Synthesis and Characterization of a Polyurethane Phase Separated to Nano Size in an Epoxy Polymer

Abstract

:1. Introduction

2. Experiments

2.1. Materials

2.2. Synthesis of Polyol: Modification of Hydrogenated Epoxy Resin with Fatty Acids

2.3. Synthesis of Polyurethane using FMEP (FMEP-PU)

2.4. Preparation of the Epoxy Compositions and Cured Thermosetting Plastics

2.5. Measurements and Analyses

3. Results and Discussion

3.1. Modification of the Epoxy Resin (FMEP)

3.2. Synthesis of PU

3.3. Mechanical Properties of the Cured Epoxy Polymer

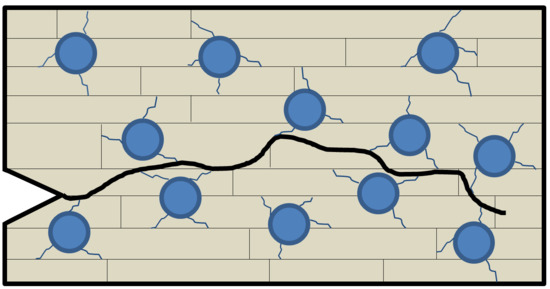

3.4. FE-SEM and TEM Images of the Fractured Epoxy Polymers Obtained after Impact Tests

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Toldy, A.; Szebényi, G.; Molnár, K.; Tóth, L.F.; Magyar, B.; Hliva, V.; Czigány, T.; Szolnoki, B. The effect of multilevel carbon reinforcements on the fire performance, conductivity, and mechanical properties of epoxy composites. Polymers 2019, 11, 303. [Google Scholar] [CrossRef] [PubMed]

- Fombuena, V.; Petrucci, R.; Dominici, F.; Jordá-Vilaplana, A.; Montanes, N.; Torre, L. Maleinized linseed oil as epoxy resin hardener for composites with high bio content obtained from linen byproducts. Polymers 2019, 11, 301. [Google Scholar] [CrossRef] [PubMed]

- Chu, W.-C.; Lin, W.-S.; Kuo, S.-W. Flexible epoxy resin formed upon blending with a triblock copolymer through reaction-induced microphase separation. Materials 2016, 9, 449. [Google Scholar] [CrossRef] [PubMed]

- Greiner, L.; Kukla, P.; Eibl, S.; Döring, M. Phosphorus containing polyacrylamides as flame retardants for epoxy-based composites in aviation. Polymers 2019, 11, 284. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Dai, X.; Wang, Y.; Sun, G.; Li, P.; Qu, L.; Sui, Y.; Dou, Y. Preparation and corrosion resistance of ETEO modified graphene oxide/epoxy resin coating. Coatings 2019, 9, 46. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, Q.; Fang, C.; Chen, J.; Su, J.; Xu, K.; Ai, L.; Liu, D. Preparation, structure, and properties of surface modified graphene/epoxy resin composites for potential application in conductive ink. Coatings 2018, 8, 387. [Google Scholar] [CrossRef]

- Wise, C.W.; Cook, W.D.; Goodwin, A.A. CTBN rubber phase precipitation in model epoxy resins. Polymer 2000, 41, 4625–4633. [Google Scholar] [CrossRef]

- Chikhi, N.; Fellahi, S.; Bakar, M. Modification of epoxy resin using reactive liquid (ATBN) rubber. Eur. Polym. J. 2002, 38, 251–264. [Google Scholar] [CrossRef]

- Yun, N.G.; Won, Y.G.; Kim, S.C. Toughening of carbon fiber/epoxy composite by inserting polysulfone film to form morphology spectrum. Polymer 2004, 45, 6953–6958. [Google Scholar] [CrossRef]

- Su, C.; Wu, C.; Yang, C. Developing the dielectric mechanisms of polyetherimide/multiwalled carbon nanotube/(Ba0.8Sr0.2)(Ti0.9Zr0.1)O3 composites. Nanoscale Res. Lett. 2012, 7, 132. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Shao, W.; Wang, Y.; Xiao, D.; Xiong, Y.; Ye, H.; Zhou, Q.; Jin, Q. Synthesis and morphological control of biocompatible fluorescent/magnetic Janus nanoparticles based on the self-assembly of fluorescent polyurethane and Fe3O4 nanoparticles. Polymers 2019, 11, 272. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.-H.; Chen, M.-H. Synthesis, thermal properties, and morphology of blocked polyurethane/epoxy full-interpenetrating polymer network. J. Appl. Polym. Sci. 2006, 100, 323–328. [Google Scholar] [CrossRef]

- Chen, C.-H.; Sun, Y.-Y. Mechanical properties of blocked polyurethane/epoxy interpenetrating polymer networks. J. Appl. Polym. Sci. 2006, 101, 1826–1832. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, B.; Gong, W.; Kong, L.; Jia, Q. Investigation of the hydrogen bonding structure and miscibility for PU/EP IPN nanocomposites by PALS. Macromolecules 2006, 39, 9441–9445. [Google Scholar] [CrossRef]

- Sahu, M.; Raichur, A.M. Toughening of high performance tetrafunctional epoxy with poly(allylamine) grafted graphene oxide. Compos. Part B Eng. 2019, 168, 15–24. [Google Scholar] [CrossRef]

- ASTM D790M Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM International: West Conshohocken, PA, USA, 1993.

- ASTM D638-14 Standard Test Method for Tensile Properties of Plastics; ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D256-10 Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics; ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D1652-11e1 Standard Test Method for Epoxy Content of Epoxy Resins; ASTM International: West Conshohocken, PA, USA, 2011.

- Hill, L.W. Calculation of crosslink density in short chain networks. Prog. Org. Coat. 1997, 31, 235–243. [Google Scholar] [CrossRef]

- Vertuccio, L.; Guadagno, L.; Spinelli, G.; Russo, S.; Iannuzzo, G. Effect of carbon nanotube and functionalized liquid rubber on mechanical and electrical properties of epoxy adhesives for aircraft structures. Compos. Part B Eng. 2017, 129, 1–10. [Google Scholar] [CrossRef]

| Compositions (g) | YD-128 | D-230 | FMEP-PU |

|---|---|---|---|

| Binder | 100 | 32.1 | – |

| PU-5 | 100 | 32.1 | 5 |

| PU-10 | 100 | 32.1 | 10 |

| PU-15 | 100 | 32.1 | 15 |

| Compositions | Storage Modulus at Tg + 40 °C (MPa) | Tg (°C, with DMA) | Cross-Linking Density (moles/cm−3) |

|---|---|---|---|

| Binder | 10.78 | 108 | 1.03 × 10−3 |

| PU-5 | 3.17 | 72 | 0.33 × 10−3 |

| PU-10 | 4.75 | 78 | 0.49 × 10−3 |

| PU-15 | 5.45 | 82 | 0.55 × 10−3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, T.H.; Kim, M.; Lee, W.; Kim, H.-G.; Lim, C.-S.; Seo, B. Synthesis and Characterization of a Polyurethane Phase Separated to Nano Size in an Epoxy Polymer. Coatings 2019, 9, 319. https://0-doi-org.brum.beds.ac.uk/10.3390/coatings9050319

Kim TH, Kim M, Lee W, Kim H-G, Lim C-S, Seo B. Synthesis and Characterization of a Polyurethane Phase Separated to Nano Size in an Epoxy Polymer. Coatings. 2019; 9(5):319. https://0-doi-org.brum.beds.ac.uk/10.3390/coatings9050319

Chicago/Turabian StyleKim, Tae Hee, Miri Kim, Wonjoo Lee, Hyeon-Gook Kim, Choong-Sun Lim, and Bongkuk Seo. 2019. "Synthesis and Characterization of a Polyurethane Phase Separated to Nano Size in an Epoxy Polymer" Coatings 9, no. 5: 319. https://0-doi-org.brum.beds.ac.uk/10.3390/coatings9050319