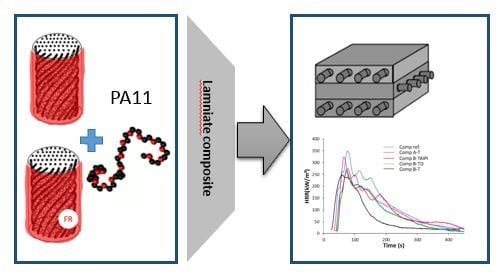

Sol–Gel Treatments to Flame Retard PA11/Flax Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sol–Gel Treatments of the Fibers

2.3. Composite Preparation

2.4. Characterization

2.4.1. Electronic Microscopy Analyses

2.4.2. Solid-State NMR Characterizations

2.4.3. Fire Tests

3. Results and Discussion

3.1. Characterization of the Fabrics

3.1.1. SEM Characterization

3.1.2. Solid-State NMR

3.2. Fire Performance of the FR Fabrics

3.3. Fire Performance of the Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lebaupin, Y.; Chauvin, M.; Hoang, T.-Q.T.; Touchard, F.; Beigbeder, A. Influence of constituents and process parameters on mechanical properties of flax fibre-reinforced polyamide 11 composite. J. Thermoplast. Compos. Mater. 2017, 30, 1503–1521. [Google Scholar] [CrossRef]

- Gourier, C.; Bourmaud, A.; le Duigou, A.; Baley, C. Influence of PA11 and PP thermoplastic polymers on recycling stability of unidirectional flax fibre reinforced biocomposites. Polym. Degrad. Stab. 2017, 136, 1–9. [Google Scholar] [CrossRef]

- Bourmaud, A.; le Duigou, A.; Gourier, C.; Baley, C. Influence of processing temperature on mechanical performance of unidirectional polyamide 11-flax fibre composites. Ind. Crop. Prod. 2016, 84, 151–165. [Google Scholar] [CrossRef]

- Lebaupin, Y.; Chauvin, M.; Truong Hoang, T.Q.; Touchard, F. Effect of stacking sequence on low velocity impact and post-impact behavior of flax/polyamide 11 composites. In Proceedings of the ECCM 2016—17th European Conference on Composite Materials, Munich, Germany, 26–30 June 2016. [Google Scholar]

- Kandola, B.K.; Horrocks, A.R.; Myler, P.; Blair, D. New developments in flame retardancy of glass-reinforced epoxy composites. J. Appl. Polym. Sci. 2003, 88, 2511–2521. [Google Scholar] [CrossRef]

- Bourbigot, S.; Bachelet, P.; Samyn, F.; Jimenez, M.; Duquesne, S. Intumescence as method for providing fire resistance to structural composites: Application to poly(ethylene terephtalate) foam sandwich-structured composite. Compos. Interface 2013, 20, 269–277. [Google Scholar] [CrossRef]

- Horrocks, A.R.; Kandola, B.K. Chapter 11. Flame resistant composites and nanocomposites. In Handbook of Fire Resistant Textiles, 1st ed.; Selcen Kilinc, F., Ed.; Woodhead Publishing: Cambridge, UK, 2013; pp. 283–321. [Google Scholar]

- Samyn, F.; Duquesne, S.; Bourbigot, S.; Ouagne, P. Finding the right balance between fire performances and mechanical properties. In Proceedings of the 25th Annual Conference on Recent Advances in Flame Retardancy of Polymeric Materials, Stamford, CT, USA, 19–21 May 2014. [Google Scholar]

- Kandare, E.; Chukwunonso, A.K.; Kandola, B.K. The effect of fire-retardant additives and a surface insulative fabric on fire performance and mechanical property retention of polyester composites. Fire Mater. 2011, 35, 143–155. [Google Scholar] [CrossRef]

- Chapple, S.; Anandjiwala, R. Flammability of natural fiber-reinforced composites and strategies for fire retardancy: A review. J. Thermoplast. Compos. Mater. 2010, 23, 871–893. [Google Scholar] [CrossRef]

- Samyn, F.; Duquesne, S.; Bourbigot, S.; Ouagne, P. Strategies for flame retarding bio-composites. In Proceedings of the 8th Asian-Australasian Conference on Composite Materials ACCM 2012-Composites: Enabling Tomorrow’s Industry Today, Kuala Lumpur, Malaysia, 6–8 November 2012; Jaafar, M., Azura, A.R., Leong, K.H., Leong, A.Y., Eds.; AACM: Phoenix, AZ, USA, 2012; pp. 155–160. [Google Scholar]

- Duquesne, S.; Samyn, F.; Ouagne, P.; Bourbigot, S. Flame retardancy and mechanical properties of flax reinforced woven for composite applications. J. Ind. Text. 2015, 44, 665–681. [Google Scholar] [CrossRef]

- Kandola, B.K.; Pornwannachai, W.; Alongi, J.; Caminade, E. Thermal protection of natural fibre thermoplastic composites using sol-gel coatings. In Proceedings of the Fire and Materials 2015—14th International Conference and Exhibition, San Francisco, CA, USA, 2–4 February 2015; pp. 453–463. [Google Scholar]

- Bourbigot, S. Flame retardancy of textiles: New approaches. In Advances in Fire Retardant Materials, 1st ed.; Horrock, A.R., Price, D., Eds.; Woodhead publishing Ltd.: Cambridge, UK, 2008; pp. 9–40. [Google Scholar]

- Horrocks, A.R.; Price, D. Fire Retardant Materials; Woodhead Publishing Ltd.: Cambridge, UK, 2001; pp. 128–181. [Google Scholar]

- Bajaj, P. Handbook of Technical Textiles; Woodhead Publishing Ltd.: Cambridge, UK, 2000; pp. 223–263. [Google Scholar]

- Alongi, J.; Malucelli, G. State of the art and perspectives on sol-gel derived hybrid architectures for flame retardancy of textiles. J. Mater. Chem. 2012, 22, 21805–21809. [Google Scholar] [CrossRef]

- Malucelli, G. Sol–gel flame retardant and/or antimicrobial finishings for cellulosic textiles. In Handbook of Renewable Materials for Coloration and Finishing; Mohd, Y., Ed.; Wiley: Hoboken, NJ, USA, 2018; pp. 501–519. [Google Scholar]

- Castellano, A.; Colleoni, C.; Iacono, G.; Mezz, A.; Plutino, M.R.; Malucelli, G.; Rosace, G. Synthesis and characterization of a phosphorous/nitrogen based sol-gel coating as a novel halogen- and formaldehyde-free flame retardant finishing for cotton fabric. Polym. Degrad. Stab. 2019, 162, 148–159. [Google Scholar] [CrossRef]

- Rosace, G.; Castellano, A.; Trovato, V.; Iacono, G.; Malucelli, G. Thermal and flame retardant behaviour of cotton fabrics treated with a novel nitrogen-containing carboxyl-functionalized organophosphorus system. Carbohydr. Polym. 2018, 196, 348–358. [Google Scholar] [CrossRef] [PubMed]

- Alongi, J.; Colleoni, C.; Rosace, G.; Malucelli, G. Phosphorus- and nitrogen-doped silica coatings for enhancing the flame retardancy of cotton: Synergisms or additive effects? Polym. Degrad. Stab. 2013, 98, 579–589. [Google Scholar] [CrossRef]

- Bounor-Legaré, V.; Cassagnau, P. In situ synthesis of organic–inorganic hybrids or nanocomposites from sol–gel chemistry in molten polymers. Prog. Polym. Sci. 2014, 39, 1473–1497. [Google Scholar] [CrossRef]

- Cardenas, A.; Hovnanian, N.; Smaihi, M. Sol-gel formation of heteropolysiloxanes from diethylphosphatoethyltriethoxysilane and tetraethoxysilane. J. Appl. Polym. Sci. 1996, 60, 2279–2288. [Google Scholar] [CrossRef]

- Hendrix, E.; Bostic, J.E.; Olson, J.S.; Barker, E.H. Pyrolysis combustion of cellulose, I. Effects of triphenyl phosphate in the presence of nitrogenous bases. J. Appl. Polym. Sci. 1970, 14, 1701–1723. [Google Scholar] [CrossRef]

- Boryniec, S.; Przygocki, W. Polymer combustion processes. 3. Flame retardants for polymeric materials. Prog. Rubber Plast. Technol. 2001, 17, 59–80. [Google Scholar]

- Bellayer, S.; Jimenez, M.; Gardelle, B.; Delaplace, G.; Bouquerel, J.; Duquesne, S.; Bourbigot, S. The electron microanalyzer (EPMA): A powerful device for the microanalysis of filled polymeric materials. Polym. Adv. Technol. 2015, 26, 1020–1026. [Google Scholar] [CrossRef]

- Glaser, R.H.; Wilkes, G.L.; Bronnimann, C.E. Solid-state 29Si NMr of TEOS-based multifunctional sol-gel materials. J. Non-Cryst. Solids 1989, 113, 73–87. [Google Scholar] [CrossRef]

- Garnier, A.; Da Cruz-Boisson, F.; Rigolet, S.; Brendlé, J.; Bounor-Legaré, V. Hydrolysis-condensation reactions of diethylphosphato-ethyltriethoxysilane involved in organic-inorganic talc-like hybrid synthesis: Liquid and solid-state NMR investigations. RSC Adv. 2016, 6, 75715–75723. [Google Scholar] [CrossRef]

- Zhang, S.; Tang, W.; Gu, X.; Jiang, P.; Sun, J.; Duquesne, S.; Bourbigot, S.; Casetta, M. Flame retardancy and thermal and mechanical performance of intercalated, layered double hydroxide composites of polyamide 11, aluminum phosphinate, and sulfamic acid. J. Appl. Polym. Sci. 2016, 133, 43370. [Google Scholar] [CrossRef]

| Code | Precursor Ratio (wt.%) | T (mL) | D (mL) | A (mL) | Additive (g) | HCl (mL) | Ethanol (mL) | Water (mL) |

|---|---|---|---|---|---|---|---|---|

| A-T | 100 | 6.84 | 8 | 5 | 80.16 | |||

| B-T | 100 | 17.25 | 20.17 | 12.61 | 50 | |||

| A-TD | 70/30 | 4.79 | 2.05 | 8 | 5 | 80.16 | ||

| B-TD * | 70/30 | 12.07 | 5.17 | 20.17 | 12.61 | 50 | ||

| A-TDA | 55/38/7 | 3.76 | 2.62 | 0.46 | 8 | 5 | 80.16 | |

| A-T/TD/TA | ||||||||

| L1:T | 100 | 6.84 | 8 | 5 | 80.16 | |||

| L2:TD | 70/30 | 4.79 | 2.05 | 8 | 5 | 80.16 | ||

| L3:TA | 85/15 | 5.81 | 1.03 | 8 | 5 | 80.16 | ||

| A-TAlPi | 100 | 6.84 | 0.8885 | 8 | 5 | 80.16 | ||

| B-TAlPi * | 100 | 17.44 | 2.2407 | 20.17 | 12.61 | 50 | ||

| A-TAlPiMPP | 100 | 6.84 | 1.044 | 8 | 5 | 80.16 |

| 29Si (ppm) | Assignment | Formula | 31P (ppm) | Assignment |

|---|---|---|---|---|

| −55 | T2 | R-Si(OH)(OSi-)2 | 63 | Not attributed yet |

| −62 | T3 | R-Si(OSi-)3 | 54 | |

| −65 | T3 | R-Si(OSi-)3 | 51 | |

| −88 | T3 | H-Si(OSi-)3 | 43–41 | AlPi |

| −96 | Q3 | Si(OH)(OSi-)3 | 34 | DEPTES |

| −105 | Q4 | Si(OSi-)4 | 33 |

| Sample Reference | Ti (s) | pHRR (kW/m2) | THR (MJ) | Residue (wt.%) |

|---|---|---|---|---|

| Comp. ref. | 45 ± 1 | 349 ± 2 | 49 ± 1 | 36 ± 1 |

| Comp. A-T | 33 ± 0 | 286 ± 20 | 43 ± 4 | 39 ± 2 |

| Comp. B-T | 28 ± 4 | 244 ± 6 | 29 ± 3 | 49 ± 0.4 |

| Comp. B-TD | 36 ± 4 | 251 ± 23 | 34 ± 7 | 45 ± 8 |

| Comp. B-AlPi | 41 ± 1 | 250 ± 35 | 39 ± 5 | 44 ± 4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samyn, F.; Vandewalle, M.; Bellayer, S.; Duquesne, S. Sol–Gel Treatments to Flame Retard PA11/Flax Composites. Fibers 2019, 7, 86. https://0-doi-org.brum.beds.ac.uk/10.3390/fib7100086

Samyn F, Vandewalle M, Bellayer S, Duquesne S. Sol–Gel Treatments to Flame Retard PA11/Flax Composites. Fibers. 2019; 7(10):86. https://0-doi-org.brum.beds.ac.uk/10.3390/fib7100086

Chicago/Turabian StyleSamyn, Fabienne, Maxence Vandewalle, Séverine Bellayer, and Sophie Duquesne. 2019. "Sol–Gel Treatments to Flame Retard PA11/Flax Composites" Fibers 7, no. 10: 86. https://0-doi-org.brum.beds.ac.uk/10.3390/fib7100086