1. Introduction

Horizontal-axis wind turbines constitute a mature technology; therefore, worldwide, there is a huge number of industrial wind farms that have been operating since approximately a couple of decades ago, which represents the end of their theoretical lifetime. Since it is well-known that performance decline with age substantially affects all the technical systems [

1], it would therefore be possible to analyze in depth this issue with regard to wind turbines, especially in light of the widespread availability of Supervisory Control And Data Acquisition (SCADA) data. This objective has scientific interest as well as practical interest, and it is connected to the perspective of refurbishing and repowering wind turbines [

2] that have been operating for a number of years.

Unexpectedly, the analysis of wind turbine aging is an overlooked topic in wind energy literature (many more studies are devoted to reliability analysis [

3,

4,

5,

6]) and few are the studies dealing with it. In [

7], public data of actual and theoretical load factors of 282 wind farms sited in UK are analyzed; the methodology is substantially statistical and it is based on the regression (possibly adjusted on the resource trend and on site-specific information) of the load factors against the age. The main result of [

7] is that wind turbines are estimated to lose

of their output per year, and this is equivalent to an increase of the 9% of the levelized cost of electricity in twenty years’ time. A similar approach is employed in [

8]: a regression between the capacity factor and the age of wind turbines in Sweden is attempted; the yearly weather fluctuations are taken into account by including sine and cosine functions of the age in the regression. The estimate is that the lifetime (20 years) energy loss is of the order of 6%, considerably lower with respect to the results in [

7].

The studies in [

7,

8] are a statistical analysis of yearly cumulative data of wind farms. Another line of research is possible as regards wind turbine aging, which consists in high-level operation data analysis: in fact, it is remarkable that several techniques have been developed and applied for wind turbine condition monitoring [

9,

10,

11,

12,

13,

14,

15] and precision performance analysis [

16,

17,

18,

19,

20,

21,

22], as is summarized for example in [

23], but very few studies are devoted to the use of the same kind of techniques for the analysis of wind turbine aging. At present, two studies of this kind are available in the literature. In [

24], the aging assessment is conducted by discussing what are the appropriate SCADA parameters to monitor and the analyzed targets are power fluctuations, vibrations and components heating. An interesting study, which constitutes the premise for the present work, is given in [

25]: the test case is the same as in this study and it is a Vestas V52 wind turbine, installed in 2005 at the Dundalk Institute of Technology in Ireland. Operation data from 2008 up to 2019 have been analyzed in [

25] and an overall wind turbine power and energy degradation in the order of 5% has been determined over the 13-year lifetime: the analysis has been based on a multivariate data-driven model whose target is the power of the wind turbine of interest. An important point of strength of the test case, and consequently of [

25] and of the present study, is that in October 2018 the gearbox of the wind turbine reached its end of life and this component was substituted in July 2019: therefore, since July 2019, the wind turbine has been running with a new gearbox and the rest of the components aged fourteen years. This situation allowed estimating in [

25], through appropriate operation data analysis, that the gearbox aging contributes approximately one third of the performance decline of the wind turbine.

Basing on the preliminary results in [

25], the general idea of the present work is studying wind turbine aging through the analysis of appropriate operation curves. The simplest and most straightforward curve of a wind turbine is the power curve [

26,

27,

28,

29], because it connects directly the input (wind intensity) to the output (produced power). There are other instructive operation curves [

30] of a wind turbine: examples can be the rotor speed–power curve, the generator speed–power curve, the blade pitch–power curve [

31] and these curves have been mainly employed in the literature for condition monitoring purposes.

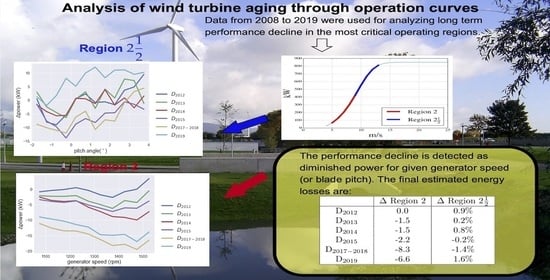

The approach of this study consists in analyzing separately the appropriate operation curves of the test case wind turbine for each region of the power curve (through the binning method, as recommended by the International Electrotechnical Commission IEC [

32]): in particular, in Region 2 (wind intensity between 5 and 9 m/s), the wind turbine operates to extract maximum power, the blade pitch angle is set to approximately

and the generator speed increases with the wind intensity. In this working region, the generator speed–power curve is selected as the operation curve of interest. In Region 2

(wind intensity between 9 and 13 m/s), the generator speed is rated and the wind turbine regulates the pitch to control the power extraction: in this working region, the operation curve of interest is the blade pitch–power curve. By analyzing the evolution in time of these curves, it is possible to appreciate the different aging depending on the operation regime: in particular, distinct aging of the generator is observed in the fact that, as years pass by, less power is extracted for given generator speed. It should be noticed that this result is scientifically novel because, to the best of the authors’ knowledge, similar conclusions have not been obtained elsewhere in the literature and, furthermore, this result has relevant practical applications in the wind turbine management.

Another key point of this study is that the curves describing the wind turbine in its early functioning years (2008) can be modeled, and in this work, a support vector regression (SVR) with Gaussian kernel is selected: the loss of energy due to aging for each operation region can therefore be estimated quantitatively by comparing the measured curves against the curves that are simulated using the SVR model which is trained with the data in the early functioning of the wind turbine. In other words, the evolution in time of the performance of the wind turbine is encoded in how the residuals between measurements and model estimate change.

It is also important to recall that since July 2019 the wind turbine has been operating with a brand new gearbox, while all the other components are aged fourteen years: by comparing this data set against the oldest ones and against the one immediately before the gearbox replacement (2018), it is possible to argue that most of the recovered energy is concentrated in Region 2

and that, as observed in [

25], only one third approximately of the overall production level of the 2008 has been recovered. The analysis of the operation curves presented in this work allows interpreting this matter of fact: most of the production, which has not been recovered with the gearbox replacement, regards Region 2 and therefore it can be stated that in Region 2 the aging of the generator has been particularly impacting along fourteen years of wind turbine lifetime. On the other hand, in Region 2

the impact of the gearbox aging dominates the generator aging because the performance of the wind turbine is more sensitive on the gearbox efficiency [

33]), since the generator speed is rated and the mechanical solicitations are highest: in this working region, it is observed that the replacement of the gearbox restores the optimal performance. Substantially, the general lesson is that the profitability of the substitution of a component for an aged wind turbine depends on how much time the wind turbine, due to the on site wind intensity conditions, operates in each working region. These kind of considerations are particularly important when conceiving possible refurbishment interventions on aged wind turbines.

The structure of the manuscript is therefore the following: in

Section 2, the test case wind turbine and the data sets at disposal for the present study are described;

Section 3 is devoted to the methods; the results are collected and discussed in

Section 4; conclusions are drawn and further directions of the present work are indicated in

Section 5.

2. The Test Case and the Data Set

The test case is the same as in the previous study [

25]: therefore, the present Section has substantial overlap with [

25], but more information is added, which is related to the improved methodology developed in this work.

In October 2005, the Dundalk Institute of Technology installed a Vestas V52 wind turbine on its campus. The turbine has a hub height of 60 m and a rotor diameter of 52 m. The wind turbine, as shown in

Figure 1 which is reported from [

25], is located at a peri-urban coastal site [

34]. The system is grid connected behind the main campus electricity meter and the produced electricity is primarily consumed onsite.

The Vestas V52 wind turbine has been widely installed worldwide in the past years: it is a semi-variable speed system with doubly fed induction generator (DFIG). The model of the generator in case is a Weier 850 kW, shown in

Figure 2, and the main features are reported in

Table 1. The wind turbine has an active pitching system: the blade pitch angles of all three rotor blades are controlled simultaneously by a hydraulic pitch control system using the Vestas Opti-tip

TM and Opti-speed

TM control mechanisms.

Time series data of a number of turbine parameters are logged by the wind turbine SCADA system in 10 min average values. The data available for the present study are indicated in

Table 2 and have been organized in 12-months packets, except for the 2019 data set, which consists in six months of data.

The data sets are therefore indicated in the following as follows:

(6 months).

In October 2018, the wind turbine gearbox, shown in

Figure 3 and principal specifications in

Table 3 which are reported from [

25], reached the end of life after thirteen years of operation and it was consequently replaced with a brand new gearbox of the same model and specifications in July 2019.

Therefore, referring to the data sets listed in

Table 2, the six months of data recorded in 2019 describe the wind turbine operating with a completely new gearbox and with the rest of the components aged 14 years. This is an important point, because it is possible to compare the 2019 data set against the one immediately before the gearbox replacement (2017–2018) and against the one in the early days of wind turbine functioning (2008).

For each data set, data have been filtered on wind turbine normal operation by employing the appropriate time counter available in the SCADA logger. Subsequently, each data set has been divided according to the operation region, as indicated in

Table 4, on the grounds of nacelle wind intensity

v. It should be noticed that in general, all the region between cut-in and rated wind speed is indicated as Region 2 but, in order to distinguish the working principles, also the notation of

Table 4 can be adopted. Region 2

and Region 2 are distinguished for the purposes of this study because the control works differently: in Region 2, the wind turbine operates at full load, the blade pitch is constant (set at a value approximately vanishing), and the generator speed increases with increasing wind intensity

v; in Region 2

, the generator speed is rated and the wind turbine works in partial load which is controlled through the blade pitch angle.

A detailed analysis of the onsite climatology is out of the scope of the present work; nevertheless an important information for understanding the net aging energy balance along all the power curve from cut-in to rated regards the fact that, during a year, the wind turbine operates in Region 2 approximately three times more time than in Region 2 . Therefore, the aging trend is substantially dominated by Region 2.

5. Conclusions

The present study has dealt with the use of operation data analysis for the assessment of wind turbine performance decline with age. This kind of study is motivated by the fact that horizontal-axis wind turbines constitute a mature technology and there are plenty of industrial wind farms reaching the end of their expected life (two decades, approximately). Nevertheless, this topic is overlooked in the scientific literature, especially as regards the application of high-level operation data analysis techniques which are commonly exploited for wind turbine control and monitoring: actually, the aging assessment can be conceived as a bird’s eye view on cumulative data or it can be conceived at the level of each wind turbine and this latter approach (the one perceived in this study) constitutes exactly a control and monitoring problem.

The test case of this study is a Vestas V52 which was installed in 2005 at the Dundalk Institute of Technology. Operation data from 2008 to the end of 2019 have been available and therefore the qualifying points of this study are

the possibility of spanning eleven years of operation data;

the type of data analysis which has been adopted, highlighting the different role of the sub-components in determining the performance decline.

The general idea of this work has actually been analyzing the aging of the wind turbine of interest by studying, in addition to the power curve, the appropriate operation curves for each working region. When the wind turbine operates at fixed pitch and maximum power extraction (Region 2: wind speed between 5 and 9 m/s), the generator speed–power curve has been analyzed; when the wind turbine operates with rated generator speed (Region 2 , wind speed between 9 and 13 m/s), the blade pitch angle–power curve has been analyzed. An interesting further added value of the present work is that the gearbox of the wind turbine was replaced in October 2018 and therefore it has been possible to study the aging of the wind turbine from 2008 to 2018 and, subsequently, the operation of the wind turbine with a new gearbox and the rest of the components aged fourteen years (data from 2019): this feature of the test case allows corroborating the interpretation about the role of the gearbox and of the generator aging in determining the actual performance decline.

From the analysis of the curves, it arises that in Region 2 the amount of power extracted for given generator speed declines progressively with the age and in ten years time this phenomenon reaches a remarkable degree of severity. Consistently, after the gearbox replacement, a very partial performance recovery has occurred in Region 2, which can be probably be explained as due to diminished bearing heating because of diminished vibrations transmitted from the gearbox. In Region 2 the average performance decline with age has become relevant after around ten years of operation and the gearbox replacement has restored optimal performance level: this can be explained as due to the fact that likely gearbox aging overwhelms generator aging in Region 2 or, in other words, wind turbine performance is more sensitive to gearbox efficiency in Region 2 .

In order to achieve a quantitative analysis of wind turbine aging for each working region, the above curves of interest have been modeled through a nonlinear regression (support vector regression with Gaussian kernel) and the aging has been estimated as follows: the regression has been trained with data describing the wind turbine at its earliest functioning (2008, the oldest data set at disposal for the study) and it has been applied to simulate the output (i.e., the power of the wind turbine) for data sets posterior to 2008. The performance aging is encoded in how the residuals between model estimates and measurements evolve in time. Through this kind of analysis, it has been observed that there is a progressive performance deterioration in Region 2, which peaks after ten years of operation, reaching order of 8%. In Region 2 , the performance decline with age is less regular in time and definitely becomes non-negligible in 2017–2018, when it reaches order of 1.3% with respect to ten years before.

Therefore, summarizing, it can be stated that in the present work the remarkable average performance decline with age (estimated in [

25] as order of 5% in 2017–2018 with respect to 2008) of the test case wind turbine is shown to be due mainly to the worsening of the generator performance: to the best of the authors’ knowledge, this is the first study containing a data-driven interpretation of wind turbine aging, which takes into accounts the behavior of the different components. Furthermore, a key result of this study is that the analysis of the appropriate operation curves depending on the working region identifies that the aging of each main sub-component impacts differently on the different regions of the power curve: this result is intuitive and consistent, but was not visualized before in the literature. In particular, the aging of the generator is a determining factor for explaining the performance in Region 2, while the aging of the gearbox should be taken into account especially in Region 2

but, at least for this kind of technology, in general it seems to be less impacting on the energy yield.

After the gearbox replacement, the production has improved substantially in Region 2

(+3% in 2019 with respect to 2018, +1.7% with respect to 2008), while in Region 2 an improvement is observed with respect to the data set immediately before the replacement (+1.9% in 2019 with respect to 2018) which does not compensate the ten years period decline (−6.5% in 2019 with respect to 2008). The results reported in the preliminary study in [

25] find an interpretation through the present analysis: the gearbox replacement has restored around only one third of the performance decline in ten years time and this has occurred because this wind turbine operates most of the time in Region 2, where the generator aging is particularly relevant. A further remark deals with the fact the wind speed–rotor speed curve has been briefly analyzed too and it results that its degradation in time is negligible: this can be interpreted as due to the fact the blade aging should not impact remarkably on energy yield deterioration.

Several are the possible further directions of the present work. The model type of the wind turbine selected for this study (Vestas V52) is widely diffuse worldwide and it would therefore be interesting to analyze how much general are the aging trends reported in the present work. One of the main novelties of the results presented in this work is, to the best of the authors’ knowledge, the quantitative estimate of the possibly remarkable impact of the generator aging on wind turbine performance: in the present study, it has not been possible to characterize this phenomenon further because the operation data available are those listed in

Section 2 and do not include electric parameters (voltage and currents), but it would be extremely valuable to analyze the operation curves involving these kind of measurements. At present, further test case studies are being conducted in order to address these issues. Another important development, which is currently at study, is the application of this kind of approach to more modern multi-MW wind turbines because many of them operating since approximately a decade: the objective is understanding the effect of aging depending on the technology development and on the increasing wind turbine size.