Uncertainty in Building Inspection and Diagnosis: A Probabilistic Model Quantification

Abstract

:1. Introduction

1.1. Background, Problem and Purpose

- During the observation, understanding and analysis of degradation phenomena, depending on:

- The knowledge and experience of the surveyor

- The circumstances of observation (for instance, means of access or weather conditions)

- The availability and effective use of expeditious means of observation (more relevant when the signs of failure are invisible to the naked eye)

- The preliminary planning of the on-site inspection (for instance, consulting available documents about the building)

- During the process of clearly identifying the defect, its causes and the best course of action to reinstate performance levels that fulfil the building element’s functional requirements, while making decisions involving:

- The determination of the need of additional in situ diagnosis methods or laboratory tests

- The choice of in situ diagnosis methods or laboratory tests, if needed, considering their contribution for a more accurate diagnosis (usefulness, intrusiveness, ease of execution, precision, type of results, cost, time needed to obtain results)

- The decision about whether eventual results of in situ diagnosis methods or laboratory tests are conclusive and enough [4]

- The identification of the defect and its causes based on all available data (information about the building, visual inspection and any additional diagnosis method)

- The development of recommendations according to the diagnosis.

- During the communication of recommendations in a non-ambiguous and detailed way, allowing stakeholders to weigh several parameters that may affect decision making

1.2. Formulations of Uncertainty

1.2.1. Bayes’ Theorem

1.2.2. Bayesian Networks

2. Materials and Methods

2.1. Development of the Model and Defining CPTs

2.2. Assessment of the BN Model

3. Results

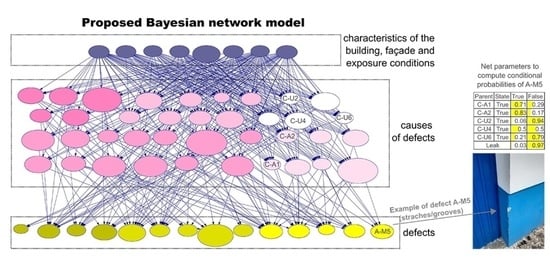

3.1. Development of the Degradation Analysis Model

3.2. Model Evaluation

3.2.1. Verification of the Model Results

- Design and execution errors’ causes have consistently lower probabilities of being true.

- Every set of causes selected for a defect has at least one cause with a probability of being true higher than 50%.

- The highest probability obtained from the verification cases was 87%, corresponding to cause “presence of water/water vapour” (C-M4) of defects “efflorescence/cryptoflorescence” (A-H4) and “infiltration/damp stains” (A-H1); this cause is a well-known part of the degradation mechanism of efflorescence and façade staining [30].

- The lowest probability obtained from the verification cases was 11%, corresponding to causes “faulty design or lack of heat insulation in walls” (C-C4) and “lack of conformity to design and/or building and construction specifications” (C-E2), attributed to the occurrence of “infiltration/damp stains” (A-H1). When thermophoresis occurs (i.e., the condensation of water vapour in the cooler areas/materials of a façade [31]), the design of a poorly insulated wall or not executing the designed wall (well insulated) may result in moisture stains highlighted by the accumulation of dirt; however, through a merely visual inspection, those causes cannot be confirmed, hence the high level of uncertainty.

3.2.2. Sensitivity Analysis

3.2.3. Case Study

- A-E2 Dirt/particle deposits

- A-H1 Infiltration/damp stains

- A-H2 Biological colonisation

- A-M1 Adhesion loss/detachment

- A-M3 Linear cracking

- A-M4 Mapped cracking

- A-M5 Scratches/grooves.

- C-M1 Airborne dirt particles

- C-M2 Solar radiation/temperature action

- C-M3 Wind and/or rainwater action

- C-M4 Presence of water/water vapour

- C-M5 High relative humidity (RH > 70%)

- C-M8 Natural wear and tear

- C-U1 Irregular cleaning/washing

- C-U2 Irregular repainting

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Silva, A.; de Brito, J.; Gaspar, P.L. Methodologies for Service Life Prediction of Buildings. With a Focus on Façade Claddings; Green Energy and Technology; Springer: Cham, Switzerland, 2016; ISBN 978-3-319-33288-8. [Google Scholar]

- Flores-Colen, I.; de Brito, J. A systematic approach for maintenance budgeting of buildings façades based on predictive and preventive strategies. Constr. Build. Mater. 2010, 24, 1718–1729. [Google Scholar] [CrossRef]

- Pereira, C.; Silva, A.; de Brito, J.; Ferreira, C.; Flores-Colen, I.; Silvestre, J.D. Uncertainty and risk analysis in inspection and diagnosis. In New Trends on Building Pathology, CIB W86 Report; CIB International Council for Research and Innovation in Building and Construction: Lisboa, Portugal, 2021. [Google Scholar]

- Flores-Colen, I.; de Brito, J.; de Freitas, V.P.; Hawreen, A. Reliability of in-situ diagnosis in external wall renders. Constr. Build. Mater. 2020, 252, 119079. [Google Scholar] [CrossRef]

- Wolf, F.M.; Gruppen, L.D.; Billi, J.E. Differential diagnosis and the competing-hypotheses heuristic. A practical approach to judgement under uncertainty and Bayesian probability. J. Am. Med. Assoc. 1985, 253, 2858–2862. [Google Scholar] [CrossRef]

- Weber, P.; Simon, C. Benefits of Bayesian Network Models; Systems and industrial engineering series—Systems dependability assessment set; ISTE Wiley: London, UK, 2016; ISBN 9781848219922. [Google Scholar]

- Verron, S.; Tiplica, T.; Kobi, A. Monitoring of complex processes with Bayesian networks. In Bayesian Network; Rebai, A., Ed.; Sciyo: Rijeka, Croatia, 2010; pp. 213–227. ISBN 978-953-307-124-4. [Google Scholar]

- Koiter, J.R. Visualizing Inference in Bayesian Networks. Master’s Thesis, Faculty of Electrical Engineering, Mathematics, and Computer Science, Delft University of Technology, Delft, The Netherlands, 16 June 2006. [Google Scholar]

- Bortolini, R.; Forcada, N. Discussion about the use of Bayesian networks models for making predictive maintenance decisions. In Proceedings of the Joint Conference on Computing in Construction (JC3), Heraklion, Greece, 4–12 July 2017; pp. 973–980. [Google Scholar]

- Bortolini, R.; Forcada, N. A probabilistic performance evaluation for buildings and constructed assets. Build. Res. Inf. 2020, 48, 838–855. [Google Scholar] [CrossRef]

- Bortolini, R.; Forcada, N. Operational performance indicators and causality analysis for non-residential buildings. Inf. la Construcción 2020, 72, 1–11. [Google Scholar]

- Luque, J.; Straub, D. Reliability analysis and updating of deteriorating systems with dynamic Bayesian networks. Struct. Saf. 2016, 62, 34–46. [Google Scholar] [CrossRef]

- Schneider, R.; Fischer, J.; Bügler, M.; Nowak, M.; Thöns, S.; Borrmann, A.; Straub, D. Assessing and updating the reliability of concrete bridges subjected to spatial deterioration - Principles and software implementation. Struct. Concr. 2015, 16, 356–365. [Google Scholar] [CrossRef]

- Gallina, G.; Graziosi, M.; Imbrenda, A. Structural repair approach for reinforcement corrosion in concrete building structure: An application case. In Proceedings of the 4th International Conference on Concrete Repair, Rehabilitation and Retrofitting (ICCRRR 2015), Leipzig, Germany, 5–7 October 2015; Dehn, F., Beushausen, H.-D., Alexander, M.G., Moyo, P., Eds.; CRC Press: Leipzig, Germany, 2015; pp. 695–702. [Google Scholar]

- Vagnoli, M.; Remenyte-Prescott, R.; Andrews, J. Structural health monitoring of bridges: A Bayesian network approach. In Proceedings of the Life-Cycle Analysis and Assessment in Civil Engineering: Towards an Integrated Vision, Ghent, Belgium, 28–31 October 2018; Caspeele, R., Taerwe, L., Frangopol, D., Eds.; Taylor & Francis: Ghent, Belgium, 2018; pp. 1983–1989. [Google Scholar]

- Sivo, M.; Ladiana, D.; Novi, F.; Salvatori, C. Maintenance-oriented design in architecture. A decision support system for the evaluation of maintenance scenarios through Bayesian networks use. A case study: The headquarters of ING groupe in Amsterdam. In Proceedings of the XV International Conference on Durability of Building Materials and Components, Barcelona, Spain, 20–23 October 2020; Serrat, C., Casas, J.R., Gibert, V., Eds.; International Center for Numerical Methods in Engineering (CIMNE): Barcelona, Spain, 2020; pp. 1695–1702. [Google Scholar]

- Asmone, A.S.; Chew, M.Y.L. Development of a design-for-maintainability assessment of building systems in the tropics. Build. Environ. 2020, 184, 107245. [Google Scholar] [CrossRef]

- BayesFusion LLC. GeNIe Academic, Version 3.0.6518.0 (32-bit); BayesFusion LLC: Pittsburgh, PA, USA, 2021. [Google Scholar]

- Sá, G.; Sá, J.; de Brito, J.; Amaro, B. Statistical survey on inspection, diagnosis and repair of wall renderings. J. Civ. Eng. Manag. 2015, 21, 623–636. [Google Scholar] [CrossRef] [Green Version]

- Henrion, M. Practical issues in constructing a Bayes’ belief network. Int. J. Approx. Reason. 1988, 2, 132–139. [Google Scholar]

- Garcia, J.; de Brito, J. Inspection and diagnosis of epoxy resin industrial floor coatings. J. Mater. Civ. Eng. 2008, 20, 128–136. [Google Scholar] [CrossRef]

- Díez, F.J. Parameter adjustment in Bayes networks. The generalized noisy OR–gate. In Proceedings of the Ninth international conference on Uncertainty in artificial intelligence (UAI’93), Washington, DC, USA, 9–11 July 1993; Heckerman, D., Mamdani, A., Eds.; Morgan Kaufmann Publishers Inc.: Washington, DC, USA, 1993; pp. 99–105. [Google Scholar]

- Sá, G.; Sá, J.; de Brito, J.; Amaro, B. Inspection and diagnosis system for rendered walls. Int. J. Civ. Eng. 2014, 12, 279–290. [Google Scholar]

- StatSoft Inc. STATISTICA (Data Analysis Software System), Version 8.0; StatSoft Inc.: Tulsa, OK, USA, 2007. [Google Scholar]

- Bashari, H.; Smith, C.S. Accommodating uncertainty in grazing land condition assessment using Bayesian Belief Networks. In Bayesian Network; Rebai, A., Ed.; Sciyo: Rijeka, Croatia, 2010; pp. 341–354. ISBN 978-953-307-124-4. [Google Scholar]

- Engel, A. Verification, Validation, and Testing of Engineered Systems; Wiley series in systems engineering and management; Wiley: Hoboken, NJ, USA, 2010; ISBN 978-0-470-52751-1. [Google Scholar]

- Pereira, C.; Silva, A.; de Brito, J.; Silvestre, J.D. Urgency of repair of building elements: Prediction and influencing factors in façade renders. Constr. Build. Mater. 2020, 249, 118743. [Google Scholar] [CrossRef]

- Sturges, H.A. The choice of a class interval. J. Am. Stat. Assoc. 1926, 21, 65–66. [Google Scholar] [CrossRef]

- Benjamin, J.R.; Cornell, C.A. Probability, Statistics, and Decision for Civil Engineers; Dover Publications, Inc.: Mineola, NY, USA, 2016; ISBN 978-0-486-78072-6. [Google Scholar]

- Pereira, C.; de Brito, J.; Silvestre, J.D. Global inspection, diagnosis and repair system for buildings: Managing the level of detail of the defects classification. In Proceedings of the Rehabend—Construction Pathology, Rehabilitation Technology and Heritage Management, Caceres, Spain, 15–18 May 2018; Villegas, L., Lombillo, I., Blanco, H., Boffil, Y., Eds.; University of Cantabria; University of Extremadura: Cáceres, Spain, 2018; pp. 572–579. [Google Scholar]

- Camuffo, D. Microclimate for Cultural Heritage: Conservation, Restoration, and Maintenance of Indoor and Outdoor Monuments, 2nd ed.; Elsevier: Boston, MA, USA, 2014; ISBN 9780444632968. [Google Scholar]

- BayesFusion LLC Strength of Influences. Available online: https://support.bayesfusion.com/docs/GeNIe/ (accessed on 9 June 2021).

- Flores-Colen, I.; de Brito, J.; Freitas, V.P. de Stains in facades’ rendering— Diagnosis and maintenance techniques’ classification. Constr. Build. Mater. 2008, 22, 211–221. [Google Scholar] [CrossRef]

- Norvaišienė, R.; Miniotaitė, R.; Stankevičius, V. Climatic and air pollution effects on building facades. Mater. Sci. 2003, 9, 102–105. [Google Scholar]

- Carvalhão, M.; Dionísio, A. Evaluation of mechanical soft-abrasive blasting and chemical cleaning methods on alkyd-paint graffiti made on calcareous stones. J. Cult. Herit. 2015, 16, 579–590. [Google Scholar] [CrossRef]

- Weaver, M.E. Removing Graffiti from Historic Masonry; Preservation Briefs 38; U.S. Department of the Interior, National Park Service Cultural Resources, Preservation Assistance: Washington, DC, USA, 1995.

- Douglas, J.; Ransom, B. Understanding Building Failures, 3rd ed.; Taylor & Francis: London, UK, 2007; ISBN 0415370825. [Google Scholar]

- Bussel, M. Effects of induced movement. In Structures & Construction in Historic Building Conservation; Forsyth, M., Ed.; Blackwell Publishing: Oxford, UK, 2007; pp. 111–139. ISBN 9781405111713. [Google Scholar]

- Sazedj, S.; Morais, A.; Pinheiro-Alves, M.T.; Silva, R. Pathologies—Incompatibility of materials and human intervention in a historic building of Elvas. In New Approaches to Building Pathology and Durability; Delgado, J.M.P.Q., Ed.; Springer: Singapore, 2016; Volume 6, ISBN 978-981-10-0647-0. [Google Scholar]

- Flores-Colen, I.; de Brito, J. Renders. In Materials for Construction and Civil Engineering: Science, Processing, and Design; Gonçalves, M.C., Margarido, F., Eds.; Springer: Cham, Switzerland, 2015; pp. 53–122. ISBN 978-3-319-08235-6. [Google Scholar]

- Honeyborne, D.B. Weathering and decay of masonry. In Conservation of Building and Decorative Stone; Ashurst, J., Dimes, F.G., Eds.; Butterworth-Heinemann: Oxford, UK, 1998; pp. 153–184. ISBN 9780750638982. [Google Scholar]

- Ferraz, G.T.; de Brito, J.; de Freitas, V.P.; Silvestre, J.D. State-of-the-art review of building inspection systems. J. Perform. Constr. Facil. 2016, 30, 04016018. [Google Scholar] [CrossRef]

- Silva, A.; de Brito, J.; Gaspar, P.L. A comparative multi-criteria decision analysis of service life prediction methodologies for rendered façades. J. Build. Eng. 2018, 20, 476–487. [Google Scholar] [CrossRef]

- Vieira, S.M.; Silva, A.; Sousa, J.M.C.; De Brito, J.; Gaspar, P.L. Modelling the service life of rendered facades using fuzzy systems. Autom. Constr. 2015, 51, 1–7. [Google Scholar] [CrossRef]

- Ferreira, C.; Barrelas, J.; Silva, A.; de Brito, J.; Dias, I.S.; Flores-Colen, I. Impact of environmental exposure conditions on the maintenance of facades’ claddings. Buildings 2021, 11, 138. [Google Scholar] [CrossRef]

- Gaspar, P.L.; de Brito, J. Service life estimation of cement-rendered facades. Build. Res. Inf. 2008, 36, 44–55. [Google Scholar] [CrossRef]

- Silva, A.; de Brito, J.; Gaspar, P.L. Stochastic approach to the factor method: Durability of rendered façades. J. Mater. Civ. Eng. 2015, 28, 04015130. [Google Scholar] [CrossRef]

- Júnior, C.M.M.; Carasek, H. Relationship between the deterioration of multi story buildings facades and the driving rain. Rev. la Construcción 2014, 13, 64–73. [Google Scholar] [CrossRef] [Green Version]

- Al-Neshawy, F. Computerised Prediction of the Deterioration of Concrete Building Facades Caused by Moisture and Changes in Temperature. Ph.D. Thesis, Aalto University, School of Engineering, Espoo, Finland, 7 June 2013. [Google Scholar]

- Erkal, A.; D’Ayala, D.; Sequeira, L. Assessment of wind-driven rain impact, related surface erosion and surface strength reduction of historic building materials. Build. Environ. 2012, 57, 336–348. [Google Scholar] [CrossRef] [Green Version]

- Kubilay, A.; Zhou, X.; Derome, D.; Carmeliet, J. Moisture modeling and durability assessment of building envelopes. Recent advances. In Building performance simulation for design and operation; Hensen, J.L.M., Lamberts, R., Eds.; Routledge: Oxon, UK, 2019; pp. 270–314. ISBN 978-0-429-40229-6. [Google Scholar]

- Kokulu, N. Determination of the deterioration characteristics of facade materials: A case study. In Proceedings of the XV International Conference on Durability of Building Materials and Components, Barcelona, Spain, 20–23 October 2020; Serrat, C., Casas, J.R., Gibert, V., Eds.; International Center for Numerical Methods in Engineering (CIMNE): Barcelona, Spain, 2020; pp. 1321–1328. [Google Scholar]

- Kim, H.-J.; Hamann, R.; Sotiralis, P.; Ventikos, N.P.; Straub, D. Bayesian network for risk-informed inspection planning in ships. Beton und Stahlbetonbau 2018, 113, 116–121. [Google Scholar] [CrossRef]

- Castillo, E.; Gutiérrez, J.M.; Hadi, A.S.; Solares, C. Symbolic propagation and sensitivity analysis in Gaussian Bayesian networks with application to damage assessment. Artif. Intell. Eng. 1997, 11, 173–181. [Google Scholar] [CrossRef] [Green Version]

- Silva, A.; de Brito, J. Do we need a buildings’ inspection, diagnosis and service life prediction software? J. Build. Eng. 2019, 22, 335–348. [Google Scholar] [CrossRef]

- de Brito, J.; Pereira, C.; Silvestre, J.D.; Flores-Colen, I. The way forward. In Expert Knowledge-Based Inspection Systems. Inspection, Diagnosis, and Repair of the Building Envelope; Springer: Cham, Switzerland, 2020; pp. 457–469. ISBN 978-3-030-42446-6. [Google Scholar]

- Pereira, C.; Silva, J.N.; Silva, A.; de Brito, J.; Silvestre, J.D. Building inspection system software based on expert-knowledge. Autom. Constr. 2021, submitted. [Google Scholar]

| Variable Designation | Abbreviation | States |

|---|---|---|

| Building characteristics and exposure | ||

| Age | Age | [2, 10], [11, 19], [20, 27], [28, 35], [36, 43], [44, 51] |

| Rain–wind action | RaWi | Mild, moderate or harsh |

| Exposure to humidity | EH | Low or high |

| Exposure to pollution | EPo | Low, average or high |

| Façade characteristics and maintenance | ||

| Orientation | FaOr | N, NE, E, SE, S, SW, W or NW |

| Type of render, execution and finish | TyRe/TyEx/Fin | Traditional, manual, textured; traditional, manual, smooth; one coat, mechanical, mineral; or one coat, mechanical, bush hammered |

| Type of washes | TyWa | Gentle or average |

| Washing frequency | WaF | Biannual, annual or less frequent |

| Probable causes of defects | ||

| C-C1 Faulty application of regulations and tenders | C-C1 | True or false |

| C-C2 Faulty design or lack of detailing | C-C2 | True or false |

| C-C3 Faulty design or lack of gutters or water drainage systems | C-C3 | True or false |

| C-C4 Faulty design or lack of heat insulation in walls | C-C4 | True or false |

| C-C6 Faulty specification of the products applied/C-U3 Poorly executed maintenance works/minor repairs | C-C6/C-U3 | True or false |

| C-E2 Lack of conformity to design and/or building and construction specifications | C-E2 | True or false |

| C-E3 Use of dirty tools during construction (contamination) | C-E3 | True or false |

| C-E4 Presence of water-soluble salts in moisture or in the materials employed | C-E4 | True or false |

| C-E5 Inappropriate mortar composition | C-E5 | True or false |

| C-E6 Excessive fines content | C-E6 | True or false |

| C-E8 Corrosion in metal elements (embedded in the rendering or affixed to its surface) | C-E8 | True or false |

| C-E9 Heterogeneity of supporting walls | C-E9 | True or false |

| C-E10 Faulty preparation of substrate walls (cleaning, roughness, wetness) | C-E10 | True or false |

| C-E12 Inadequate rendering thickness | C-E12 | True or false |

| C-E13 Inadequate rendering texture | C-E13 | True or false |

| C-E14 Lack of monitoring of the rendering during curing/ C-E7 Excess water/moisture in construction (mortar and/or substrate walls) | C-E14/C-E7 | True or false |

| C-E15 Lack of sufficient water vapour permeability in rendering or painting | C-E15 | True or false |

| C-E16 Use of dark colours in external walls | C-E16 | True or false |

| C-M1 Airborne dirt particles | C-M1 | True or false |

| C-M2 Solar radiation/temperature action | C-M2 | True or false |

| C-M3 Wind and/or rainwater action | C-M3 | True or false |

| C-M4 Presence of water/water vapour | C-M4 | True or false |

| C-M5 High relative humidity (RH > 70%) | C-M5 | True or false |

| C-M6 Poor ventilation | C-M6 | True or false |

| C-M7 Reduced natural lighting/sun exposure or lack thereof | C-M7 | True or false |

| C-M8 Natural wear and tear | C-M8 | True or false |

| C-A1 Abrasion | C-A1 | True or false |

| C-A2 Shocks/bumping | C-A2 | True or false |

| C-A3 Wall cracking (propagation to the rendering) | C-A3 | True or false |

| C-A4 Supporting wall shrinkage | C-A4 | True or false |

| C-A5 Rendering shrinkage | C-A5 | True or false |

| C-A6 Structural motions (settlement and deformation) | C-A6 | True or false |

| C-A7 Stress concentration/C-C5 Faulty design or lack of reinforcement systems for protection against mechanical action | C-A7/C-C5 | True or false |

| C-U1 Irregular cleaning/washing | C-U1 | True or false |

| C-U2 Irregular repainting | C-U2 | True or false |

| C-U4 Accidental actions related to user occupation, traffic and wear | C-U4 | True or false |

| C-U5 Lack of fittings (piping, drains, gutters, rainwater vertical piping) | C-U5 | True or false |

| C-U6 Vandalism | C-U6 | True or false |

| Defects | ||

| A-E1 Graffiti | A-E1 | True or false |

| A-E2 Dirt/particle deposits | A-E2 | True or false |

| A-E3 Corrosion stains | A-E3 | True or false |

| A-E4 Colour change/discoloration | A-E4 | True or false |

| A-H1 Infiltration/damp stains | A-H1 | True or false |

| A-H2 Biological colonisation | A-H2 | True or false |

| A-H3 Vegetation growth | A-H3 | True or false |

| A-H4 Efflorescence/cryptoflorescence | A-H4 | True or false |

| A-H5 Carbonation | A-H5 | True or false |

| A-M1 Adhesion loss/detachment | A-M1 | True or false |

| A-M2 Cohesion loss/crumbling | A-M2 | True or false |

| A-M3 Linear cracking | A-M3 | True or false |

| A-M4 Mapped cracking | A-M4 | True or false |

| A-M5 Scratches/grooves | A-M5 | True or false |

| Causes | Age | FaOr | RaWi | EH | TyRe | TyEx | Fin | EPo | TyWa | WaF |

|---|---|---|---|---|---|---|---|---|---|---|

| C-C1 | −0.12 | −0.07 | −0.05 | 0.02 | 0.07 | 0.07 | 0.11 | −0.02 | 0.00 | −0.06 |

| C-C2 | 0.06 | 0.01 | 0.05 | 0.09 | 0.03 | 0.03 | 0.00 | 0.00 | 0.01 | 0.10 |

| C-C3 | −0.04 | −0.05 | −0.05 | 0.00 | −0.05 | −0.05 | 0.03 | 0.08 | −0.09 | −0.14 |

| C-C4 | −0.01 | 0.12 | 0.06 | −0.07 | −0.01 | −0.01 | −0.02 | −0.04 | −0.07 | 0.16 |

| C-C5 | −0.13 | 0.01 | −0.07 | 0.04 | 0.01 | 0.01 | 0.03 | −0.10 | −0.05 | 0.00 |

| C-C6 | −0.08 | −0.14 | −0.09 | −0.02 | −0.02 | −0.02 | 0.05 | −0.08 | −0.01 | 0.08 |

| C-E1 | −0.04 | −0.11 | −0.07 | 0.07 | −0.02 | −0.02 | 0.11 | −0.05 | −0.03 | −0.04 |

| C-E2 | −0.06 | −0.08 | −0.10 | 0.06 | 0.02 | 0.02 | 0.06 | −0.09 | 0.00 | −0.08 |

| C-E3 | 0.08 | −0.05 | 0.05 | 0.05 | −0.02 | −0.02 | −0.03 | 0.10 | 0.13 | −0.03 |

| C-E4 | 0.02 | −0.07 | −0.01 | −0.05 | −0.04 | −0.04 | 0.00 | 0.05 | 0.10 | 0.00 |

| C-E5 | −0.04 | −0.16 | −0.05 | 0.03 | −0.02 | −0.02 | 0.10 | −0.12 | 0.00 | 0.02 |

| C-E6 | 0.04 | −0.04 | 0.07 | 0.05 | −0.04 | −0.04 | 0.00 | −0.07 | 0.03 | 0.00 |

| C-E7 | −0.08 | −0.13 | −0.03 | 0.09 | 0.07 | 0.07 | 0.15 | −0.06 | −0.04 | −0.05 |

| C-E8 | −0.05 | −0.02 | −0.03 | −0.09 | −0.09 | −0.09 | −0.04 | −0.10 | −0.04 | −0.01 |

| C-E9 | −0.03 | 0.05 | −0.01 | −0.19 | 0.08 | 0.08 | 0.04 | −0.08 | −0.02 | 0.14 |

| C-E10 | 0.08 | 0.10 | 0.13 | −0.06 | −0.06 | −0.06 | −0.10 | 0.10 | −0.03 | −0.07 |

| C-E11 | −0.04 | −0.11 | −0.07 | 0.07 | −0.02 | −0.02 | 0.11 | −0.05 | −0.03 | −0.04 |

| C-E12 | 0.04 | 0.14 | 0.01 | −0.11 | 0.03 | 0.03 | 0.00 | −0.06 | −0.08 | 0.19 |

| C-E13 | −0.04 | −0.04 | 0.01 | 0.02 | 0.02 | 0.02 | 0.01 | 0.01 | 0.02 | −0.03 |

| C-E14 | −0.11 | −0.12 | −0.10 | 0.00 | 0.14 | 0.14 | 0.19 | 0.00 | −0.04 | −0.06 |

| C-E15 | −0.03 | −0.03 | 0.07 | −0.05 | −0.04 | −0.04 | 0.00 | −0.02 | −0.04 | −0.06 |

| C-E16 | 0.04 | 0.04 | −0.07 | 0.02 | 0.12 | 0.12 | 0.05 | 0.02 | 0.03 | −0.01 |

| C-M1 | −0.04 | 0.03 | 0.01 | −0.03 | −0.03 | −0.03 | −0.06 | −0.02 | −0.03 | 0.03 |

| C-M2 | −0.02 | 0.02 | −0.03 | −0.09 | 0.00 | 0.00 | −0.05 | −0.08 | −0.02 | −0.01 |

| C-M3 | −0.06 | −0.09 | −0.06 | 0.13 | 0.04 | 0.04 | 0.00 | −0.04 | 0.04 | −0.04 |

| C-M4 | 0.02 | −0.04 | 0.06 | 0.05 | −0.11 | −0.11 | −0.07 | 0.14 | 0.08 | −0.05 |

| C-M5 | 0.05 | 0.15 | 0.02 | 0.18 | 0.07 | 0.07 | 0.10 | 0.07 | −0.03 | −0.08 |

| C-M6 | 0.10 | −0.14 | −0.03 | 0.03 | −0.04 | −0.04 | 0.03 | 0.05 | 0.08 | 0.10 |

| C-M7 | 0.00 | 0.06 | −0.08 | 0.06 | 0.03 | 0.03 | 0.03 | −0.09 | 0.00 | 0.05 |

| C-M8 | 0.06 | −0.02 | −0.03 | −0.04 | −0.03 | −0.03 | −0.03 | −0.03 | 0.01 | −0.06 |

| C-A1 | −0.02 | −0.10 | 0.12 | 0.06 | −0.05 | −0.05 | −0.03 | 0.00 | 0.00 | −0.08 |

| C-A2 | −0.13 | −0.19 | 0.09 | 0.00 | 0.09 | 0.09 | 0.02 | −0.01 | 0.01 | −0.07 |

| C-A3 | 0.08 | 0.08 | 0.10 | −0.01 | −0.06 | −0.06 | −0.07 | 0.21 | −0.08 | −0.11 |

| C-A4 | −0.04 | −0.03 | −0.07 | −0.07 | −0.02 | −0.02 | −0.04 | −0.05 | −0.03 | −0.04 |

| C-A5 | 0.04 | −0.13 | −0.05 | 0.00 | −0.06 | −0.06 | 0.05 | −0.06 | 0.03 | 0.07 |

| C-A6 | 0.02 | 0.10 | −0.03 | −0.09 | 0.07 | 0.07 | 0.04 | −0.06 | −0.04 | −0.05 |

| C-A7 | −0.15 | −0.02 | −0.03 | 0.02 | −0.01 | −0.01 | 0.00 | −0.04 | −0.04 | −0.02 |

| C-U1 | −0.06 | −0.02 | −0.04 | 0.00 | 0.08 | 0.08 | 0.06 | 0.07 | 0.11 | −0.02 |

| C-U2 | 0.00 | −0.06 | −0.13 | −0.06 | −0.08 | −0.08 | −0.03 | −0.10 | −0.01 | 0.00 |

| C-U3 | 0.02 | 0.03 | 0.03 | −0.01 | −0.02 | −0.02 | 0.00 | 0.02 | −0.04 | 0.10 |

| C-U4 | −0.12 | −0.08 | −0.01 | −0.05 | 0.05 | 0.05 | 0.01 | −0.07 | 0.03 | 0.00 |

| C-U5 | −0.05 | 0.08 | −0.06 | 0.11 | 0.03 | 0.03 | 0.05 | −0.10 | 0.00 | −0.08 |

| C-U6 | −0.03 | −0.01 | 0.05 | −0.07 | 0.03 | 0.03 | 0.10 | 0.03 | −0.06 | −0.05 |

| Causes | A-E1 | A-E2 | A-E3 | A-E4 | A-H1 | A-H2 | A-H3 | A-H4 | A-H5 | A-M1 | A-M2 | A-M3 | A-M4 | A-M5 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C-C1 | −0.07 | −0.14 | −0.06 | −0.09 | 0.01 | −0.06 | −0.03 | 0.09 | −0.01 | 0.02 | −0.03 | 0.45 | −0.04 | −0.04 |

| C-C2 | −0.13 | 0.17 | −0.07 | −0.16 | 0.22 | 0.22 | 0.12 | −0.05 | −0.02 | −0.13 | −0.05 | −0.16 | −0.07 | −0.08 |

| C-C3 | −0.11 | 0.28 | −0.04 | −0.14 | 0.03 | 0.12 | 0.04 | −0.04 | −0.02 | −0.07 | −0.04 | −0.14 | −0.06 | −0.06 |

| C-C4 | −0.05 | 0.29 | −0.04 | −0.06 | −0.05 | −0.06 | −0.02 | −0.02 | −0.01 | −0.05 | −0.02 | −0.06 | −0.02 | −0.03 |

| C-C5 | −0.06 | −0.12 | −0.05 | −0.08 | −0.06 | −0.08 | −0.02 | −0.02 | −0.01 | −0.03 | 0.05 | 0.53 | −0.03 | −0.04 |

| C-C6 | −0.09 | −0.18 | −0.07 | 0.38 | −0.01 | −0.10 | −0.04 | −0.03 | −0.02 | 0.02 | −0.03 | 0.11 | 0.05 | −0.05 |

| C-E1 | −0.02 | −0.04 | −0.02 | −0.03 | 0.24 | −0.03 | −0.01 | −0.01 | 0.00 | −0.02 | −0.01 | −0.03 | −0.01 | −0.01 |

| C-E2 | −0.04 | 0.06 | −0.03 | 0.01 | 0.10 | 0.00 | −0.02 | −0.01 | −0.01 | −0.04 | −0.01 | −0.05 | −0.02 | −0.02 |

| C-E3 | −0.02 | −0.03 | −0.01 | −0.02 | −0.02 | −0.02 | −0.01 | 0.50 | 0.00 | −0.01 | −0.01 | −0.02 | −0.01 | −0.01 |

| C-E4 | −0.03 | −0.06 | −0.02 | −0.04 | −0.03 | −0.04 | −0.01 | 1.00 | −0.01 | −0.03 | −0.01 | −0.04 | −0.02 | −0.02 |

| C-E5 | −0.06 | −0.11 | −0.04 | −0.07 | 0.00 | −0.07 | −0.02 | −0.02 | −0.01 | 0.11 | 0.06 | −0.02 | 0.68 | −0.03 |

| C-E6 | −0.03 | −0.06 | −0.02 | −0.04 | −0.03 | −0.04 | −0.01 | −0.01 | −0.01 | 0.28 | −0.01 | −0.04 | 0.10 | −0.02 |

| C-E7 | −0.03 | −0.05 | −0.02 | −0.03 | 0.22 | −0.03 | −0.01 | −0.01 | 0.33 | −0.02 | −0.01 | −0.03 | −0.01 | −0.02 |

| C-E8 | −0.07 | −0.14 | 0.93 | −0.09 | −0.08 | −0.10 | −0.03 | −0.03 | −0.01 | 0.06 | −0.03 | −0.09 | −0.04 | −0.04 |

| C-E9 | −0.08 | 0.09 | −0.06 | −0.10 | −0.08 | −0.11 | −0.03 | −0.03 | −0.01 | −0.08 | −0.03 | 0.42 | −0.04 | −0.05 |

| C-E10 | −0.05 | −0.10 | −0.04 | −0.06 | −0.05 | −0.07 | −0.02 | 0.08 | −0.01 | 0.56 | −0.02 | −0.06 | −0.03 | −0.03 |

| C-E11 | −0.02 | −0.04 | −0.02 | −0.03 | 0.24 | −0.03 | −0.01 | −0.01 | 0.00 | −0.02 | −0.01 | −0.03 | −0.01 | −0.01 |

| C-E12 | −0.05 | 0.15 | 0.04 | −0.07 | −0.06 | −0.07 | −0.02 | −0.02 | −0.01 | 0.09 | −0.02 | −0.07 | 0.10 | −0.03 |

| C-E13 | −0.07 | 0.35 | −0.06 | −0.09 | −0.07 | −0.01 | −0.03 | −0.03 | −0.01 | −0.07 | −0.03 | −0.09 | −0.04 | −0.04 |

| C-E14 | −0.03 | −0.06 | −0.02 | −0.04 | 0.16 | −0.04 | −0.01 | −0.01 | −0.01 | −0.03 | 0.49 | −0.04 | −0.02 | −0.02 |

| C-E15 | −0.03 | −0.06 | −0.02 | −0.04 | −0.03 | −0.04 | −0.01 | 0.49 | −0.01 | 0.17 | −0.01 | −0.04 | −0.02 | −0.02 |

| C-E16 | −0.05 | −0.09 | −0.04 | 0.42 | −0.05 | −0.06 | −0.02 | −0.02 | −0.01 | −0.05 | −0.02 | −0.06 | −0.02 | −0.03 |

| C-M1 | −0.17 | 1.00 | −0.13 | −0.21 | −0.17 | −0.22 | −0.07 | −0.06 | −0.03 | −0.16 | −0.06 | −0.21 | −0.09 | −0.10 |

| C-M2 | −0.10 | −0.20 | −0.08 | 0.59 | −0.04 | −0.13 | −0.04 | −0.04 | −0.02 | −0.10 | −0.04 | 0.11 | 0.01 | −0.06 |

| C-M3 | −0.17 | 0.44 | 0.02 | −0.08 | 0.11 | −0.06 | −0.07 | −0.06 | 0.03 | −0.16 | 0.07 | −0.17 | −0.08 | −0.10 |

| C-M4 | −0.15 | −0.29 | 0.21 | −0.20 | 0.13 | 0.49 | 0.23 | 0.20 | 0.10 | 0.05 | −0.05 | −0.17 | −0.08 | −0.09 |

| C-M5 | −0.13 | −0.09 | 0.07 | −0.17 | 0.20 | 0.34 | −0.05 | −0.05 | −0.02 | 0.10 | −0.01 | −0.14 | −0.07 | −0.08 |

| C-M6 | −0.03 | −0.06 | −0.03 | −0.04 | 0.22 | 0.00 | −0.01 | −0.01 | −0.01 | 0.07 | −0.01 | −0.04 | −0.02 | −0.02 |

| C-M7 | −0.05 | −0.11 | −0.04 | −0.07 | 0.18 | 0.25 | −0.02 | −0.02 | −0.01 | −0.01 | −0.02 | −0.07 | −0.03 | −0.03 |

| C-M8 | −0.11 | −0.22 | −0.01 | 0.61 | −0.07 | −0.14 | −0.04 | −0.04 | −0.02 | 0.08 | 0.05 | −0.06 | 0.04 | −0.07 |

| C-A1 | −0.04 | −0.08 | −0.03 | −0.05 | −0.04 | −0.05 | −0.02 | −0.01 | −0.01 | −0.04 | 0.37 | −0.05 | −0.02 | 0.56 |

| C-A2 | −0.05 | −0.11 | −0.04 | −0.07 | −0.06 | −0.07 | −0.02 | −0.02 | −0.01 | −0.05 | 0.28 | −0.07 | −0.03 | 0.87 |

| C-A3 | −0.06 | −0.11 | −0.04 | −0.07 | −0.06 | −0.07 | −0.02 | −0.02 | −0.01 | 0.57 | 0.05 | −0.02 | −0.03 | −0.03 |

| C-A4 | −0.02 | −0.04 | −0.02 | −0.03 | −0.02 | −0.03 | −0.01 | −0.01 | 0.00 | −0.02 | −0.01 | 0.20 | −0.01 | −0.01 |

| C-A5 | −0.05 | −0.10 | −0.04 | −0.06 | −0.05 | −0.07 | −0.02 | −0.02 | −0.01 | 0.08 | −0.02 | −0.06 | 0.89 | −0.03 |

| C-A6 | −0.03 | −0.05 | −0.02 | −0.03 | −0.03 | −0.04 | −0.01 | −0.01 | 0.00 | −0.03 | −0.01 | 0.25 | −0.01 | −0.02 |

| C−A7 | −0.07 | −0.14 | −0.06 | −0.09 | −0.07 | −0.10 | −0.03 | −0.03 | −0.01 | −0.02 | −0.03 | 0.63 | −0.04 | −0.04 |

| C-U1 | 0.21 | 0.01 | −0.07 | −0.11 | −0.09 | 0.25 | 0.12 | −0.03 | −0.02 | −0.09 | −0.03 | −0.11 | −0.05 | −0.05 |

| C-U2 | 0.03 | 0.04 | −0.03 | 0.35 | −0.04 | −0.15 | −0.04 | −0.04 | −0.02 | −0.11 | −0.04 | −0.14 | 0.03 | 0.05 |

| C-U3 | −0.06 | −0.11 | −0.04 | 0.47 | −0.06 | −0.07 | −0.02 | −0.02 | −0.01 | 0.00 | −0.02 | −0.07 | −0.03 | −0.03 |

| C-U4 | −0.03 | −0.06 | −0.02 | 0.04 | −0.03 | −0.04 | −0.01 | −0.01 | −0.01 | −0.03 | 0.24 | −0.04 | −0.02 | 0.29 |

| C-U5 | −0.07 | −0.01 | −0.06 | −0.09 | 0.35 | 0.11 | −0.03 | −0.03 | −0.01 | −0.07 | −0.03 | −0.09 | −0.04 | −0.04 |

| C-U6 | 0.86 | −0.19 | −0.08 | −0.13 | −0.10 | −0.13 | −0.04 | −0.04 | −0.02 | −0.10 | 0.05 | −0.12 | −0.05 | 0.36 |

| Input Data | Input Defect (Detected by the Surveyor) | Causes (Pointed Out by the Surveyor) | p (True)— Uncertainty Measure |

|---|---|---|---|

| A-H1 Infiltration/damp stains | C-M4 Presence of water/water vapour | 85% |

| C-C6 Faulty specification of the products applied/C-U3 Poorly executed maintenance works/minor repairs | 43% | ||

| A-H4 Efflorescence/cryptoflorescence | C-C2 Faulty design or lack of detailing | 39% | |

| C-E4 Presence of water-soluble salts in moisture or in the materials employed | 28% | ||

| C-E14 Lack of monitoring of the rendering during curing/ C-E7 Excess water/moisture in construction (mortar and/or substrate walls) | 14% | ||

| C-M4 Presence of water/water vapour | 87% | ||

| C-C6 Faulty specification of the products applied/C-U3 Poorly executed maintenance works/minor repairs | 43% | ||

| A-M3 Linear cracking | C-M2 Solar radiation/temperature action | 58% | |

| C-M8 Natural wear and tear | 62% | ||

| C-A7 Stress concentration/C-C5 Faulty design or lack of reinforcement systems for protection against mechanical action | 67% | ||

| A-M4 Mapped cracking | C-M8 Natural wear and tear | 65% | |

| C-A7 Stress concentration/C-C5 Faulty design or lack of reinforcement systems for protection against mechanical action | 62% | ||

| A-H1 Infiltration/damp stains | C-C2 Faulty design or lack of detailing | 61% |

| C-C3 Faulty design or lack of gutters or water drainage systems | 49% | ||

| C-M8 Natural wear and tear | 63% | ||

| A-M3 Linear cracking | C-M2 Solar radiation/temperature action | 58% | |

| C-A7 Stress concentration/C-C5 Faulty design or lack of reinforcement systems for protection against mechanical action | 65% | ||

| A-M1 Adhesion loss/detachment | C-E8 Corrosion in metal elements (embedded in the rendering or affixed to its surface) | 31% | |

| C-A7 Stress concentration/C-C5 Faulty design or lack of reinforcement systems for protection against mechanical action | 59% | ||

| A-H1 Infiltration/damp stains | C-C2 Faulty design or lack of detailing | 39% |

| C-M8 Natural wear and tear | 63% | ||

| C-C6 Faulty specification of the products applied/C-U3 Poorly executed maintenance works/minor repairs | 43% | ||

| C-U5 Lack of fittings (piping, drains, gutters, rainwater vertical piping) | 33% | ||

| A-M5 Scratches/grooves | C-A2 Shocks/bumping | 61% | |

| C-C6 Faulty specification of the products applied/C-U3 Poorly executed maintenance works/minor repairs | 43% | ||

| A-H1 Infiltration/damp stains | C-C2 Faulty design or lack of detailing | 39% |

| C-C3 Faulty design or lack of gutters or water drainage systems | 51% | ||

| C-C4 Faulty design or lack of heat insulation in walls | 11% | ||

| C-E2 Lack of conformity to design and/or building and construction specifications | 11% | ||

| C-M4 Presence of water/water vapour | 87% | ||

| C-M5 High relative humidity (RH > 70%) | 75% | ||

| C-M7 Reduced natural lighting/sun exposure or lack thereof | 29% | ||

| C-C6 Faulty specification of the products applied/C-U3 Poorly executed maintenance works/minor repairs | 43% |

| Node | State |

|---|---|

| Age of the building | 36–43 years |

| Façade orientation | NW, NE, SE and SW |

| Rain–wind action | Harsh |

| Exposure to humidity | Low |

| Type of render/type of execution/type of finish | Traditional/manual/smooth |

| Exposure to polluting agents | High |

| C-U6 Vandalism | False |

| Defect | Occurrence | |

|---|---|---|

| True | False | |

| A-E1 Graffiti | 28–30% | 70–72% |

| A-E2 Dirt/particle deposits | 99% | 1% |

| A-E3 Corrosion stains | 52–53% | 47–48% |

| A-E4 Colour change/discolouration | 80–81% | 19–20% |

| A-H1 Infiltration/damp stains | 58–61% | 39–42% |

| A-H2 Biological colonisation | 84–86% | 14–16% |

| A-H3 Vegetation growth | 12–13% | 87–88% |

| A-H4 Efflorescence/cryptoflorescence | 15% | 85% |

| A-H5 Carbonation | 3% | 97% |

| A-M1 Adhesion loss/detachment | 68–69% | 31–32% |

| A-M2 Cohesion loss/crumbling | 19–21% | 79–81% |

| A-M3 Linear cracking | 79–81% | 19–21% |

| A-M4 Mapped cracking | 34–37% | 63–66% |

| A-M5 Scratches/grooves | 28–33% | 67–72% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira, C.; Silva, A.; Ferreira, C.; de Brito, J.; Flores-Colen, I.; Silvestre, J.D. Uncertainty in Building Inspection and Diagnosis: A Probabilistic Model Quantification. Infrastructures 2021, 6, 124. https://0-doi-org.brum.beds.ac.uk/10.3390/infrastructures6090124

Pereira C, Silva A, Ferreira C, de Brito J, Flores-Colen I, Silvestre JD. Uncertainty in Building Inspection and Diagnosis: A Probabilistic Model Quantification. Infrastructures. 2021; 6(9):124. https://0-doi-org.brum.beds.ac.uk/10.3390/infrastructures6090124

Chicago/Turabian StylePereira, Clara, Ana Silva, Cláudia Ferreira, Jorge de Brito, Inês Flores-Colen, and José D. Silvestre. 2021. "Uncertainty in Building Inspection and Diagnosis: A Probabilistic Model Quantification" Infrastructures 6, no. 9: 124. https://0-doi-org.brum.beds.ac.uk/10.3390/infrastructures6090124