2.1. Selection of Renewable Deep Eutectic Solvents (Re-DESs)

Five types of

Re-DESs were in-house synthesized from different hydrogen-bond donors (HBD) and choline chloride (ChCl) as the hydrogen-bond acceptor (HBA). Once the solvents were formed, two model substrates (i.e., vinyl laurate and glucose) were added to the reaction media under continuous agitation and heating (

Table 1). The main focus was on determining glucose solubilization (i.e., lack of a solid precipitate) and emulsifying of the lipidic substrate (i.e., one liquid phase).

In the selection of

Re-DESs, a favorable result implies (1) the nonprecipitation of glucose in the solvent, (2) emulsification and (3) lower viscosity (e.g., more favorable for mass transfer) in this heterogeneous catalytic reaction. According to the first criterion,

ChCl-Glc is an attractive option since it has been used simultaneously as a solvent and substrate to produce sugar-based surfactants [

5,

10,

16]. However, the formation of an emulsion was not observed, and even at 70 °C and 1400 rpm, the

ChCl-Glc had a high viscosity (i.e., 4470 cP) [

11]. Therefore, to decrease viscosity in the system, the temperature should be increased, compromising the biocatalyst stability. Another option is to add glycerol, which effectively decreases viscosity on DES [

11]. For this reason, a

Re-DES was prepared from glucose and glycerol, which showed a considerable decrease in viscosity compared to

Re-DES prepared from glucose. Previous results have shown an important decrease in viscosity when glycerol was used, for instance, viscosity decreased for

ChCl-Glc from 34,400 cP (without glycerol) to 930 cP (with 50% molar of glycerol as HBD), at 50 °C [

11].

The second selection criterion is the formation of an emulsion between the

Re-DES and vinyl laurate. Although the viscosity (third criterion) of DESs has been reported to be the most determining factor in the reaction [

10,

14,

17], when hydrophilic solvents are used, the total or partial insolubility of fatty acid esters is a persistent problem, which can affect glycolipid synthesis yields [

18]. Therefore,

Re-DESs that allow greater integration of vinyl laurate were selected, in this case (

Table 1),

ChCl-Gly and

ChCl-Gly-Clc.Nevertheless, due to their high polarity, by themselves,

ChCl-Gly and ChCl-Gly-Clc are deficient in facilitating the polar (sugars) and nonpolar (fatty acids) interactions necessary for catalyst contact to both substrates. As an alternative, the possibility of adding nonpolar (i.e., organic) solvents to the

Re-DES was evaluated to integrate the phases of the heterogeneous media following previously reported results from a multiphase system using DES [

19].

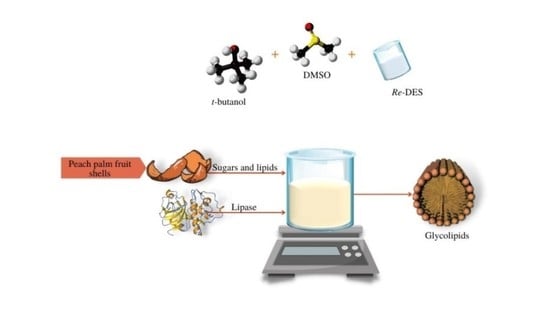

2.3. Enzymatic Synthesis of Glycolipids

Three different reaction systems were prepared, using the selected

Re-DESs, DMSO, and

t-butanol (

Table 2), to evaluate the influence of organic solvents in the heterogeneous media. In these systems, glycolipid synthesis (i.e., glucose laurate) was carried out through the catalytic action of a free enzyme or its immobilized version, under constant stirring and heating (500 rpm and 50 °C, respectively). The main result was to determine whether or not adding organic solvents improved the phase reaction of glucose (polar) and vinyl laurate (nonpolar) in

Re-DESs medium (polar) and, consequently, favored conversion in the enzymatic reaction.

At 50 °C, the viscosity of

ChCl-Gly (64 cP) [

20] facilitated the agitation and dispersion of substrates; however, the resulting conversion was low since part of the glucose precipitated and therefore was not available for reaction. At the same temperature,

ChCl-Gly-Glc showed a higher viscosity (930 cP) [

11], and the system

ChCl-Gly-Glc:t-butanol also presented a low conversion. The main reason for the low conversion in these systems can be associated with the higher viscosity and lower substrate availability, as the glucose was supplied as HBD and was less available for reaction, being trapped in the strong hydrogen bond network forming the DES [

21].

Regarding the novel cosolvent system,

ChCl-Gly:DMSO:

t-butanol, the conversion achieved indicates that adding DMSO and

t-butanol improved the glucose and vinyl laurate solubility in the medium. Although successful acylation reactions have been carried out in the bisolvent system DES: DMSO [

22], it has not been tested as a reaction media in glycolipid synthesis. On the contrary, less than a 15% conversion has been reported in other similar systems including or not cosolvent (

Table 3).

In

Table 3, we compiled the results reported in two studies in which DESs were used with either solvent or bi-solvent in the reaction. In both studies, the lower conversions obtained could be explain by an insufficient integration of the substrates to the medium, which affect the biocatalyst−substrate contact. On the other hand, the results in

Table 2 show that the reaction media

ChCl-Gly:DMSO:

t-butanol was a more attractive option, which marked a path in the formulation of cosolvent systems to favor glycolipid synthesis by promoting glucose solubilization and availability (the main contribution of DMSO) and phase interaction with vinyl laurate (the main contribution of

t-butanol). Thus, it was possible to propose a reaction media that would supply the specific task of synthesizing glycolipids with a higher conversion.

In the formulation of the proposed ternary system, it was considered that: (

i) organic solvents with negative log

p (polar solvents) interfere with lipase hydration, leaving them in an inactive form [

23]. For this reason, tertiary alcohols such as

t-butanol (log

p 0.5) are more suitable since they provide high stability and enzymatic activity and present steric limitations that prevent them from being used as a substrate by the enzyme [

17]. (

ii) Contrary to what happens with organic solvents, some hydrophilic DESs favor the activity and stability of lipases [

24,

25,

26]. Indeed, it was recently found that a greater portion of glycerol in DES increased the relative stability of the enzyme, compared to the behavior of the catalyst in ionic liquids [Bmim] [BF4] and acetone [

27]. In conclusion, the conformed mixture of

t-butanol, DMSO, and

ChCl-Gly, under the evaluated conditions, favored reaction advance due to the increased interactions between phases and improved lipase stability in these nonconventional media.

In

Table 2, a conversion of 21.01% was reached with the cosolvent system

ChCl-Gly:DMSO:

t-butanol and the immobilized enzyme. Recent reports have demonstrated that for immobilized lipases exposed to reaction systems containing DES, their relative activities depend on three factors: (1) enzyme kind, (2) its immobilization support, and (3) DES composition [

28]. For example, lipase from

Candida antartica supported on the acrylic resin (recombinant, expressed in

Aspergillus niger, the same used in this work) showed inhibition by glycerol-based DESs (e.g., involving factors 1 and 3 in the previous sentence). The inhibitory effect of glycerol-based DESs could be explained due to the change in polarity associated with the interactions between the terminal enzyme groups and the chemical nature of support. However, the main factor contributing to a lower conversion than the free enzyme on the same system label is immobilization support. The support creates an additional solid phase, further limiting mass transfer. Both substrates, glucose and vinyl laurate, should diffuse through the acrylic resin support to find the enzyme, react and the product should leave the support to allow new reactions. Diffusion of both substrates and product release from the catalyst support explained a lower conversion compared to the free enzyme.

2.4. Enzymatic Synthesis of Glycolipids from Peach Palm Fruit Shells

Once the cosolvent reaction system was defined, the aim was to evaluate a more sustainable process for glycolipid synthesis by using as substrates the sugars and fatty acids extracted from peach palm fruit shells. Regarding the lipidic fraction, the main fatty acids extracted from the agricultural residue were (>90% composition) oleic, palmitic, linoleic and palmitoleic acids (

Table 4). Glucose was the main sugar obtained from the peach palm fruit shells by the enzymatic hydrolysis of its carbohydrates using amylases, cellulases, and hemicellulases (

Table 5).

In this test, sugar hydrolysates were used in two modalities: (

i)

Re-DES was prepared from the sugars, glycerol, and choline chloride, which would function as the substrate and solvent at the same time. (

ii) Additionally, for

ChCl-Gly:DMSO:

t-butanol system, the sugars were added as a free-substrate to the reaction media (

Figure 2).

The system

ChCl-Gly-Sugars showed a low viscosity, attributable to glycerol in the mixture and water in the sugar stream used in the solvent formation. A similar case was reported by Siebenhaller and coworkers [

29], where a DES, prepared from sugar hydrolysates of lignocellulosic biomass and choline chloride, presented a viscosity of 2.540 cP at 50 °C, a much lower value if compared with the viscosity of DES from choline chloride and pure glucose (34,400 cP) [

11]. This decrease in viscosity, due to the water content in the

Re-DES causes four times higher conversions achieved with

ChCl-Gly-Sugars:

t-butanol (

Table 6) compared to

ChCl-Gly-Glu:

t-butanol.

In addition to affecting the DES viscosity [

30,

31,

32], the water in the sugar stream can interact through hydrogen bonds with choline chloride (i.e., HBA) [

33]. Because water can form hydrogen bonds with the HBA, it increases the sugar bioavailability for the reaction because it replaces the hydrogen bonds formed between the sugars and the HBA. If the hydrogen donor contains hydroxyl groups, a stronger interaction with the HBA is established, requiring a more significant amount of water to interrupt the association [

30]. Therefore, as a strategy to improve the system, decrease viscosity, and increase the availability of sugars (i.e., the substrate), it is essential to determine the optimum water content that does not compromise the reaction equilibrium.

In the system ChCl-Gly-Sugars:t-butanol, a low conversion was obtained when using the lipidic extract from peach palm fruit shells as the presence of fatty acids promotes the formation of water throughout the reaction. Although water favors Re-DES by decreasing viscosity, an excess of it can lead to glycolipid hydrolysis. Therefore, it is suggested to esterificate the fatty acids to obtain fatty acid esters that will not release water throughout the reaction.

Conversely, a trend was observed in the conversion obtained in the treatments with ChCl-Gly:DMSO:t-butanol, using model compounds or the sugar extract. In this system, values close to 19% and 25% were reached, depending on whether an immobilized or free enzyme was used, which indicates that the formulated cosolvent is robust enough to facilitate mass transfer in the reaction when using a stream of single or various carbohydrates.

2.5. Characterization of Synthesized Glycolipid

The glucose-laurate molecule in the concentration range between 0.001% and 0.05% is in a free solution zone. The surfactant aggregation trend is almost null, due to the attraction between the molecules and the solvent media (

Figure 3). For this reason, the observed changes in surface tension were minimal because the glycolipid molecules were distributed between the bulk medium and the air−water interphase. When increasing the surfactant concentration from 0.5% to 20%, although the glucose laurate molecules were attracted to each other, the molecules mainly migrated to the air−water interphase. In this zone, surfactant molecules suffer a spatial rearrangement. They locate their hydrophobic tails towards the air and their hydrophilic heads in contact with the aqueous medium, forming a stable monolayer (zone of stability) [

34]. This location or rearrangement process leads to a decrease in the water surface tension, indicating the glucose laurate tensioactivity. Finally, at higher surfactant concentration values (20% and 40%), it can be observed that surface tension changes are trending to a constant zone. At this point, the glucose-laurate has saturated the air−water interphase. The excess molecules begin to be integrated into the medium in a thermodynamically more favorable conformation to avoid the hydrophobic effect between the tail and the water [

35]. In this way, micelle formation occurs carrying the system to a considerable decrease in surface tension to 27.94 mN/m. The concentration of 20%, where micelle formation occurs, is called critical micellar concentration (CMC).

The discussion is also supported by the changing of the transversal area calculated using Gibb’s excess function (

Table 7), where it is observed that the transition between a free solution zone to a micellar formation zone indicates a diminishing in the interphase available area. In addition, the calculated values for the surface area were dynamic since the surfactant molecules were able to migrate between the interphase, the bulk aqueous medium and the micellar structure, while adopting a different configuration (

Figure 3A).

Due to the concentration required to reach the micellar formation zone (

Figure 3B), the studied glycolipid is an unattractive option as a foaming agent [

36]. Even so, its nonionic nature and its hydrophobic tail give it an emulsifying capacity to reduce the surface tension between lipidic compounds and aqueous media. For this reason, glucose laurate is an alternative to alcohol ethoxylates, industrially produced at high temperatures to emulsify solutions. Thus, although sophisticated or straightforward chromatographic and spectrophotometric methods are the most widely used [

37], measurement of surface tension, as a function of concentration, provided an approximation to the application of glucose laurate.