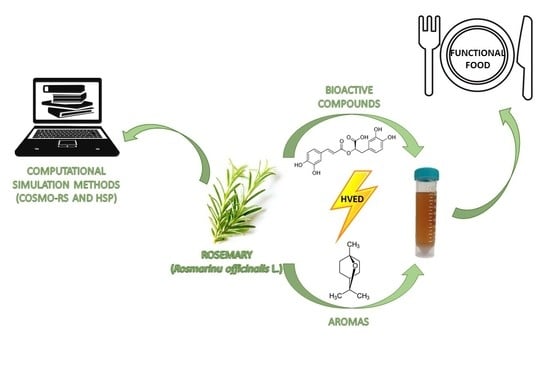

The Potential of High Voltage Discharges for Green Solvent Extraction of Bioactive Compounds and Aromas from Rosemary (Rosmarinus officinalis L.)—Computational Simulation and Experimental Methods

Abstract

:1. Introduction

2. Results

2.1. Computational Simulation Methods for Assessing Solubility of Rosemary Compounds

2.2. Experimental Method for Extraction of Bioactive Compounds and Aromas from Rosemary by High Voltage Electrical Discharges

2.2.1. Determination of Physical Parameters of Rosemary Extracts

2.2.2. Determination of Phenols and Antioxidant Activity of Rosemary Extracts

2.2.3. Near Infrared Spectroscopy and Qualitative Modeling

2.2.4. Determination of Color of Rosemary Extracts

2.2.5. Principal Component Analysis (PCA) of Rosemary Extracts

2.2.6. Ultra-Performance Liquid Chromatography–Tandem Mass Spectrometry (UPLC–MS/MS) Analysis of Phenolic Compounds from Rosemary Extracts

2.2.7. Determination of Volatile Compounds from Rosemary Extracts

2.2.8. Determination of Pesticides and Metals

3. Discussion

3.1. Computational Simulation Methods for Assessing Solubility of Rosemary Compounds

3.2. Experimental Analysis of Extraction of BACs and Aromas from Rosemary Using HVED

3.2.1. Physical Parameters of Rosemary Extracts

3.2.2. Total Phenolic Content and Antioxidant Activity of Rosemary Extracts

3.2.3. Near Infrared Spectroscopy of Rosemary Extracts and Modeling

3.2.4. Colorimetric Analysis of Rosemary Extracts

3.2.5. Principal Component Analysis (PCA) of Rosemary Extracts

3.2.6. Analysis of Individual Bioactive Compounds from Rosemary Extracts

3.2.7. Analysis of Volatile Compounds from Rosemary Extracts

3.2.8. Analysis of Pesticides and Metals

4. Materials and Methods

4.1. Plant Materials

4.2. Computational Simulation Methods

4.2.1. Hansen Solubility Parameters (HSPs)

4.2.2. COSMO–RS Software

4.3. High Voltage Electrical Discharge (HVED) and Conventional Extraction (CE)

4.4. Analytical Methods

4.4.1. Determination of Total Phenolic Content (TPC)

4.4.2. 2-Diphenyl-2-Picrylhydrazyl (DPPH) Free Radical Assay

4.4.3. Ferric Reducing Antioxidant Power (FRAP) Assay

4.4.4. Near Infrared Spectroscopy (NIR)

4.4.5. Colorimetric Evaluation of Rosemary Extracts

4.4.6. Ultra-Performance Liquid Chromatography-Tandem Mass Spectrometry Characterization of Phenolic Compounds (UPLC–MS/MS)

4.4.7. Headspace Solid-Phase Microextraction (HS–SPME) Followed by Gas Chromatography and Mass Spectrometry Analysis (GC–MS)

4.4.8. Determination of Pesticides and Metals in Rosemary Samples

4.5. Experimental Design and Statistical Analysis

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ali, A.; Chua, B.L.; Chow, Y.H. An insight into the extraction and fractionation technologies of the essential oils and bioactive compounds in Rosmarinus officinalis L.: Past, present and future. TrAC-Trends Anal. Chem. 2019, 118, 338–351. [Google Scholar] [CrossRef]

- Babovic, N.; Djilas, S.; Jadranin, M.; Vajs, V.; Ivanovic, J.; Petrovic, S.; Zizovic, I. Supercritical carbon dioxide extraction of antioxidant fractions from selected Lamiaceae herbs and their antioxidant capacity. Innov. Food Sci. Emerg. Technol. 2010, 11, 98–107. [Google Scholar] [CrossRef]

- Viuda-Martos, M.; Ruiz Navajas, Y.; Sánchez Zapata, E.; Fernández-López, J.; Pérez-Álvarez, J.A. Antioxidant activity of essential oils of five spice plants widely used in a Mediterranean diet. Flavour Fragr. J. 2010, 25, 13–19. [Google Scholar] [CrossRef]

- Moore, J.; Yousef, M.; Tsiani, E. Anticancer effects of rosemary (Rosmarinus officinalis L.) extract and rosemary extract polyphenols. Nutrients 2016, 8, 731. [Google Scholar] [CrossRef]

- Haloui, M.; Louedec, L.; Michel, J.B.; Lyoussi, B. Experimental diuretic effects of Rosmarinus officinalis and Centaurium erythraea. J. Ethnopharmacol. 2000, 71, 465–472. [Google Scholar] [CrossRef]

- Rožman, T.; Jeršek, B. Antimicrobial activity of rosemary extracts (Rosmarinus officinalis L.) against different species of Listeria. Acta Agric. Slov. 2009, 93, 51–58. [Google Scholar] [CrossRef] [Green Version]

- Sánchez-Camargo, A.P.; Mendiola, J.A.; Valdés, A.; Castro-Puyana, M.; García-Cañas, V.; Cifuentes, A.; Herrero, M.; Ibáñez, E. Supercritical antisolvent fractionation of rosemary extracts obtained by pressurized liquid extraction to enhance their antiproliferative activity. J. Supercrit. Fluids 2016, 107, 581–589. [Google Scholar] [CrossRef]

- Takaki, I.; Bersani-Amado, L.E.; Vendruscolo, A.; Sartoretto, S.M.; Diniz, S.P.; Bersani-Amado, C.A.; Cuman, R.K.N. Anti-inflammatory and antinociceptive effects of Rosmarinus officinalis L. essential oil in experimental animal models. J. Med. Food 2008, 11, 741–746. [Google Scholar] [CrossRef]

- Naimi, M.; Vlavcheski, F.; Shamshoum, H.; Tsiani, E. Rosemary extract as a potential anti-hyperglycemic agent: Current evidence and future perspectives. Nutrients 2017, 9, 968. [Google Scholar] [CrossRef] [Green Version]

- FDA Code of Federal Regulations (CFR). Title 21: Food and Drugs. Chapter I–Food and Drug Administration, Department of Health and Human Services (Continued), Subchapter B–Food for Human Consumption, Part 182–Substances Generally Recognized as Safe (GRAS). Available online: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=182.10 (accessed on 9 June 2020).

- del Pilar Sánchez-Camargo, A.; Herrero, M. Rosemary (Rosmarinus officinalis) as a functional ingredient: Recent scientific evidence. Curr. Opin. Food Sci. 2017, 14, 13–19. [Google Scholar] [CrossRef]

- Azmir, J.; Zaidul, I.S.M.; Rahman, M.M.; Sharif, K.M.; Mohamed, A.; Sahena, F.; Jahurul, M.H.A.; Ghafoor, K.; Norulaini, N.A.N.; Omar, A.K.M. Techniques for extraction of bioactive compounds from plant materials: A review. J. Food Eng. 2013, 117, 426–436. [Google Scholar] [CrossRef]

- Jacotet-Navarro, M.; Rombaut, N.; Fabiano-Tixier, A.S.; Danguien, M.; Bily, A.; Chemat, F. Ultrasound versus microwave as green processes for extraction of rosmarinic, carnosic and ursolic acids from rosemary. Ultrason. Sonochem. 2015, 27, 102–109. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Švarc-Gajić, J.; Stojanović, Z.; Segura Carretero, A.; Arráez Román, D.; Borrás, I.; Vasiljević, I. Development of a microwave-assisted extraction for the analysis of phenolic compounds from Rosmarinus officinalis. J. Food Eng. 2013, 119, 525–532. [Google Scholar] [CrossRef]

- Zermane, A.; Larkeche, O.; Meniai, A.H.; Crampon, C.; Badens, E. Optimization of Algerian rosemary essential oil extraction yield by supercritical CO2 using response surface methodology. In Proceedings of the Comptes Rendus Chimie; Elsevier: Amsterdam, The Netherlands, 2016; Volume 19, pp. 538–543. [Google Scholar]

- Mouahid, A.; Dufour, C.; Badens, E. Supercritical CO2 extraction from endemic Corsican plants; Comparison of oil composition and extraction yield with hydrodistillation method. J. CO2 Util. 2017, 20, 263–273. [Google Scholar] [CrossRef]

- Tena, M.T.; Valcárcel, M.; Hidalgo, P.J.; Ubera, J.L. Supercritical Fluid Extraction off Natural Antioxidants from Rosemary: Comparison with Liquid Solvent Sonication. Anal. Chem. 1997, 69, 521–526. [Google Scholar] [CrossRef] [PubMed]

- Nieto, A.; Borrull, F.; Pocurull, E.; Marcé, R.M. Pressurized liquid extraction: A useful technique to extract pharmaceuticals and personal-care products from sewage sludge. TrAC-Trends Anal. Chem. 2010, 29, 752–764. [Google Scholar] [CrossRef]

- Smith, R.M. Extractions with superheated water. J. Chromatogr. A 2002, 975, 31–46. [Google Scholar] [CrossRef]

- Hossain, M.B.; Barry-Ryan, C.; Martin-Diana, A.B.; Brunton, N.P. Optimisation of accelerated solvent extraction of antioxidant compounds from rosemary (Rosmarinus officinalis L.), marjoram (Origanum majorana L.) and oregano (Origanum vulgare L.) using response surface methodology. Food Chem. 2011, 126, 339–346. [Google Scholar] [CrossRef] [Green Version]

- Albu, S.; Joyce, E.; Paniwnyk, L.; Lorimer, J.P.; Mason, T.J. Potential for the use of ultrasound in the extraction of antioxidants from Rosmarinus officinalis for the food and pharmaceutical industry. In Proceedings of the Ultrasonics Sonochemistry; Elsevier: Amsterdam, The Netherlands, 2004; Volume 11, pp. 261–265. [Google Scholar]

- Paniwnyk, L.; Cai, H.; Albu, S.; Mason, T.J.; Cole, R. The enhancement and scale up of the extraction of anti-oxidants from Rosmarinus officinalis using ultrasound. Ultrason. Sonochem. 2009, 16, 287–292. [Google Scholar] [CrossRef]

- Bellumori, M.; Innocenti, M.; Binello, A.; Boffa, L.; Mulinacci, N.; Cravotto, G. Selective recovery of rosmarinic and carnosic acids from rosemary leaves under ultrasound-and microwave-assisted extraction procedures. Comptes Rendus Chim. 2016, 19, 699–706. [Google Scholar] [CrossRef]

- Chemat, F.; Abert Vian, M.; Fabiano-Tixier, A.-S.; Nutrizio, M.; Režek Jambrak, A.; Munekata, P.E.S.; Lorenzo, J.M.; Barba, F.J.; Binello, A.; Cravotto, G. A review of sustainable and intensified techniques for extraction of food and natural products. Green Chem. 2020, 22, 2325–2353. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Fan, Y.; Xi, J. Recent advances in high voltage electric discharge extraction of bioactive ingredients from plant materials. Food Chem. 2019, 277, 246–260. [Google Scholar] [CrossRef] [PubMed]

- Almohammed, F.; Koubaa, M.; Khelfa, A.; Nakaya, M.; Mhemdi, H.; Vorobiev, E. Pectin recovery from sugar beet pulp enhanced by high-voltage electrical discharges. Food Bioprod. Process. 2017, 103, 95–103. [Google Scholar] [CrossRef]

- Boussetta, N.; Vorobiev, E.; Reess, T.; De Ferron, A.; Pecastaing, L.; Ruscassié, R.; Lanoisellé, J.L. Scale-up of high voltage electrical discharges for polyphenols extraction from grape pomace: Effect of the dynamic shock waves. Innov. Food Sci. Emerg. Technol. 2012, 16, 129–136. [Google Scholar] [CrossRef]

- Gu, Y.; Jérôme, F. Bio-based solvents: An emerging generation of fluids for the design of eco-efficient processes in catalysis and organic chemistry. Chem. Soc. Rev. 2013, 42, 9550–9570. [Google Scholar] [CrossRef]

- Chemat, F.; Vian, M.A.; Cravotto, G. Green extraction of natural products: Concept and principles. Int. J. Mol. Sci. 2012, 13, 8615–8627. [Google Scholar] [CrossRef] [Green Version]

- Barbieri, J.B.; Goltz, C.; Batistão Cavalheiro, F.; Theodoro Toci, A.; Igarashi-Mafra, L.; Mafra, M.R. Deep eutectic solvents applied in the extraction and stabilization of rosemary (Rosmarinus officinalis L.) phenolic compounds. Ind. Crops Prod. 2020, 144, 112049. [Google Scholar] [CrossRef]

- Sicaire, A.-G.; Vian, M.A.; Fine, F.; Carré, P.; Tostain, S.; Chemat, F. Experimental approach versus COSMO-RS assisted solvent screening for predicting the solubility of rapeseed oil. OCL 2015, 22, D404. [Google Scholar] [CrossRef] [Green Version]

- Belščak-Cvitanović, A.; Valinger, D.; Benković, M.; Tušek, A.J.; Jurina, T.; Komes, D.; Gajdoš Kljusurić, J. Integrated approach for bioactive quality evaluation of medicinal plant extracts using HPLC-DAD, spectrophotometric, near infrared spectroscopy and chemometric techniques. Int. J. Food Prop. 2017, 20, S2463–S2480. [Google Scholar] [CrossRef]

- Valinger, D.; Kušen, M.; Jurinjak Tušek, A.; Panić, M.; Jurina, T.; Benković, M.; Radojčić Redovniković, I.; Gajdoš Kljusurić, J. Development of near infrared spectroscopy models for quantitative prediction of the content of bioactive compounds in olive leaves. Chem. Biochem. Eng. Q. 2018, 32, 535–543. [Google Scholar] [CrossRef]

- Kljusurić, J.G.; Jurina, T.; Valinger, D.; Benkovi, M.; Tušek, A.J. NIR spectroscopy and management of bioactive components, antioxidant activity, and macronutrients in fruits. In Fruit Crops; Elsevier: Amsterdam, The Netherlands, 2020; pp. 95–109. [Google Scholar]

- Wang, W.; Paliwal, J. Near-infrared spectroscopy and imaging in food quality and safety. Sens. Instrum. Food Qual. Saf. 2007, 1, 193–207. [Google Scholar] [CrossRef]

- Oliveira, L.S.; Franca, A.S. Applications of near infrared spectroscopy (NIRS) in food quality evaluation. In Food Quality: Control, Analysis and Consumer Concerns; Medina, D.A., Laine, A.M., Eds.; Nova Science Publishers: Hauppauge, NY, USA, 2011. [Google Scholar]

- Dyrby, M.; Engelsen, S.B.; Nørgaard, L.; Bruhn, M.; Lundsberg-Nielsen, L. Chemometric Quantitation of the Active Substance (Containing C≡N) in a Pharmaceutical Tablet Using Near-Infrared (NIR) Transmittance and NIR FT-Raman Spectra. Appl. Spectrosc. 2002, 56, 579–585. [Google Scholar] [CrossRef]

- Patel, H. Near Infrared Spectroscopy: Basic principles and use in tablet evaluation. Int. J. Chem. Life Sci. 2017, 6, 2006–2015. [Google Scholar] [CrossRef]

- Yara-Varón, E.; Fabiano-Tixier, A.S.; Balcells, M.; Canela-Garayoa, R.; Bily, A.; Chemat, F. Is it possible to substitute hexane with green solvents for extraction of carotenoids? A theoretical versus experimental solubility study. RSC Adv. 2016, 6, 27750–27759. [Google Scholar] [CrossRef] [Green Version]

- Maeda, K.; Maeno, K.; Fukui, K.; Moritoki, M.; Kuramochi, H. Electrical conductivity of aqueous ethanol solutions containing ammonium salts under high pressure at 298 K. J. Chem. Eng. Data 2013, 58, 264–270. [Google Scholar] [CrossRef]

- Tanzi, C.D.; Vian, M.A.; Ginies, C.; Elmaataoui, M.; Chemat, F. Terpenes as green solvents for extraction of oil from microalgae. Molecules 2012, 17, 8196–8205. [Google Scholar] [CrossRef] [Green Version]

- Wolfson, A.; Dlugy, C.; Shotland, Y. Glycerol as a green solvent for high product yields and selectivities. Environ. Chem. Lett. 2007, 5, 67–71. [Google Scholar] [CrossRef] [Green Version]

- Neveu, V.; Perez-Jiménez, J.; Vos, F.; Crespy, V.; du Chaffaut, L.; Mennen, L.; Knox, C.; Eisner, R.; Cruz, J.; Wishart, D.; et al. Phenol-Explorer: An Online Comprehensive Database on Polyphenol Contents in Foods-PubMed. Database 2010, 2010, bap024. [Google Scholar] [CrossRef]

- Rothwell, J.A.; Perez-Jimenez, J.; Neveu, V.; Medina-Remón, A.; M’hiri, N.; García-Lobato, P.; Manach, C.; Knox, C.; Eisner, R.; Wishart, D.S.; et al. Phenol-Explorer 3.0: A major update of the Phenol-Explorer database to incorporate data on the effects of food processing on polyphenol content | Database | Oxford Academic. Database 2013, bat070. [Google Scholar] [CrossRef]

- Kujundžić, D.; Režek Jambrak, A.; Vukušić, T.; Stulić, S.; Gajdoš Kljusurić, J.; Banović, M.; Herceg, Z. Near-infrared spectroscopic characterization of steviol glycosides extracted from Stevia rebaudiana Bertoni using high-power ultrasound and gas-phase plasma. J. Food Nutr. Res. 2017, 56, 109–120. [Google Scholar]

- Hertwig, C.; Reineke, K.; Ehlbeck, J.; Erdoğdu, B.; Rauh, C.; Schlüter, O. Impact of remote plasma treatment on natural microbial load and quality parameters of selected herbs and spices. J. Food Eng. 2015, 167, 12–17. [Google Scholar] [CrossRef]

- Mahnič-Kalamiza, S.; Vorobiev, E.; Miklavčič, D. Electroporation in Food Processing and Biorefinery. J. Membr. Biol. 2014, 247, 1279–1304. [Google Scholar] [CrossRef]

- Fincan, M.; DeVito, F.; Dejmek, P. Pulsed electric field treatment for solid–liquid extraction of red beetroot pigment. J. Food Eng. 2004, 64, 381–388. [Google Scholar] [CrossRef]

- Rodríguez, Ó.; Gomes, W.F.; Rodrigues, S.; Fernandes, F.A.N. Effect of indirect cold plasma treatment on cashew apple juice (Anacardium occidentale L.). LWT 2017, 84, 457–463. [Google Scholar] [CrossRef]

- Massini, L.; Rico, D.; Martin-Diana, A.B. Quality Attributes of Apple Juice: Role and Effect of Phenolic Compounds. Fruit Juices 2018, 45–57. [Google Scholar]

- Hirondart, M.; Rombaut, N.; Fabiano-Tixier, A.S.; Bily, A.; Chemat, F. Comparison between pressurized liquid extraction and conventional Soxhlet extraction for rosemary antioxidants, yield, composition, and environmental footprint. Foods 2020, 9, 584. [Google Scholar] [CrossRef]

- Nutrizio, M.; Maltar-Strmečki, N.; Chemat, F.; Duić, B.; Jambrak, A.R. High-Voltage Electrical Discharges in Green Extractions of Bioactives from Oregano Leaves (Origanum vulgare L.) Using Water and Ethanol as Green Solvents Assessed by Theoretical and Experimental Procedures. Food Eng. Rev. 2020, 1–14. [Google Scholar] [CrossRef]

- Carrillo, J.D.; Tena, M.T. Determination of volatile compounds in antioxidant rosemary extracts by multiple headspace solid-phase microextraction and gas chromatography. Flavour Fragr. J. 2006, 21, 626–633. [Google Scholar] [CrossRef]

- Mena, P.; Cirlini, M.; Tassotti, M.; Herrlinger, K.; Dall’Asta, C.; Del Rio, D. Phytochemical Profiling of Flavonoids, Phenolic Acids, Terpenoids, and Volatile Fraction of a Rosemary (Rosmarinus officinalis L.) Extract. Molecules 2016, 21, 1576. [Google Scholar] [CrossRef]

- Pereira, C.G.; Meireles, M.A.A. Economic analysis of rosemary, fennel and anise essential oils obtained by supercritical fluid extraction. Flavour Fragr. J. 2007, 22, 407–413. [Google Scholar] [CrossRef]

- Zabot, G.L.; Moraes, M.N.; Carvalho, P.I.N.; Meireles, M.A.A. New proposal for extracting rosemary compounds: Process intensification and economic evaluation. Ind. Crops Prod. 2015, 77, 758–771. [Google Scholar] [CrossRef]

- Aissou, M.; Chemat-Djenni, Z.; Yara-Varón, E.; Fabiano-Tixier, A.-S.; Chemat, F. Limonene as an agro-chemical building block for the synthesis and extraction of bioactive compounds. Comptes Rendus Chim. 2017, 20, 346–358. [Google Scholar] [CrossRef]

- Klamt, A. Prediction of the mutual solubilities of hydrocarbons and water with COSMO-RS. Fluid Phase Equilib. 2003, 206, 223–235. [Google Scholar] [CrossRef] [Green Version]

- Shortle, E.; O’Grady, M.N.; Gilroy, D.; Furey, A.; Quinn, N.; Kerry, J.P. Influence of extraction technique on the anti-oxidative potential of hawthorn (Crataegus monogyna) extracts in bovine muscle homogenates. Meat Sci. 2014, 98, 828–834. [Google Scholar] [CrossRef] [PubMed]

- Žuntar, I.; Putnik, P.; Bursać Kovačević, D.; Nutrizio, M.; Šupljika, F.; Poljanec, A.; Dubrović, I.; Barba, F.J.; Režek Jambrak, A. Phenolic and Antioxidant Analysis of Olive Leaves Extracts (Olea europaea L.) Obtained by High Voltage Electrical Discharges (HVED). Foods 2019, 8, 248. [Google Scholar]

- Arranz, E.; Santoyo, S.; Jaime, L.; Fornari, T.; Reglero, G.; Guri, A.; Corredig, M. Improved Bioavailability of Supercritical Rosemary Extract Through Encapsulation in Different Delivery Systems After In Vitro Digestion. Food Dig. 2015, 6, 30–37. [Google Scholar]

- Jerković, I.; Marijanović, Z.; Kuś, P.M.; Tuberoso, C.I.G. Comprehensive Study of Mediterranean (Croatian) Propolis Peculiarity: Headspace, Volatiles, Anti-Varroa-Treatment Residue, Phenolics, and Antioxidant Properties. Chem. Biodivers. 2016, 13, 210–218. [Google Scholar] [CrossRef]

- El-Sayed, A.M. The Pherobase: Database of Insect Pheromones and Semiochemicals. 2014. Available online: http://www.pherobase.com/ (accessed on 24 June 2020).

- Cortés, V.; Blasco, J.; Aleixos, N.; Cubero, S.; Talens, P. Monitoring strategies for quality control of agricultural products using visible and near-infrared spectroscopy: A review. Trends Food Sci. Technol. 2019, 85, 138–148. [Google Scholar] [CrossRef]

- Wang, H.; Peng, J.; Xie, C.; Bao, Y.; He, Y. Fruit quality evaluation using spectroscopy technology: A review. Sensors 2015, 15, 11889–11927. [Google Scholar] [CrossRef] [Green Version]

Sample Availability: Samples of the compounds for UPLC-MS/MS and GC-MS are available from the authors. |

| Compounds | n-Hexane | Ethyl Acetate | Methyl Acetate | Ethyl Oleate | Ethanol | 1-Butanol | Isopro-panol | Methanol | Limonene | α-Pinene | Cymene | β-Myrcene | CPME | Dimethyl Carbonate | MeTHF | Water | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Solvents | |||||||||||||||||

| Monoterpenes | |||||||||||||||||

| β-myrcene | 1.04 | 1.45 | 2.77 | 0.1 | 4.5 | 3.39 | 3.56 | 5.57 | 0.67 | 0.32 | 0.67 | 0 | 0.5 | 2.36 | 0.91 | 10.49 | |

| p-cymen-7-ol | 3.01 | 1.37 | 1.68 | 1.93 | 2.97 | 1.96 | 2.15 | 4.13 | 1.48 | 2.17 | 1.82 | 1.99 | 1.59 | 1.66 | 1.32 | 8.84 | |

| α-pinene | 0.94 | 1.75 | 3.05 | 0.4 | 4.77 | 3.64 | 3.82 | 5.86 | 0.72 | 0 | 0.59 | 0.32 | 0.77 | 2.65 | 1.18 | 10.75 | |

| β-pinene | 0.83 | 1.79 | 3.09 | 0.43 | 4.82 | 3.69 | 3.87 | 5.9 | 0.83 | 0.11 | 0.7 | 0.34 | 0.82 | 2.69 | 1.23 | 10.8 | |

| camphene | 0.83 | 1.79 | 3.09 | 0.43 | 4.82 | 3.69 | 3.87 | 5.9 | 0.83 | 0.11 | 0.7 | 0.34 | 0.82 | 2.69 | 1.23 | 10.8 | |

| sabinene | 1.03 | 1.74 | 3.08 | 0.42 | 4.78 | 3.67 | 3.85 | 5.87 | 0.7 | 0.15 | 0.47 | 0.37 | 0.74 | 2.6 | 1.14 | 10.77 | |

| α-phellandrene | 1.19 | 1.48 | 2.75 | 0.25 | 4.46 | 3.34 | 3.52 | 5.56 | 0.46 | 0.32 | 0.51 | 0.22 | 0.5 | 2.38 | 0.9 | 10.44 | |

| α-terpinene | 1.35 | 1.46 | 2.66 | 0.4 | 4.34 | 3.21 | 3.4 | 5.46 | 0.3 | 0.47 | 0.51 | 0.38 | 0.52 | 2.35 | 0.87 | 10.32 | |

| δ-terpinene | 1.33 | 1.42 | 2.63 | 0.35 | 4.33 | 3.2 | 3.1 | 5.44 | 0.34 | 0.46 | 0.54 | 0.34 | 0.48 | 2.32 | 0.84 | 15.5 | |

| Oxygenated monoterpenes | |||||||||||||||||

| camphor | 1.88 | 1.42 | 2.93 | 0.99 | 4.49 | 3.5 | 3.67 | 5.52 | 1.02 | 1.14 | 0.73 | 1.06 | 0.83 | 1.99 | 0.87 | 10.45 | |

| borneol | 2.28 | 0.91 | 1.72 | 1.22 | 3.33 | 2.23 | 2.42 | 4.46 | 0.9 | 1.5 | 1.3 | 1.28 | 0.9 | 1.63 | 0.71 | 9.3 | |

| α-terpineol | 2.37 | 0.98 | 1.68 | 1.32 | 3.26 | 2.15 | 2.34 | 4.4 | 0.97 | 1.58 | 1.38 | 1.37 | 1.01 | 1.67 | 0.82 | 9.22 | |

| piperitone | 1.82 | 1.18 | 2.62 | 0.8 | 4.22 | 3.19 | 3.37 | 5.28 | 0.74 | 1.02 | 0.63 | 0.88 | 0.55 | 1.86 | 0.57 | 10.19 | |

| Sesquiterpenes | |||||||||||||||||

| β-caryophyllene | 1.04 | 1.73 | 2.97 | 0.42 | 4.68 | 3.54 | 3.73 | 5.78 | 0.61 | 0.14 | 0.57 | 0.33 | 0.74 | 2.63 | 1.15 | 10.65 | |

| Diterpenes | |||||||||||||||||

| carnosol | 2.49 | 1.55 | 2.37 | 1.45 | 3.78 | 2.73 | 2.93 | 4.95 | 0.87 | 1.57 | 1.12 | 1.49 | 1.21 | 2.1 | 1.12 | 9.65 | |

| carnosic acid | 2.99 | 1.69 | 2.05 | 1.94 | 3.29 | 2.26 | 2.46 | 4.48 | 1.38 | 2.1 | 1.72 | 1.98 | 1.66 | 2.09 | 1.48 | 9.09 | |

| rosmanol | 2.95 | 1.42 | 1.78 | 1.88 | 3.07 | 2.05 | 2.24 | 4.24 | 1.4 | 2.09 | 1.74 | 1.93 | 1.56 | 1.78 | 1.32 | 8.93 | |

| epirosmanol | 2.95 | 1.42 | 1.78 | 1.88 | 3.07 | 2.05 | 2.24 | 4.24 | 1.4 | 2.09 | 1.74 | 1.93 | 1.56 | 1.78 | 1.32 | 8.93 | |

| rosmadial | 2.6 | 1.25 | 2.42 | 1.53 | 3.8 | 2.88 | 3.05 | 4.85 | 1.25 | 1.75 | 1.28 | 1.61 | 1.19 | 1.56 | 0.94 | 9.69 | |

| Triterpenes | |||||||||||||||||

| betulinic acid | 2.05 | 1.51 | 2.63 | 1.04 | 4.15 | 3.08 | 3.27 | 5.3 | 0.49 | 1.11 | 0.62 | 1.07 | 0.88 | 2.2 | 0.94 | 10.08 | |

| ursolic acid | 2.12 | 1.54 | 2.6 | 1.11 | 4.11 | 3.03 | 3.23 | 5.26 | 0.53 | 1.18 | 0.71 | 1.14 | 0.94 | 2.22 | 0.99 | 10.02 | |

| rosmarinic acid | 4.56 | 2.95 | 2.76 | 3.49 | 3.11 | 2.55 | 2.69 | 4.2 | 2.93 | 3.65 | 3.18 | 3.53 | 3.17 | 2.85 | 2.91 | 8.29 | |

| Flavonoids | |||||||||||||||||

| apigenin | 4.37 | 2.78 | 2.61 | 3.30 | 3.07 | 2.43 | 2.59 | 4.19 | 2.74 | 3.46 | 3.01 | 3.35 | 2.99 | 2.74 | 2.74 | 8.35 | |

| hispidulin | 4.44 | 2.88 | 2.71 | 3.37 | 3.14 | 2.52 | 2.67 | 4.26 | 2.8 | 3.52 | 3.07 | 3.42 | 3.07 | 2.85 | 2.83 | 8.38 | |

| diosmetin | 4.13 | 2.63 | 2.6 | 3.07 | 3.21 | 2.5 | 2.66 | 4.35 | 2.5 | 3.21 | 2.75 | 3.11 | 2.77 | 2.65 | 2.53 | 8.59 | |

| hesperidin | 4.92 | 2.87 | 2.43 | 3.82 | 2.38 | 2.19 | 2.26 | 3.27 | 3.42 | 4.09 | 3.67 | 3.9 | 3.44 | 2.4 | 3.08 | 7.53 | |

| cirsimaritin | 4.13 | 2.64 | 2.6 | 3.07 | 3.21 | 2.49 | 2.65 | 4.36 | 2.5 | 3.22 | 2.76 | 3.12 | 2.78 | 2.68 | 2.55 | 8.59 | |

| genkwanin | 4.04 | 2.49 | 2.45 | 2.97 | 3.11 | 2.36 | 2.53 | 4.26 | 2.41 | 3.12 | 2.67 | 3.01 | 2.66 | 2.52 | 2.42 | 8.55 | |

| Solvents | n-Hexane | Ethyl Acetate | Methyl Acetate | Ethyl Oleate | Ethanol | 1-Butanol | Isopro-panol | Methanol | Limonene | α-Pinene | Cymene | β-myrcene | CPME | Dimethyl-Carbonate | MeTHF | Water | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compounds | |||||||||||||||||

| Monoterpenes | |||||||||||||||||

| β-myrcene | 69.18 | 81.28 | 60.26 | 100.00 | 11.22 | 20.89 | 16.98 | 4.17 | 95.50 | 81.28 | 100.00 | 100.00 | 100.00 | 39.81 | 100.00 | 0.00 | |

| α-pinene | 99.08 | 42.66 | 26.92 | 100.00 | 10.47 | 22.91 | 17.38 | 3.63 | 95.50 | 100.00 | 83.18 | 87.10 | 89.13 | 16.60 | 85.11 | 0.00 | |

| β-pinene | 95.50 | 57.54 | 34.67 | 100.00 | 12.59 | 25.70 | 19.95 | 4.57 | 97.95 | 99.08 | 89.13 | 89.13 | 97.72 | 22.39 | 95.50 | 0.00 | |

| camphene | 97.72 | 51.29 | 34.67 | 100.00 | 12.59 | 25.70 | 19.95 | 4.68 | 97.95 | 99.31 | 89.13 | 91.20 | 97.72 | 22.39 | 93.33 | 0.00 | |

| sabinene | 87.10 | 66.07 | 46.77 | 100.00 | 13.49 | 25.70 | 20.42 | 5.13 | 99.98 | 93.97 | 95.50 | 95.50 | 100.00 | 30.90 | 100.00 | 0.00 | |

| α-phellandrene | 87.10 | 63.10 | 44.67 | 100.00 | 12.30 | 24.55 | 19.50 | 4.57 | 100.00 | 95.50 | 95.50 | 95.50 | 100.00 | 28.84 | 100.00 | 0.00 | |

| β-phellandrene | 83.56 | 69.18 | 48.98 | 100.00 | 12.88 | 25.12 | 19.95 | 4.79 | 100.00 | 93.33 | 95.50 | 97.72 | 100.00 | 32.36 | 100.00 | 0.00 | |

| Oxygenated monoterpenes | |||||||||||||||||

| camphor | 48.54 | 86.98 | 70.07 | 99.25 | 44.06 | 70.94 | 58.92 | 21.45 | 85.15 | 63.09 | 91.76 | 89.39 | 95.89 | 53.75 | 100.00 | 0.10 | |

| borneol | 11.22 | 100.00 | 89.13 | 81.28 | 85.11 | 100.00 | 100.00 | 41.69 | 17.78 | 13.49 | 16.98 | 16.60 | 100.00 | 38.02 | 100.00 | 0.02 | |

| α-terpineol | 11.22 | 75.86 | 57.54 | 50.12 | 60.26 | 87.10 | 77.62 | 30.90 | 20.42 | 14.45 | 20.89 | 20.42 | 97.72 | 31.62 | 100.00 | 0.02 | |

| piperitone | 32.36 | 100.00 | 89.13 | 85.11 | 91.20 | 100.00 | 100.00 | 51.29 | 72.44 | 46.77 | 87.10 | 83.18 | 87.10 | 70.79 | 100.00 | 0.07 | |

| Sesquiterpenes | |||||||||||||||||

| β-caryophyllene | 99.95 | 53.70 | 33.11 | 100.00 | 7.94 | 18.62 | 14.13 | 2.34 | 100.00 | 100.00 | 89.13 | 89.54 | 100.00 | 18.20 | 100.00 | 0.00 | |

| Diterpenes | |||||||||||||||||

| carnosol | 2.86 | 100.00 | 100.00 | 60.81 | 100.00 | 100.00 | 100.00 | 58.48 | 10.59 | 4.67 | 13.46 | 11.99 | 100.00 | 100.00 | 100.00 | 0.00 | |

| carnosic acid | 0.86 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 3.37 | 1.41 | 3.89 | 3.49 | 100.00 | 100.00 | 100.00 | 0.00 | |

| rosmanol | 0.69 | 100.00 | 100.00 | 41.70 | 100.00 | 100.00 | 100.00 | 100.00 | 3.22 | 1.23 | 4.33 | 3.76 | 100.00 | 100.00 | 100.00 | 0.00 | |

| epirosmanol | 0.69 | 100.00 | 100.00 | 41.70 | 100.00 | 100.00 | 100.00 | 100.00 | 3.22 | 1.23 | 4.33 | 3.76 | 100.00 | 100.00 | 100.00 | 0.00 | |

| rosmadial | 0.58 | 100.00 | 100.00 | 38.89 | 100.00 | 100.00 | 100.00 | 96.82 | 4.06 | 1.22 | 6.35 | 5.58 | 100.00 | 100.00 | 100.00 | 0.00 | |

| Triterpenes | |||||||||||||||||

| betulinic acid | 6.64 | 100.00 | 100.00 | 48.56 | 68.99 | 93.73 | 90.54 | 22.83 | 17.90 | 9.08 | 19.53 | 17.24 | 100.00 | 45.69 | 100.00 | 0.00 | |

| ursolic acid | 1.07 | 100.00 | 100.00 | 83.73 | 100.00 | 100.00 | 100.00 | 100.00 | 2.78 | 1.39 | 2.59 | 2.32 | 100.00 | 45.15 | 100.00 | 0.00 | |

| rosmarinic acid | 0.00 | 100.00 | 100.00 | 34.92 | 100.00 | 100.00 | 100.00 | 100.00 | 0.07 | 0.01 | 0.13 | 0.11 | 100.00 | 100.00 | 100.00 | 0.02 | |

| Flavonoids | |||||||||||||||||

| apigenin | 0.00 | 100.00 | 100.00 | 25.70 | 100.00 | 100.00 | 100.00 | 100.00 | 0.02 | 0.00 | 0.03 | 0.03 | 100.00 | 100.00 | 100.00 | 0.18 | |

| hispidulin | 0.02 | 100.00 | 100.00 | 25.13 | 100.00 | 100.00 | 100.00 | 100.00 | 0.26 | 0.05 | 0.47 | 0.41 | 100.00 | 100.00 | 100.00 | 0.00 | |

| diosmetin | 0.00 | 100.00 | 100.00 | 23.44 | 100.00 | 100.00 | 100.00 | 100.00 | 0.02 | 0.00 | 0.03 | 0.03 | 100.00 | 100.00 | 100.00 | 0.07 | |

| hesperidin | 0.00 | 100.00 | 100.00 | 0.72 | 100.00 | 100.00 | 100.00 | 100.00 | 0.00 | 0.00 | 0.00 | 0.00 | 100.00 | 100.00 | 100.00 | 0.00 | |

| cirsimaritin | 0.03 | 100.00 | 100.00 | 13.12 | 100.00 | 100.00 | 100.00 | 100.00 | 0.38 | 0.09 | 0.71 | 0.63 | 100.00 | 100.00 | 100.00 | 0.00 | |

| genkwanin | 0.03 | 100.00 | 100.00 | 13.48 | 100.00 | 100.00 | 100.00 | 100.00 | 0.35 | 0.08 | 0.65 | 0.57 | 100.00 | 100.00 | 100.00 | 0.00 | |

| Sample | Treatment Time (min) | Voltage (kV) | Ethanol Content (%) | Stirring Time (min) | Extraction Type |

|---|---|---|---|---|---|

| 3 R0 | 0 | 0 | 0 | 3 | CE |

| 9 R0 | 0 | 0 | 0 | 9 | |

| 3 R25 | 0 | 0 | 25 | 3 | |

| 9 R25 | 0 | 0 | 25 | 9 | |

| 3 R50 | 0 | 0 | 50 | 3 | |

| 9 R50 | 0 | 0 | 50 | 9 | |

| RN1 | 3 | 20 | 50 | / | HVED |

| RN2 | 9 | 20 | 0 | / | |

| RN3 | 3 | 20 | 0 | / | |

| RN4 | 3 | 25 | 0 | / | |

| RN5 | 9 | 25 | 25 | / | |

| RN6 | 9 | 20 | 25 | / | |

| RN7 | 9 | 20 | 50 | / | |

| RN8 | 9 | 25 | 50 | / | |

| RN9 | 3 | 25 | 25 | / | |

| RN10 | 9 | 25 | 0 | / | |

| RN11 | 3 | 25 | 50 | / | |

| RN12 | 3 | 20 | 25 | / | |

| RA1 | 3 | 15 | 50 | / | |

| RA2 | 9 | 15 | 0 | / | |

| RA3 | 3 | 15 | 0 | / | |

| RA4 | 3 | 20 | 0 | / | |

| RA5 | 9 | 20 | 25 | / | |

| RA6 | 9 | 15 | 25 | / | |

| RA7 | 9 | 15 | 50 | / | |

| RA8 | 9 | 20 | 50 | / | |

| RA9 | 3 | 20 | 25 | / | |

| RA10 | 9 | 20 | 0 | / | |

| RA11 | 3 | 20 | 50 | / | |

| RA12 | 3 | 15 | 25 | / |

| Sample | L* | a* | b* | C | h | ∆C | ∆E | ∆H | Extraction Type |

|---|---|---|---|---|---|---|---|---|---|

| 3 R0 | 86.01 ± 2.01 | 3.87 ± 0.52 | 35.77 ± 1.79 | 35.98 ± 1.03 | 1.46 ± 0.02 | / | / | / | CE |

| 9 R0 | 82.09 ± 3.64 | 7.09 ± 1.07 | 44.15 ± 0.61 | 44.72 ± 1.56 | 1.41 ± 0.43 | / | / | / | |

| 3 R25 | 95.13 ± 1.97 | −0.77 ± 0.03 | 15.26 ± 3.72 | 15.28 ± 0.82 | −1.52 ± 0.06 | / | / | / | |

| 9 R25 | 93.55 ± 2.27 | −0.41 ± 0.04 | 20.56 ± 4.08 | 20.56 ± 1.35 | −1.55 ± 0.15 | / | / | / | |

| 3 R50 | 95.32 ± 4.31 | −1.16 ± 0.37 | 13.79 ± 1.06 | 13.84 ± 1.10 | −1.49 ± 0.09 | / | / | / | |

| 9 R50 | 94.11 ± 2.55 | −0.77 ± 0.15 | 15.79 ± 2.35 | 15.81 ± 2.74 | −1.52 ± 0.07 | / | / | / | |

| RN1 | 88.56 ± 1.96 | −1.81 ± 1.06 | 43.33 ± 1.71 | 43.37 ± 2.67 | −1.53 ± 0.16 | 29.53 | 30.31 | 1.03 | HVED |

| RN2 | 80.89 ± 1.74 | 6.58 ± 1.21 | 49.65 ± 2.09 | 50.08 ± 1.65 | 1.44 ± 0.27 | 5.37 | 5.65 | 1.30 | |

| RN3 | 83.86 ±0.72 | 4.45 ± 0.47 | 43.24 ± 2.52 | 43.47 ± 1.79 | 1.47 ± 0.20 | 7.49 | 7.79 | 0.21 | |

| RN4 | 84.41 ± 1.82 | 4.38 ± 0.69 | 43.40 ± 1.79 | 43.62 ± 3.40 | 1.47 ± 0.13 | 7.64 | 7.81 | 0.28 | |

| RN5 | 92.19 ± 4.18 | −1.70 ± 0.82 | 28.03 ± 0.67 | 28.08 ± 1.06 | −1.51 ± 0.06 | 7.52 | 7.70 | 0.98 | |

| RN6 | 92.22 ± 2.33 | −2.38 ± 0.04 | 28.18 ± 1.38 | 28.28 ± 1.75 | −1.49 ± 0.00 | 7.72 | 7.98 | 1.55 | |

| RN7 | 92.42 ± 1.79 | −5.22 ± 0.57 | 36.22 ± 1.64 | 36.59 ± 0.89 | −1.43 ± 0.14 | 20.79 | 20.98 | 2.27 | |

| RN8 | 92.52 ± 0.64 | −4.07 ± 0.03 | 32.48 ± 0.82 | 32.73 ± 2.07 | −1.45 ± 0.01 | 16.93 | 17.09 | 1.73 | |

| RN9 | 92.40 ± 2.87 | −5.28 ± 0.50 | 37.19 ± 2.07 | 37.56 ± 1.46 | −1.43 ± 0.03 | 22.28 | 22.55 | 2.17 | |

| RN10 | 81.96 ± 2.91 | 6.35 ± 0.73 | 47.41 ± 4.23 | 47.83 ± 2.37 | 1.44 ± 0.12 | 3.12 | 3.35 | 1.21 | |

| RN11 | 91.92 ± 5.01 | −4.42 ± 0.06 | 36.02 ± 3.16 | 36.29 ± 1.68 | −1.45 ± 0.07 | 22.45 | 22.72 | 0.86 | |

| RN12 | 95.30 ± 2.69 | −1.86 ± 0.07 | 18.18 ± 1.06 | 18.27 ± 0.69 | −1.47 ± 0.06 | 3.00 | 3.12 | 0.86 | |

| RA1 | 92.23 ± 3.15 | −2.04 ± 0.00 | 28.69 ± 2.74 | 28.76 ± 1.41 | −1.50 ± 0.04 | 14.92 | 15.24 | 0.26 | |

| RA2 | 82.44 ± 1.82 | 5.79 ± 1.14 | 43.08 ± 1.95 | 43.47 ± 2.38 | 1.44 ± 0.19 | −1.25 | 1.72 | 1.13 | |

| RA3 | 86.00 ± 2.47 | 3.43 ± 0.97 | 36.88 ± 0.56 | 37.04 ± 1.06 | 1.48 ± 0.02 | 1.06 | 1.19 | 0.55 | |

| RA4 | 84.95 ± 0.53 | 3.72 ± 0.38 | 38.07 ± 2.03 | 38.25 ± 0.76 | 1.47 ± 0.14 | 2.27 | 2.54 | 0.38 | |

| RA5 | 90.25 ± 2.74 | −0.73 ± 0.05 | 30.17 ± 1.73 | 30.18 ± 0.19 | −1.55 ± 0.12 | 9.61 | 10.17 | 0.11 | |

| RA6 | 90.89 ± 3.17 | −0.76 ± 0.14 | 28.81 ± 2.49 | 28.82 ± 1.03 | −1.54 ± 0.10 | 8.26 | 8.68 | 0.16 | |

| RA7 | 92.36 ±1.56 | −2.91 ± 0.09 | 29.96 ± 0.86 | 30.10 ± 2.07 | −1.47 ± 0.06 | 14.29 | 14.44 | 1.05 | |

| RA8 | 91.24 ± 2.40 | −2.84 ± 0.16 | 33.36 ± 1.78 | 33.48 ± 1.56 | −1.49 ± 0.15 | 17.67 | 17.92 | 0.83 | |

| RA9 | 92.84 ± 3.77 | −1.43 ± 0.62 | 24.87 ± 0.93 | 24.91 ± 0.59 | −1.51 ± 0.08 | 9.63 | 9.90 | 0.14 | |

| RA10 | 81.04 ± 1.82 | 5.72 ± 0.11 | 43.50 ± 2.00 | 43.87 ± 2.24 | 1.44 ± 0.20 | −0.84 | 1.84 | 1.26 | |

| RA11 | 94.56 ± 3.09 | −2.81 ± 0.23 | 23.50 ± 1.37 | 23.67 ± 1.38 | −1.45 ± 0.04 | 9.83 | 9.88 | 0.63 | |

| RA12 | 93.93 ± 2.66 | −1.57 ± 0.07 | 21.44 ± 1.08 | 21.50 ± 1.59 | −1.50 ± 0.13 | 6.22 | 6.35 | 0.41 |

| Sample | Apigenin | Carnosol | Diosmetin | Hydroxytyrosol | Luteolin | Oleanolic Acid | Quercetin | Rosmarinic Acid | p-Cymene | Camphor | Thymol | Carvacrol | Extraction Type |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 R0 | 44.460 | 0.940 | 115.897 | 0.394 | 180.406 | / | / | 13.030 | 0.009 | 0.602 | 0.002 | 0.013 | CE |

| 9 R0 | 32.818 | 0.869 | 111.415 | 0.104 | 152.254 | / | / | 0.408 | 0.059 | 0.038 | 0.002 | 0.001 | |

| 3 R25 | 29.996 | 1.849 | 80.044 | 3.241 | 154.296 | / | 0.035 | 0.767 | / | 0.007 | 0.032 | 0.002 | |

| 9 R25 | 27.342 | 2.410 | 82.583 | 2.983 | 147.022 | / | / | 0.761 | 0.070 | 0.003 | 0.002 | 0.002 | |

| 3 R50 | 66.946 | 69.323 | 140.454 | 15.749 | 107.979 | 307.057 | 0.481 | 4756.226 | 0.033 | 0.949 | 0.031 | 0.029 | |

| 9 R50 | 90.244 | 34.363 | 179.350 | 59.951 | 236.985 | 390.762 | 0.711 | 5100.455 | 0.729 | 0.251 | 0.020 | 0.300 | |

| RN1 | 159.160 | 207.346 | 310.578 | 68.141 | 305.866 | 288.807 | 11.271 | 5797.821 | 0.001 | 0.066 | 0.001 | 0.035 | HVED |

| RN2 | 80.659 | 2.548 | 255.637 | 0.362 | 291.207 | / | / | 23.421 | / | 0.003 | 1.576 | / | |

| RN3 | 50.146 | 1.143 | 166.246 | 0.583 | 239.840 | / | / | 5.173 | 0.012 | 0.214 | 0.062 | 0.224 | |

| RN4 | 60.764 | 1.317 | 218.043 | 0.469 | 399.846 | / | / | 2.544 | 0.001 | 0.069 | 0.001 | 0.000 | |

| RN5 | 137.663 | 27.816 | 376.440 | 96.537 | 415.194 | / | 1.608 | 4228.058 | 0.010 | 0.238 | / | / | |

| RN6 | 107.933 | 8.988 | 314.863 | 61.995 | 326.021 | / | 0.269 | 3591.086 | 0.025 | 0.005 | 0.094 | 0.004 | |

| RN7 | 119.723 | 349.797 | 177.469 | 39.265 | 126.156 | 2091.128 | 1.510 | 5950.966 | 0.001 | 0.003 | 0.002 | 0.001 | |

| RN8 | 164.683 | 117.627 | 335.963 | 72.962 | 304.784 | 325.866 | 7.824 | 5745.552 | 0.002 | 0.004 | 0.003 | 0.005 | |

| RN9 | 123.606 | 303.095 | 191.720 | 37.747 | 122.569 | 2053.066 | 1.380 | 6002.350 | / | 0.006 | 0.205 | 0.000 | |

| RN10 | 95.125 | 3.532 | 362.800 | 3.845 | 600.262 | 4.907 | / | 29.489 | 0.001 | 0.153 | 0.001 | 0.000 | |

| RN11 | 116.828 | 195.651 | 194.323 | 38.968 | 124.223 | 1464.630 | 1.115 | 5700.140 | 0.001 | 0.015 | 0.001 | 0.000 | |

| RN12 | 50.827 | 6.240 | 125.214 | 11.977 | 167.060 | 14.068 | / | 68.983 | 0.000 | 0.007 | 0.000 | 0.000 | |

| RA1 | 112.850 | 286.709 | 206.963 | 37.852 | 167.721 | 920.212 | 3.707 | 5648.074 | 0.002 | 0.054 | 0.005 | 0.069 | |

| RA2 | 71.536 | 2.555 | 179.178 | 0.377 | 246.834 | / | / | 32.988 | 0.032 | 1.776 | 7.304 | 0.011 | |

| RA3 | 42.925 | 1.156 | 141.806 | 0.298 | 151.249 | / | / | 16.758 | 0.009 | 0.239 | 0.000 | 0.000 | |

| RA4 | 42.412 | 0.521 | 140.039 | 0.268 | 181.444 | / | / | 1.106 | 0.002 | 0.003 | 0.000 | 0.687 | |

| RA5 | 95.701 | 11.270 | 266.810 | 58.260 | 285.150 | / | 0.124 | 236.826 | 0.001 | 0.030 | 0.013 | 0.059 | |

| RA6 | 73.333 | 7.219 | 207.054 | 18.538 | 197.301 | / | / | 9.584 | 0.001 | 0.007 | 0.000 | 0.000 | |

| RA7 | 90.353 | 236.740 | 164.949 | 40.098 | 127.597 | 954.465 | 2.300 | 5829.363 | 0.001 | / | 0.000 | 0.000 | |

| RA8 | 111.501 | 291.279 | 193.902 | 39.888 | 159.881 | 1001.253 | 4.224 | 5872.906 | 0.018 | 0.019 | 0.000 | 0.000 | |

| RA9 | 56.649 | 10.003 | 173.879 | 11.916 | 203.449 | / | / | 30.652 | 0.019 | 0.137 | 0.000 | 0.000 | |

| RA10 | 34.136 | 1.326 | 111.703 | 0.276 | 239.407 | / | / | 5.206 | 0.000 | 0.006 | 0.000 | 0.001 | |

| RA11 | 76.580 | 157.254 | 131.357 | 26.408 | 98.402 | 757.572 | 1.479 | 5531.217 | 0.002 | / | 0.002 | 0.001 | |

| RA12 | 38.301 | 7.088 | 129.120 | 5.393 | 148.453 | / | 0.022 | 21.810 | 0.000 | 0.015 | 0.001 | / |

| Sample | Area (%) | Extraction Type | |||

|---|---|---|---|---|---|

| Eucalyptol (RI = 1038) | Camphor (RI = 1150) | Borneol (RI = 1172) | Linalool (RI = 1103) | ||

| 3 R0 | 40.33 | 26.70 | 13.46 | / | CE |

| 9 R0 | 34.89 | 24.81 | 15.78 | / | |

| 3 R25 | / | / | / | / | |

| 9 R25 | / | / | / | / | |

| 3 R50 | / | / | / | / | |

| 9 R50 | / | / | / | / | |

| RN1 | / | / | / | / | HVED |

| RN2 | 31.04 | 22.8 | 14.73 | 3.46 | |

| RN3 | 39.44 | 24.63 | 15.58 | 2.96 | |

| RN4 | 32.56 | 22.19 | 13.42 | 2.79 | |

| RN5 | 2.52 | 1.12 | 0.24 | / | |

| RN6 | 2.28 | 0.99 | 0.40 | / | |

| RN7 | / | / | / | / | |

| RN8 | / | / | / | / | |

| RN9 | / | / | / | / | |

| RN10 | 25.66 | 20.88 | 15.99 | / | |

| RN11 | / | / | / | / | |

| RN12 | / | / | / | / | |

| RA1 | / | / | / | / | |

| RA2 | 28.36 | 25.01 | 15.91 | 1.56 | |

| RA3 | 34.58 | 24.14 | 11.60 | / | |

| RA4 | 30.27 | 24.64 | 9.51 | / | |

| RA5 | 3.92 | 2.07 | 0.46 | / | |

| RA6 | 3.20 | 1.68 | 0.61 | / | |

| RA7 | / | / | / | / | |

| RA8 | / | / | / | / | |

| RA9 | / | / | / | / | |

| RA10 | 30.65 | 37.83 | 6.22 | 1.19 | |

| RA11 | / | / | / | / | |

| RA12 | / | / | / | / | |

| Component | MRL (mg/kg) | Content (mg/kg) | HVED Extracts | ||||

|---|---|---|---|---|---|---|---|

| RA8 | RN7 | RN9 | RN11 | ||||

| Pesticides | Alachlor | 0.02 | <0.005 | / | / | / | / |

| Aldrin and Dieldrin (Aldrin and dieldrin combined expressed as dieldrin) | 0.01 | <0.002 | / | / | / | / | |

| Captan (Sum of captan and THPI, expressed as captan) | 0.06 | <0.020 | / | / | / | / | |

| DDT (sum of p,p′-DDT, o,p′-DDT, p-p′-DDE and p,p′-TDE (DDD) expressed as DDT) | 0.05 | <0.004 | / | / | / | / | |

| Endosulfan (sum of alpha- and beta-isomers and endosulfan-sulphate expresses as endosulfan) | 0.05 | <0.002 | / | / | / | / | |

| Endrin | 0.01 | <0.004 | / | / | / | / | |

| Heptachlor (sum of heptachlor and heptachlor epoxide expressed as heptachlor) | 0.01 | <0.002 | / | / | / | / | |

| Hexachlorobenzene | 0.01 | <0.002 | / | / | / | / | |

| Hexachlorocyclohexane (HCH), alpha-isomer | 0.01 | <0.002 | / | / | / | / | |

| Hexachlorocyclohexane (HCH), beta-isomer | 0.01 | <0.002 | / | / | / | / | |

| Iprodione | 0.02 | <0.010 | / | / | / | / | |

| Lindane (Gamma-isomer of hexachlorocyclohexane (HCH)) | 0.01 | <0.002 | / | / | / | / | |

| Methoxychlor | 0.01 | <0.010 | / | / | / | / | |

| Tolylfluanid (Sum of tolylfluanid and dimethylaminosulfotoluidide expressed as tolylfluanid) | 0.05 | <0.020 | / | / | / | / | |

| Vinclozolin | 0.02 | <0.004 | / | / | / | / | |

| Metals | Lead (Pb) | 3.00 | <0.050 | / | / | / | / |

| Cadmium (Cd) | 1.00 | <0.006 | / | / | / | / | |

| Mercury (Hg) | 0.10 | 0.026 | / | / | / | / | |

| Chromium (Cr) | / | 0.240 | 55.3 | 66.1 | 71.0 | 60.5 | |

| Nickel (Ni) | / | 0.322 | 2.10 | 1.10 | 1.20 | 0.950 | |

| Manganese (Mn) | / | 21.00 | 7.10 | 5.10 | 5.45 | 6.20 | |

| Iron (Fe) | / | 163 | 23.6 | 17.6 | 17.0 | 19.8 | |

| Copper (Cu) | / | 6.40 | 3.00 | 3.75 | 3.95 | 6.90 | |

| Zinc (Zn) | / | 26.0 | 6.65 | 9.10 | 10.7 | 20.5 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nutrizio, M.; Gajdoš Kljusurić, J.; Marijanović, Z.; Dubrović, I.; Viskić, M.; Mikolaj, E.; Chemat, F.; Režek Jambrak, A. The Potential of High Voltage Discharges for Green Solvent Extraction of Bioactive Compounds and Aromas from Rosemary (Rosmarinus officinalis L.)—Computational Simulation and Experimental Methods. Molecules 2020, 25, 3711. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules25163711

Nutrizio M, Gajdoš Kljusurić J, Marijanović Z, Dubrović I, Viskić M, Mikolaj E, Chemat F, Režek Jambrak A. The Potential of High Voltage Discharges for Green Solvent Extraction of Bioactive Compounds and Aromas from Rosemary (Rosmarinus officinalis L.)—Computational Simulation and Experimental Methods. Molecules. 2020; 25(16):3711. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules25163711

Chicago/Turabian StyleNutrizio, Marinela, Jasenka Gajdoš Kljusurić, Zvonimir Marijanović, Igor Dubrović, Marko Viskić, Elena Mikolaj, Farid Chemat, and Anet Režek Jambrak. 2020. "The Potential of High Voltage Discharges for Green Solvent Extraction of Bioactive Compounds and Aromas from Rosemary (Rosmarinus officinalis L.)—Computational Simulation and Experimental Methods" Molecules 25, no. 16: 3711. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules25163711