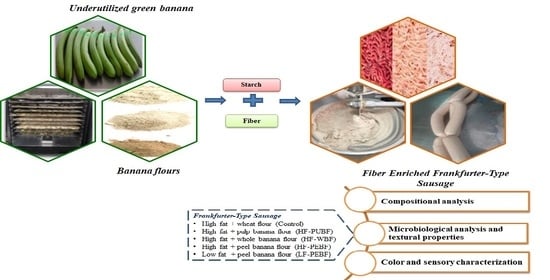

Underutilized Green Banana (Musa acuminata AAA) Flours to Develop Fiber Enriched Frankfurter-Type Sausages

Abstract

:1. Introduction

2. Materials and Methods

2.1. Elaboration of Banana Flour

2.2. Frankfurter-Type Sausage Preparations

2.3. Cooking Loss

2.4. Proximal Analysis

2.5. Energy Value

2.6. pH and Acidity

2.7. Texture

2.8. Color Determination

2.9. Microbiological Analysis

2.10. Sensory Analysis

2.11. Experimental Analysis

3. Results and Discussion

3.1. Cooking Loss

3.2. Proximal Composition and Nutritional Estimations

3.3. pH and Acidity

3.4. Textural Properties

3.5. Appearance and Color

3.6. Microbiological Analysis

3.7. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dos Santos Alves, L.A.A.; Lorenzo, J.M.; Gonçalves, C.A.A.; Dos Santos, B.A.; Heck, R.T.; Cichoski, A.J.; Campagnol, P.C.B. Production of healthier bologna type sausages using pork skin and green banana flour as a fat replacers. Meat Sci. 2016, 121, 73–78. [Google Scholar] [CrossRef] [PubMed]

- Jiménez-Colmenero, F.; Carballo, J.; Cofrades, S. Healthier meat and meat products: Their role as functional foods. Meat Sci. 2001, 59, 5–13. [Google Scholar] [CrossRef]

- Yadav, S.; Malik, A.; Pathera, A.; Islam, R.U.; Sharma, D. Development of dietary fibre enriched chicken sausages by incorporating corn bran, dried apple pomace and dried tomato pomace. Nutr. Food Sci. 2016, 46, 16–29. [Google Scholar] [CrossRef]

- Elizabeth, L.; Machado, P.; Zinöcker, M.; Baker, P.; Lawrence, M. Ultra-Processed Foods and Health Outcomes: A Narrative Review. Nutrients 2020, 12, 1955. [Google Scholar] [CrossRef]

- GBD 2017 Diet Collaborators. Health effects of dietary risks in 195 countries, 1990–2017: A systematic analysis for the Global Burden of Disease Study 2017. Lancet 2019, 393, 1958–1972. [Google Scholar] [CrossRef] [Green Version]

- Nair, K.P. Overweight and Obesity: The Bane of Modern Times. In Food and Human Responses; Springer Science and Business Media LLC: Berlin, Germany, 2020; pp. 173–203. [Google Scholar]

- FAO. The Future of Food and Agriculture: Trends and Challenges; The Food and Agriculture Organization (FAO): Rome, Italy, 2017. [Google Scholar]

- Rosero-Chasoy, G.; Serna-Cock, L. Effect of Plantain (Musa paradisiaca L. Cv. Dominico Harton) Peel Flour as Binder in Frankfurter-Type Sausage. Acta Agron. 2017, 66, 305–310. [Google Scholar] [CrossRef]

- Fernández-López, J.; Sendra, E.; Sayas-Barberá, E.; Navarro, C.; Pérez-Alvarez, J.A. Physico-Chemical and Microbiological Profiles of “Salchichón” (Spanish Dry-Fermented Sausage) Enriched with Orange Fiber. Meat Sci. 2008, 80, 410–417. [Google Scholar] [CrossRef]

- Fernández-Ginés, J.M.; Fernández-López, J.; Sayas-Barberá, E.; Sendra, E.; Pérez-Alvarez, J.A. Effect of Storage Conditions on Quality Characteristics of Bologna Sausages Made with Citrus Fiber. J. Food Sci. 2003, 68, 710–714. [Google Scholar] [CrossRef]

- Shand, P.J. Textural, Water Holding, and Sensory Properties of Low-Fat PORK Bologna with Normal or Waxy Starch Hull-Less Barley. J. Food Sci. 2000, 65, 101–107. [Google Scholar] [CrossRef]

- Andréa, D.A.S.; Barbosa, J.L., Jr.; Barbosa, M.I.M.J. Farinha de Banana Verde Como Ingrediente Funcional em Produtos Alimentícios. Cienc. Rural. 2015, 45, 2252–2258. [Google Scholar]

- Ninan, G.; Aswathy, K.S.; Joshy, C.G. Development of Dietary Fiber-Incorporated Fish Sausage. FishTech Rep. 2018, 4, 16. [Google Scholar]

- Barış, Y.; Kaban, G.; Kaya, M. The Effects of Different Levels of Orange Fiber and Fat on Microbiological, Physical, Chemical and Sensorial Properties of Sucuk. Food Microbiol. 2012, 29, 255–259. [Google Scholar]

- FAO. Banana Market Review: Preliminary Results for 2018; The Food and Agriculture Organization (FAO): Rome, Italy, 2019; p. 12. [Google Scholar]

- Sartori, T.; Menegalli, F.C. Development and characterization of unripe banana starch films incorporated with solid lipid microparticles containing ascorbic acid. Food Hydrocoll. 2016, 55, 210–219. [Google Scholar] [CrossRef]

- Stanley, R. Commercial Feasibility of Banana Waste Utilisation in the Processed Food Industry; Hort Innovation: Sydney, Australia, 2017. [Google Scholar]

- Pereira, A.; Maraschin, M. Banana (Musa spp) from peel to pulp: Ethnopharmacology, source of bioactive compounds and its relevance for human health. J. Ethnopharmacol. 2015, 160, 149–163. [Google Scholar] [CrossRef] [PubMed]

- Auriema, B.E.; Corrêa, F.J.B.; Guimarães, J.D.T.; Soares, P.T.D.S.; Rosenthal, A.; Zonta, E.; Rosa, R.C.C.; Luchese, R.H.; Esmerino, E.A.; Mathias, S.P. Green banana biomass: Physicochemical and functional properties and its potential as a fat replacer in a chicken mortadella. LWT 2021, 140, 110686. [Google Scholar] [CrossRef]

- Alkarkhi, A.F.; Bin Ramli, S.; Yong, Y.S.; Easa, A.M. Comparing physicochemical properties of banana pulp and peel flours prepared from green and ripe fruits. Food Chem. 2011, 129, 312–318. [Google Scholar] [CrossRef]

- Bi, Y.; Zhang, Y.; Jiang, H.; Hong, Y.; Gu, Z.; Cheng, L.; Li, Z.; Li, C. Molecular structure and digestibility of banana flour and starch. Food Hydrocoll. 2017, 72, 219–227. [Google Scholar] [CrossRef]

- Raigond, P.; Ezekiel, R.; Raigond, B. Resistant starch in food: A review. J. Sci. Food Agric. 2015, 95, 1968–1978. [Google Scholar] [CrossRef] [PubMed]

- AOAC. Official Methods of Analysis, 18th ed.; The Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Choe, J.-H.; Kim, H.-Y.; Lee, J.-M.; Kim, Y.-J.; Kim, C.-J. Quality of frankfurter-type sausages with added pig skin and wheat fiber mixture as fat replacers. Meat Sci. 2013, 93, 849–854. [Google Scholar] [CrossRef] [PubMed]

- Henning, S.S.; Tshalibe, P.; Hoffman, L.C. Physico-chemical properties of reduced-fat beef species sausage with pork back fat replaced by pineapple dietary fibres and water. LWT 2016, 74, 92–98. [Google Scholar] [CrossRef]

- Choi, Y.-S.; Kim, H.-W.; Hwang, K.-E.; Song, D.-H.; Choi, J.-H.; Lee, M.-A.; Chung, H.-J.; Kim, C.-J. Physicochemical properties and sensory characteristics of reduced-fat frankfurters with pork back fat replaced by dietary fiber extracted from makgeolli lees. Meat Sci. 2014, 96, 892–900. [Google Scholar] [CrossRef] [PubMed]

- Chin, K.B.; Lee, H.L.; Chun, S.S. Product Characteristics of Comminuted Sausages as Affected by Various Fat and Moisture Combinations. Asian Australas. J. Anim. Sci. 2004, 17, 538–542. [Google Scholar] [CrossRef]

- Chang, H.-C.; Carpenter, J.A. Optimizing Quality of Frankfurters Containing Oat Bran and Added Water. J. Food Sci. 1997, 62, 194–197. [Google Scholar] [CrossRef]

- Choe, J.; Kim, H.-Y. Quality characteristics of reduced fat emulsion-type chicken sausages using chicken skin and wheat fiber mixture as fat replacer. Poult. Sci. 2019, 98, 2662–2669. [Google Scholar] [CrossRef] [PubMed]

- Melissa, A.; Santana-Gálvez, J.; Santacruz, A.; Carranza-Montealvo, L.D.; Ortega-Hernández, E.; Tirado-Escobosa, J.; Cisneros-Zevallos, L.; Jacobo-Velázquez, D.A. Using a Functional Carrot Powder Ingredient to Produce Sausages with High Levels of Nutraceuticals. J. Food Sci. 2018, 83, 2351–2361. [Google Scholar]

- Méndez-Zamora, G.; García-Macías, J.A.; Santellano-Estrada, E.; Chávez-Martínez, A.; Durán-Meléndez, L.A.; Silva-Vázquez, R.; Quintero-Ramos, A. Fat reduction in the formulation of frankfurter sausages using inulin and pectin. Food Sci. Technol. 2015, 35, 25–31. [Google Scholar] [CrossRef] [Green Version]

- Mehta, N.; Ahlawat, S.S.; Sharma, D.P.; Dabur, R.S. Novel trends in development of dietary fiber rich meat products—A critical review. J. Food Sci. Technol. 2013, 52, 633–647. [Google Scholar] [CrossRef] [Green Version]

- The European Parliament. Regulation (Ec) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on Nutrition and Health Claims Made on Foods. Corrigendum to Regulation (Ec) No 1924/2006. (2006R1924-ES-13.12.2014-004.001-2). 2006. Available online: https://eur-lex.europa.eu/legal-content/ES/TXT/PDF/?uri=CELEX:02006R1924-20141213&from=EN (accessed on 13 December 2014).

- Fernández-Ginés, J.; Fernández-López, J.; Sayas-Barberá, E.; Sendra, E.; Pérez-Álvarez, J. Lemon albedo as a new source of dietary fiber: Application to bologna sausages. Meat Sci. 2004, 67, 7–13. [Google Scholar] [CrossRef]

- Salcedo-Sandoval, L.; Cofrades, S.; Pérez, C.R.-C.; Solas, M.; Jimenez-Colmenero, F. Healthier oils stabilized in konjac matrix as fat replacers in n−3 PUFA enriched frankfurters. Meat Sci. 2013, 93, 757–766. [Google Scholar] [CrossRef]

- WHO. Diet, Nutrition and the Prevention of Chronic Diseases; Technical Report Series 916; World Health Organization: Geneva, Switzerland, 2003. [Google Scholar]

- Moss, H.; Miskelly, D.; Moss, R. The effect of alkaline conditions on the properties of wheat flour dough and cantonese-style noodles. J. Cereal Sci. 1986, 4, 261–268. [Google Scholar] [CrossRef]

- Saifullah, R.; Abbas FM, A.; Yeoh, S.Y.; Azhar, M.E. Utilization of Green Banana Flour as a Functional Ingredient in Yellow Noodle. Int. Food Res. J. 2009, 16, 373–379. [Google Scholar]

- Choi, Y.-S.; Park, K.-S.; Kim, H.-W.; Hwang, K.-E.; Song, D.-H.; Choi, M.-S.; Lee, S.-Y.; Paik, H.-D.; Kim, C.-J. Quality characteristics of reduced-fat frankfurters with pork fat replaced by sunflower seed oils and dietary fiber extracted from makgeolli lees. Meat Sci. 2013, 93, 652–658. [Google Scholar] [CrossRef] [PubMed]

- Pietrasik, Z.; Janz, J. Utilization of pea flour, starch-rich and fiber-rich fractions in low fat bologna. Food Res. Int. 2010, 43, 602–608. [Google Scholar] [CrossRef]

- Yorleny, A.; Morales-Torres, A.; Wexler, L.; Vargas-Aguilar, P. Technological Potential of Green Banana Flour with Peel (Musa AAB) as a Fat Substitute for Meat Gels. INNOTEC. 2014, pp. 50–60. Available online: https://ojs.latu.org.uy/index.php/INNOTEC/article/view/256 (accessed on 13 December 2014).

- Flores, J.L. Efecto de la Harina de Fibra de Trigo (Triticum aestivum) o de Soya (Glycine max) en la Elaboración de Chorizos Parrilleros Como Fuente de Fibra; Zamorano Pan-American Agricultural School: Tegucigalpa, Honduras, 2016. [Google Scholar]

- Mehdi, A.; Hojjatoleslamy, M.; Boroujeni, L.S. The Influence of Fat Substitution with Κ-Carrageenan, Konjac, and Tragacanth on the Textural Properties of Low-Fat Sausage. Food Sci. Nutr. 2018, 6, 1015–1022. [Google Scholar]

- Tahmasebi, M.; Labbafi, M.; Emam-Djomeh, Z.; Yarmand, M.S. Manufacturing the novel sausages with reduced quantity of meat and fat: The product development, formulation optimization, emulsion stability and textural characterization. LWT 2016, 68, 76–84. [Google Scholar] [CrossRef]

- Huang, S.; Bohrer, B.M. The effect of tropical flours (breadfruit and banana) on structural and technological properties of beef emulsion modeling systems. Meat Sci. 2020, 163, 108082. [Google Scholar] [CrossRef] [PubMed]

- dos Santos, M.; Munekata, P.E.; Pateiro, M.; Magalhães, G.C.; Barretto, A.C.S.; Lorenzo, J.M.; Pollonio, M.A.R. Pork skin-based emulsion gels as animal fat replacers in hot-dog style sausages. LWT 2020, 132, 109845. [Google Scholar] [CrossRef]

- Pereira, J.; Brohi, S.A.; Malairaj, S.; Zhang, W.; Zhou, G.-H. Quality of fat-reduced frankfurter formulated with unripe banana by-products and pre-emulsified sunflower oil. Int. J. Food Prop. 2020, 23, 420–433. [Google Scholar] [CrossRef] [Green Version]

- Kaack, K.; Pedersen, L. Application of by-products from industrial processing of potato flour and yellow peas as ingredients in low-fat high-fibre sausages. Eur. Food Res. Technol. 2005, 221, 313–319. [Google Scholar] [CrossRef]

- Choi, Y.-S.; Choi, J.-H.; Han, D.-J.; Kim, H.-Y.; Lee, M.-A.; Jeong, J.-Y.; Chung, H.-J.; Kim, C.-J. Effects of replacing pork back fat with vegetable oils and rice bran fiber on the quality of reduced-fat frankfurters. Meat Sci. 2010, 84, 557–563. [Google Scholar] [CrossRef]

- Dzudie, T.; Scher, J.; Hardy, J. Common bean flour as an extender in beef sausages. J. Food Eng. 2002, 52, 143–147. [Google Scholar] [CrossRef]

- Mansour, E.H.; Khalil, A.H. Characteristics of low-fat beefburgers as influenced by various types of wheat fibres. J. Sci. Food Agric. 1999, 79, 493–498. [Google Scholar] [CrossRef]

- Choi, Y.-S.; Choi, J.-H.; Han, D.-J.; Kim, H.-Y.; Lee, M.-A.; Kim, H.-W.; Jeong, J.-Y.; Kim, C.-J. Effects of rice bran fiber on heat-induced gel prepared with pork salt-soluble meat proteins in model system. Meat Sci. 2011, 88, 59–66. [Google Scholar] [CrossRef] [PubMed]

- Ranucci, D.; Roila, R.; Andoni, E.; Braconi, P.; Branciari, R. Punica granatum and Citrus spp. Extract Mix Affects Spoilage Microorganisms Growth Rate in Vacuum-Packaged Cooked Sausages Made from Pork Meat, Emmer Wheat (Triticum dicoccum Schübler), Almond (Prunus dulcis Mill.) and Hazelnut (Corylus avellana L.). Foods 2019, 8, 664. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cerón-Guevara, M.I.; Rangel-Vargas, E.; Lorenzo, J.M.; Bermúdez, R.; Pateiro, M.; Rodríguez, J.A.; Sánchez-Ortega, I.; Santos, E.M. Reduction of Salt and Fat in Frankfurter Sausages by Addition of Agaricus Bisporus and Pleurotus Ostreatus Flour. Foods 2020, 9, 760. [Google Scholar] [CrossRef]

- Sachindra, N.; Sakhare, P.; Yashoda, K.; Rao, D.N. Microbial profile of buffalo sausage during processing and storage. Food Control 2005, 16, 31–35. [Google Scholar] [CrossRef]

- Almeida, M.C.B.D.M.; Costa, S.D.S.; Cavalcanti, M.T.; Almeida, E.L. Characterization of Prata Banana (Musa AAB- Prata) Starch: Native and Modified by Annealing. Starch Stärke 2020, 72, 1900137. [Google Scholar] [CrossRef]

- Lin, L.; Hu, J.Y.; Wu, Y.; Chen, M.; Ou, J.; Yan, W.L. Assessment of the inhibitory effects of sodium nitrite, nisin, potassium sorbate, and sodium lactate on Staphylococcus aureus growth and staphylococcal enterotoxin A production in cooked pork sausage using a predictive growth model. Food Sci. Hum. Wellness 2018, 7, 83–90. [Google Scholar] [CrossRef]

- Jakobsen, L.M.A.; Vuholm, S.; Aaslyng, M.D.; Kristensen, M.; Sørensen, K.V.; Raben, A.; Kehlet, U. Sensory characteristics and consumer liking of sausages with 10% fat and added rye or wheat bran. Food Sci. Nutr. 2014, 2, 534–546. [Google Scholar] [CrossRef]

| Properties | Control | HF-PUBF | HF-WBF | HF-PEBF | LF-PEBF |

|---|---|---|---|---|---|

| Cooking loss (%) | 5.35 ± 0.05 b | 4.88 ± 0.03 d | 5.03 ± 0.03 c | 4.41 ± 0.04 e | 5.65 ± 0.05 a |

| Moisture (%) | 56.77 ± 0.12 c | 57.22 ± 0.14 b | 56.86 ± 0.14 c | 58.69 ± 0.04 a | 55.12 ± 0.07 d |

| Ash (%) | 0.63 ± 0.12 c | 0.22 ± 0.07 d | 0.44 ± 0.17 cd | 0.79 ± 0.21 b | 1.61 ± 0.07 a |

| Protein (%) | 10.15 ± 0.01 c | 10.49 ± 0.02 b | 10.71 ± 0.01 a | 10.50 ± 0.01 b | 9.56 ± 0.01 d |

| Fat (%) | 24.78 ± 0.01 b | 22.25 ± 0.05 a | 23.62 ± 0.01 c | 21.06 ± 0.02 d | 12.69 ± 0.01 e |

| Fiber (%) | 4.31 ± 0.01 e | 5.37 ± 0.01 c | 5.19 ± 0.01 d | 7.30 ± 0.01 b | 10.42 ± 0.01 a |

| Carbohydrates (%) | 3.36 ± 0.07 b | 4.36 ± 0.07 d | 3.19 ± 0.29 b | 1.64 ± 0.21 c | 10.60 ± 0.14 a |

| Calories (Kcal/100 g) | 285.66 ± 0.20 b | 271.2 ± 0.42 a | 278.53 ± 1.06 c | 251.67 ± 0.78 d | 215.71 ± 0.53 e |

| Fat Calories (Kcal/100 g) | 223.02 ± 0.05 a | 201.06 ± 0.14 c | 212.58 ± 0.10 b | 189.63 ± 0.18 d | 114.21 ± 0.14 e |

| CH & F Calories (Kcal/100 g) | 22.14 ± 0.3 cd | 28.18 ± 0.27 b | 22.64 ± 0.18 c | 20.08 ± 0.28 d | 63.22 ± 0.50 a |

| Protein Calories (Kcal/100 g) | 40.6 ± 0.05 c | 41.96 ± 0.06 b | 42.84 ± 0.04 a | 42.0 ± 0.05 b | 38.24 ± 0.02 d |

| pH | 6.69 ± 0.03 a | 6.56 ± 0.04 b | 6.54 ± 0.04 b | 6.45 ± 0.02 c | 6.42 ± 0.03 c |

| Acidity (g/100 g) | 0.63 ± 0.01 c | 0.75 ± 0.01 a | 0.62 ± 0.01 c | 0.63 ± 0.01 c | 0.69 ± 0.01 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salazar, D.; Arancibia, M.; Calderón, L.; López-Caballero, M.E.; Montero, M.P. Underutilized Green Banana (Musa acuminata AAA) Flours to Develop Fiber Enriched Frankfurter-Type Sausages. Foods 2021, 10, 1142. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10051142

Salazar D, Arancibia M, Calderón L, López-Caballero ME, Montero MP. Underutilized Green Banana (Musa acuminata AAA) Flours to Develop Fiber Enriched Frankfurter-Type Sausages. Foods. 2021; 10(5):1142. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10051142

Chicago/Turabian StyleSalazar, Diego, Mirari Arancibia, Lenin Calderón, María Elvira López-Caballero, and María Pilar Montero. 2021. "Underutilized Green Banana (Musa acuminata AAA) Flours to Develop Fiber Enriched Frankfurter-Type Sausages" Foods 10, no. 5: 1142. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10051142