3.1.1. Aldehydes

Aldehydes can be formed through either the degradation of milk fat (unsaturated fatty acids are oxidized to hydroperoxides, which in turn yield aldehydes through the action of hydroperoxidelase) or from amino acid catabolism [

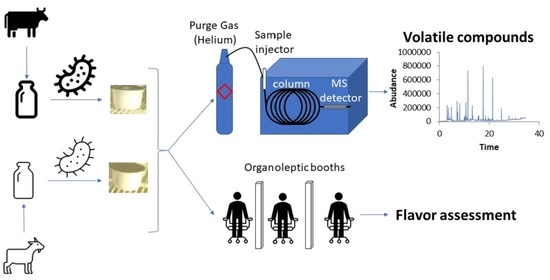

6,

21]. However, aldehydes can also be oxidized to produce carboxylic acids or be reduced to yield alcohols via enzymatic reactions. Therefore, the final amount of aldehydes in yogurts is dependent on the activity of the enzymes present in microorganisms [

21]. With regard to the aldehydes identified in cow dessert yogurts, without the addition of

Bifidobacterium BB-12, only acetaldehyde was determined (54.87 ± 12.15 mg kg

−1), in the sample prepared using the classic culture. In contrast, when

Bifidobacterium BB-12 was added, acetaldehyde, pentanal, hexanal, and nonanal were determined in dessert yogurts (total aldehyde content: 30.36 ± 23.66 mg kg

−1 for the classic and 12.86 ± 0.47 mg kg

−1 for the acidic culture). The addition of

Bifidobacterium BB-12 led to changes in the pH and composition of milk during fermentation (unlike dessert yogurts prepared without the addition of probiotic bacteria). The initial pH of cow milk was 6.70 and for goat milk it was 6.65. On day 21, The pH of cow dessert yogurt without

Bifidobacterium BB-12 was: 4.36 for the mild culture, 4.28 for the classic culture, 4.23 for the acidic culture and with

Bifidobacterium BB-12: 4.31 for the mild culture, 4.22 for the classic culture and 4.16 for the acidic culture. These pH changes caused the activation of enzymes in

Bifidobacterium BB-12, resulting in their combination with oxidation in the production of other aldehydes, in addition to acetaldehyde [

8,

9].

Acetaldehyde is one of the most important compounds in fermented dairy products, as it contributes a light, fresh, green, and strong odor [

6,

10]. Generally, it has been suggested that acetaldehyde may result from the degradation of various compounds such as fatty acids, glucose, catechol, glyceraldehydes, and amino acids such as threonine and glycine [

11]. However, the most important pathway of acetaldehyde formation is reported to be the breakdown of threonine into acetaldehyde and glycine, which is catalyzed by the enzyme threonine aldolase [

12]. This enzyme is present in both the

Streptococcus thermophilus and

Lactobacillus bulgaricus microorganisms, but the production of acetaldehyde by the two microorganisms is not identical. Bacterial cultures that allow acetaldehyde to form without particularly acidifying the yogurt are more desirable [

13]. Acetaldehyde was mainly identified in larger amounts in the cow milk; the dessert yogurt prepared using the classic culture was found to be consistent with previous studies in which the classic culture produces a more desirable aroma in the dessert yogurt due to acetaldehyde [

14].

However, the above-mentioned trend was not observed in the dessert yogurts from goat milk. Both with the addition or in the absence of

Lactobacillus acidophilus LA-5, no aldehydes other than acetaldehyde were determined (7.12 ± 4.08 mg kg

−1 for the mild and 66.09 ± 18.12 mg kg

−1 for the classic culture in the absence of

Lactobacillus acidophilus LA-5 and 54.50 ± 1.00 mg kg

−1 for the mild, 11.13 ± 0.04 mg kg

−1 for the classic and 17.06 ± 4.35 mg kg

−1 for the acidic culture in the presence of

Lactobacillus acidophilus LA-5). This may be due to the fact that different probiotic bacterial strains were used to prepare dessert yogurts from cow and goat milk. Similarly, differences in the amount of acetaldehyde in goat dessert yogurts with the addition of

Lactobacillus acidophilus LA-5 compared to those prepared without

Lactobacillus acidophilus LA-5 may be due to the specific enzymatic activity of

Lactobacillus acidophilus LA-5 bacteria [

22,

23]. On day 21 of storage, the pH values for the goat dessert yogurt without

Lactobacillus acidophilus LA-5 were: 4.29 for the mild culture, 4.26 for the classic culture, 4.24 for the acidic culture and with

Lactobacillus acidophilus LA5: 4.24 for the mild culture, 4.21 for the classic culture and 4.12 for the acidic culture. The lower pH values observed with the addition of

Lactobacillus acidiphilus LA-5, compared to the addition of

Bifidobacterium BB-12, confirms the stronger acidifying effect of the former bacterial strain.

According to Sandine et al. [

24], good yogurt flavor is produced when 8.0 ppm or more of acetaldehyde is produced. In the present study, the acetaldehyde concentrations recorded were, in most cases, quite high, ranging from 6.60 ± 0.12 to 66.09 ± 18.12 mg kg

−1. The lack of alcohol dehydrogenase enzyme in the bacteria, which is responsible for the conversion of acetaldehyde into ethanol, is suggested to be the reason behind the high acetaldehyde content [

12]. As a result, ethanol, a documented volatile compound of yogurt [

6,

7] was not determined in any of the dessert yogurts in the present study. According to the literature [

25] yogurt products with a very low acetaldehyde content still have a typical yogurt aroma, suggesting that acetaldehyde is only one component of yogurt aroma and does not account for the overall yogurt aroma. Pentanal, hexanal and octanal and nonanal have also been reported as components of the volatile fraction of yogurt [

6] formed during the oxidation of milk fat. Of these, pentanal, hexanal and nonanal were determined in the present study in cow yogurt with the addition of

Bifidobacterium BB-12. The presence of such aldehydes in the probiotic yogurt prepared with

Bifidobacterium BB-12 may be associated with its relatively low acceptability by consumers (see organoleptic evaluation).

3.1.2. Ketones

Ketones are a major class of volatile compounds identified in yogurt. They are derived both from raw milk (and as such, dessert yogurts from cow milk are expected to differ from those from goat milk in their ketone content) and from the processing parameters of yogurt production, due to the β-oxidation metabolic pathway of unsaturated fatty acids [

15,

26]. Dessert yogurts made from cow milk, prepared with the mild culture, without the addition of Bifidobacterium BB-12, had had a ketones content of around three times lower than the corresponding dessert yogurts prepared with the classic and acidic cultures (52.52 ± 12.98 mg kg

−1 for the mild, 160.90 ± 52.47 mg kg

−1 for the classic and 147.60 ± 50.54 mg kg

−1 for the acidic culture), probably due to the specific action of the mild culture. The same difference in the content of ketones was observed between the dessert yogurts from cow milk with different cultures, to which Bifidobacterium BB-12 were added (68.39 ± 39.45 mg kg

−1 for the mild, 143.46 ± 23.83 mg kg

−1 for the classic and 202.52 ± 5.98 mg kg

−1 for the acidic culture). However, for a given culture, no significant differences were observed in the ketone content between yogurts with or without Bifidobacterium BB-12, which could be associated with the specific culture used and not with the addition of Bifidobacterium BB-12.

In the case of dessert yogurts from goat milk without

Lactobacillus acidophilus LA-5, the same rough tendency was observed in the content of ketones. That is, dessert yogurts with the mild culture had a significantly lower content of ketones than those prepared with the classic and acidic culture (128.72 ± 69.16 mg kg

−1 for the mild, 184.22 ± 26.41 mg kg

−1 for the classic and 187.93 ± 77.79 mg kg

−1 for the acidic culture). However, the case of dessert yogurts from goat milk to which

Lactobacillus acidophilus LA-5 was added was quite different. In this case, the dessert yogurts with the mild culture had ca. a 2.6 times higher content of ketones, compared to the corresponding dessert yogurts to which no

Lactobacillus acidophilus LA-5 were added (338.34 ± 128.24 mg kg

−1 vs. 128.72 ± 69.16 mg kg

−1). This value was ca. 4 times higher than that of ketones in dessert yogurts with

Lactobacillus acidophilus LA-5, which were prepared using the classic and acidic cultures (338.34 ± 128.24 mg kg

−1 vs. 87.85 ± 18.30 and 74.04 ± 10.97 mg kg

−1). These two dessert yogurts showed ca. 50% reduction in the content of their ketones, compared to desserts prepared without

Lactobacillus acidophilus LA-5 (87.85 ± 18.30 vs. 184.22 ± 26.41 mg kg

−1 for the classic and 74.04 ± 10.97 vs. 187.93 ± 77.79 mg kg

−1 for the acidic culture). This finding is consistent with results previously reported in the literature, as it is reported that the addition of bacterial strains that grow easily in milk, such as

Lactobacillus acidophilus, affects the formation of ketones [

27]. Therefore, in the case of dessert yogurts derived from cow milk, the addition of

Bifidobacterium BB-12 does not seem to significantly affect their ketone content and as such, their odor. In contrast, in dessert yogurts from goat milk, the addition of

Lactobacillus acidophilus LA-5 significantly increased the ketone content when the mild culture was used while decreasing the ketone content when the other two cultures were used.

Among the determined ketones, diacetyl (2,3-butanedione) is an important aroma compound, contributing to yogurt aroma with buttery notes. It is formed through the fermentation of citrate present in milk. Typical concentrations of diacetyl in yogurt range from 0.2–3 mg kg

−1 [

28]. In the present study, substantially higher concentrations of diacetyl were recorded. Acetoin (3-hydroxy-2-butanone) is a common flavor constituent in many fermented dairy products that is readily converted from diacetyl [

6]. It has a mild creamy, butter-like flavor, similar to that of diacetyl but considerably weaker. Acetoin is readily formed from diacetyl by the enzyme diacetyl reductase. Typical acetoin concentrations in yogurt range from 1.2 to 28 mg kg

−1 [

28]. In the present work, significantly higher concentrations of acetoin were recorded. Acetone (2-propanone) originates either from milk or from the yogurt bacterial cultures and is of minor importance to flavor contribution in dairy products [

29]. It has a sweet fruity aroma and contributes positively to the flavor of yogurt. The typical acetone content in yogurt varies from 0.3 to 4 mg kg

−1 [

27,

28]. In the present study, significantly higher concentrations of acetone were recorded.

In general, the presence of Bifidobacteria has not been reported to affect the production of ketones by the microorganisms of the starter culture, whereas, on the contrary, the probiotic microorganism

Lactobacillus acidophilus affects the production of ketones [

27]. This can be due to the increased rate of their citrate metabolism [

30]. This was validated from our findings, since the cow dessert yogurts that were fortified with Bifidobacteria showed no increase in their flavor, compared to goat dessert yogurts that contained

Lactobacillus acidophilus and exhibited an improvement in flavor (

Section 3.2). Beshkova et al. [

31] reported concentrations of 14.1 to 17.3 mg kg

−1 for acetaldehyde; 1.6 to 2.0 mg kg

−1 for diacetyl; 1.7 to 2.2 mg kg

−1 for acetoin and 0.66 to 0.75 mg kg

−1 for acetone in Bulgarian yogurts. 2-pentanone, 2-heptanone and 2-nonanone have also been recorded in the flavor profile of yogurts [

6]. Imhof et al., [

32,

33] determined the key aroma components in Switzerland yogurts and identified six volatiles (acetaldehyde, dimethylsulphide, diacetyl, 2,3-pentanedione, l-limonene, and undecanal) as having a high impact on yogurt flavor. These researchers noted that the obtained results should be interpreted with caution because the main ingredients (fat, proteins, and carbohydrates) in yogurt can significantly reduce the actual release of volatiles. Other carbonyl compounds including 2,3-pentanedione were found to contribute to the aroma of yogurt [

32]. Specifically, 2,3-pentanedione is an impact flavor compound of yoghurt [

34] and may be formed from a-aceto-a-hydroxybutyrate, an intermediate of isoleucine metabolism [

33] 2,3-pentanedione was also determined in the flavor profile of all yogurt samples in the present study.

3.1.3. Volatile Acids

Both non-volatile and volatile carboxylic acids are important flavor compounds in dairy products, as they enhance product sensory properties [

35]. Even though lactic acid is not a volatile carboxylic acid, it is included in the present discussion due to its crucial importance in yogurt flavor. Lactic acid is the prime source of flavor in fermented dairy products, responsible for the refreshing sour/acidic flavor of yogurt [

36]. During fermentation, a good portion (20–40%) of lactose is transformed into lactic acid. Acidity is a key factor in yogurt flavor, producing a pH of around 4.4–4.2. Ott et al. [

37] showed that there are important flavor differences between traditional acidic and mild, less acidic yogurts, which are mainly due to the differences in acidity and not due to different concentrations of the three flavor impact compounds (acetaldehyde, diacetyl, and 2,3-pentanedione). These authors considered lactic acid as the most important component of yogurt flavor. Carboxylic acids usually derive from lipolysis, proteolysis or lactose metabolism [

15,

38].

Regarding the volatile acid content of the yogurt samples, it was observed that the different samples contained different carboxylic acids. More specifically, in dessert yogurts made from cow milk without the addition of Bifidobacterium BB-12, hexanoic acid (contributing with pungent, rancid, flowery notes) was determined in small amounts in the case of the mild and classic cultures, while in the case of the acidic culture, no volatile acids were identified. When Bifidobacterium BB-12 was added, acetic acid was determined in particularly high concentrations (120 to 151 mg kg

−1), except in the case of the classic culture. In a previous study, it was reported that the main difference in volatiles between cow milk either unfermented or fermented with Bifidibacterium BB-12, was the high concentration of acetic acid produced in the latter [

9]. Despite the weak ability of bifidobacteria to ferment lactose, the acetic acid content in fermented milk confirmed their heterofermentative nature.

Acetic acid imparts a vinegar flavor to yogurt; therefore, when found at high concentrations, it can render the dessert yogurt unacceptable by consumers. Therefore, these samples are expected to show inferior organoleptic properties compared to yogurt desserts from cow milk, to which no Bifidobacterium BB-12 are added. This was validated, as can be seen from the organoleptic evaluation results in

Section 3.2. Alonso and Fraga [

39] reported an acetic acid concentration ranging from 0.5 to 18.8 mg kg

−1 in commercial yogurts.

In the case of dessert yogurts from goat milk without the addition of

Lactobacillus acidophilus LA-5, no volatile acids were identified, while in dessert yogurts prepared with the addition of

Lactobacillus acidophilus LA-5, only butanoic acid was identified. Butanoic acid imparts a cheesy flavor, and therefore the corresponding samples are expected to have improved organoleptic properties [

38]. This was validated, as can be seen from the organoleptic evaluation results in

Section 3.2.

The thermophilic Streptococcus and Lactobacillus cultures are known to produce acetic, butyric, and caproic (hexanoic) acids [

31].

3.1.4. Hydrocarbons

Hydrocarbons are primarily by-products of the lipid oxidation of raw milk. Although identified in almost all samples, hydrocarbons do not contribute to yogurt aroma due to their low concentrations and high odor threshold [

40].

Hydrocarbons were determined in all samples (3.51–16.47 mg kg

−1 in the cases of cow dessert yogurts without the addition of

Bifidobacterium BB-12, and 12.58–19.89 mg kg

−1 in the cases with the addition of

Bifidobacterium BB-12. The respective hydrocarbon content ranged between 12.01–40.03 mg kg

−1 in goat dessert yogurts with the addition of

Lactobacillus acidophilus LA-5), while no hydrocarbons were determined in dessert yogurts from goat milk, to which no

Lactobacillus acidophilus LA-5 were added. The carbohydrate content of dessert yogurts from cow milk with the addition of

Bifidobacterium BB-12 was generally higher than that without the addition of

Bifidobacterium BB-12, while the corresponding dessert yogurts from goat milk had a considerably higher content of hydrocarbons. In general, it has been reported that different hydrocarbons in different amounts are produced when either

Streptococcus thermophilus or

Lactobacillus bulgaricus are added individually to milk or when they are used in combination in the starter culture for fermentation [

41]. Therefore, the observed differences in carbohydrate content and their amount among the dessert yogurts may be attributed to the use of different starter cultures, but also to specific probiotics used as is the case of

Lactobacillus acidophilus LA-5. According to the literature, the presence of specific hydrocarbons observed in dessert yogurts may also be due to various parameters during the milk transport and storage process [

42].