3D Printing Filaments Facilitate the Development of Evanescent Wave Plastic Optical Fiber (POF) Chemosensors

Abstract

:1. Introduction

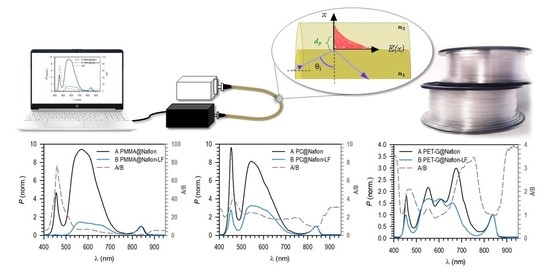

2. Materials and Methods

2.1. Optimization of the Cladding Removal Protocol of a Commercially Available POF

2.2. Selection of the Experimental Conditions for the Chemical Removal of the Cladding of Commercial Optical Fibers

2.3. Nafion Coating of the Uncladded Plastic Waveguides

2.4. Indicator Immobilization in the Nafion Cladding of the Manufactured Optical Fibers

2.5. Spectroscopic Characterization and Calibration of Sensitive Optical Fibers

3. Results and Discussion

3.1. Chemical Removal of the Commercial POF Cladding

3.2. Analytical Characterization of the FA-OFS Manufactured from Commercial POF

3.3. 3D Printing Filament Selection to Manufacture the Novel FA-Sensitive Optical Fibers

3.4. Analytical Characterization of the FA-Sensitive EWOFS Fabricated from PMMA Filaments

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, X.; Thomas, P.J.; Hellevang, J.O. A Review of Methods for Fibre-Optic Distributed Chemical Sensing. Sensors 2019, 19, 2876. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Culshaw, B.; Kersey, A. Fiber-Optic Sensing: A Historical Perspective. J. Lightw. Technol. 2008, 26, 1064–1078. [Google Scholar] [CrossRef]

- Jiao, L.; Zhong, N.; Zhao, X.; Ma, S.; Fu, X.; Dong, D. Recent advances in fiber-optic evanescent wave sensors for monitoring organic and inorganic pollutants in water. TrAC Trends Anal. Chem. 2020, 127, 115892. [Google Scholar] [CrossRef]

- Potyrailo, R.A.; Hobbs, S.E.; Hieftje, G.M. Near-Ultraviolet Evanescent-Wave Absorption Sensor Based on a Multimode Optical Fiber. Anal. Chem. 1998, 70, 1639–1645. [Google Scholar] [CrossRef]

- Girei, S.H.; Alkhabet, M.M.; Kamil, Y.M.; Lim, H.N.; Mahdi, M.A.; Yaacob, M.H. Wavelength Dependent Graphene Oxide-Based Optical Microfiber Sensor for Ammonia Gas. Sensors 2021, 21, 556. [Google Scholar] [CrossRef]

- Valadez, A.; Lana, C.; Tu, S.-I.; Morgan, M.; Bhunia, A. Evanescent Wave Fiber Optic Biosensor for Salmonella Detection in Food. Sensors 2009, 9, 5810–5824. [Google Scholar] [CrossRef] [Green Version]

- Sai, V.V.R.; Kundu, T.; Deshmukh, C.; Titus, S.; Kumar, P.; Mukherji, S. Label-free fiber optic biosensor based on evanescent wave absorbance at 280nm. Sens. Actuators B Chem. 2010, 143, 724–730. [Google Scholar] [CrossRef]

- Azargoshasb, T.; Navid, H.A.; Parvizi, R.; Heidari, H. Evanescent Wave Optical Trapping and Sensing on Polymer Optical Fibers for Ultra-Trace Detection of Glucose. ACS Omega 2020, 5, 22046–22056. [Google Scholar] [CrossRef]

- Nag, P.; Sadani, K.; Mohapatra, S.; Mukherji, S.; Mukherji, S. Evanescent Wave Optical Fiber Sensors Using Enzymatic Hydrolysis on Nanostructured Polyaniline for Detection of β-Lactam Antibiotics in Food and Environment. Anal. Chem. 2021, 93, 2299–2308. [Google Scholar] [CrossRef]

- Türkmen, D.; Krug, A.; Mizaikoff, B. Monitoring Corrosion Processes via Visible Fiber-Optic Evanescent Wave Sensor. Chemosensors 2020, 8, 76. [Google Scholar] [CrossRef]

- Cennamo, N.; Pesavento, M.; Zeni, L. A review on simple and highly sensitive plastic optical fiber probes for bio-chemical sensing. Sens. Actuators B Chem. 2021, 331, 129393. [Google Scholar] [CrossRef]

- Bartlett, R.J.; Philip-Chandy, R.; Eldridge, P.; Merchant, D.F.; Morgan, R.; Scully, P.J. Plastic optical fibre sensors and devices. Trans. Inst. Meas. Control 2000, 22, 431–457. [Google Scholar] [CrossRef]

- Bunge, C.A.; Bremer, K.; Lustermann, B.; Woyessa, G. Polymer Optical Fibres; Elsevier: Amsterdam, The Netherlands, 2017; ISBN 9780081000397. [Google Scholar]

- Merchant, D.F.; Scully, P.J.; Schmitt, N.F. Chemical tapering of polymer optical fibre. Sens. Actuators A Phys. 1999, 76, 365–371. [Google Scholar] [CrossRef]

- Lee, J.R.; Dhital, D.; Yoon, D.J. Investigation of cladding and coating stripping methods for specialty optical fibers. Opt. Lasers Eng. 2011, 49, 324–330. [Google Scholar] [CrossRef]

- An, J.; Zhao, Y.; Jin, Y.; Shen, C. Relative humidity sensor based on SMS fiber structure with polyvinylalcohol coating. Optik (Stuttg.) 2013, 124, 6178–6181. [Google Scholar] [CrossRef]

- Darder, M.M.; Serrano, L.A.; Moreno-bondi, M.C.; Alba, M.A.; Orellana, G. Fiberoptic Formaldehyde Field Sensors for Industrial Environments: Capitalizing on Evanescent-Wave. Spectroscopy 2020, s6, 25–29. [Google Scholar]

- Directive EU 2019/983. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32019L0983 (accessed on 17 August 2021).

- Darder, M.d.M.; Bedoya, M.; Serrano, L.A.; Alba, M.Á.; Orellana, G. Fiberoptic colorimetric sensor for in situ measurements of airborne formaldehyde in workplace environments. Sens. Actuators B Chem. 2022, 353, 131099. [Google Scholar] [CrossRef]

- Liao, C.; Shi, J.; Zhang, M.; Dalapati, R.; Tian, Q.; Chen, S.; Wang, C.; Zang, L. Optical chemosensors for the gas phase detection of aldehydes: Mechanism, material design, and application. Mater. Adv. 2021, 2, 6213–6245. [Google Scholar] [CrossRef]

- Sharma, A.K.; Gupta, J.; Sharma, I. Fiber optic evanescent wave absorption-based sensors: A detailed review of advancements in the last decade (2007–18). Optik (Stuttg.) 2019, 183, 1008–1025. [Google Scholar] [CrossRef]

- Gupta, B.D.; Dodeja, H.; Tomar, A.K. Fibre-optic evanescent field absorption sensor based on a U-shaped probe. Opt. Quantum Electron. 1996, 28, 1629–1639. [Google Scholar] [CrossRef]

- Azkune, M.; Ruiz-Rubio, L.; Aldabaldetreku, G.; Arrospide, E.; Pérez-Álvarez, L.; Bikandi, I.; Zubia, J.; Vilas-Vilela, J. U-Shaped and Surface Functionalized Polymer Optical Fiber Probe for Glucose Detection. Sensors 2017, 18, 34. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Iadicicco, A.; Paladino, D.; Campopiano, S.; Bock, W.J.; Cutolo, A.; Cusano, A. Evanescent wave sensor based on permanently bent single mode optical fiber. Sens. Actuators B Chem. 2011, 155, 903–908. [Google Scholar] [CrossRef]

- Raichlin, Y.; Katzir, A. Fiber-optic evanescent wave spectroscopy in the middle infrared. Appl. Spectrosc. 2008, 62. [Google Scholar] [CrossRef] [PubMed]

- McCormick, R.M.; Karger, B.L. Guidelines For Data Acquisition And Data Quality Evaluation In Environmental Chemistry. Anal. Chem. 1980, 52, 2242–2249. [Google Scholar] [CrossRef]

- López-Higuera, J.M. Handbook of Optical Fibre Sensing Technology; John Wiley and Sons: West Sussex, UK, 2002; ISBN 978-0-471-82053-6. [Google Scholar]

- Grot, W. Copyright. In Fluorinated Ionomers, 2nd ed.; Grot, W., Ed.; William Andrew (Elsevier): Kidlington, UK, 2011; ISBN 9781437744613. [Google Scholar]

- Rudolf Kingslake, R.B.J. Lens Design Fundamentals; Academic Press: Burlington, MA, USA, 2010; ISBN 9780123743015. [Google Scholar]

- Suzuki, Y.; Nakano, N.; Suzuki, K. Portable Sick House Syndrome Gas Monitoring System Based on Novel Colorimetric Reagents for the Highly Selective and Sensitive Detection of Formaldehyde. Environ. Sci. Technol. 2003, 37, 5695–5700. [Google Scholar] [CrossRef]

- Guo, X.-L.; Chen, Y.; Jiang, H.-L.; Qiu, X.-B.; Yu, D.-L. Smartphone-Based Microfluidic Colorimetric Sensor for Gaseous Formaldehyde Determination with High Sensitivity and Selectivity. Sensors 2018, 18, 3141. [Google Scholar] [CrossRef] [Green Version]

- Park, J.J.; Kim, Y.; Lee, C.; Kook, J.W.; Kim, D.; Kim, J.H.; Hwang, K.S.; Lee, J.Y. Colorimetric visualization using polymeric core-shell nanoparticles: Enhanced sensitivity for formaldehyde gas sensors. Polymers (Basel) 2020, 12, 998. [Google Scholar] [CrossRef]

| Code | Calibration Equation a | r2 | LoD (ppmv) | LoQ (ppmv) |

|---|---|---|---|---|

| 37.5UA | ΔP575/455 = 0.0010 + 0.042 [HCHO] − 0.0010 [HCHO]² | 0.980 | 0.19 | 1.10 |

| 37.5UB | ΔP575/455 = 0.0014 + 0.034 [HCHO] − 0.0002 [HCHO]² | 0.983 | 0.28 | 1.74 |

| 37.5UC | ΔP575/455 = 0.0010 + 0.043 [HCHO] − 0.0010 [HCHO]² | 0.999 | 0.58 | 2.0 |

| Code | Calibration Equation a | r2 | LoD (ppmv) | LoQ (ppmv) |

|---|---|---|---|---|

| 37.5UFA | ΔP575/455 = 0.0017 + 0.089 [HCHO] − 0.0050 [HCHO]² | 0.996 | 0.08 | 0.32 |

| 37.5UFB | ΔP575/455 = 0.0015 + 0.083 [HCHO] − 0.00020 [HCHO]² | 0.998 | 0.05 | 0.22 |

| 37.5UFC | ΔP575/455 = 0.0010 + 0.095 [HCHO] − 0.0050 [HCHO]² | 0.997 | 0.06 | 0.25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Darder, M.d.M.; Serrano, L.A.; Bedoya, M.; Orellana, G. 3D Printing Filaments Facilitate the Development of Evanescent Wave Plastic Optical Fiber (POF) Chemosensors. Chemosensors 2022, 10, 61. https://0-doi-org.brum.beds.ac.uk/10.3390/chemosensors10020061

Darder MdM, Serrano LA, Bedoya M, Orellana G. 3D Printing Filaments Facilitate the Development of Evanescent Wave Plastic Optical Fiber (POF) Chemosensors. Chemosensors. 2022; 10(2):61. https://0-doi-org.brum.beds.ac.uk/10.3390/chemosensors10020061

Chicago/Turabian StyleDarder, Maria del Mar, Luis A. Serrano, Maximino Bedoya, and Guillermo Orellana. 2022. "3D Printing Filaments Facilitate the Development of Evanescent Wave Plastic Optical Fiber (POF) Chemosensors" Chemosensors 10, no. 2: 61. https://0-doi-org.brum.beds.ac.uk/10.3390/chemosensors10020061