009, 21, 280–286. [Google Scholar] [CrossRef]

- Bayer, C.L.; Konuk, A.A.; Peppas, N.A. Development of a protein sensing device utilizing interactions between polyaniline and a polymer acid dopant. Biomed. Microdevices 2010, 12, 435–442. [Google Scholar] [CrossRef]

- Raitman, O.A.; Katz, E.; Bückmann, A.F.; Willner, I. Integration of polyaniline/poly(acrylic acid) films and redox enzymes on electrode supports: An in situ electrochemical/surface plasmon resonance study of the bioelectrocatalyzed oxidation of glucose or lactate in the integrated bioelectrocatalytic systems. J. Am. Chem. Soc. 2002, 124, 6487–6496. [Google Scholar] [CrossRef]

- Tang, Y.; Pan, K.; Wang, X.; Liu, C.; Luo, S. Electrochemical synthesis of polyaniline in surface-attached poly(acrylic acid) network, and its application to the electrocatalytic oxidation of ascorbic acid. Microchim. Acta 2010, 168, 231–237. [Google Scholar] [CrossRef]

- Bonastre, A.M.; Sosna, M.; Bartlett, P.N. An analysis of the kinetics of oxidation of ascorbate at poly(aniline)-poly(styrene sulfonate) modified microelectrodes. Phys. Chem. Chem. Phys. 2011, 13, 5365–5372. [Google Scholar] [CrossRef]

- Bartlett, P.N.; Wang, J.H. Electroactivity, stability and application in an enzyme switch at pH 7 of poly(aniline)-poly(styrenesulfonate) composite films. J. Chem. Soc. Faraday Trans. 1996, 92, 4137–4143. [Google Scholar] [CrossRef]

- Łapkowski, M.; Vieil, E. Control of polyaniline electroactivity by ion size exclusion. Synth. Met. 2000, 109, 199–201. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Choi, G.-R.; Lim, H.; Lee, K.-M.; Lee, S.-K. Electronic transport characteristics of electrolyte-gated conducting polyaniline nanowire field-effect transistors. Appl. Phys. Lett. 2009, 95, 013113:1–013113:3. [Google Scholar]

- Lee, S.-Y.; Lee, S.-K.; Lim, H.; Choi, G.-R. Irreversible degradation behaviors of an electrolyte-gated polyaniline (PANI) nanowire field-effect transistor. J. Korean Phys. Soc. 2010, 57, 1416–1420. [Google Scholar] [CrossRef]

- He, H.; Zhu, J.; Tao, N.J.; Nagahara, L.A.; Amlani, I.; Tsui, R. A conducting polymer nanojunction switch. J. Am. Chem. Soc. 2001, 123, 7730–7731. [Google Scholar]

- Song, E.; Choi, J.-W. An On-chip Chemiresistive Polyaniline Nanowire-based pH Sensor with Self-calibration Capability. In Proceedings of the 2012 Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), San Diego, CA, USA, 28 August–1 September 2012; pp. 4018–4021.

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Song, E.; Choi, J.-W. Conducting Polyaniline Nanowire and Its Applications in Chemiresistive Sensing. Nanomaterials 2013, 3, 498-523. https://0-doi-org.brum.beds.ac.uk/10.3390/nano3030498

Song E, Choi J-W. Conducting Polyaniline Nanowire and Its Applications in Chemiresistive Sensing. Nanomaterials. 2013; 3(3):498-523. https://0-doi-org.brum.beds.ac.uk/10.3390/nano3030498

Chicago/Turabian StyleSong, Edward, and Jin-Woo Choi. 2013. "Conducting Polyaniline Nanowire and Its Applications in Chemiresistive Sensing" Nanomaterials 3, no. 3: 498-523. https://0-doi-org.brum.beds.ac.uk/10.3390/nano3030498