Mechanical Behavior of Steel Fiber-Reinforced Concrete Beams Bonded with External Carbon Fiber Sheets

Abstract

:1. Introduction

2. Hybrid Jointing Technique

3. Experimental Program

4. Test Results and Discussion

4.1. Flexural Stiffness

4.2. Cracking Behaviour

4.3. Residual Strength of the Cracked Concrete

- Although the source curves were different, the resultant stress-strain diagrams of the composite beams are practically equivalent: the trend-lines practically coincide. The oscillations in the stress-strain diagrams could be attributed to the sensitivity of the inverse procedure to the cracking process in the beams with relatively small size (refer to [32] for a more detailed description of this issue).

- The inversely determined diagrams consist of the genuine stresses corresponding to the tension-stiffening effect and the residual stresses due to fiber interaction with the concrete. Earlier investigations of RC bending members [34,35] have shown that the tension-stiffening effect practically disappears at the tensile deformation of 2000–2500 micro-strains, which was suggested by Gribniak et al. [34] as the limit for quantifying the residual stresses of SFRC. The latter parameters were experimentally determined using the RILEM methodology [27] (details have been reported in Section 3) as corresponding to 31.1% and 32.7% of the theoretical tensile strength of concrete (assessed per Eurocode 2, based on fctm = 4.11 MPa) at the crack mouth opening displacement of 0.5 mm and 3.5 mm, respectively. However, the trend-lines indicate an almost constant portion of tensile stresses associated with the cracked concrete. In relative terms, the respective average stresses of the reference and the externally bonded beams represent 54.7% and 88.9% of the strength fctm. In fact, these values reflect the overall tension-stiffening effects consisting of the components of internal and external reinforcement. Thus, taking into account the effect of tension-stiffening, the residual strength is not only a material property of SFRC, it is associated with the characteristics and amount of the structural reinforcement.

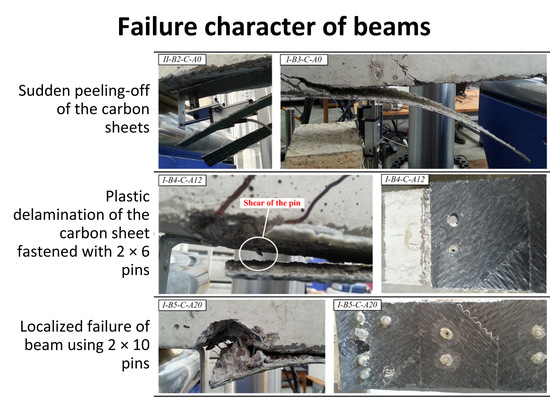

- The ultimate strains of the stress-strain diagrams are quite different. Accounting for the theoretical cracking strain of the concrete (assessed per Eurocode 2, εcr = fctm/Ecm = 0.109 mm/m), the ultimate normalized strain in the reference beams, being dependent on the yielding strain of the steel reinforcement, did not exceed 40εcr. Specimens with external CFRP sheets possessed the tensile strain over 70εcr (not shown in Figure 17b), whereas additional mechanical fastenings increased the ultimate deformations up to 125εcr. The observed reduction of the ultimate deformation (90εcr) in the beam with 2 × 10 pins (Figure 17b) could be related to the localized failure in the anchorage zone. This effect is discussed in the next section.

4.4. Structural Integrity

- The fibers had a limited effect on the flexural stiffness, nevertheless they are very effective in preventing brittle failure of the concrete.

- Debonding of the CFRP sheets caused brittle failure of the composite beams made of SFRC.

- Mechanical fastenings increased the ultimate deformations (ductility) of the composite beams.

5. Summary and Conclusions

- The external sheets, by transferring stresses through the crack planes, were effective in suppressing the localization of the discrete cracks. The final crack pattern manifested multiple cracks smeared in the tensile zone.

- The inverse analysis of the moment-curvature response indicated a constant level of tensile stress associated with the cracked concrete. In relative terms, the respective average stresses of the reference and the externally bonded beams represent 54.7% and 88.9% of the theoretical tensile strength of the concrete fctm assessed per Eurocode 2, and these values reflect the tension-stiffening effects which consist of the components of internal and external reinforcement. In other words, the simplified tension-stiffening model (with a constant residual strength of the cracked concrete ≈ 0.9fctm) is adequate for representing the deformation behavior of the beams with the external CFRP sheets.

- Accounting for the theoretical cracking strain of the concrete assessed per Eurocode 2, the ultimate normalized strain in the reference beams, being dependent on the yielding strain of the reinforcing steel, did not exceed 40εcr, whereas for the specimen with external CFRP sheets, the tensile strain was over 70εcr. The additional mechanical fastening increased the ultimate deformations up to 125εcr.

- The hybrid jointing increased the ultimate deformations (ductility) of the composite beams by 20% on average. Furthermore, the failure process became gradual and visually apparent.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rasheed, R.A. Strengthening Design of Reinforced Concrete with FRP; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Firmo, J.P.; Correia, J.R.; Pitta, D.; Tiago, C.; Arruda, M.R.T. Experimental characterization of the bond between externally bonded reinforcement (EBR) CFRP strips and concrete at elevated temperatures. Cem. Concr. Compos. 2015, 60, 44–54. [Google Scholar] [CrossRef]

- Gribniak, V.; Arnautov, A.K.; Kaklauskas, G.; Jakstaite, R.; Tamulenas, V.; Gudonis, E. Deformation analysis of RC ties externally strengthened with FRP sheets. Mech. Compos. Mater. 2014, 50, 669–676. [Google Scholar] [CrossRef]

- Nguyen, D.M.; Chan, T.K.; Cheong, H.K. Brittle failure and bond development length of CFRP-concrete beams. J. Compos. Constr. 2001, 5, 12–17. [Google Scholar] [CrossRef]

- Buyukozturk, O.; Gunes, O.; Karaca, E. Progress on understanding debonding problems in reinforced concrete and steel members strengthened using FRP composites. Constr. Build. Mater. 2004, 18, 9–19. [Google Scholar] [CrossRef]

- Ceroni, F.; Ianniciello, M.; Pecce, M. Bond behavior of FRP carbon plates externally bonded over steel and concrete elements: Experimental outcomes and numerical investigations. Compos. B Eng. 2016, 92, 434–446. [Google Scholar] [CrossRef]

- Sharaky, I.A.; Torres, L.; Sallam, H.E.M. Experimental and analytical investigation into the flexural performance of RC beams with partially and fully bonded NSM FRP bars/strips. Compos. Struct. 2015, 122, 113–126. [Google Scholar] [CrossRef]

- Zhou, A.; Qin, R.; Feo, L.; Penna, R.; Lau, R. Investigation on interfacial defect criticality of FRP-bonded concrete beams. Compos. B Eng. 2017, 113, 80–90. [Google Scholar] [CrossRef]

- Gao, B.; Leung, C.K.; Kim, J.K. Failure diagrams of FRP strengthened RC beams. Compos. Struct. 2007, 77, 493–508. [Google Scholar] [CrossRef]

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites; Taylor & Francis: London, UK; New York, NY, USA, 2007. [Google Scholar]

- Tejchman, J.; Kozicki, J. Experimental and Theoretical Investigations of Steel-Fibrous Concrete; Springer: Berlin/Heidelberg, Germany, 2010; ISBN 978-3-642-14602-2. [Google Scholar]

- Deluce, J.R.; Vecchio, F.J. Cracking behavior of steel fiber-reinforced concrete members containing conventional reinforcement. ACI Struct. J. 2013, 110, 481–490. [Google Scholar]

- Amin, A.; Foster, S.J.; Watts, M. Modelling the tension stiffening effect in SFR-RC. Mag. Conc. Res. 2016, 68(7), 339–352. [Google Scholar] [CrossRef]

- Bernardi, P.; Michelini, E.; Minelli, F.; Tiberti, G. Experimental and numerical study on cracking process in RC and R/FRC ties. Mater. Struct. 2016, 49, 261–277. [Google Scholar] [CrossRef]

- Yin, J.; Wu, Z.S. Structural performances of short steel-fiber reinforced concrete beams with externally bonded FRP sheets. Constr. Build. Mater. 2003, 17, 463–470. [Google Scholar] [CrossRef]

- Li, L.; Guo, Y.; Liu, F. Test analysis of FRC beams strengthened with externally bonded FRP sheets. Constr. Build. Mater. 2008, 22, 315–323. [Google Scholar] [CrossRef]

- De Rivaz, B. Steel fiber reinforced concrete (SFRC): The use of SFRC in precast segment for tunnel lining. Water Energy Intern. 2009, 66, 75–84. [Google Scholar]

- International Tunnelling and Underground Space Association. Twenty Years of FRC Tunnel Segments Practice: Lessons Learnt and Proposed Design Principles; ITA Report No. 16; ITA-AITES: Lausanne, Switzerland, 2016; p. 71. ISBN 978-2-970-1013-5-2. [Google Scholar]

- ACI Committee 544. Report on Design and Construction of Fiber Reinforced Precast Concrete Tunnel Segments; ACI 544.7R-16; American Concrete Institute: Farmington Hills, MI, USA, 2016; p. 36. [Google Scholar]

- Groli, G.; Caldentey, A.P. Improving cracking behaviour with recycled steel fibres, targeting specific applications.Analysis according to MC2010. Struct. Concr. 2017, 18, 29–39. [Google Scholar] [CrossRef]

- Arnautov, A.K.; Nasibullins, A.; Gribniak, V.; Blumbergs, I.; Hauka, M. Experimental characterization of the properties of double-lap needled and hybrid joints of carbon/epoxy composites. Materials 2015, 8, 7578–7586. [Google Scholar] [CrossRef]

- Arnautov, A.K.; Kulakov, V.; Andersons, J.; Gribniak, V.; Juozapaitis, A. Experimental investigation on stiffness and strength of single-lap joints in a laminated CFRP stress-ribbon strip. Baltic J. Road Bridge Eng. 2016, 11, 120–126. [Google Scholar] [CrossRef]

- Gribniak, V.; Arnautov, A.K.; Norkus, A.; Tamulenas, V.; Gudonis, E.; Sokolov, A. Experimental investigation of the capacity of steel fibers to ensure the structural integrity of reinforced concrete specimens coated with CFRP sheets. Mech. Compos. Mater. 2016, 52, 401–410. [Google Scholar] [CrossRef]

- Mendes, P.; Barros, J.A.O.; Sena-Cruz, J.; Teheri, M. Influence of fatigue and aggressive exposure on GFRP girder to SFRSCC deck all-adhesive connection. Compos. Struct. 2014, 110, 152–162. [Google Scholar] [CrossRef]

- Yeh, F.-Y.; Chang, K.-C.; Sung, Y.-C.; Hung, H.-H.; Chou, C.-C. A novel composite bridge for emergency disaster relief: Concept and verification. Compos. Struct. 2015, 127, 199–210. [Google Scholar] [CrossRef]

- Sánchez-Aparicio, L.; Ramos, L.; Sena-Cruz, J.; Barros, J.A.O.; Riveiro, B. Experimental and numerical approaches for structural assessment in new footbridge designs (SFRSCC–GFPR hybrid structure). Compos. Struct. 2015, 134, 95–105. [Google Scholar] [CrossRef]

- Schnütgen, B.; Vandewalle, L. Test and Design Methods for Steel Fiber Reinforced Concrete: Background and Experiences. In Proceedings of the RILEM TC 162-TDF Workshop, Bochum, Germany; RILEM Publications SARL: Bagneux, France. ISBN 2-912143-38-1.

- Wang, Y.; Lakho, D.A.; Yao, D. Effect of additives on the rheological properties of fast curing epoxy resins. Éptőanyag J. Silicate Based Compos. Mater 2015, 67, 132–134. [Google Scholar] [CrossRef]

- Gopalaratnam, V.S. On the characterization of flexural toughness in fiber reinforced concretes. Cement Concr. Compos. 1995, 17, 239–254. [Google Scholar] [CrossRef]

- Gribniak, V.; Kaklauskas, G.; Torres, L.; Daniunas, A.; Timinskas, E.; Gudonis, E. Comparative analysis of deformations and tension-stiffening in concrete beams reinforced with GFRP or steel bars and fibers. Compos. B Eng. 2013, 50, 158–170. [Google Scholar] [CrossRef]

- Gribniak, V.; Cervenka, V.; Kaklauskas, G. Deflection prediction of reinforced concrete beams by design codes and computer simulation. Eng. Struct. 2013, 56, 2175–2186. [Google Scholar] [CrossRef]

- Gribniak, V.; Kaklauskas, G.; Juozapaitis, A.; Kliukas, R.; Meskenas, A. Efficient technique for constitutive analysis of reinforced concrete flexural members. Inverse Problems Sci. Eng. 2017, 25, 27–40. [Google Scholar] [CrossRef]

- Gribniak, V.; Arnautov, A.K.; Kaklauskas, G.; Tamulenas, V.; Timinskas, E.; Sokolov, A. Investigation on application of basalt materials as reinforcement for flexural elements of concrete bridges. Baltic J. Road Bridge Eng. 2015, 10, 201–206. [Google Scholar] [CrossRef]

- Gribniak, V.; Kaklauskas, G.; Kwan, A.K.H.; Bacinskas, D.; Ulbinas, D. Deriving stress-strain relationships for steel fibre concrete in tension from tests of beams with ordinary reinforcement. Eng. Struct. 2012, 42, 387–395. [Google Scholar] [CrossRef]

- Gribniak, V.; Kaklauskas, G.; Cygas, D.; Bacinskas, D.; Kupliauskas, R.; Sokolov, A. Investigation of concrete cracking effect in deck slab of continuous bridges. Baltic J. Road Bridge Eng. 2010, 5, 83–88. [Google Scholar] [CrossRef]

- Grelle, S.V.; Sneed, L.H. Review of anchorage systems for externally bonded FRP laminates. Int. J. Concr. Struct. Mater. 2013, 7, 17–33. [Google Scholar] [CrossRef]

- Iqbal, S.; Ali, A.; Holschemacher, K.; Bier, T.A. Mechanical properties of steel fiber reinforced high strength lightweight self-compacting concrete (SHLSCC). Constr. Build. Mater. 2015, 98, 325–333. [Google Scholar] [CrossRef]

- Van Zijl, G.P.A.G.; Zeranka, S. The impact of rheology on the mechanical performance of steel fiber-reinforced concrete. In High Performance Fiber Reinforced Cement Composites 6 (HPFRCC 6); Parra-Montesinos, G.J., Reinhardt, H.W., Naaman, A.E., Eds.; Springer: Berlin, Germany, 2012; pp. 59–66. [Google Scholar] [CrossRef]

- Svec, O.; Skocek, J.; Olesen, J.F.; Stang, H. Fibre reinforced self-compacting concrete flow simulations in comparison with L-box experiments using Carbopol. In 8th RILEM International Symposium on Fiber Reinforced Concrete: Challenges and Opportunities (BEFIB 2012), Guimarães, Portugal; Barros, J.A.O., Ed.; RILEM Publications SARL: Bagneux, France, 2012; pp. 897–905. [Google Scholar]

- Ponikiewski, T.; Katzer, J.; Bugdol, M.; Rudzki, M. Steel fibre spacing in self-compacting concrete precast walls by X-ray computed tomography. Mater. Struct. 2015, 48, 3863–3874. [Google Scholar] [CrossRef]

- Herrmann, H.; Lees, A. On the influence of the rheological boundary conditions on the fibre orientations in the production of steel fibre reinforced concrete elements. Proc. Est. Acad. Sci. 2016, 65, 408–413. [Google Scholar] [CrossRef]

- Herrmann, H.; Pastorelli, E.; Kallonen, A.; Suuronen, J.P. Methods for fibre orientation analysis of X-ray tomography images of steel fibre reinforced concrete (SFRC). J. Mater. Sci. 2016, 51, 3772–3783. [Google Scholar] [CrossRef]

| Material | Amount (kg/m3) |

|---|---|

| Sand 0/4 mm | 865 ± 1% |

| Crushed aggregate 4/8 mm | 404 ± 2% |

| Crushed aggregate 8/11 mm | 606 ± 2% |

| Cement CEM IIA-LL 52.5 R | 300 ± 0.5% |

| Water | 150 ± 3% |

| Superplasticizer MC-PowerFlow 3100 | 4.0 ± 1% |

| Steel fibers Krampe Harex | 65 |

| Group | Beam | h mm | d mm | a2 mm | b mm | As1 mm2 | As2 mm2 | ACFRP mm2 | t Days | Layout of Pins |

|---|---|---|---|---|---|---|---|---|---|---|

| I | I-B1-Ref | 204.7 | 181.4 | 23 | 103.4 | 100.5 | 56.5 | – | 68 | – |

| I-B2-C-A0 | 200.4 | 181.1 | 24 | 100.8 | 100.5 | 56.5 | 16.6 | 69 | – | |

| I-B3-C-A0 | 196.0 | 172.5 | 23 | 101.7 | 100.5 | 56.5 | 16.6 | 70 | – | |

| I-B4-C-A12 | 200.8 | 179.3 | 23 | 101.8 | 100.5 | 56.5 | 16.6 | 69 | 2 × 6 | |

| I-B5-C-A20 | 208.7 | 186.2 | 24 | 99.8 | 100.5 | 56.5 | 16.6 | 73 | 2 × 10 | |

| II | II-B1-Ref | 200.5 | 176.2 | 23 | 100.2 | 100.5 | 56.5 | – | 83 | – |

| II-B2-C-A0 | 197.0 | 171.6 | 24 | 101.6 | 100.5 | 56.5 | 16.6 | 87 | – | |

| II-B3-C-A0 | 199.6 | 175.6 | 23 | 102.2 | 100.5 | 56.5 | 16.6 | 88 | – | |

| II-B4-C-A12 | 202.3 | 181.8 | 24 | 97.5 | 100.5 | 56.5 | 16.6 | 89 | 2 × 6 | |

| II-B5-C-A20 | 201.1 | 177.4 | 23 | 100.8 | 100.5 | 56.5 | 16.6 | 89 | 2 × 10 |

| Beam | Number of Pins | Slip Initiation Moment (kNm) | Failure Moment (kNm) | Maximum Slip (mm) |

|---|---|---|---|---|

| I-B1-Ref | – | – | 14.40 | – |

| I-B2-C-A0 | – | 8.79 | 22.71 | 0.43 |

| I-B3-C-A0 | – | 8.01 | 21.87 | 0.23 |

| I-B4-C-A12 | 2 × 6 | 11.44 | 22.46 | 0.36 |

| I-B5-C-A20 | 2 × 10 | 16.06 | 24.60 | 1.50 |

| II-B1-Ref | – | – | 13.83 | – |

| II-B2-C-A0 | – | 3.62 | 19.69 | 1.00 |

| II-B3-C-A0 | – | – | 25.72 | – |

| II-B4-C-A12 | 2 × 6 | 13.09 | 25.61 | 2.32 |

| II-B5-C-A20 | 2 × 10 | 10.70 | 24.46 | 1.03 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gribniak, V.; Tamulenas, V.; Ng, P.-L.; Arnautov, A.K.; Gudonis, E.; Misiunaite, I. Mechanical Behavior of Steel Fiber-Reinforced Concrete Beams Bonded with External Carbon Fiber Sheets. Materials 2017, 10, 666. https://0-doi-org.brum.beds.ac.uk/10.3390/ma10060666

Gribniak V, Tamulenas V, Ng P-L, Arnautov AK, Gudonis E, Misiunaite I. Mechanical Behavior of Steel Fiber-Reinforced Concrete Beams Bonded with External Carbon Fiber Sheets. Materials. 2017; 10(6):666. https://0-doi-org.brum.beds.ac.uk/10.3390/ma10060666

Chicago/Turabian StyleGribniak, Viktor, Vytautas Tamulenas, Pui-Lam Ng, Aleksandr K. Arnautov, Eugenijus Gudonis, and Ieva Misiunaite. 2017. "Mechanical Behavior of Steel Fiber-Reinforced Concrete Beams Bonded with External Carbon Fiber Sheets" Materials 10, no. 6: 666. https://0-doi-org.brum.beds.ac.uk/10.3390/ma10060666