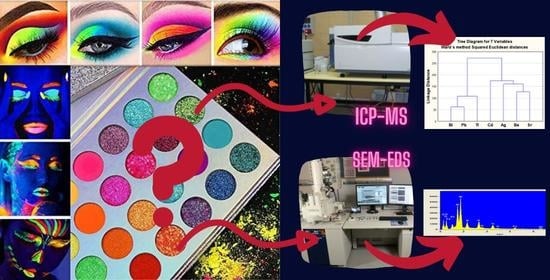

Determination of Metallic Impurities by ICP-MS Technique in Eyeshadows Purchased in Poland. Part I

Abstract

:1. Introduction

2. Results and Discussion

2.1. The Permissible Values

2.1.1. The General Data Analysis

2.1.2. The Lowest Results in This Study for All Studied Metals

2.1.3. The Highest Results in This Study for Cd and Pb

2.1.4. The Highest Results in This Study for Ag, Ba, Bi, Sr and Tl

2.1.5. The Summary of the Quantitative Data

2.2. Statistical Analysis

2.2.1. The Influence of the Color

- -

- for Ag in eye shadows of navy blue, copper and sea color;

- -

- for Ba in eye shadow of pink color;

- -

- for Bi in eye shadows of light grey, brown and sea color;

- -

- for Cd in eye shadows of green, pink and light grey color;

- -

- for Pb in eye shadows of sea and purple color;

- -

- for Sr in eye shadows of purple, pink and sea color;

- -

- for Tl in eye shadow of sea color.

2.2.2. The Influence of the Type

2.2.3. The Influence of the User

2.2.4. The Influence of the Price

2.2.5. The Influence of the Country of Origin

2.2.6. The Influence of the Brand

2.2.7. Summary of the Parameters Studied

2.3. Multivariate Analysis of Studied Eyeshadows

3. Materials and Methods

3.1. Samples

- product intended user (two groups): products dedicated for children (n = 10; one producer, ten different colors: yellow, light grey, beige, pink, sea green, navy blue, gold, copper, purple and green) and adults (n = 84; twelve different colors from seven different manufacturers: yellow, brown, light grey, beige, pink, sea green, navy blue, gold, copper, purple, dark grey and green);

- colors (12 groups): yellow (n = 8), brown (n = 7), light grey (n = 8), beige (n = 8), pink (n = 8), sea green (n = 8), navy blue (n = 8), gold (n = 8), copper (n = 8), purple (n = 8), dark grey (n = 7) and green (n = 8);

- type of product (two groups): matte (n = 19) and pearl shades (n = 75);

- country of origin (four groups): China (n = 26; company A, C, E and L), Poland (n = 50; company B, F, G, K and L), Italy (n = 11; company E and C), Canada (n = 7; company E);

- brands (eight groups): A (n = 12; China), B (n = 12; Poland), C (n = 12; China (n = 4), Italy (n = 8)); E (n = 12; Italy (n = 3), China (n = 2), Canada (n = 7)), F (n = 12; Poland), G (n = 12; Poland), K (n = 12; Poland), L (n = 10; China (n = 8), Poland (n = 2));

- price range (four groups) based on the price of products calculated against one gram of product, from which the following groups were distinguished: the cheapest products (group “1”, n = 36, to which brands B, F and G belong), medium price products (group “2”, n = 34, to which brands A, K and L belonged), expensive (group “3”, n = 12, represented exclusively by brand C) and very expensive (group “4”, n = 12, represented only by brand E).

3.2. Samples Preparation and Equipment

ICP-ToF-MS

- Stage I (25 min): max. pressure inside the reactor 120 bar, max. temperature inside the reactor 250 °C with a microwave power of 1500 W (the power is adjusted in such a way that, at the end of stage I, the temperature of 250 °C will be reached inside the reactor);

- Stage II (10 min): max. pressure inside the reactor 120 bar, max. temperature inside the reactor 250 °C with a microwave power of 1500 W (in this stage, the power will be adjusted that the temperature of 250 °C will be sustained during this step).

3.3. Data Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Farrag, E.; Abu-se’leek, M. Study of heavy metals concentration in cosmetics purchased from Jordan markets by ICP-MS and ICP-OES. Int. J. Appl. Environ. Sci. 2015, 7, 383–393. [Google Scholar]

- Nouioui, M.A.; Mahjoubi, S.; Ghorbel, A.; Ben Haj Yahia, M.; Amira, D.; Ghorbel, H.; Hedhili, A. Health Risk Assessment of Heavy Metals in Traditional Cosmetics Sold in Tunisian Local Markets. Int. Sch. Res. Not. 2016, 2016. [Google Scholar] [CrossRef] [Green Version]

- Sahu, R.; Saxena, P.; Johnson, S.; Mathur, H.B.; Agarwal, H.C. Heavy Metals in Cosmetics; Centre for Science and Environment: New Delhi, India, 2014. [Google Scholar]

- Sani, A.; Bello Gaya, M.; Aliyu Abubakar, F. Determination of some heavy metals in selected cosmetic products sold in kano metropolis, Nigeria. Toxicol. Rep. 2016, 3, 866–869. [Google Scholar] [CrossRef]

- Alsaffar, N.M.; Hussein, H.J. Determination of heavy metals in some cosmetics available in locally markets. IOSR-JESTFT 2014, 8, 9–12. [Google Scholar] [CrossRef]

- Environmental Defence, Heavy Metal Hazard the Health Risks of Hidden Heavy Metals in Face Makeup. Available online: https://d36rd3gki5z3d3.cloudfront.net/wp-content/uploads/2016/01/HeavyMetalHazard-FINAL.pdf (accessed on 11 April 2021).

- Mousavi, Z.; Ziarati, P.; Shariatdoost, A. Determination and Safety Assessment of Lead and Cadmium in Eye Shadows Purchased in Local Market in Tehran. J. Environ. Anal. Toxicol. 2013, 7. [Google Scholar] [CrossRef]

- Contado, C.; Pagnoni, A. A new strategy for pressed powder eye shadow analysis: Allergenic metal ion content and particle size distribution. Sci. Total. Environ. 2012, 432, 173–179. [Google Scholar] [CrossRef]

- Omolaoye, J.A.; Uzairu, A.; Gimba, C.E. Heavy metal assessment of some eye shadow products imported into Nigeria from China. Arch. Appl. Sci. Res. 2010, 2, 76–84. [Google Scholar]

- Temesvári, E.; Pónyai, G.; Németh, I.; Hidvégi, B.; Sas, A.; Kárpáti, S. Periocular dermatitis: A report of 401 patients. JEADV 2009, 23, 124–128. [Google Scholar] [CrossRef] [PubMed]

- Nourmoradi, H.; Foroghi, M.; Farhadkhani, M.; Vahid Dastjerdi, M. Assessment of Lead and Cadmium Levels in Frequently Used Cosmetic Products in Iran. J. Environ. Public Health 2013, 2013, 962727. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Świerczek, L.; Cieślik, B.; Matysiak, A.; Konieczka, P. Determination of heavy metals in eyeshadows from China. Mon. Chem. Chem. Mon. 2019, 150, 1675–1680. [Google Scholar] [CrossRef] [Green Version]

- Issa, S.Y.I.R.; Maguid, A.; Al Mazroua, M.K. Determination of Toxic Contents and Metals in Different Cosmetic Products in the Arabian Market. J. Pharmacol. Clin. Toxicol. 2016, 6, 376. [Google Scholar] [CrossRef]

- Volpe, M.G.; Nazzaro, M.; Coppola, R.; Rapuano, F.; Aquino, R.P. Determination and assessments of selected heavy metals in eye shadow cosmetics from China, Italy and USA. Microchem. J. 2012, 101, 65–69. [Google Scholar] [CrossRef]

- Sainio, E.L.; Jolanki, R.; Hakala, E.; Kanerva, L. Metals and arsenic in eye shadows. Contact Dermat. 2000, 42, 5–10. [Google Scholar] [CrossRef] [PubMed]

- Barros, A.I.; Silva, T.V.; Ferreira, E.C.; Gomes Neto, J.A. Determination of lead in eye shadow and blush by high-resolution continuum source graphite furnace atomic absorption spectrometry employing direct solid sampling. J. Braz. Chem. Soc. 2015, 26, 140–146. [Google Scholar] [CrossRef]

- Iwegbue, C.M.A.; Bassey, F.I.; Obi, G.; Tesi, G.O.; Martincigh, B.S. Concentrations and exposure risks of some metals in facial cosmetics in Nigeria. Toxicol. Rep. 2016, 3, 464–472. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kalicanin, B.; Velimirovic, D. A study of the possible harmful effects of cosmetic beauty products on human health. Biol. Trace Elem. Res. 2016, 170, 476–484. [Google Scholar] [CrossRef]

- Igwo-Ezikpe, M.N.; Olasore, H.S.A.; Osuala, F.I.; Obidi, O.F.; Ayanshina, O.A.; Taiwo, F.O.; Sotinala, O.T. Heavy metals and Polycyclic Aromatic Hydrocarbons in Some Facial Makeup Cosmetics Commonly Used in Lagos, Nigeria. Biokemistri 2017, 29, 110–125. [Google Scholar]

- Abrar, S.N.A.; Perveen, F.; Abbas, M. Evaluation of metals and organic contents in locally available eye shadow products in lahore, Pakistan, pak. J. Sci. Ind. Res. 2018, 61, 51–56. [Google Scholar]

- Sogut, O.; Reyhanlioglu, H.; Ezer, M.; Baltas, H. Elemental compositions of some cosmetic products marketed in Turkey. Fresenius Environ. Bull. 2016, 25, 1068–1077. [Google Scholar]

- Lim, J.S.J.; Ho, Y.B.; Hamsan, H. Heavy metals contamination in eye shadows sold in Malaysia and user’s potential health risks. Ann. Trop. Public Health 2017, 10, 56–64. [Google Scholar]

- Ahmed, H.A.M.; Al-Qahtani, K.M.A.; Emara, H.; Janjua, M.N.; Alhafez, N.; Al-Otaibi, M.B. Determination of Some Heavy Metals in Eye Shadows Cosmetics. Asian J. Chem. 2017, 29, 1441–1446. [Google Scholar] [CrossRef]

- Hepp, N.M.; Mindak, W.R.; Gasper, J.W.; Thompson, C.B.; Barrows, J.N. Survey of cosmetics for arsenic, cadmium, chromium, cobalt, lead, mercury, and nickel content. Int. J. Cosmet. Sci. 2014, 65, 125–145. [Google Scholar]

- Zainy, F. Determination of Some Toxic and Nontoxic Metals on Cheaper Brands of Cosmetic Products. J. Biochem. Technol. 2019, 10, 66–75. [Google Scholar]

- Santos, B.V.; de Oliveira, J.M., Jr.; Bonventi, W., Jr.; Hanai-Yoshida, V.M. Assessment of chemical elements in cosmetics’ eyeshadows by X-ray fluorescence and International Nomenclature of Cosmetic Ingredients characterization. X-Ray Spectrom. 2018, 47, 242–251. [Google Scholar] [CrossRef]

- Foster Mesko, M.; La Rosa Novo, D.; Caldeira Costa, V.; Schneider Henn, A.; Moraes Flores, E.M. Toxic and potentially toxic elements determination in cosmetics used for make-up: A critical review. Anal. Chim. Acta 2020, 1098, 1–26. [Google Scholar] [CrossRef]

- Atz, V.L.; Pozebon, D. Graphite furnace atomic absorption spectrometry (GFAAS) methodology for trace element determination in eye shadow and lipstick. Atom. Spectros 2009, 30, 82–91. [Google Scholar]

- Draelos, Z.D. Special considerations in eye cosmetics. Clin. Dermatol. 2001, 19, 424–430. [Google Scholar] [CrossRef]

- USTAWA z Dnia 4 Października 2018 r. o Produktach Kosmetycznych, Dziennik Ustaw, Warszawa, Dnia 29 Listopada 2018 r. Poz. 2227 (Dz.U. 2018 poz. 2227). Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20180002227 (accessed on 24 September 2021).

- Regulation (EC) No 1223/2009 of the European Parliament and of the Council of 30 November 2009 on Cosmetic Products, Official Journal of the European Union. Available online: https://ec.europa.eu/health/sites/default/files/endocrine_disruptors/docs/cosmetic_1223_2009_regulation_en.pdf (accessed on 24 September 2021).

- Urbanek-Karłowska, B.; Śmietanka, B.; Pawłowska, K.; Biernat, U.; Burzyńska, I. Nadzór nad środkami kosmetycznymi. Roczn. PZH 2001, 52, 257–265. [Google Scholar]

- The United States Government; FDA’s Testing of Cosmetics of Arsenic, Cadmium, Chromium, Cobalt, Mercury and Nickel Content. Available online: https://www.fda.gov/cosmetics/potential-contaminants-cosmetics/fdas-testingcosmetics-arsenic-cadmium-chromium-cobalt-lead-mercury-and-nickel-content#limits (accessed on 5 January 2021).

- Government of Canada; Guidance on Heavy Metal Impurities in Cosmetics. 2012. Available online: https://www.canada.ca/en/health-canada/services/consumer-product-safety/reportspublications/industry-professionals/guidance-heavy-metal-impurities-cosmetics.html (accessed on 5 January 2021).

- Bund, B.V.L. Technically avoidable heavy metal contents in cosmetic products. J. Consum. Prot. Food Saf. 2017, 12, 51–53. [Google Scholar] [CrossRef] [Green Version]

- The Drugs and Cosmetics Act and Rules: The Manufacture of Cosmetics for Sale or Distribution, Part XIV, Rules 138. Available online: https://cdn.cseindia.org/userfiles/Heavy_Metals_in_Cosmetics_Report.pdf (accessed on 23 September 2021).

- Pawlaczyk, A.; Gajek, M.; Jozwik, K.; Szynkowska, M.I. Multielemental Analysis of Various Kinds of Whisky. Molecules 2019, 24, 1193. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gajek, M.; Pawlaczyk, A.; Szynkowska-Jozwik, M.I. MultiElemental Analysis of Wine Samples in Relation to Their Type. Origin, and Grape Variety. Molecules 2021, 26, 214. [Google Scholar] [CrossRef] [PubMed]

- Stanisz, A. Przystępny Kurs Statystyki; StatSoft: Krakow, Poland, 2007. [Google Scholar]

| Metal | USA | India | Canada | Germany | Poland |

|---|---|---|---|---|---|

| Cd | not indicated | not indicated | <3 mg/kg | <0.1 mg/kg | <0.5 mg/kg |

| Pb | <10 mg/kg (<20 mg/kg for color products) | <20 mg/kg | <10 mg/kg | <2 mg/kg | <10 mg/kg |

| Elements | (µg/kg) | N | Mean | Median | Min | Max | Range | Variance | Std.Dev. |

| Ag | 94 | 123.8 | 93.58 | <QL | 1271 | 1271 | 168.0 | ||

| Ba | 82,247 | 18,061 | 1602 | 2,153,693 | 2,152,091 | 282,543 | |||

| Bi | 14,755 | 303.6 | 25.68 | 1,184,575 | 1,184,550 | 122,339 | |||

| Cd | 100.2 | 37.24 | <QL | 3985 | 3985 | 414.9 | |||

| Pb | 1543 | 806.5 | 95.68 | 15,953 | 15,858 | 2249 | |||

| Sr | 4119 | 1600 | 301.0 | 62,837 | 62,536 | 7528 | |||

| Tl | 106.9 | 72.44 | <QL | 672 | 671 | 123.2 |

| Element | LOQ (µg/kg) | SD (µg/kg) | Selected Isotope |

|---|---|---|---|

| Ag | 0.29 | 0.02 | 107Ag |

| Ba | 0.19 | 0.01 | 137Ba |

| Bi | 0.13 | 0.01 | 209Bi |

| Cd | 0.11 | 0.01 | 111Cd |

| Pb | 0.25 | 0.02 | 208Pb |

| Sr | 0.35 | 0.03 | 88Sr |

| Tl | 0.13 | 0.01 | 205Tl |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pawlaczyk, A.; Gajek, M.; Balcerek, M.; Szynkowska-Jóźwik, M.I. Determination of Metallic Impurities by ICP-MS Technique in Eyeshadows Purchased in Poland. Part I. Molecules 2021, 26, 6753. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26216753

Pawlaczyk A, Gajek M, Balcerek M, Szynkowska-Jóźwik MI. Determination of Metallic Impurities by ICP-MS Technique in Eyeshadows Purchased in Poland. Part I. Molecules. 2021; 26(21):6753. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26216753

Chicago/Turabian StylePawlaczyk, Aleksandra, Magdalena Gajek, Martyna Balcerek, and Małgorzata I. Szynkowska-Jóźwik. 2021. "Determination of Metallic Impurities by ICP-MS Technique in Eyeshadows Purchased in Poland. Part I" Molecules 26, no. 21: 6753. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules26216753