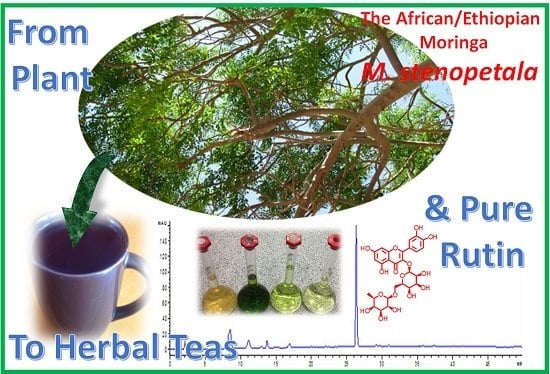

Extractability of Rutin in Herbal Tea Preparations of Moringa stenopetala Leaves

Abstract

:1. Introduction

2. Experimental Section

2.1. Chemicals

2.2. Plant Material Samples

2.3. Extraction

2.3.1. Extractability of Rutin from M. stenopetala Leaves

2.3.2. Determination of the Maximum Amount of Extractible Rutin

2.3.3. Large Scale Extraction for Activity Studies

2.4. HPLC Analysis

2.5. Isolation of Rutin

2.5.1. Solid Phase Extraction (SPE)

2.5.2. Combiflash Chromatography System

2.5.3. Crystallization of Rutin

2.6. DPPH Radical Scavenging

2.7. General Phytochemical Analysis Methodology

2.8. Statistical Analysis

3. Results and Discussion

3.1. HPLC Profile of M. stenopetala and M. oleifera

3.2. Comparative Antioxidant Analysis of M. stenopetala and M. oleifera

| Treatment | IC50 Values (µg/mL) |

|---|---|

| M. stenopetala extract (methanol) | 36.00 ± 6.47 * |

| M. stenopetala extract (water) | 40.00 ± 6.12 * |

| M. oleifera extract (water) | 215.0 ± 40.52 |

| Rutin | 5.00 ± 0.98 |

3.3. Extractability and Quantification of Rutin in Herbal Teas

3.4. Isolation of Rutin

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Anwar, F.; Latif, S.; Ashraf, M.; Gilani, A.H. Moringa oleifera: A food plant with multiple medicinal uses. Phytother. Res. 2007, 21, 17–25. [Google Scholar]

- Melesse, A.; Steingass, H.; Boguhn, J.; Schollenberger, M.; Rodehutscord, M. Altitudinal and seasonal variations in nutritional composition of leaf and green pod fractions of Moringa stenopetala and Moringa oleifera. Agroforest. Syst. 2012, 86, 505–518. [Google Scholar] [CrossRef]

- GLTI (Global Team for Local Initiatives). Helping People Help Themselves. Available online: http://gtli.us/ (accessed on 7 July 2015).

- Abuye, C.; Urga, K.; Knapp, H.; Selmar, D.; Omwega, A.M.; Imungi, J.K.; Winterhalter, P.A. Compositional study of Moringa stenopetala leaves. East. Afr. Med. J. 2003, 80, 51–56. [Google Scholar] [CrossRef]

- Aberra, M. Comparative assessment on chemical compositions and feeding values of leaves of Moringa stenopetala and Moringa oleifera using in vitro gas production method. J. Appl. Sci. Technol. 2011, 2, 31–41. [Google Scholar]

- Bosch, C.H. Moringa stenopetala (Baker f.) Cufod. PROTA 2004, 2, 395–397. [Google Scholar]

- Meskerem, A.; Boonkaewwan, C. Protective Effects of Moringa stenopetala leaf supplemented Diets on Eimeria tenella Infected Broiler Chickens in Debre Zeit, Central, Ethiopia. Kasetsart J. Nat. Sci. 2013, 47, 398–406. [Google Scholar]

- Mekonnen, Y.; Yardley, V.; Rock, P.; Croft, S. In vitro antitrypanosomal activity of Moringa stenopetala leaves and roots. Phytother. Res. 1999, 13, 538–539. [Google Scholar] [CrossRef]

- Nibret, E.; Wink, M. Trypanocidal an antileukaemic effects of the essential oils of Hagenia abyssinica, Leonotis ocymifolia, Moringa stenopetala and their main individual constituents. Phytomedicne 2010, 17, 911–920. [Google Scholar] [CrossRef] [PubMed]

- Mengistu, M.; Abebe, Y.; Mekonnen, Y.; Tolessa, T. In vivo and in vitro hypotensive effect of aqueous extract of Moringa stenopetala. Afr. Health Sci. 2012, 12, 545–551. [Google Scholar] [CrossRef] [PubMed]

- Mekonnen, Y. Effects of ethanol extract of Moringa stenopetala leaves on guinea-pig and mouse smooth muscle. Phytother. Res. 1999, 13, 442–444. [Google Scholar] [CrossRef]

- Ghebreselassie, D.; Mekonnen, Y.; Gebru, G.; Ergete, W.; Huruy, K. The effects of Moringa stenopetala on blood parameters and histopathology of liver and kidney in mice. Ethiop. J. Health Dev. 2011, 25, 51–57. [Google Scholar] [CrossRef]

- Nardos, A.; Makonnen, Y.; Debella, A. Hypoglycemic and antihyperglycemic activities of Ethanol extract and fractions of moringa stenopetala leaves in normoglycemic and alloxan induced diabetic mice. Afr. J. Pharm. Pharmacol. 2011, 20, 2220–2225. [Google Scholar]

- Toma, A.; Makonnen, E.; Debella, A.; Tesfaye, B. Antihyperglycemic effect on chronic administration of butanol fraction of ethanol extract of Moringa Stenopetala leaves in alloxan induced diabetic mice. Asian Pac. J. Trop. Biomed. 2012, 2, S1606–S1610. [Google Scholar] [CrossRef]

- Habtemariam, S. Investigation into the antioxidant and antidiabetic potential of Moringa stenopetala: Identification of the active principles. Nat. Prod. Commun. 2015, 10, 475–478. [Google Scholar] [PubMed]

- Habtemariam, S.; Lenti, G. The therapeutic potential of rutin for diabetes: An update. Mini Rev. Med. Chem. 2015, 15, 524–528. [Google Scholar] [CrossRef] [PubMed]

- Habtemariam, S.; Jackson, C. Antioxidant and cytoprotective activity of leaves of Peltiphyllum peltatum (Torr.) Engl. Food Chem. 2007, 105, 498–503. [Google Scholar] [CrossRef]

- Sando, C.E.; Lloyd, J.R. The isolation and identification of rutin from the flowers of elder (Sambucus canadebsis L.). J. Biol. Chem. 1924, 58, 737–745. [Google Scholar]

- Habtemariam, S.; Varghese, G.K. The antidiabetic therapeutic potential of dietary polyphenols. Curr. Pharm. Biotechnol. 2014, 15, 391–400. [Google Scholar] [CrossRef] [PubMed]

- Kalinova, J.; Dadakova, E. Varietal differences of rutin in common buckwheat (Fagopyrum esculentum Moench) determined by Micellar Electrokinetic Capillary Chromatography. In Proceedings of the 9th International Symposium on Buckwheat, Prague, Czech, 18–22 August 2014; pp. 719–722.

- Fabjan, N.; Rode, N.; Košir, I.J.; Wang, Z.; Zhang, Z.; Kreft, I. Tartary Buckwheat (Fagopyrum tataricum Gaertn.) as a source of dietary rutin and quercitrin. J. Agric. Food Chem. 2003, 51, 6452–6455. [Google Scholar] [PubMed]

- Suzuki, T.; Honda, Y.; Mukasa, Y. Effects of UV-B radiation, cold and desiccation stress on rutin concentration and rutin glucosidase activity in tartary buckwheat (Fagopyrum tataricum) leaves. Plant Sci. 2005, 168, 1303–1307. [Google Scholar] [CrossRef]

- Ohsawa, R.; Tsutsumi, T. Improvement of rutin content in buckwheat flour. In Current Advances in Buckwheat Research, Proceedings of the 10th International Symposium on Buckwheat, Yangling, China, 14–18 August 2007.

- Hagels, H. Fagopyrum esculentum Moench. Chemical review. Zb. BFUL 1999, 73, 29–38. [Google Scholar]

- Harborne, J.B.; Williams, C.A. Advances in flavonoid research since 1992. Phytochemistry 2000, 55, 481–504. [Google Scholar] [CrossRef]

- Li, S.Q.; Zhang, Q.H. Advances in the development of functional food from buckwheat. Crit. Rev. Food Sci. Nutr. 2001, 41, 451–464. [Google Scholar] [CrossRef] [PubMed]

- Wieslander, G.; Norbäck, D. Buckwheat allergy. Allergy 2001, 56, 703–704. [Google Scholar] [CrossRef] [PubMed]

- Bennett, R.N.; Mellon, F.A.; Foidl, N.; Pratt, J.H.; Dupont, M.S.; Perkins, L.; Kroon, P.A. Profiling glucosinolates and phenolics in vegetative and reproductive tissues of the multi-purpose trees Moringa oleifera L. (horseradish tree) and Moringa stenopetala L. J. Agric. Food Chem. 2003, 51, 3546–3553. [Google Scholar] [CrossRef] [PubMed]

- Moyo, B.; Oyedemi, S.; Masika, P.J.; Muchenje, V. Polyphenolic content and antioxidant properties of Moringa oleifera leaf extracts and enzymatic activity of liver from goats supplemented with Moringa oleifera leaves/sunflower seed cake. Meat Sci. 2012, 91, 441–447. [Google Scholar] [CrossRef] [PubMed]

- Charoensin, S. Antioxidant and anticancer activities of Moringa oleifera leaves. J. Med. Plant Res. 2014, 8, 318–325. [Google Scholar]

- Pedriali, C.A.; Fernandes, A.U.; de Cássia Bernusso, L.; Polakiewicz, B. The synthesis of a water-soluble derivative of rutin as an antiradical agent. Quím. Nova 2008, 31, 2147–2151. [Google Scholar] [CrossRef] [Green Version]

- Krewson, C.F.; Naghski, J. Some physical properties of rutin. J. Am. Pharm. Assoc. 2006, 41, 582–587. [Google Scholar] [CrossRef]

- Habtemariam, S. Knipholone anthrone from Kniphofia foliosa induces a rapid onset of necrotic cell death in cancer cells. Fitoterapia 2010, 81, 1013–1019. [Google Scholar] [CrossRef] [PubMed]

- Habtemariam, S. Methyl-3-O-methyl gallate and gallic acid from the leaves of Peltiphyllum peltatum: Isolation and comparative antioxidant, prooxidant, and cytotoxic effects in neuronal cells. J. Med. Food 2011, 14, 1412–1418. [Google Scholar] [CrossRef] [PubMed]

- Habtemariam, S. Activity-guided isolation and identification of free radical-scavenging components from ethanolic extract of boneset (leaves of Eupatorium perfoliatum). Nat. Prod. Commun. 2008, 3, 1317–1320. [Google Scholar]

- Roselli, M.; Lentini, G.; Habtemariam, S. Phytochemical, antioxidant and anti-alpha-glucosidase activity evaluations of Bergenia cordifolia. Phytother. Res. 2012, 26, 908–914. [Google Scholar] [CrossRef] [PubMed]

- Juan-Badaturugea, M.; Habtemariam, S.; Jackson, C.; Thomas, M.J.K. Antioxidant principles of Tanacetum vulgare L. aerial part. Nat. Prod. Commun. 2009, 4, 1561–1564. [Google Scholar]

- Habtemariam, S. Antihyperlipidemic components of Cassia auriculata aerial parts: Identification through in vitro studies. Phytother. Res. 2013, 27, 152–155. [Google Scholar] [CrossRef] [PubMed]

- Hevesi, B.T.; Houghton, P.J.; Habtemariam, S.; Kéry, Á. Antioxidant and antiinflammatory effect of Epilobium parviflorum Schreb. Phytother. Res. 2009, 23, 719–724. [Google Scholar] [CrossRef] [PubMed]

- Habtemariam, S. Activity-guided isolation and identification of antioxidant components from ethanolic extract of Peltiphyllum peltatum (Torr.) Engl. Nat. Prod. Commun. 2008, 3, 1321–1324. [Google Scholar]

- Habtemariam, S.; Cowley, R.A. Antioxidant and anti-α-glucosidase ccompounds from the rhizome of Peltiphyllum peltatum (Torr.) Engl. Phytother. Res. 2012, 26, 1656–1660. [Google Scholar] [CrossRef] [PubMed]

- Habtemariam, S.; Dagne, E. Comparative antioxidant, prooxidant and cytotoxic activity of sigmoidin A and eriodictyol. Planta Med. 2010, 76, 589–594. [Google Scholar] [CrossRef] [PubMed]

- Motlhanka, D.M.T.; Habtemariam, S.; Houghton, P. Free radical scavenging activity of crude extracts and 4′-O-Methyl-(−)epigallocatechin isolated from roots of Cassine transvaalensis from Botswana. Afr. J. Biomed. Res. 2008, 11, 55–63. [Google Scholar]

- Curti, V.; Capelli, E.; Nabavi, S.F.; Habtemariam, S.; Nabavi, S.M.; Daglia, M. Modulation of human miR-17-3p expression by methyl 3-O-methyl gallate as explanation of its in vivo protective activities. Mol. Nutr. Food Res. 2014, 58, 1776–1784. [Google Scholar] [CrossRef] [PubMed]

- Habtemariam, S.; Sureda, A.; Moghaddam, A.H.; Nabavi, S.F.; Nabavi, S.M.; Abolhasani, F. Protective role of gallic acid isolated from Peltiphyllum peltatum against sodium fluoride-induced oxidative stress in rat’s heart. Lett. Drug Des. Discov. 2013, 10, 277–282. [Google Scholar]

- Nabavi, S.F.; Nabavi, S.M.; Habtemariam, S.; Sureda, A.; Jafari, M.; Abolhasani, F.; Moghaddam, A.H. Hepatoprotective effect of gallic acid isolated from Peltiphyllum peltatum against sodium fluoride-induced oxidative stress. Ind. Crops Prod. 2013, 44, 50–55. [Google Scholar] [CrossRef]

- Nabavi, S.M.; Habtemariam, S.; Nabavi, S.F.; Sureda, A.; Jafari, M.; Abolhasani, F.; Moghaddam, A.H. Protective effect of gallic acid against sodium fluoride-induced oxidative stress in rat’s kidney. Mol. Cell. Biochem. 2012, 372, 233–239. [Google Scholar] [CrossRef] [PubMed]

- Nabavi, S.F.; Nabavi, S.M.; Habtemariam, S.; Abolhasani, F.; Daglia, M.; Moghaddam, A.H. Protective effect of methyl-3-O-methyl gallate against sodium fluoride-induced oxidative stress in rat’s cardiac tissues. Fluoride 2012, 45, 290–296. [Google Scholar]

- Nabavi, S.F.; Nabavi, S.M.; Latifi, A.M.; Mirzaei, M.; Habtemariam, S.; Moghaddam, A.H. Mitigating role of quercetin against sodium fluoride induced oxidative stress in rat’s brain. Pharm. Biol. 2012, 50, 1380–1383. [Google Scholar] [CrossRef] [PubMed]

- Nabavi, S.F.; Habtemariam, S.; Jafari, M.; Sureda, A.; Nabavi, S.M. Protective role of gallic acid on sodium fluoride induced oxidative stress in rat brain. Bull. Environ. Contam. Toxicol. 2012, 89, 73–77. [Google Scholar] [CrossRef] [PubMed]

- Nabavi, S.F.; Sureda, A.; Nabavi, S.M.; Habtemariam, S. In vivo protective effects of gallic acid isolated from Peltiphyllum peltatum against sodium fluoride-induced oxidative stress in erythrocytes. Arch. Ind. Hyg. Toxicol. 2013, 64, 563–569. [Google Scholar] [CrossRef] [PubMed]

- Nabavi, S.M.; Habtemariam, S.; Nabavi, S.F.; Sureda, A.; Moghaddam, A.H.; Latifi, A.M. Prophylactic effect of methyl-3-O-methyl gallate against sodium fluoride-induced oxidative stress in rat’s erythrocytes in vivo. J. Pharm. Pharmacol. 2013, 65, 868–873. [Google Scholar] [CrossRef] [PubMed]

- Nabavi, S.F.; Nabavi, S.M.; Habtemariam, S.; Sureda, A.; Moghaddam, A.H.; Latifi, A.M. Neuroprotective effects of methyl-3-O-methyl gallate against sodium fluoride-induced oxidative stress in brain of rats. Cell. Mol. Neurobiol. 2013, 33, 261–267. [Google Scholar] [CrossRef] [PubMed]

- Nabavi, S.M.; Nabavi, S.F.; Habtemariam, S.; Moghaddam, A.H.; Latifi, A.M. Ameliorative effects of quercetin on sodium fluoride-induced oxidative stress in rat’s kidney. Renal Fail. 2012, 34, 901–906. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Habtemariam, S.; Varghese, G.K. Extractability of Rutin in Herbal Tea Preparations of Moringa stenopetala Leaves. Beverages 2015, 1, 169-182. https://0-doi-org.brum.beds.ac.uk/10.3390/beverages1030169

Habtemariam S, Varghese GK. Extractability of Rutin in Herbal Tea Preparations of Moringa stenopetala Leaves. Beverages. 2015; 1(3):169-182. https://0-doi-org.brum.beds.ac.uk/10.3390/beverages1030169

Chicago/Turabian StyleHabtemariam, Solomon, and George K. Varghese. 2015. "Extractability of Rutin in Herbal Tea Preparations of Moringa stenopetala Leaves" Beverages 1, no. 3: 169-182. https://0-doi-org.brum.beds.ac.uk/10.3390/beverages1030169