1. Introduction

Worldwide, subsurface infrastructure contains millions of isolated structures. Every day, workers routinely enter these structures to perform work tasks. Most, if not all, of these structures meet requirements for classification as confined spaces [

1]. Entry and work involving individual confined spaces of this type may not occur for decades.

Ventilation of these structures by air exchange induced by natural forces was first documented in 1936 in a report published by investigators at the (US) Bureau of Mines [

2]. Follow-up investigation provided additional detail about the process [

3,

4,

5]. Continuous ventilation of these spaces through air exchange between the external atmosphere and the atmosphere in the airspace induced by natural forces is critically important to safety [

6]. Air exchange requires at least one defined path (an opening in the manhole cover or access hatch) [

2,

6,

7].

The fundamental importance of the discoveries of investigators at the Bureau of Mines cannot be overstated [

2,

3,

4,

5]. Active, continuous air exchange occurring between entry and work through a defined path in isolated subsurface structures has the potential to minimize or eliminate contamination encountered at the time of preparing the space for entry and work. The possibility of contamination in the airspace of the structure is the basis for the requirement to test atmospheric conditions prior to opening the manhole cover. Despite the benefit obtained from this action, atmospheric testing prior to opening the access cover to install the ventilation duct does not always occur. In addition, sensors in the instrument may not respond to the contaminant. Hence, minimizing the potential for existence of a contaminated atmosphere in the airspace of the structure adds a layer of protection to the defense intrinsic in regulatory requirements, namely atmospheric testing, ventilation and use of preventive and protective measures. The philosophy underlying defense in depth is that the multiple layers that maintain safety protect against failure involving one or more of them [

8].

The discoveries of the investigators at the Bureau of Mines were lost because of World War II and became available recently through indexing in on-line search engines. In recent times, Wiegand and Dunne [

9] studied the effect of opening the manhole cover in preparation for entry using a well-mixed atmosphere containing N

2O-contaminated air contained in a subsurface telephone vault. Gribble [

10] commented about the need for ventilation in tombs in ancient Egypt to facilitate the mining processes involved in this work. Slight change in elevation in the floor of a horizontal structure is sufficient to promote or hinder ventilation induced by natural forces.

The fundamental importance of this knowledge cannot be overemphasized. Yet, enquiry of about 100 practitioners in occupational health and safety, educated formally in this field and knowledgeable about confined spaces at a recent conference held in Vancouver, Canada indicated complete absence of knowledge about ventilation of isolated subsurface structures induced by natural forces [

11]. Follow-up inquiries of individuals and groups domestically and internationally indicated similar lack of knowledge. One of the reasons for this lack of knowledge is the absence of discussion in this area.

This article is one in a series describing an investigation of ventilation induced by natural forces in isolated subsurface structures. McManus and Haddad [

6] showed that absence of a defined path for air exchange in isolated subsurface structures is a factor in fatal incidents in confined spaces involving hazardous atmospheres and that air exchange in isolated subsurface structures containing one or more openings is actively occurring in a predictable manner. McManus [

7] followed up and considerably extended work of investigators at the Bureau of Mines using a hazardous atmosphere reflective of real-world situations. This air exchange is a critical factor in minimizing risk to passersby and workers who must open and enter these structures. McManus [

7] and McManus and Haddad [

12] showed the linkage between work of investigators at the Bureau of Mines [

2,

3,

4,

5] and more modern work performed by Wiegand and Dunne [

9]. Work performed by these two groups contained sufficient information to make the argument for ventilation of isolated subsurface structures induced by natural forces. McManus [

7] and McManus and Haddad [

13] showed the critical relationship between effectiveness of ventilation and the number/area of openings in the manhole cover previously reported by investigators at the Bureau of Mines [

2]. The relationship between the number/area of openings in work performed by both groups was approximately the same. McManus [

7] and McManus and Haddad [

13] also showed that the mathematics of decrease in concentration of N

2O through the open manhole and decrease in concentration of CO through opening(s) in the manhole cover were similar. This work also showed that the atmosphere inside the structure under study was rapidly and thoroughly well-mixed.

Investigators at the Bureau of Mines [

2,

3,

4,

5] and Wiegand and Dunne [

9] commented about influence of surface wind flow in the process. McManus [

7] and McManus and Haddad [

14] investigated surface air motion. When measured once per second or once per two seconds, wind speed changes rapidly and unpredictably. Zero is a common value in all samples except in June and July. A peak occurs in all samples a 10.7 m/min (3 ft/min). Zero values and the peak at 10.7 m/min are linked. As the number of zeros in a test decreases, the height and width of the peak at 10.7 m/min increases. These changes occur in an annual cycle.

The work discussed in the previous section has advanced this subject considerably. It has, however, also created a mystery: how does air exchange through the opening(s) and what occurs in the airspace to produce the rapid and thorough mixing observed in instrumental readings. While air exchange through two or more openings involving interaction with air flowing along the surface of the ground is somewhat intuitive, air exchange involving a single opening is not at all intuitive. Air exchange induced by natural forces occurs through inhalation and exhalation. These processes can occur discretely as occurs inside the human respiratory system, continuously with simultaneous inhalation and exhalation or through a combination of both actions. In human respiration, inhalation at the level of the opening of the nose and mouth is separate from exhalation.

At this point, the dynamics of the process in isolated subsurface structures remain undiscussed in the literature. The literature is also silent about how to visualize and record the interaction between near surface and surface air motion and the openings in manhole covers in outdoor workplaces. Visualization is essential in order to complete the sequence of movement of the air during ventilation by induced by natural forces.

Visualization to show the sequence of movement of air is considerably more than an academic curiosity. The mechanism by which air exchange occurs has critical importance in design of manhole covers in order to optimize air exchange. Improvements in design are important elements in the Prevention through Design initiative championed by NIOSH [

15]. McManus and Haddad [

6] advocated for application of Prevention through Design to ventilation of isolated subsurface structures induced by natural forces. As determined by McManus [

7], there are limitations to what instruments can provide with regard to movement of air. Visualization provides the means to describe and resolve other problems and to identify opportunities involving ventilation.

A possible starting point for study of this phenomenon in a real-world environment is the methodology used to visualize and study air motion in buildings. Visualization of air motion in buildings is a standard and essential technique to identify and diagnose problems with installed ventilation. This technique can visualize absence and very small changes in air motion. The product used in these applications is known colloquially as the ‘smoke’ tube [

16,

17]. Emissions from these tubes when in contact with air resemble white ‘smoke’. The investigator makes small gentle puffs so as not to influence air movement. The ‘art’ involved in creating the puff is to minimize momentum imparted to the puff and the air in the area under investigation. A properly created puff remains motionless unless influenced by moving air. A properly created puff rises in rising air, descends in descending air and moves horizontally in horizontally moving air. That is, the puff adopts the behavior of the air.

The ‘smoke’ is readily detectable by eye and should be detectable by the sensors in a camera. This work occurred early in the morning prior to sunrise under calm conditions. This schedule provided the opportunity to capture images in the monochrome blue conditions that exist at this time of day. Monochrome lighting enables better capture of the white wisps of ‘smoke’ created by the ‘smoke’ tubes because of the contrast between the background and the white of the ‘smoke’. Polychromatic bright light from the sun degrades registration of the wisps of ‘smoke’.

An important contributor to understanding and appreciating the processes that occur during ventilation of isolated subsurface structures induced by natural forces is video capture and recording. Predicting the manner in which air exchange occurs from instrumental measurements in the absence of other research is not possible. Video is needed from both outside and inside the chamber in order to show the complete sequence of air exchange to enable further analysis. The ‘smoke’ is readily detectable by eye and should be detectable by the sensors in a camera even at the low level of natural illumination available early in the morning prior to sunrise.

Cameras require sensors capable of capturing video in low light at high resolution (at least 720 p) and at least normally viewed frame-rates. The latter features are essential for capturing still images having high resolution from the video by frame-capture software in order to facilitate analysis of the movement (not performed during this work). Still images having high resolution are required for use in presentations and publications. Current retail cameras provide such capability at reasonable cost.

The environment inside the chamber introduced additional challenges. The cameras require wide-angle lenses in order to frame the image inside the chamber. The internal environment is hostile to the delicate mechanisms that cover the lenses in high-performance cameras because of condensation and dripping. These cameras require protection against contact with surface and condensed water and possibly against impact by mud, sand and small stones that fall from the rim during closing and opening of the manhole cover. Cameras sold for outdoor use under extreme conditions include waterproof cases. Protective cases for other cameras are available as accessories.

Lighting inside the structure is another important consideration. Lighting used externally is less critical than lighting used in the chamber. The only light entering the chamber from the exterior passes through the opening(s) in the manhole cover. This level of lighting is insufficient for producing usable video. Light sources used in the chamber must not radiate heat. Radiated heat potentially can distort movement of the atmosphere in the airspace. The only light sources capable of satisfying the requirement for high output and absence of heat are high-output, battery-powered, portable LED products. Products currently available in retail outlets for home use are suitable for use in this application.

2. Materials and Methods

This study occurred in the yard of a construction company located in Vancouver, Canada. The yard contained the installed, isolated subsurface structure (precast concrete vault) under study [

7,

14] as well as equipment and vehicles used by work crews. Work crews left the yard in the vehicles and equipment early in the morning and returned late in the afternoon.

Video recording occurred in the ambient atmosphere of the structure. Video recording required considerable attention to detail and occurred over a short period (10 to 15 min). Video recording was incompatible with simultaneous, multi-hour operation of the monitoring instruments described previously (McManus, 2016). This work occurred prior to sunrise. A building obstructed exposure to direct light from the sun on the horizon as dawn approached (McManus and Haddad, 2018a).

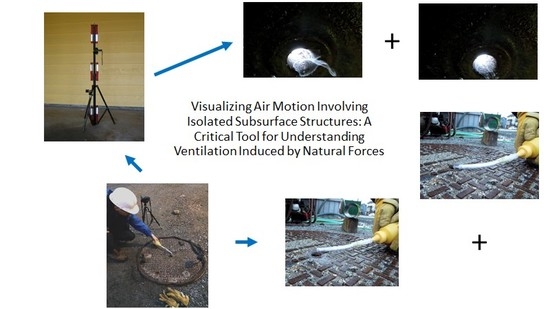

Cameras used for exterior work (Nikon Coolpix P300 and Nikon Coolpix P7000, Nikon Canada Inc., Mississauga, ON) were mounted on tripods and operated in video mode (

Figure 1 and

Figure 2). The external tripod was positioned to capture movement of the ‘smoke’ along the ground. Experience showed the best placement for video capture was a shallow angle with respect to the surface of the ground. The wall of a building blocked exposure to the direct path of light from the approaching daybreak. The combination of the shallow angle of capture and blockage of the direct path of light from the sun by the wall of the building produced the dark monochrome blue background needed to contrast the ‘smoke’ for optimum video capture.

During interior work, the cameras (GoPro HERO4 Black, GoPro, Inc., San Mateo, CA, USA, and occasionally the Nikon Coolpix P300, Nikon Canada Inc., Mississauga, ON, Canada) were attached to the instrument stand and positioned to capture video from the center opening and one opening on the circumference of the manhole cover. The cameras were started manually prior to insertion into the vault.

‘Smoke’ tubes (Dräger Canada, Mississauga, ON and Mine Safety Appliances (MSA) Company, Cranberry Township, PA, USA) were used to visualize air movement along the surface of the ground and inside the structure. The ‘smoke’ tube was activated by breaking open the ends and positioning into the top of the plastic container that provided the controlled pressure needed to force air through the tube (

Figure 1).

The Safety Data Sheet (SDS) for the Dräger product (Air Current Tubes, CH 25 301) indicates that the tubes contain anhydrous fuming sulfuric acid and produce a mist when air containing moisture passes through the interior [

16]. The Safety Data Sheet for the MSA product indicates that reaction between acetic acid and 1,2-diaminoethane produces diethylamine diacetate smoke [

17]. Diethylamine diacetate exists as a solid at ambient temperatures [

18]. Sulfuric acid mist is a liquid aerosol [

16]. Smokes contain particle sizes ranging from around 0.01 µm to 1 µm and mists from 0.05 µm to 10 µm [

19].

The end of the ‘smoke’ tube was positioned horizontally or at a shallow angle in the direction of the wind on or very close to the manhole cover near the opening of interest and the plastic container gently squeezed to expel non-aggressive puffs of ‘smoke’ in a horizontal direction directed toward the opening (

Figure 1). ‘Non-aggressive’ has the meaning of avoiding propulsion to minimize forward momentum such that the wind entrained the ‘smoke’. This action is critical to ensure that natural forces acting on the air + puff create the movement observed and not bias introduced by aggressive expulsion of ‘smoke’ from the end of the tube. Discharge of the ‘smoke’ occurred in several directions in an attempt to create entry into the airstream prevailing at the time of the test.

Video was reviewed for editing using VLC Media Player, Version 2.0.8.0,

www.videolan.org. Videos obtained from more than one camera required a common event for synchronization (time stamp). In this case, closure of the manhole cover provided the time stamp. This point of synchronization in some of the videos enabled comparison of subsequent events outside and inside the structure according to occurrence in time. Frame capture from the videos occurred using the capture function of VLC Media Player (

www.videolan.org). High-resolution video (as described in a previous section) contained the detail needed to enable capture of high-resolution still images suitable for use in presentations and publications.

3. Results

Video obtained during this work provided information not available through instrumental monitoring for gases such as CO and therefore was critically important to understanding the manner in which ventilation of subsurface isolated structures occurs through the action of natural forces. The literature does not provide information about entry of air into opening(s) in manhole covers during ventilation induced by natural forces. There are no precedents from which to draw inferences in order to create expectations.

‘Smoke’ directed horizontally toward the opening in the manhole cover and entrained in near-surface wind flow generally did not enter the opening. During this behavior, the ‘smoke’ often moved across the opening without change in direction (

Figure 3), sometimes moved around the opening along the top surface of the manhole cover (

Figure 4), or sometimes moved partially across the opening and then veered upward (

Figure 5). The deflected and upward motion indicated escape of air from inside the airspace of the structure through the opening. Deflection of smoke around the opening in the manhole cover (

Figure 4) was very unusual and indicative of both air movement along the surface of the ground in the opposite direction and emission of the atmosphere from the opening in the manhole cover. The situation shown in

Figure 5 in which the ‘smoke’ deflected upward at the edge of the opening in the manhole cover was unusual and suggestive of emission of a column of air from the interior airspace of the structure.

On occasion (

Figure 6), the ‘smoke’ made an abrupt 90° change of direction at the edge of the opening in the manhole cover and moved downward toward the airspace of the structure when entrained in near-surface wind flow. Entry of ‘smoke’ in this manner was not predictable in time or duration.

The preceding observations from video monitoring of a manhole cover containing a single opening also applied to a manhole cover containing two openings. Partial or full entry occurred when more than one opening was present. Entry of ‘smoke’ was considerably more aggressive and prolonged than when a single opening was present and was not predictable in time or duration.

‘Smoke’ directed horizontally and entrained into surface airflow readily entered the opening in the upwind position. ‘Smoke’ did not readily enter the opening in the downwind position. ‘Smoke’ entered the upstream opening more aggressively and continuously when the two openings are more closely spaced together (center + circumference) than when further apart (circumferential openings opposite each other). This comment reflects instrumental observations [

7,

13]. ‘Smoke’ entered both openings in the manhole cover although not necessarily at the same moment in time. (Testing to determine whether simultaneous entry can occur was not feasible in the circumstances described here.)

Previous discussion has focused on entry of air from the external atmosphere into one or more openings in the manhole cover. Video obtained inside the structure corresponding to the same moments in time showed movement of ‘smoke’ through the opening(s) in the manhole cover and downward and outward into the airspace, respectively, when one or two openings were present. Closure of the manhole cover was a common ‘time stamp’ for coordinating all videos.

As established from video showing external activity, video for a single opening obtained inside the structure showed that, on occasion, ‘smoke’ passed through the opening in the manhole cover into the airspace. The ‘smoke’ appeared to be ‘wispy’ or ‘diaphanous’ or ‘curtain-like’ with folds during the initial passage down the cylinder forming the opening and into the open airspace. There was some similarity with the appearance of the ‘Aurora Borealis’ (Northern Lights). Downward rotational (

Figure 7) and vertical flaring (

Figure 8) movement were observable in the opening.

When a single opening was present, the ‘smoke’ immediately veered horizontally at the bottom of the opening and flowed along the underside of the manhole cover toward the outer wall of the structure in the direction opposite surface air motion. Horizontal movement began immediately after the ‘smoke’ descended below the lower surface of the manhole cover. Descent of ‘smoke’ into the airspace was observable on the sidewall on the upstream side of surface air motion. The ‘smoke’ dispersed rapidly downward into the airspace. Bulk downward movement of the dispersed smoke was visible in the airspace on the side of the structure opposite the direction of surface air movement on the top of the manhole cover.

When two openings (center + circumference) were present, ‘smoke’ entered the center opening considerably more ‘forcefully’ than when a single opening was present. The ‘smoke’ spread and descended rapidly on the side of the center opening upstream from the airflow compared to the situation involving a single central opening. (In this situation, the circumferential opening was at the upstream side of surface airflow along the manhole cover.) The ‘smoke’ migrated along the underside of the manhole cover and descended rapidly down the sidewall in the direction opposite surface air motion. (In this situation, the circumferential opening was at the upstream side of the manhole cover.) ‘Smoke’ entering the opening on the upstream side descended rapidly into the airspace, more so than for ‘smoke’ entering by the center opening. Movement generally occurred in the downward vertical and horizontal direction opposite the direction of movement of smoke observable on the surface of the manhole.

When two openings (center + circumference) were present, ‘smoke’ entered the downstream opening in similar fashion to the central opening when one opening was present. ‘Smoke’ entered the upstream opening as described for the corresponding situation in center + circumference.

4. Discussion

Controlled movement of air in structures is critically important in ventilation to provide comfort and control of contaminants, yet little discussion about how air actually moves appears in the technical literature. Movement of air observed in this investigation was not unusual compared to what is observable under other circumstances. To illustrate, entry of air into fans mounted on walls and roofs of buildings and operated in exhaust mode to withdraw air from the enclosed airspace occurs in a similar manner. Incoming air typically flows along surfaces and makes abrupt changes of directions to enter the opening of the fan. These installations have geometry similar to the surface of the ground and opening(s) in the manhole cover (flanged opening) [

20].

Observation using ‘smoke’ tubes used in the same manner in this study indicated that large quantities of air flow along the surface of the ground and make an abrupt 90° change of direction during entry into the opening(s) in the manhole cover. A relatively small quantity of air enters the opening from above. The tendency of moving air to follow surfaces in this manner is known as the Coanda effect [

21,

22]. Such movement was observable during this study during entry of air into the opening in the manhole cover.

Many years of experience with the products chosen for use in this application indicates that the ‘smoke’ follows and visualizes air movement but does not influence it when used in the appropriate manner. In open air, the ‘smoke’ moves in the direction of air motion. Air motion visualized in this manner occurs horizontally, vertically upward and downward as well as obliquely upward and downward. When emitted from the glass tube in small non-propulsive puffs in still air, the puff remains in place and intact for a considerable period prior to dispersing.

When a single opening in the manhole cover was present, air flowed across the surface in the direction of the prevailing wind. Infrequently, the air made an unpredictable change of direction and passed downward into the opening in the manhole cover. That is, inflow of air from the exterior visualized in this manner was discrete and not continuous. The plume of air flowing downward into the airspace widened almost immediately and moved horizontally along the underside of the manhole cover in the direction opposite surface air motion and then downward into the airspace. The uncontaminated air diluted the contaminated air in the upper airspace of the structure and continued the process as it descended as shown by dispersion of the ‘smoke’. This movement is consistent with the rapid and thorough mixing observed during instrumental studies [

7,

13].

Availability of the second opening enhanced these processes. This observation also is consistent with the rapid and thorough mixing observed during instrumental studies [

7,

13]. Non-entry movement of air across a single opening can induce a decrease in static air pressure in an airspace below the pressure of the external atmosphere [

20]. This negative pressure could withdraw air from the airspace of the structure. This process is suggested in

Figure 3,

Figure 4 and

Figure 5 through movement of the ‘smoke’ entrained in air flowing along the upper surface of the manhole cover near the opening. Inhalation of air from the exterior through the opening into the airspace potentially occurs discretely suggesting that this occurs only when the negative static pressure decreases below a ‘trigger’ or ‘tipping’ point. At this point inward flow of ‘smoke’ + air occurs. Inhalation occurred briefly again suggesting another point of control of this part of the process. Surface air movement and difference in temperature between the exterior and the upper airspace and difference in temperature between the upper and lower airspace may influence the process of air exchange. The influence of these factors on this process remains to be investigated.

Video obtained in this study when two openings were present showed considerably greater inflow of air into the interior of the structure than when a single opening was present. This corroborated information provided by instrumental measurements [

2,

7,

13]. Despite the availability of the second opening, inflow was not continuous. When a second opening was present, air entered more aggressively and more regularly and could enter either of the openings depending on the direction of air motion along the surface of the manhole cover. ‘Smoke’ entered the upstream opening more aggressively and continuously when the two openings were more closely spaced together (center + circumference) than when further apart (circumferential openings opposite each other). Video showing movement inside the structure indicated that air moved downward through the opening in a straight or swirl motion and spread more rapidly horizontally toward the sidewall opposite surface air motion and then moved vertically downward in the unrestricted airspace.

McManus and Haddad [

13] showed similarities between ventilation effectiveness (efficiency) in work performed by investigators at the Bureau of Mines [

2] and McManus [

7]. Ventilation effectiveness (efficiency) was greatest for the single opening, less for two openings and less again and approximately equal for more than two openings. Two openings provide a ‘pressure-balanced’ path for the flow of air along the upper and lower surfaces of the manhole cover and inside the airspace. Positive static pressure induced at one opening potentially balances negative static pressure induced at the other because the openings are present in the same airspace. The increase in flow of air readily visible in the video suggests that the ‘pressure-balanced path is considerably more favorable to the process than when a single opening is present. The greater increase in flow when the openings are closer together (center + circumference) versus opposite sides of the circumference suggests that the pressure changes induced in the openings act through a distance relationship.

Video assessment discussed in this report is essential for furthering design of manhole covers and access hatches used to provide access to isolated subsurface structures. Optimizing ventilation induced by natural forces between openings is an important improvement for minimizing the risk of work for workers who enter and work in these structures. Video assessment as shown in this study also emphasizes the importance of maintaining the defined path(s) for exchange between the atmosphere confined in the airspace and the external atmosphere in open and unobstructed condition [

2,

7,

13]. Another application of the technique used in this study is determination of the path emission and exposure to atmospheres confined in other isolated structures such as tanks [

9]. Overexposure to the atmosphere above the contents that emits from openings during these activities can cause exposure at high level.

The area of physics and engineering with insight into resolving questions concerned with flow of liquids and compressible gases is fluid kinematics [

23]. Fluid kinematics uses tracers to document flow as occurred during this study. These studies often involve wind tunnels having the ability to produce motion of fluids under highly controlled conditions to study flow characteristics for example around new vehicles. This equipment uses various techniques to visualize or otherwise render identifiable movement of liquids and gases along surfaces and across gaps and against obstructions. In this investigation, the study occurred outdoors using an actual structure under actual conditions of operation and not a laboratory representation as the model for investigation.

A structure of the type utilized in this study is called a deep cavity with (a) circular opening(s) with flow involving a compressible fluid [

23]. A deep versus shallow cavity flow depends on the ratio of the (diameter of the opening)/(depth of the depression). Such flows along surfaces also have considerable implication in design and performance of depressions in the surface of aircraft and the open cavity in a vehicle containing a sunroof. Quantitation of surface airflow observed in this study in another report in this series [

14] provides additional detail for consideration.