Composites of Polymer Hydrogels and Nanoparticulate Systems for Biomedical and Pharmaceutical Applications

Abstract

:1. Hydrogels and Their Biomedical and Pharmaceutical Applications

2. Nanoparticles and Their Biomedical and Pharmaceutical Applications

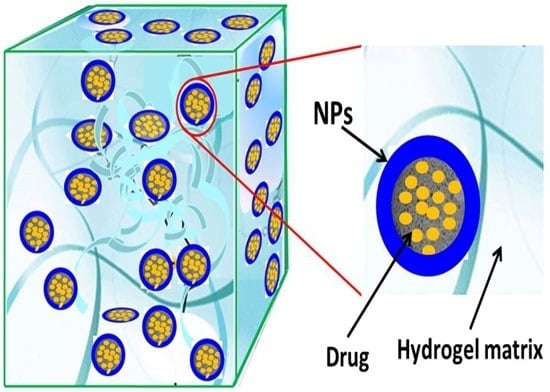

3. Composites of Hydrogels and Nanoparticles

3.1. Nanocomposite Hydrogels: A Brief Overview

3.2. Nanocomposite Hydrogels from Hydrogels and Carbon-based NPs

| Fillers | Hydrogels | Applications and Functions | Ref. |

|---|---|---|---|

| Carbon Nanotubes (CNTs) | PVA | Drug delivery; Incorporation of CNTs caused a significant increase in tensile strength, decrease in elongation at break, and increase in Young’s modulus of the PVA hydrogels; Improved the electrical conductivity and antibacterial activities of the hydrogel systems; CNTs imparted to hydrogels the ability of electrical stimulation-controlled drug release | [105,106] |

| PHEMA | Tissue engineering; CNTs were added to improve electrical conductivity and mechanical properties; CNTs makes hydrogel more suitable as nerve conduits | [87] | |

| PNIPAM | Tissue engineering; Incorporation of CNTs could improve the bioactivities, especially supportive adhesion of PNIPAM to encapsulated cells and favor their efficacy in myocardial repair | [88] | |

| PAM | Biomaterials; CNTs can significantly improve the mechanical properties and swelling behavior of PAM hydrogels | [89] | |

| P(AM-co-EBA) | Drug delivery; CNTs was covalently included into films and acted as a functional element for both improving the electro-responsivity and modulating the release of anionic and cationic drugs | [90] | |

| P(EGDMA-co-HEMA) | Tissue engineering; CNTs can improve the swelling and mechanical properties | [107] | |

| P(VPB-co-DMA) | Biomaterials; CNTs could increase storage moduli of the hydrogel and endow the hydrogel with self-healing property | [96] | |

| MPEG/α-CD | Drug delivery; CNTs improved the hydrophobic drug loading amount; MPEG not only dispersed CNTs in aqueous solution, but also functioned as hydrogel matrix by interacting with α-CD | [108] | |

| GG-g-AA | Drug delivery; CNTs can increase the hydrophobicity of hydrogel, ensure the high environmental stability and drug retention properties of hydrogel | [109] | |

| BC/SA | Drug delivery; CNTs can be used to obtain the composite hydrogel with the highest electric sensitivity; Drug release from hybrid hydrogels showed a significant pulsatile characteristic | [110] | |

| DNA | Tissue engineering; Incorporation of CNTs significantly strengthens the mechanical properties of DNA hydrogel; DNA improved the biocompatibility of CNTs and the resulting hybrid hydrogel | [111] | |

| PEI-Fc | Drug delivery; CNTs can improve the electrical sensitivity properties of hydrogel and can be used to tune the stiffness and degree of swelling | [112] | |

| GEL | Tissue engineering; CNTs supported the contractile property of engineered cardiac tissues, improved the formation of gap junction and enhanced the excitation-contraction coupling | [113] | |

| CS | Antimicrobial biomaterials; The addition of CNTs in the composite hydrogel scaffold significantly reduced the water uptake ability, increased the antimicrobial activity and decreased the toxicity | [114] | |

| COL | Tissue engineering; CNTs enhanced the proliferative potential of the cells; Hydrogel offers excellent 3-D conditions for the growth of cells; CNTs within the hydrogel significantly stimulate cell secretion of neurotrophic factors and expression of neural markers | [115] | |

| Ambidextrous gelators | Biomaterials; The inclusion of SWNTs within the ambidextrous gels improved the mechanical rigidity of the resulting soft nanocomposites | [116] | |

| Peptide | Tissue engineering; Peptide enables the dispersion of the CNTs in aqueous media; CNTs make hybrid hydrogels have superior physical and mechanical properties | [117] | |

| Lysozyme | Drug delivery and tissue engineering; CNTs contributed to gelation, improved mechanical properties and improved the biological activity of hydrogels | [118] | |

| Graphene | PAA | Drug delivery; Graphene/PAA hydrogel was prepared with pH-sensitive, good thermal, strong mechanical and excellent elastic properties | [119] |

| PMAA | Drug delivery; The graphene hybrid hydrogels with enhanced mechanical, electrical, and thermal properties were prepared by in situ free radical polymerization, which exhibited controlled drug release in a pulsatile fashion upon the ON/OFF application of low electrical voltages | [120] | |

| PVA/P(MA-co-NIPAM) | Drug delivery; Small amounts of embedded graphene affect the behavior of mechanical and thermal properties of the hydrogel without altering its hydration state; The entrapment of graphene increase the possibility for functionalization and its dispersibility in water | [91] | |

| Bacterial cellulose | Tissue engineering; Graphene was used to reinforce various hydrogels, leading to excellent mechanical, electrical and biological properties; Graphene also changed the crystallinity of bacterial cellulose | [103] | |

| CS/GEL | Neural tissue engineering; Graphene improved the electrical conductivity and mechanical properties, but decreased the porosity, swelling ratio and in vitro biodegradability | [92] | |

| β-CD /PDMA | Drug delivery; β-CD endowed the self-healing property of hydrogel as anticancer drug carrier, more drug loading and better drug release behavior | [121] | |

| Graphene Oxide (GO) & reduced graphene oxide ( rGO) | PEG | Drug delivery; PEG endowed GO high aqueous solubility and stability in physiological solutions; GO imparted to hydrogel superior loading capacity for hydrophobic drug | [93] |

| PLA–PEG–PLA | Drug delivery; Hydrogel can serve as a sustained delivery depot of the drugs. GO can increase drug loading capacity | [94] | |

| PEGDGE | Drug delivery; Enhanced mechanical and electrical properties were observed with increased rGO content; Hydrogel can greatly improve the stability of rGO dispersions | [101] | |

| PAA/GEL | Tissue engineering; GO worked as reinforcement agent can significantly increase the tensile strength (71%) and elongation at break (26%) of composite hydrogels | [122] | |

| GEL | Drug delivery; GO worked as physical crosslinker, and the multiple crosslinking sites between gelatin chain and GO nanosheet rendered GO–gelatin hybrid hydrogels high mechanical performance; Drug release behaviors from these hydrogels could be manipulated by controlling the crosslinking density and pore sizes of the hydrogels | [123] | |

| α-CD/PEO-PPO | Drug delivery; The incorporation of GO enhanced the mechanical strength and stability of the hybrid hydrogels enormously; Hybrid hydrogels can really exhibit a sustained drug release effect | [102,124] | |

| Peptide | Drug delivery; Mechanical stability, syringe-injectability, low erosion rate, and near-infrared light triggered release functionalities | [99] | |

| KGM/SA | Drug delivery; GO as a drug-binding effector for anticancer drug loading and release; SA as the pH sensitive agent | [125] | |

| CS | Blood toxins adsorption; The incorporation of graphene oxide into the chitosan matrix improved both the Young’s modulus and the compressive strength of the hybrid hydrogel, as well as its adsorption capacity for bilirubin | [126] | |

| clay-PDMA | Biomaterial dressing; GO sheets in the hybrid hydrogels acted as not only a collaborative cross-linking agent but also as a NIR absorber to absorb the NIR irradiation energy and transform it to thermal energy rapidly and efficiently, resulting in a rapid temperature increase of the GO containing gels. | [127] | |

| Fullerene (C60) | PNIPAM | Drug delivery; The incorporation C60 improved the mechanical strength and decreased the swelling ratio and reduced the lower critical solution temperature of PNIPAM | [128] |

| PHEMA | Drug delivery; Equilibrium swelling ratio is lower due to the presence of hydrophobic fullerene moieties; The glass transition temperature and thermo-stability were increased with increasing fullerene content | [129] | |

| GC-g-DMA | Tumor therapy; The incorporation C60 endowed the hydrogel an advanced property for endosomal pH targeting and an elevated photodynamic tumor cell ablation at pH 5.0 through an enhanced singlet oxygen generation at pH 5.0 | [130] |

3.3. Nanocomposite Hydrogels from Hydrogels and Inorganic NPs or Semiconductor NPs

| Fillers | Hydrogels | Applications and Functions | Ref. |

|---|---|---|---|

| Silica (SiO2) particles or NPs | HA/PNIPAM | Tissue engineering; SiO2 NPs improve mechanical properties; HA can improve biocompatibility; The stability and the rigidity increase with the amount of PNIPAM | [159] |

| PNIPAM | Drug delivery and tissue engineering; SiO2 NPs improve the thermal and mechanical properties but decrease the swelling ratio | [160,161,162,163,164,165,166,167,168] | |

| PAM | Compression strength and elastic modulus of the composite hydrogels were significantly improved by adding SiO2 NPs compared with pure PAM hydrogels | [169,170,171,172,173] | |

| Silicone | Implantable medical devices; SiO2 can increase swelling behavior and improve stiffness of the hydrogel; Hybrid hydrogel can be used to decrease the protein absorption and the growth of bacteria | [174] | |

| PHEA | Drug delivery; The silica particles were well dispersed in hydrogels; The release rate of aspirin decreased with the increasing content of silica | [175] | |

| PVA | Biomaterials; The tensile strength of PVA hydrogel increased with SiO2 NPs content. Proper content of SiO2 NPs could also enhance the permeability and swelling property, resulting in the improvement of the capillary water absorption capacity of PVA hydrogel | [176] | |

| CS | Bone tissue engineering; SiO2 NPs have a positive effect on cell viability and induce the occurrence of mineralization not only at the surface of the material but also in its entire volume; CS as bioactive injectable systems for bone tissue repair can undergo in situ gelation under physiological temperatures | [177,178] | |

| Peptide | Biosensor; PEG/peptide can form enzyme responsive hydrogel and collapse in response to diverse biological stimuli; The negatively charged silica NPs used are also at a sufficiently high concentration to form a regular periodic structure within the hydrogel, acting as a photonic bandgap which can reflect visible wavelengths of light | [138,140] | |

| Cellulose | Tissue engineering and cell cultures; SiO2 preserves extracellular matrix-like materials and cellular proteins; The intact 3D spheroids can be recovered from the hydrogel by a cellulase enzyme for downstream applications | [179] | |

| PMAA or PAA | SiO2 as adhesive fillers that interacted with PMAA chains can improved viscoelastic moduli (up to 8.7 times) and enhanced elasticity | [180,181] | |

| ALG or COL | Tissue engineering; SiO2 can improve the mechanical properties, including surface roughness and hardness, of the hydrogel | [182,183,184] | |

| PEG | Drug delivery; Hydrogel can form sustained-release depot systems; Incorporation of SiO2 NPs can regulate the pores size, gelation time and viscosity of the hydrogel; The drug loading capacity and drug release profiles could be tuned | [185,186] | |

| MSNs | CS | Drug delivery; MSNs facilitate the drug loading and their subsequent release; CS enables pH-triggered drug release and improves the endocytosis of target cells and cell biocompatibility | [187] |

| Drug delivery; The introduction of MSNs into CS will facilitate the gelation process at body temperature and also promote the elastic modulus; MSNs can load small drug molecules and then steadily release them for a long time period | [178] | ||

| PClAETA | Biomaterials; Introduction of non-functionalized MSNs can improve the water absorption of the hydrogel | [188] | |

| Poly(aspartic acid) | Biomaterials; MSNs as crosslinker can optimize the pore morphology, improve thermal stability increase swelling ratio and enhance salt tolerance of the composite; MSNs can be uniformly and stably dispersed in the structure of the hydrogel | [189] | |

| PNIPAM | Biomaterials; MSNs can be used as effective “topological crosslinkers” to reinforce the PNIPAM hydrogels | [190] | |

| HAP and nBG | GEL | Bone tissue regeneration; HAP significantly improves the stiffness of GEL hydrogels, while it maintains their structural integrity and swelling ratio; Introduction of HAP results in a lower swelling ratio, higher mechanical moduli, and better biocompatibility and promotes cell functional expression for osteon biofabrication; Gelatin hydrogels also provide natural cell binding motifs, making them amenable for 3D cell encapsulation; GEL provide cell-responsive characteristics, cell adhesion sites, and proteolytic degradability | [191,192,193] |

| Silk fibroin | Bone tissue regeneration; HAP can increase compression modulus and mechanical properties, decrease the water uptake ability, improve metabolic and alkaline phosphatase activities of osteoblastic cells; Hydrogel plays regulatory role in oriented nucleation and growth of HAP crystals | [133,194,195,196,197] | |

| PAM | Tissue engineering; SiO2 can improve the mechanical properties, including surface roughness and hardness | [198] | |

| CS | Bone tissue regeneration; HAP enhances swelling, protein adsorption, exogenous biomineralization and osteoblast differentiation and also accelerates bone formation; Zn possessing excellent antimicrobial properties can tackle implant-associated microbial infections; CS can minimize immune response | [199,200,201,202] | |

| PVA | Bone tissue regeneration; Hydrogels are employed as a matrix gel in a mineralization solution; HAP was formed in the polymer matrix under mild conditions, mimicking mineralization in natural bone formation | [132,203,204] | |

| Pullulan | Bone tissue regeneration; Addition of HAP can improve compressive modulus of the scaffold, provide sites for cell adhesion, and render them osteoconductive in vitro; Hydrogels work as scaffolds for mineralization | [205] | |

| PECE | Tissue engineering; PECE endowed hydrogel good thermosensitivity and injectability; HAP can improve mechanical properties of hydrogel | [206] | |

| PEG | Bone substitute material; The formation of HAP in hydrogel matrices enable the acquisition of bioactive composites materials with desired shapes. | [207,208] | |

| ALG | Bone tissue engineering; Incorporation of nBG into hydrogel can combine excellent cellular adhesion, proliferation and differentiation properties, good biocompatibility and predictable degradation rates; ALG can increase lactate dehydrogenase and mitochondrial activity | [135,209,210,211] | |

| CHS | Bone tissue engineering; nBG shows an excellent stimulatory effect on bone formation; CHS improves integration of the nBG to prevent particle migration and promotes bone regeneration; The composite can encapsulate bone marrow to form a mechanically stable construct | [212] | |

| COL | Tissue engineering; Incorporation of nBG NPs improves mechanical stability and enhanced the proliferation rate and osteogenic differentiation | [136,213,214,215] | |

| LAP | GEL/PAM | Tissue engineering; Incorporation of LAP can enhance thermal stability, tensile and stretching properties; GEL can significantly improve the hydrogel’s pH-responsive properties and enhance the antithrombogenicity but decrease the degree of hemolysis of the gels | [216] |

| PEG/GEL | Tissue engineering; Hydrogel remain stable and provide a cell supportive microenvironment under normal cell culture conditions. LAP can preferentially induce osteogenic differentiation of human mesenchymal stem cells | [217] | |

| PEG | Tissue engineering; Incorporation of LAP significantly reduced the cure time while enhancing the adhesive and bulk mechanical properties of the hydrogel; PEG adsorbed onto LAP, forms a compact layer of mostly loops and trains on top of the nanoparticle and large loops around the edge of the particles; PEG elicits minimal inflammatory response and exhibits an enhanced level of cellular infiltration | [218,219] | |

| PAM | Tissue engineering; The incorporation of catechol on the PAM exhibits a strong affinity toward LAP and enhances stiffness and a viscous dissipation property | [220,221,222] | |

| P(MEOMA-OEGMA) | Drug delivery and tissue engineering; LAP as physical cross-linker had significant influence on the microstructure and swelling/deswelling behaviors of hydrogels.; OEGMA can increase equilibrium swelling ratio and water retention; Hydrogel can provide thermosensitivity and the excellent biocompatibility | [223] | |

| P(AM-DMAEMA) | Tissue engineering, cell culture substrates and biosensors; LAP serves as a physical cross-linker and can change the mechanical strength of the hydrogel under direct-current electric field | [224] | |

| PNIPAM | Tissue engineering; LAP can influence the polymeric chain arrangement and increase the mechanical toughness and thermal stability | [225,226] | |

| Pluronic F127 | Tissue engineering; The interactions between LAP and Pluronic F127 may contribute to rearrangements of network structures at high deformations, leading to high elongations and improved toughness | [227] | |

| GMA | Biomaterials; LAP can reinforce mechanical toughness and elasticity; GMA regulates equilibrium swelling ratio and improves water content; Integrating LAP and GMA can improve self-standing ability and rheological, compression, and tensile properties | [228] | |

| MMT | CS | Drug delivery; MMT can enhance the loading of positively charged drug and affect the hydrogel’s drug release mechanism and swelling properties; The hydrogel can be used for controlled- release of drugs | [137,229] |

| CS-g-PAM | Superabsorbent polymer composites; Incorporation of MMT can optimize their absorption capacity, improve their swelling rate and salt-resistant ability; Composites exhibit moderate antibacterial activity in acidic medium | [230] | |

| PAM | Drug delivery; MMT effects the equilibrium swelling and drug release behavior of the composite; MMT can improve the barrier property of nanocomposite hydrogels and decrease the burse effect. MA effects the pH-responsivity on equilibrium swelling and release of drug | [231,232,233] | |

| P(ATC-AM) | Drug delivery; MMT serves as chemical cross-linker to enhance strength and toughness and decrease the swelling degree; ATC is cationic monomer and exist cation- exchange reaction with MMT | [234] | |

| GEL or COL | Drug delivery and wound dressing; Drug intercalation results in changes in MMT layered space; Integration of drug loaded MMT and gelatin creates biodegradable composite hydrogels with controlled drug release property, improved mechanical and thermal properties | [235,236] | |

| PAA or PMA | Biomaterial implants; MMT is used for adsorbing drug, achieving high drug loading; PAA is used for pH/bacteria- responsive releasing | [237] | |

| Polysaccharide | MMT can enhance strength and toughness and decrease the swelling degree | [238] | |

| PNIPAM | Tissue engineering; MMT can influence the polymeric chain arrangement and the pore size and increase the complex viscosity and adhesion strength as well as thermal stability | [239,240,241,242,243] | |

| Other silicate particles | P(AM-IA) | Drug delivery; Incorporation of hectorite offers the hydrogel with suitable water absorbency, shear-resistance, high gel strength and good thermal stability; IA provides pH-responsivity on drug release | [244,245,246] |

| ALG | Drug delivery; Halloysite nanotubes improve complex surface topography and structural integrity and achieve a sustained release of the growth factor; The composites enhance repair and regeneration in damaged or diseased tissues | [139] | |

| PEG/P(AA-VP) | Drug delivery; Phyllosilicate enhances the water uptake with a desirable strength; Hydrogels are used for pH responsible and controlled release | [247] | |

| PCL-PEG-PCL | Bone regeneration; Mesoporous magnesium silicate can enhance the compressive strength, elastic modulus, and hydrophilicity of hydrogel, and promote cell attachment and proliferation and increase the degradability of the hydrogel | [248] | |

| PAM | Tissue engineering; Attapulgite nanorods grafted with vinyl groups serve as macro-crosslinkers, which can significantly increase the modulus, strength, and toughness of hydrogels; | [249] | |

| P(AA-NIPAM) | Tissue engineering; The presence of imogolite nanotubes produced strong hydrogels that exhibit thermo-responsive volume transition because of the coil/globule transition of PNIPAM chains. | [250] |

3.4. Nanocomposite Hydrogels from Hydrogels and Metal NPs or Metal Oxide NPs

| Fillers | Hydrogels | Applications and Functions | Ref. |

|---|---|---|---|

| Ag NPs | PAM | Wound dressing; Ag NPs demonstrate excellent antibacterial activity; Polymer hydrogels were used to keep the NPs stable and contact with skin | [254,255,293,294,295,296,297] |

| Biosensor; Ag NPs can change the strength of the localized surface plasm on resonance by regulating interparticle distances; PAM can be swelling with ionic strength change | [256] | ||

| PVP or PVA | Wound dressing or tissue engineering; Ag NPs are antibacterial agents and enhance the mechanical and thermal strength of the hydrogel; Hydrogels work as an efficient stabilizer of Ag NPs and control the release of the Ag NPs | [257,258,298,299,300,301,302] | |

| PNIPAM | Antibiotic materials; Ag NPs work as antimicrobial agents; PNIPAM is temperature-responsive component and make Ag NPs stable and uniformly distributed | [259,303,304,305,306] | |

| PEGDMA | Contact lenses; Ag NPs work as antimicrobial agents | [307] | |

| Acrylate-based copolymers | Biosensors and drug delivery; Ag NPs work as antimicrobial agents; Copolymer hydrogel with different swelling properties is used to disperse Ag NPs | [262,266,308,309,310] | |

| Ophthalmic lenses; The addition of Ag NPs is associated with the reduction of UV-B transmittance and increase in tensile strength | [311] | ||

| AMPS-Na | Burn wound dressing; Silver hydrogel is efficient at preventing bacterial colonization of wounds and has good inhibitory action against bacteria | [263,312] | |

| NaDOC | Antibacterial materials; Ag NPs are antibacterial agents; NaDOC can immobilize Ag NPs via pH-induced self-assembly | [313] | |

| Graphene | Wound dressing; Ag NPs are antibacterial agents; Graphene is conductive to cellular adhesion and growth; The composite can significantly accelerate the healing rate of artificial wounds | [264] | |

| Silicone | Adhesion to catheters to prevent urinary tract infections; Ag NPs work as antimicrobial agents | [265] | |

| Lysine gelator | Nanomedicine; Gelator exhibits good gelation ability, low haemolytic activity and high biocompatibility to mammalian cells; Incorporation of Ag NPs exhibits excellent antibacterial activity and significant mechanical strength | [314] | |

| Peptides | Wound healing and sustained Ag NPs release; Ag NPs inhibit bacterial growth; Peptide fibers prevent aggregation of Ag NPs and improve the biocompatibility of the system | [267] | |

| Antibacterial materials and bioimaging; Fluorescent Ag NPs show excellent optical properties and antibacterial activity; Peptides make the Ag NPs stable | [315] | ||

| PAA | Drug delivery; PAA is used to control the release of antibacterial drugs; Ag NPs can enhance the antibacterial activity | [316] | |

| Cellulose | Wound dressing and antimicrobial materials; Ag NPs show high antibacterial activity against Gram positive and Gram negative bacteria; Cellulose serves as a gelling agent as well as a reducing agent for AgNO3 and a stabilizer for Ag NPs | [247,261,317] | |

| GEL or COL | Wound dressing; Ag NPs are antibacterial agents; Hydrogel is used for stabling Ag NPs | [268,318,319] | |

| GEL/CS | Drug delivery and tissue engineering; Benzotriazole maleimide functionalized Ag NPs work as cross-linkers, improve the storage modulus and decrease swelling ratios | [320] | |

| AG-CS | Biosensor; Ag NPs improve the conductivity and mechanical strength of the hydrogels and also have antimicrobial activity; Biopolymer moieties act as both reducing and stabilizing agents | [321] | |

| AG | Antibiotic materials; Hydrogels promote the Ag NPs protection and inhibit their aggregation; Ag NPs can produce Ag + to kill bacteria | [322,323] | |

| Au NPs | PNIPAM | Drug delivery; Au NPs can be used as a photoabsorbing agent to generate heat from optical energy; PNIPAM is thermo-responsive to control the release of drugs | [270,324,325,326] |

| Biosensor for the detection of DNA; Au NPs immobilize DNA strands | [278] | ||

| PEG | Tissue engineering; RGD modified gold nanoarrays as scaffold to control cell localization and differentiation | [279] | |

| Drug delivery; Au NPs are utilized as building blocks; α-CD and PEG form temperature-responsive reversible supramolecular hydrogel through host–guest interaction | [271] | ||

| PEGDA | Tumor therapy; Au NRs can be used as a photoabsorbing agent to generate heat from optical energy; The introduction of Au NRs is conducive to the formation of the hydrogel and accelerates the rate of cytotoxic singlet oxygen generation; PEGDA can stabilize Au NRs | [275] | |

| PPy | Clinical diagnosis; Au NPs can further increase the specific surface area to capture a large amount of antibodies as well as improve the capability of electron transfer | [327] | |

| PEDOT | Electroporation-assisted cell uptakes; Au NPs work as microelectrode; PEDOT modification is effective in preventing electrolysis during the electroporation | [328] | |

| CS | Drug delivery; Au NPs act as a role of physical cross-linking agents; This physical cross-linked hydrogel shows excellent drug loading ability | [272] | |

| GEL | Bone tissue engineering; The hydrogels loaded with Au NPs promote proliferation, differentiation, and alkaline phosphate activities of human adipose-derived stem cells and have a significant influence on new bone formation; GEL is a photo-curable hydrogel to embed Au NPs | [280] | |

| Peptide | Tissue engineering; Au NPs act as cross-linking agents and strengthen the prepared hydrogel | [329] | |

| DNA | Drug delivery and photothermal therapy; Au NPs can generate heat upon laser excitation and be used for photothermal therapy; DNA hydrogel can be fragmented by heat generations to release drugs and Au NPs | [273] | |

| DNAzyme | Detection of lead; Au NPs are used for visual detection; DNAzyme can be activated by lead and conducive to dissolve the hydrogel to release Au NPs | [330] | |

| Graphene | Biosensor for nitric oxide detection; Au NPs catalyze the electrochemical oxidation of NO; Graphene is used for uniformly depositing Au NPs | [331] | |

| Fe3O4 NPs | κ-carrageenan | Drug delivery; Fe3O4 NPs offer the hydrogel with magnetic-responsiveness properties; κ-carrageenan is pH responsive | [332,333,334,335] |

| Starch | Drug delivery; Fe3O4 NPs endow the hydrogel with magnetic sensitivity; The composite also shows temperature/pH sensitivity | [336,337,338] | |

| Cellulose | Drug delivery; Magnetic nanoparticles are used as cross-linkers; The release of DOX is significantly enhanced at external magnetic field | [339,340] | |

| Fibrin | Tissue engineering; Fe3O4 NPs make the hydrogel show excellent hyperthermia properties under exposure to an alternating magnetic field; The presence of Fe3O4 NPs in the fibrin can improve cell adhesion and colonization of osteogenic cells | [282,341] | |

| HA | Magnetic resonance imaging and drug delivery; HA can be degraded by hyaluronidase and release hydrophobic drugs; Fe3O4 NPs serve as imaging agents to track the hydrogel degradation and degradation products in vivo | [342] | |

| CS | Drug delivery; The presence of Fe3O4 NPs can make the hydrogels have magnetic response property and deliver and release encapsulated anticancer agent at the tumor by the weak magnetic field | [343,344,345] | |

| ALG | Cell encapsulation; Alginate cell capsules with Fe3O4 NPs can be easily controlled and manipulated by external magnetic fields | [346] | |

| COL-HA-PEG | Cartilage tissue engineering; The presence of Fe3O4 NPs can make the hydrogel travel to the tissue defect sites under remote magnetic guidance | [288] | |

| Guar gum | Drug delivery and theranostic; The NPs work as imaging agents and produce hyperthermia; Aminated guar gum can form the hydrogel without using toxic crosslinking agents | [347] | |

| PPZ | Drug delivery and biodetection; Ferrite nanoparticles is used for long-term magnetic response theragnosis; The composite can be used for sustainedly releasing cargos | [348] | |

| PAM | Drug delivery and protein separation; The presence of Fe3O4 NPs can make the hydrogel exhibit higher dielectric constants and magnetic responsiveness; The composite also has the properties of fast adsorption | [349,350,351] | |

| Drug delivery; Incorporation of Fe3O4 NPs endows the hydrogel with the ability of direction-dependent thermogenesis in an alternating magnetic field; The novel magnetic hydrogel shows a direction-dependent release of drugs that has a 3.4-fold difference between the two directions | [352] | ||

| PNIPAM | Drug delivery; Incorporation of magnetic nanoparticles endows the hydrogel with on-demand pulsatile drug release triggered by alternating magnetic field | [353] | |

| PVP or PVA | Drug delivery; Fe3O4 NPs are used for magnetic drug targeting; The hydrogel is used for carry cancer therapeutic agent | [354,355,356] | |

| PEGDA | Cell patterning; Incorporation of Fe3O4 NPs can manipulate space pattern of the hydrogel; PEGDA blocks are used as a stencil to define the area for cell adhesion and the second types of cells could be seeded after the magnetic block was removed to create heterotypic cell patterns | [357] | |

| Acrylate/acrylamide-based copolymers | Drug delivery and protein immobilization; Fe3O4 NPs endow the hydrogel with properties of magnetic stimuli-responsive; The copolymer hydrogel exhibits pH- and thermosensitive properties | [88,358,359,360,361] | |

| P(HEMA-GMA)-PANI | Immobilization of glucoamylase; Fe3O4 NPs show super-paramagnetism and make the hydrogel easily dispersed or separated from the medium without needing high magnetic intensity; Grafting of polyaniline on the hydrogel increases 3.4 times maximum adsorption capacity | [362] | |

| Cu or CuO NPs | PVP/PVA | Bioimaging and drug delivery; Cu NPs with red emission properties are used for optical imaging as well as for flow cytometric probe of cellular uptake; Cu NPs also generate reactive oxygen species to enhance the efficiency of killing cancer cells; PVP is used for stabling the NPs and delivering drugs | [363] |

| PEGDA | Antibacterial material; Cu NPs-modified hydrogel can be used for preventing bacterial infections | [364] | |

| Cellulose | Antibacterial material; CuO NPs endow the hydrogel with antibacterial activity | [365] | |

| ZnO NPs | PAM | Wound dressing; ZnO NPs endow the hydrogel with antibacterial activity; PAM provides uniform distribution and binding of the NPs to the fiber surface and to prevent their agglomeration | [366] |

| Cellulose | Antibacterial materials; ZnO NPs endow the hydrogel with antibacterial activity; The composite shows a pH and salt sensitive swelling behavior | [367,368] | |

| Chitin | Wound dressing; ZnO NPs endow the hydrogel with antibacterial activity and blood clotting ability; Incorporation of ZnO NPs improve healing rate and collagen deposition ability of composite bandages | [369] | |

| ZnS NPs | PHEMA/PAA | Artificial cornea implants; ZnS NPs can improve the refractive index of the polymer | [370] |

| Pt NPs | Polyimide | Biosensor; Pt NPs work as microelectrades; The composite works as microsensor to detect glutamate in vivo | [371] |

| Ni NPs | Cellulose | Responsive biomaterials; Ni NPs offer the gel with magnetic response properties with can be changed by temperature and the size of the NPs | [289] |

| Co NPs | PHEMA | Tissue engineering; Co NPs enable the hydrogel that combine the use of saturation magnetizations and high particle loading, flexibility, and shape memory; PHEMA can reduce magnetic particle migration or loss | [290] |

| MnO2 NPs | CS | Biosensor; MnO2 NPs work as catalytic for H2O2; The composite can be used for detections of choline chloride | [372] |

| TiO2 NPs | PAM/PNIPAM | Responsive biomaterials; Modified TiO2 NPs serve as cross-linker and enhance the mechanical strength; The hydrogel bilayer is able to bend to opposite directions to form hydrogel circles in pure water and 20% NaCl solution | [373] |

3.5. Nanocomposite Hydrogels from Hydrogels and Polymeric NPs or Liposomes

| Fillers | Hydrogels | Applications and Functions | Ref. |

|---|---|---|---|

| PLGA particles or NPs | PVA | Loading and delivery of biomacromolecular drugs; PLGA can increase drug loading and decrease burst release; Hydrogel can prevent the foreign body reaction(FBR), promote angiogenesis around subcutaneous implants and extend the lifetime of implantable biosensors | [375,376] |

| Drug delivery; PVA hydrogel acts as a hydrophilic base to support the microspheres; PLGA microspheres serve as drug reservoirs to continuously drug release | [377,378,379,380,381] | ||

| ALG | Drug delivery; Maintain consistent release of rhBMP-2; Improve bone formation and osseous integration | [382] | |

| PuraMatrixTM peptide | Drug delivery; PuraMatrixTM peptide hydrogel as vaccine adjuvants to recruit and activate immune cells | [383] | |

| F127 | Drug delivery; Sustained release of protein drugs; Temper burst release and prolong delivery of drugs at the site of a spinal cord injury | [384,385] | |

| P407 | Tissue engineering; Preserve protein structure and integrity, allowing a better and prolonged release profile and the maintenance of their biological activity. Hydrogel further protected it from the hydrophobic environment | [386] | |

| ALG | Cell-based tissue engineering; Offer a continuous and localized release of drug; Provide a physical support for microcapsules, facilitating administration, ensuring retention and recuperation and preventing dissemination; Reduce post-transplantation inflammation and foreign body reaction, thus prolonging the lifetime of the implant | [387] | |

| PEI-PEGDA | Drug delivery; Hydrogels are used for carrying dual or multi-molecular compounds and releasing them in a bimodal, sequential manner | [388] | |

| HAMC | Drug delivery; HAMC hydrogel is well-tolerated, having a minimal inflammatory response; NPs offer sustained release while the HAMC gel localizes the NPs at the site of injection | [389,390,391,392,393,394,395] | |

| PAM | Antivirulence treatment of local bacterial infection; RBC-coated NPs is an effective detoxification platform against bacterial infections; Hydrogels preserve the structural integrity and the functionalities of the contained NPs and offer additional engineering flexibility to improve the therapeutic efficacy | [396] | |

| MC | Drug delivery; Particle localization, decreases initial burst, and further prolongs release | [397] | |

| GG | Sustained local delivery of drug; For the local treatment of osteoporosis and other bone tissue disorder; Improve the low bioavailability and decrease the high toxicity of sodium alendronate | [398] | |

| PNIPAM | Drug delivery; PLGA used for the isolation of the drug, a slower drug-release rate, and the achievement of different drug release profiles | [399] | |

| PAMAM | Drug delivery; The residence time of pilocarpine can be prolonged by hydrogel; PLGA nanoparticles are safe for delivery of ophthalmic agents and are capable of sustained delivery of antiglaucoma agents | [400] | |

| Fmoc-peptide | Drug delivery and tissue engineering; Peptide hydrogel will likely be more stable in vivo; Sustained release of drug | [401] | |

| DBM-BHPEA NPs | Silicone | Protect the eyes from UV rays; Increase the pore size, allowing the particles to diffuse into the lenses. | [402] |

| HPMC-PEG NPs | Branched PAA | Drug delivery; Optimize drug therapies in which the release of hydrophobic compounds; Selectively direct to specific cell lines; Able to stay localized at the injection site | [403] |

| Silk fibroin particles | Silk fibroin | Tissue engineering; Offering well suited rheological features for injectability, and shape conformability into defect sites as well as controlled delivery rate | [404] |

| PHBV NPs | GG | Drug delivery; Minimally invasive administration and the controlled delivery of the active agent | [405] |

| PEG-PLA NPs | HPMC | Drug delivery; Shear-thinning and self-healing properties; Dual loading of a hydrophobic molecule into the NPs and a second hydrophilic molecule into the aqueous bulk of the gel, and thus enabled simultaneous release of both hydrophobic and hydrophilic drug in vivo from a single gel. | [406] |

| PPy NPs | ALG | Drug delivery and tissue engineering; PPy is stable in solution over the period of a month, and have good drug loading capacity; Localized depot releasing systems; Pulsatile releasing behaviors and maintain morphology and mechanical strength. | [407,408] |

| PHBHHx NPs | CS/GP | Drug delivery; Relatively strict control of long-term insulin release | [409] |

| PGT NPs | Silicone | Drug delivery in eye; Increase patient compliance and the bioavailability; Increase the release duration from the contact lenses; Establish safety and efficacy of glaucoma therapy by extended wear of nanoparticle loaded contact lenses | [410] |

| CS NPs | GX | Scaffold system for dual growth factor delivery in bone regeneration; Develop an in situ gelling biomaterial combining the viscoelasticity of natural polymers with the powerful antimicrobial properties of chitosan | [411] |

| PMMA NPs | Polysaccharide-PAA | Drug delivery; Hydrogels can remain localized at the site of injection, showing high biocompatibility and good ability to provide short term delivery. PMMA based NPs can be traced both in vitro and in vivo biological studies over a long period of time without side effects due to the biodegradation process | [412] |

| PβAE NPs | PAMAM-DEX | siRNA delivery; High transfection efficiency and low cytotoxicity; Sustained delivery of the siRNA; Enhance the stability of the NPs | [413] |

| PLA particles | PECE | Drug delivery and tissue engineering; Increase the thickness of the corium; Increase cell adhesion of microspheres | [414] |

| PAMAM dendrimer | CS-PEG | Drug delivery; Dendrimer was used to increase the solubility, loading efficiency and homogeneity of hydrophobic drug; Hydrogel provide a local drug delivery depot for a prolonged drug release | [415] |

| COL | Drug delivery; Dendrimer can improve the biostability and structural integrity of COL, which can make COL have higher denature temperature and resistance against collagenase digestion | [416] | |

| HA | Biofabrication; Form a fast cross-linking hydrogel; Improved the cell viability, proliferation, and attachment | [417] | |

| PEG-LA-DA | Tissue engineering; The multiple cross-linking sites present on the dendrimers can increase the cross-linking density at lower concentrations; The spherical dendrimers may provide discrete “molecular islands” in the network to limit swelling and improve mechanical properties; The multiple end-groups on the dendrimers facilitate the introduction of functional groups into the system at the nanoscale level | [418] | |

| Carbopol 980 | Drug delivery; PAMAM dendrimers strongly affects their influence on the improvement of solubility and antifungal activity of drug | [419] | |

| PEG | Tissue engineering and drug delivery; Hydrogel crosslinked with dendrimers, showing improved cytocompatibility, controlled swelling and degradation | [420] | |

| Solid lipid NPs | Poloxamer | Drug delivery; NPs can increase gel strength and mucoadhesive force; Easy to administer rectally; Gelled rapidly inside the body; Increased dissolution rate of the drug; Reduced initial burst effect | [421] |

| Liposomes | PAM | Drug delivery and antibacterial; Hydrogel can stabilize liposomes against fusion and preserves the structural integrity of the liposomes; The hydrogel formulation allows for controllable viscoeleasticity and tunable liposome release rate | [422] |

| Peptide | Tissue regeneration; Liposomes can enhance binding of growth factors to peptide fibers of the gel matrix and achieve delayed release; Bimodal drug release | [423] | |

| HA | Drug delivery; Strengthen the network formed by HA chains, high efficiency encapsulation, easily injectable and less invasive, delay and control the release of drugs for local delivery | [424,425,426,427] | |

| PNIPAM | Drug delivery; The intact liposomes with their content can be controlled to release from hydrogel by changing the temperature, which can be used for temperature-triggered on-demand delivery | [428] | |

| PVA | Tissue engineering; Hydrogel can retain the structural integrity and contents of liposomes | [429] | |

| PVP-PAA-PBMA | Drug delivery, Hydrogel can ensure liposomes original vesicle structure; Liposomes can improve viscoelastic features and drug release profiles | [430] | |

| Micelles | PECA | Drug delivery; Improve docetaxel solubility and permeability; The pH-responsive hydrogel controlled the micelles diffusion excellently in intestinal environment, thus achieving the target delivery of drug-loaded micelles to small intestine and significantly improvement of the oral bioavailability of docetaxel | [431] |

| PEG-PCL-PEG | Drug delivery and wound dressing; High drug loading and encapsulation efficiency; Improve combined curcumin solubility and permeability; Exhibit excellent wound healing activity and promote tissue reconstruction processes | [432] | |

| Agarose | Drug delivery; Achieve functional hydrogels capable of stimulus-triggered drug release | [433] | |

| PEG | Gene delivery; The incorporation of the nanosized micelles provided an excellent mean to tune physical properties of the hydrogels, such as increasing porosity and tunable mechanical property of the hydrogels and providing the best balance among hydrogel stiffness and porosity for cell survival | [434] | |

| Nanogels or microgels | PEG | Tissue engineering; Hydrogel can control the degradation and release of nanogels; Possess relatively strong mechanical properties, biodegradability; Nanogels can trap proteins by hydrophobic interactions; Sustainedly release proteins in their native form | [435] |

| PAM | Obtain macroscopic hydrogels with a fast response to external stimuli; Obtain strong hydrogel matrixes and composite gels with an internal structure | [436] | |

| PEG | Drug delivery; Multidrug delivery system; High drug loading and encapsulation efficiency; Encapsulate various hydrophobic substances | [437] | |

| DEX | Drug delivery; Both proteins and poorly water-soluble low-molecular-weight drugs can be efficiently encapsulated in the nanogels; Eliminating the initial burst release; Offer a maximum pharmacological efficiency at a minimum drug dose, reducing administration frequency and improving patient compliance | [438] | |

| Carbohydrate | Drug delivery; Improve loading or prolong delivery of a target drug; Prevent migration of the microgels from target sites; Provide an additional diffusive barrier for drug release; Reducing burst release effects and prolonging drug release kinetics | [439] | |

| CHP nanogel | Hyaluronan | Drug delivery; Minimize denaturation by trapping the protein in a hydrated polymer network; Simultaneously achieved both simple drug loading and controlled release with no denaturation of the protein drugs | [440] |

| Vesicles | CS | Functional biomaterials; The vesicle serves as reversible “dynamic” crosslinks that hydrophobic chains can be either embedded into the bilayers of vesicle or pulled out; Vesicles can afford multi-action sites for hydrophobic interaction, indicating that the self-healing rate of such a hydrogel would be much faster | [441] |

| PVA | Drug delivery; The vesicles can be evenly dispersed in PVA and are stable. The release can be triggered and the calcein diffuses afterwards quickly throughout the gel | [442] | |

| Xanthan | Drug delivery; The hydrogel shows a protective effect on vesicle integrity and leads to a slow release of the loaded model molecules from the polysaccharidic system; The vesicular structures may enhance the delivery of drug in the stratum corneum due to their specific constituents | [443] | |

| Micro-droplet | ALG | Drug delivery and bone tissue engineering; Facilitate the regional regulation of encapsulated cell fate; In situ formation of localized, sustained bioactive molecule delivery to encapsulate stem cells for therapeutic applications | [444] |

| Virus | ALG | Regenerative medicine; Significant improvement in cell attachment; Mimic the biological niche of a functional tissue; Localization, delivery, and differentiation of stem cells | [445] |

4. Conclusions and Future Perspective

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hoare, T.R.; Kohane, D.S. Hydrogels in drug delivery: Progress and challenges. Polymer 2008, 49, 1993–2007. [Google Scholar] [CrossRef]

- Li, Y.; Rodrigues, J.; Tomas, H. Injectable and biodegradable hydrogels: Gelation, biodegradation and biomedical applications. Chem. Soc. Rev. 2012, 41, 2193–2221. [Google Scholar] [CrossRef] [PubMed]

- Annabi, N.; Tamayol, A.; Uquillas, J.A.; Akbari, M.; Bertassoni, L.E.; Cha, C.; Camci-Unal, G.; Dokmeci, M.R.; Peppas, N.A.; Khademhosseini, A. 25th Anniversary article: Rational design and applications of hydrogels in regenerative medicine. Adv. Mater. 2014, 26, 85–124. [Google Scholar] [CrossRef] [PubMed]

- Caló, E.; Khutoryanskiy, V.V. Biomedical applications of hydrogels: A review of patents and commercial products. Eur. Polym. J. 2015, 65, 252–267. [Google Scholar] [CrossRef]

- Seliktar, D. Designing cell-compatible hydrogels for biomedical applications. Science 2012, 336, 1124–1128. [Google Scholar] [CrossRef] [PubMed]

- Hoffman, A.S. Hydrogels for biomedical applications. Adv. Drug Deliv. Rev. 2012, 64, 18–23. [Google Scholar] [CrossRef]

- Peppas, N.A.; Hilt, J.Z.; Khademhosseini, A.; Langer, R. Hydrogels in biology and medicine: From molecular principles to bionanotechnology. Adv. Mater. 2006, 18, 1345–1360. [Google Scholar] [CrossRef]

- Slaughter, B.V.; Khurshid, S.S.; Fisher, O.Z.; Khademhosseini, A.; Peppas, N.A. Hydrogels in regenerative medicine. Adv. Mater. 2009, 21, 3307–3329. [Google Scholar] [CrossRef] [PubMed]

- Miyata, T.; Uragami, T.; Nakamae, K. Biomolecule-sensitive hydrogels. Adv. Drug Deliv. Rev. 2002, 54, 79–98. [Google Scholar] [CrossRef]

- Qiu, Y.; Park, K. Environment-sensitive hydrogels for drug delivery. Adv. Drug Deliv. Rev. 2012, 64, 49–60. [Google Scholar] [CrossRef]

- Hoffman, A.S. Stimuli-responsive polymers: Biomedical applications and challenges for clinical translation. Adv. Drug Deliv. Rev. 2013, 65, 10–16. [Google Scholar] [CrossRef] [PubMed]

- Ward, M.A.; Georgiou, T.K. Thermoresponsive polymers for biomedical applications. Polymers 2011, 3, 1215–1242. [Google Scholar] [CrossRef]

- Wichterle, O.; Lim, D. Hydrophilic gels for biological use. Nature 1960, 185, 117–118. [Google Scholar] [CrossRef]

- Zhu, J.M. Bioactive modification of poly(ethylene glycol) hydrogels for tissue engineering. Biomaterials 2010, 31, 4639–4656. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.-C. Recent advances in crosslinking chemistry of biomimetic poly(ethylene glycol) hydrogels. RSC Adv. 2015, 5, 39844–39853. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maitra, J.; Shukla, V.K. Cross-linking in Hydrogels—A Review. Am. J. Polym. Sci. 2014, 4, 25–31. [Google Scholar]

- Ebara, M.; Kotsuchibashi, Y.; Narain, R.; Idota, N.; Kim, Y.-J.; Hoffman, J.M.; Uto, K.; Aoyagi, T. Smart Hydrogels. In Smart Biomaterials; Ebara, M., Kotsuchibashi, Y., Narain, R., Idota, N., Kim, Y.J., Hoffman, J.M., Uto, K., Aoyagi, T., Eds.; Springer: Tokyo, Japan, 2014; pp. 9–65. [Google Scholar]

- Huang, P.; Wang, W.; Zhou, J.; Zhao, F.; Zhang, Y.; Liu, J.; Liu, J.; Dong, A.; Kong, D.; Zhang, J. Amphiphilic polyelectrolyte/prodrug nanoparticles constructed by synergetic electrostatic and hydrophobic interactions with cooperative pH-sensitivity for controlled doxorubicin delivery. ACS Appl. Mater. Interfaces 2015, 7, 6340–6350. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Lin, X.; Liu, J.; Zhao, J.; Dong, H.; Deng, L.; Liu, J.; Dong, A. Sequential thermo-induced self-gelation and acid-triggered self-release process of drug-conjugated nanoparticles: A strategy for sustained and controlled drug delivery to tumor. J. Mater. Chem. B 2013, 1, 4667–4677. [Google Scholar] [CrossRef]

- Thomas, V.; Namdeo, M.; Mohan, Y.M.; Bajpai, S.K.; Bajpai, M. Review on polymer, hydrogel and microgel metal nanocomposites: A facile nanotechnological approach. J. Macromol. Sci. Pure Appl. Chem. 2008, 45, 107–119. [Google Scholar] [CrossRef]

- Hu, Z.; Chen, G. Novel nanocomposite hydrogels consisting of layered double hydroxide with ultrahigh tensibility and hierarchical porous structure at low inorganic content. Adv. Mater. 2014, 26, 5950–5956. [Google Scholar] [CrossRef] [PubMed]

- Merino, S.; Martin, C.; Kostarelos, K.; Prato, M.; Vazquez, E. Nanocomposite Hydrogels: 3D Polymer-Nanoparticle Synergies for On-Demand Drug Delivery. ACS Nano 2015, 9, 4686–4697. [Google Scholar] [CrossRef] [PubMed]

- Bonanno, L.M.; Segal, E. Nanostructured porous silicon-polymer-based hybrids: From biosensing to drug delivery. Nanomedicine 2011, 6, 1755–1770. [Google Scholar] [CrossRef] [PubMed]

- Ye, E.; Loh, X.J. Polymeric Hydrogels and Nanoparticles: A Merging and Emerging Field. Aust. J. Chem. 2013, 66, 997–1007. [Google Scholar] [CrossRef]

- Gaharwar, A.K.; Peppas, N.A.; Khademhosseini, A. Nanocomposite hydrogels for biomedical applications. Biotechnol. Bioeng. 2014, 111, 441–453. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Deng, L.; Zhang, J.; Yin, L.; Dong, A. Composites of electrospun-fibers and hydrogels: A potential solution to current challenges in biological and biomedical field. J. Biomed. Mater. Res. B 2015. [Google Scholar] [CrossRef] [PubMed]

- Thoniyot, P.; Tan, M.J.; Karim, A.A.; Young, D.J.; Loh, X.J. Nanoparticle-hydrogel composites: Concept, design,and applications of these promising, multi-functional materials. Adv. Sci. 2015, 1–2. [Google Scholar] [CrossRef]

- De, M.; Ghosh, P.S.; Rotello, V.M. Applications of Nanoparticles in Biology. Adv. Mater. 2008, 20, 4225–4241. [Google Scholar] [CrossRef]

- Thanh, N.T.K.; Green, L.A.W. Functionalisation of nanoparticles for biomedical applications. Nano Today 2010, 5, 213–230. [Google Scholar] [CrossRef]

- Kim, T.; Hyeon, T. Applications of inorganic nanoparticles as therapeutic agents. Nanotechnology. 2014, 25. [Google Scholar] [CrossRef] [PubMed]

- Doane, T.L.; Burda, C. The unique role of nanoparticles in nanomedicine: Imaging, drug delivery and therapy. Chem. Soc. Rev. 2012, 41, 2885–2911. [Google Scholar] [CrossRef] [PubMed]

- Nicolas, J.; Mura, S.; Brambilla, D.; Mackiewicz, N.; Couvreur, P. Design, functionalization strategies and biomedical applications of targeted biodegradable/biocompatible polymer-based nanocarriers for drug delivery. Chem. Soc. Rev. 2013, 42, 1147–1235. [Google Scholar] [CrossRef] [PubMed]

- Arvizo, R.R.; Bhattacharyya, S.; Kudgus, R.A.; Giri, K.; Bhattacharya, R.; Mukherjee, P. Intrinsic therapeutic applications of noble metal nanoparticles: Past, present and future. Chem. Soc. Rev. 2012, 41, 2943–2970. [Google Scholar] [CrossRef] [PubMed]

- Elsabahy, M.; Wooley, K.L. Design of polymeric nanoparticles for biomedical delivery applications. Chem. Soc. Rev. 2012, 41, 2545–2561. [Google Scholar] [CrossRef] [PubMed]

- Hong, H.; Chen, F.; Cai, W. Pharmacokinetic issues of imaging with nanoparticles: Focusing on carbon nanotubes and quantum dots. Mol. Imaging Biol. 2013, 15, 507–520. [Google Scholar] [CrossRef] [PubMed]

- Chung, C.; Kim, Y.K.; Shin, D.; Ryoo, S.R.; Hong, B.H.; Min, D.H. Biomedical applications of graphene and graphene oxide. Acc. Chem. Res. 2013, 46, 2211–2224. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Barnes, J.C.; Bosoy, A.; Stoddart, J.F.; Zink, J.I. Mesoporous silica nanoparticles in biomedical applications. Chem. Soc. Rev. 2012, 41, 2590–2605. [Google Scholar] [CrossRef] [PubMed]

- Bitar, A.; Ahmad, N.M.; Fessi, H.; Elaissari, A. Silica-based nanoparticles for biomedical applications. Drug Discov. Today 2012, 17, 1147–1154. [Google Scholar] [CrossRef] [PubMed]

- Soenen, S.J.; Parak, W.J.; Rejman, J.; Manshian, B. (Intra)cellular stability of inorganic nanoparticles: Effects on cytotoxicity, particle functionality, and biomedical applications. Chem. Rev. 2015, 115, 2109–2135. [Google Scholar] [CrossRef] [PubMed]

- Dou, Q.Q.; Guo, H.C.; Ye, E. Near-infrared upconversion nanoparticles for bio-applications. Mater. Sci. Eng. C 2014, 45, 635–643. [Google Scholar] [CrossRef] [PubMed]

- Min, Y.; Li, J.; Liu, F.; Padmanabhan, P.; Yeow, E.; Xing, B. Recent advance of biological molecular imaging based on lanthanide-doped upconversion-luminescent nanomaterials. Nanomaterials 2014, 4, 129–154. [Google Scholar] [CrossRef]

- Bhattacharya, R.; Mukherjee, P. Biological properties of “naked” metal nanoparticles. Adv. Drug Deliv. Rev. 2008, 60, 1289–1306. [Google Scholar] [CrossRef] [PubMed]

- Dykman, L.; Khlebtsov, N. Gold nanoparticles in biomedical applications: Recent advances and perspectives. Chem. Soc. Rev. 2012, 41, 2256–2282. [Google Scholar] [CrossRef] [PubMed]

- Dreaden, E.C.; Alkilany, A.M.; Huang, X.; Murphy, C.J.; El-Sayed, M.A. The golden age: Gold nanoparticles for biomedicine. Chem. Soc. Rev. 2012, 41, 2740–2779. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, P.; Vig, K.; Dennis, V.; Singh, S. Functionalized gold nanoparticles and their biomedical applications. Nanomaterials 2011, 1, 31–63. [Google Scholar] [CrossRef]

- Wei, L.; Lu, J.; Xu, H.; Patel, A.; Chen, Z.S.; Chen, G. Silver nanoparticles: Synthesis, properties, and therapeutic applications. Drug Discov. Today 2015, 20, 595–601. [Google Scholar] [CrossRef] [PubMed]

- Gupta, A.K.; Gupta, M. Synthesis and surface engineering of iron oxide nanoparticles for biomedical applications. Biomaterials 2005, 26, 3995–4021. [Google Scholar] [CrossRef] [PubMed]

- Ling, D.; Hyeon, T. Chemical design of biocompatible iron oxide nanoparticles for medical applications. Small 2013, 9, 1450–1466. [Google Scholar] [CrossRef] [PubMed]

- Gregoriadis, G. Engineering liposomes for drug delivery: Progress and problems. Trends Biotechnol. 1995, 13, 527–537. [Google Scholar] [CrossRef]

- Lasic, D.D. Novel applications of liposomes. Trends Biotechnol. 1998, 16, 307–321. [Google Scholar] [CrossRef]

- Torchilin, V.P. Recent advances with liposomes as pharmaceutical carriers. Nat. Rev. Drug Discov. 2005, 4, 145–160. [Google Scholar] [CrossRef] [PubMed]

- Shang, L.; Nienhaus, K.; Nienhaus, G.U. Engineered nanoparticles interacting with cells: Size matters. J. Nanobiotechnol. 2014, 12, 5–15. [Google Scholar] [CrossRef] [PubMed]

- Verma, A.; Stellacci, F. Effect of surface properties on nanoparticle-cell interactions. Small 2010, 6, 12–21. [Google Scholar] [CrossRef] [PubMed]

- Duan, X.; Li, Y. Physicochemical characteristics of nanoparticles affect circulation, biodistribution, cellular internalization, and trafficking. Small 2013, 9, 1521–1532. [Google Scholar] [CrossRef] [PubMed]

- Jo, D.H.; Kim, J.H.; Lee, T.G.; Kim, J.H. Size, surface charge, and shape determine therapeutic effects of nanoparticles on brain and retinal diseases. Nanomedicine 2015, 11, 1603–1611. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Li, Y.; Yu, J.C. Chemical modification of inorganic nanostructures for targeted and controlled drug delivery in cancer treatment. J. Mater. Chem. B 2014, 2, 452–470. [Google Scholar] [CrossRef]

- Kobayashi, K.; Wei, J.; Iida, R.; Ijiro, K.; Niikura, K. Surface engineering of nanoparticles for therapeutic applications. Polym. J. 2014, 46, 460–468. [Google Scholar] [CrossRef]

- Albanese, A.; Tang, P.S.; Chan, W.C. The effect of nanoparticle size, shape, and surface chemistry on biological systems. Annu. Rev. Biomed. Eng. 2012, 14, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Erathodiyil, N.; Ying, J.Y. Functionalization of inorganic nanoparticles for bioimaging applications. Acc. Chem. Res. 2011, 44, 925–935. [Google Scholar] [CrossRef] [PubMed]

- Deng, H.; Liu, J.; Zhao, X.; Zhang, Y.; Liu, J.; Xu, S.; Deng, L.; Dong, A.; Zhang, J. PEG-b-PCL copolymer micelles with the ability of pH-controlled negative-to-positive charge reversal for intracellular delivery of doxorubicin. Biomacromolecules 2014, 15, 4281–4292. [Google Scholar] [CrossRef] [PubMed]

- Shin, S.; Song, I.; Um, S. Role of physicochemical properties in nanoparticle toxicity. Nanomaterials 2015, 5, 1351–1365. [Google Scholar] [CrossRef]

- Decuzzi, P.; Lee, S.; Bhushan, B.; Ferrari, M. A theoretical model for the margination of particles within blood vessels. Ann. Biomed. Eng. 2005, 33, 179–190. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Wang, H.; Liu, J.; Deng, L.; Liu, J.; Dong, A.; Zhang, J. Comb-like amphiphilic copolymers bearing acetal-functionalized backbones with the ability of acid-triggered hydrophobic-to-hydrophilic transition as effective nanocarriers for intracellular release of curcumin. Biomacromolecules 2013, 14, 3973–3984. [Google Scholar] [CrossRef] [PubMed]

- Song, F.; Li, X.; Wang, Q.; Liao, L.; Zhang, C. Nanocomposite hydrogels and their applications in drug delivery and tissue engineering. J. Biomed. Nanotechnol. 2015, 11, 40–52. [Google Scholar] [CrossRef] [PubMed]

- Usuki, A.; Kojima, Y.; Kawasumi, M.; Okada, A.; Fukushima, Y.; Kurauchi, T.; Kamigaito, O. Mechanical properties of nylon 6-clay hybrid. J. Mater. Res. 1993, 8, 1179–1184. [Google Scholar] [CrossRef]

- Yano, K.; Usuki, A.; Okada, A.; Kurauch, T.; Kamigaito, O. Synthesis and properties of polyimide-clay hybrid. J. Polym. Sci. A Polym. Chem. 1993, 31, 2493–2498. [Google Scholar] [CrossRef]

- Kokabi, M.; Sirousazar, M.; Hassan, Z.M. PVA-clay nanocomposite hydrogels for wound dressing. Eur. Polym. J. 2007, 43, 773–781. [Google Scholar] [CrossRef]

- Liu, Y.; Meng, H.; Konst, S.; Sarmiento, R.; Rajachar, R.; Lee, B.P. Injectable dopamine-modified poly(ethylene glycol) nanocomposite hydrogel with enhanced adhesive property and bioactivity. ACS Appl. Mater. Interfaces 2014, 6, 16982–16992. [Google Scholar] [CrossRef] [PubMed]

- Guo, R.; Du, X.; Zhang, R.; Deng, L.; Dong, A.; Zhang, J. Bioadhesive film formed from a novel organic-inorganic hybrid gel for transdermal drug delivery system. Eur. J. Pharm. Biopharm. 2011, 79, 574–583. [Google Scholar] [CrossRef] [PubMed]

- Mohan, Y.M.; Lee, K.; Premkumar, T.; Geckeler, K.E. Hydrogel networks as nanoreactors: A novel approach to silver nanoparticles for antibacterial applications. Polymer 2007, 48, 158–164. [Google Scholar] [CrossRef]

- Suvorova, E.I.; Klechkovskaya, V.V.; Kopeikin, V.V.; Buffat, P.A. Stability of Ag nanoparticles dispersed in amphiphilic organic matrix. J. Cryst. Growth 2005, 275, 2351–2356. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, J.; Paquet, C.; Lin, Y.; Kumacheva, E. From hybrid microgels to photonic crystals. Adv. Funct. Mater. 2003, 13, 468–472. [Google Scholar] [CrossRef]

- Sershen, S.R.; Westcott, S.L.; Halas, N.J.; West, J.L. Independent optically addressable nanoparticle-polymer optomechanical composites. Appl. Phys. Lett. 2002, 80, 4609–4611. [Google Scholar] [CrossRef]

- Holtz, J.H.; Asher, S.A. Polymerized colloidal crystal hydrogel films as intelligent chemical sensing materials. Nature 1997, 389, 829–832. [Google Scholar] [CrossRef]

- Xia, Y.; Yang, P.; Sun, Y.; Wu, Y.; Mayers, B.; Gates, B.; Yin, Y.; Kim, F.; Yan, H. One-dimensional nanostructures: Synthesis, characterization, and applications. Adv. Mater. 2003, 15, 353–389. [Google Scholar] [CrossRef]

- Pardo-Yissar, V.; Gabai, R.; Shipway, A.N.; Bourenko, T.; Willner, I. Gold nanoparticle/hydrogel composites with solvent-switchable electronic properties. Adv. Mater. 2001, 13, 1320–1323. [Google Scholar] [CrossRef]

- Sheeney-Haj-Ichia, L.; Sharabi, G.; Willner, I. Control of the electronic properties of thermosensitive poly(N-isopropylacrylamide) and Au-nano-particle/poly(N-isopropylacrylamide) composite hydrogels upon phase transition. Adv. Funct. Mater. 2002, 12, 27–31. [Google Scholar] [CrossRef]

- Jones, C.D.; Lyon, L.A. Photothermal patterning of microgel/gold nanoparticle composite colloidal crystals. J. Am. Chem. Soc. 2003, 125, 460–465. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Flynn, N.T.; Langer, R. Controlled structure and properties of thermoresponsive nanoparticle-hydrogel composites. Adv. Mater. 2004, 16, 1074–1079. [Google Scholar] [CrossRef]

- Castaneda, L.; Valle, J.; Yang, N.; Pluskat, S.; Slowinska, K. Collagen cross-linking with Au nanoparticles. Biomacromolecules 2008, 9, 3383–3388. [Google Scholar] [CrossRef] [PubMed]

- Rose, S.; Prevoteau, A.; Elziere, P.; Hourdet, D.; Marcellan, A.; Leibler, L. Nanoparticle solutions as adhesives for gels and biological tissues. Nature 2014, 505, 382–385. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Yu, G.; Pan, L.; Liu, N.; McDowell, M.T.; Bao, Z.; Cui, Y. Stable Li-ion battery anodes by in-situ polymerization of conducting hydrogel to conformally coat silicon nanoparticles. Nat. Commun. 2013, 4. [Google Scholar] [CrossRef] [PubMed]

- Cha, C.; Shin, S.R.; Annabi, N.; Dokmeci, M.R.; Khademhosseini, A. Carbon-Based Nanomaterials: Multifunctional Materials for Biomedical Engineering. ACS Nano 2013, 7, 2891–2897. [Google Scholar] [CrossRef] [PubMed]

- Goenka, S.; Sant, V.; Sant, S. Graphene-based nanomaterials for drug delivery and tissue engineering. J. Control. Release 2014, 173, 75–88. [Google Scholar] [CrossRef] [PubMed]

- Adhikari, B.; Banerjee, A. Short peptide based hydrogels: Incorporation of graphene into the hydrogel. Soft Matter 2011, 7, 9259–9266. [Google Scholar] [CrossRef]

- Shin, S.R.; Hojae, B.; Cha, J.M.; Mun, J.Y.; Chen, Y.C.; Tekin, H.; Shin, H.; Farshch, S.; Dokmeci, M.R.; Tang, S.; et al. Carbon nanotube reinforced hybrid microgels as scaffold materials for cell encapsulation. ACS Nano 2012, 6, 362–372. [Google Scholar] [CrossRef] [PubMed]

- Arslantunali, D.; Budak, G.; Hasirci, V. Multiwalled CNT-pHEMA composite conduit for peripheral nerve repair. J. Biomed. Mater. Res. A 2014, 102, 828–841. [Google Scholar] [CrossRef] [PubMed]

- Davaran, S.; Alimirzalu, S.; Nejati-Koshki, K.; Nasrabadi, H.T.; Akbarzadeh, A.; Khandaghi, A.A.; Abbasian, M.; Alimohammadi, S. Physicochemical characteristics of Fe3O4 magnetic nanocomposites based on poly(N-isopropylacrylamide) for anti-cancer drug delivery. Asian Pac. J. Cancer Prev. 2014, 15, 49–54. [Google Scholar] [CrossRef] [PubMed]

- Evingur, G.A.; Pekcan, O. Effect of multiwalled carbon nanotube (MWNT) on the behavior of swelling of polyacrylamide-MWNT composites. J. Reinf. Plast. Comp. 2014, 33, 1199–1206. [Google Scholar] [CrossRef] [Green Version]

- Curcio, M.; Spizzirri, U.G.; Cirillo, G.; Vittorio, O.; Picci, N.; Nicoletta, F.P.; Iemma, F.; Hampel, S. On demand delivery of ionic drugs from electro-responsive CNT hybrid films. RSC Adv. 2015, 5, 44902–44911. [Google Scholar] [CrossRef]

- Toumia, Y.; Orlanducci, S.; Basoli, F.; Licoccia, S.; Paradossi, G. “Soft” confinement of graphene in hydrogel matrixes. J. Phys. Chem. B 2015, 119, 2051–2061. [Google Scholar] [CrossRef] [PubMed]

- Baniasadi, H.; Ramazani, S.A.A.; Mashayekhan, S. Fabrication and characterization of conductive chitosan/gelatin-based scaffolds for nerve tissue engineering. Int. J. Biol. Macromol. 2015, 74, 360–366. [Google Scholar] [CrossRef] [PubMed]

- Tian, L.; Pei, X.; Zeng, Y.; He, R.; Li, Z.; Wang, J.; Wan, Q.; Li, X. Functionalized nanoscale graphene oxide for high efficient drug delivery of cisplatin. J. Nanopart. Res. 2014, 16, 1–4. [Google Scholar] [CrossRef]

- Guo, Q.F.; Cao, H.; Li, X.H.; Liu, S.W. Thermosensitive hydrogel drug delivery system containing doxorubicin loaded CS–GO nanocarriers for controlled release drug in situ. Mater. Technol. 2015, 30, 294–300. [Google Scholar] [CrossRef]

- Byrne, M.T.; Guńko, Y.K. Recent advances in research on carbonnanotube-polymer composites. Adv. Mater. 2010, 22, 1672–1688. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Liu, M.; Chen, H.; Xu, J.; Gao, Y.; Li, H. Phenylboronate-diol crosslinked polymer/SWCNT hybrid gels with reversible sol-gel transition. Polym. Adv. Technol. 2014, 25, 233–239. [Google Scholar] [CrossRef]

- Huang, X.; Qi, X.; Boey, F.; Zhang, H. Graphene-based composites. Chem. Soc. Rev. 2012, 41, 666–686. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.S.; Faĺko, V.I.; Colombo, L.; Gellert, P.R.; Schwab, M.G.; Kim, K. A roadmap for graphene. Nature 2012, 490, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Chen, A.; Qin, M.; Huang, R.; Zhang, G.; Xue, B.; Wei, J.; Li, Y.; Cao, Y.; Wang, W. Hierarchical construction of a mechanically stable peptide-graphene oxide hybrid hydrogel for drug delivery and pulsatile triggered release in vivo. Nanoscale 2015, 7, 1655–1660. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yuan, H.; Vondem-Bussche, A.; Creighton, M.; Hurt, R.H.; Kane, A.B.; Gaoa, H. Graphene microsheets enter cells through spontaneous membrane penetration at edge asperities and corner sites. Proc. Natl. Acad. Sci. USA 2013, 110, 12295–12300. [Google Scholar] [CrossRef] [PubMed]

- Mac Kenna, N.; Calvert, P.; Morrin, A.; Wallacec, G.G.; Moulton, S.E. Electro-stimulated release from a reduced graphene oxide composite hydrogel. J. Mater. Chem. B 2015, 3, 2530–2537. [Google Scholar] [CrossRef]

- Shen, J.; Xu, G.; Xin, X.; Wang, L.; Song, Z.; Zhang, H.; Tong, L.; Yang, Z. Supramolecular hydrogels of α-cyclodextrin/reverse poloxamines/carbon-based nanomaterials and its multi-functional application. RSC Adv. 2015, 5, 40173–40182. [Google Scholar] [CrossRef]

- Luo, H.; Xiong, G.; Yang, Z.; Raman, S.R.; Si, H.; Wan, Y. A novel three-dimensional graphene/bacterial cellulose nanocomposite prepared by in situ biosynthesis. RSC Adv. 2014, 4, 14369–14372. [Google Scholar] [CrossRef]

- Kun, J.; Ye, C.; Zhang, P.; Wang, X.; Zhao, Y. One-pot controlled synthesis of homopolymers and diblock copolymers grafted graphene oxide using couplable raft agents. Macromolecules 2012, 45, 1346–1355. [Google Scholar]

- Mohammad Mahdi Dadfar, S.; Kavoosi, G.; Mohammad Ali Dadfar, S. Investigation of mechanical properties, antibacterial features, and water vapor permeability of polyvinyl alcohol thin films reinforced by glutaraldehyde and multiwalled carbon nanotube. Polym. Compos. 2014, 35, 1736–1743. [Google Scholar] [CrossRef]

- Choi, E.J.; Shin, J.; Khaleel, Z.H.; Cha, I.; Yun, S.-H.; Cho, S.W.; Song, C. Synthesis of electroconductive hydrogel films by an electro-controlled click reaction and their application to drug delivery systems. Polym. Chem. 2015, 6, 4473–4478. [Google Scholar] [CrossRef]

- Wang, P.; Wang, S.; Lian, L.; Liu, Y.; Zhang, M. Preparation and properties of novel microporous hydrogels with poly(ethylene glycol) dimethacrylate and carboxylated carbon nanotubes. J. Control. Release 2015, 213, e86. [Google Scholar] [CrossRef]

- Mu, S.; Liang, Y.; Chen, S.; Zhang, L.; Liu, T. MWNT-hybrided supramolecular hydrogel for hydrophobic camptothecin delivery. Mater. Sci. Eng. C 2015, 50, 294–299. [Google Scholar] [CrossRef] [PubMed]

- Giri, A.; Bhunia, T.; Goswami, L.; Panda, A.B.; Bandyopadhyay, A. Fabrication of acrylic acid grafted guar gum-multiwalled carbon nanotube hydrophobic membranes for transdermal drug delivery. RSC Adv. 2015, 5, 41736–41744. [Google Scholar] [CrossRef]

- Shi, X.; Zheng, Y.; Wang, C.; Yue, L.; Qiao, K.; Wang, G.; Wang, L.; Quan, H. Dual stimulus responsive drug release under the interaction of pH value and pulsatile electric field for a bacterial cellulose/sodium alginate/multi-walled carbon nanotube hybrid hydrogel. RSC Adv. 2015, 5, 41820–41829. [Google Scholar] [CrossRef]

- Zinchenko, A.; Taki, Y.; Sergeyev, V.; Murata, S. DNA-assisted solubilization of carbon nanotubes and construction of DNA-MWCNT cross-linked hybrid hydrogels. Nanomaterials 2015, 5, 270–283. [Google Scholar] [CrossRef]

- Sun, Y.X.; Ren, K.F.; Chang, G.X.; Zhao, Y.X.; Liu, X.S.; Ji, J. Enhanced electrochemical stimuli multilayers based on a ferrocene-containing polymer. Sci. Bull. 2015, 60, 936–942. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, J.; Sun, H.; Qiu, X.; Mou, Y.; Liu, Z.; Zhao, Y.; Li, X.; Han, Y.; Duan, C.; et al. Engineering the heart: Evaluation of conductive nanomaterials for improving implant integration and cardiac function. Sci. Rep. 2014, 4, 313–317. [Google Scholar] [CrossRef] [PubMed]

- Venkatesan, J.; Jayakumar, R.; Mohandas, A.; Bhatnagar, I.; Kim, S.K. Antimicrobial activity of chitosan-carbon nanotube hydrogels. Materials 2014, 7, 3946–3955. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, J.Y.; Yang, S.H.; Lee, E.J.; Kim, H.W. Carbon nanotube-collagen three-dimensional culture of mesenchymal stem cells promotes expression of neural phenotypes and secretion of neurotrophic factors. Acta Biomater. 2014, 10, 4425–4436. [Google Scholar] [CrossRef] [PubMed]

- Mandal, D.; Kar, T.; Das, P.K. Pyrene-based fluorescent ambidextrous gelators: Scaffolds for mechanically robust SWNT-gel nanocomposites. Chem. Eur. J. 2014, 20, 1349–1358. [Google Scholar] [CrossRef] [PubMed]

- Sheikholeslam, M.; Pritzker, M.; Chen, P. Hybrid peptide-carbon nanotube dispersions and hydrogels. Carbon 2014, 71, 284–293. [Google Scholar] [CrossRef]

- Tardani, F.; La Mesa, C. Effects of single-walled carbon nanotubes on lysozyme gelation. Colloid Surface B 2014, 121, 165–170. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Cui, L.; Kong, N.; Barrow, C.J.; Yang, W. RAFT controlled synthesis of graphene/polymer hydrogel with enhanced mechanical property for pH-controlled drug release. Eur. Polym. J. 2014, 50, 9–17. [Google Scholar] [CrossRef]

- Servant, A.; Leon, V.; Jasim, D.; Methven, L.; Limousin, P.; Fernandez-Pacheco, E.V.; Prato, M.; Kostarelos, K. Graphene-based electroresponsive scaffolds as polymeric implants for on-demand drug delivery. Adv. Healthc. Mater. 2014, 3, 1334–1343. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.; Wang, X.; Wang, G.Y.; Duo, Y.R.; Zhang, X.Y.; Hu, X.H.; Zhang, X.J. Double network self-healing graphene hydrogel by two step method for anticancer drug delivery. Mater. Technol. 2014, 29, 210–213. [Google Scholar] [CrossRef]

- Faghihi, S.; Karimi, A.; Jamadi, M.; Imani, R.; Salarian, R. Graphene oxide/poly(acrylic acid)/gelatin nanocomposite hydrogel: Experimental and numerical validation of hyperelastic model. Mater. Sci. Eng. C 2014, 38, 299–305. [Google Scholar] [CrossRef] [PubMed]

- Piao, Y.; Chen, B. Self-assembled graphene oxide-gelatin nanocomposite hydrogels: Characterization, formation mechanisms, and pH-sensitive drug release behavior. J. Polym. Sci. Polym. Phys. 2015, 53, 356–367. [Google Scholar] [CrossRef]

- Shen, J.; Xin, X.; Zhang, Y.; Song, L.; Wang, L.; Tang, W.; Ren, Y. Manipulation the behavior of supramolecular hydrogels of alpha-cyclodextrin/star-like block copolymer/carbon-based nanomaterials. Carbohydr. Polym. 2015, 117, 592–599. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Liu, C.; Shuai, Y.; Cui, X.; Nie, L. Controlled release of anticancer drug using graphene oxide as a drug-binding effector in konjac glucomannan/sodium alginate hydrogels. Colloid. Surface. B 2014, 113, 223–229. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.; Han, L.; Tang, Y.; Ren, J.; Zhao, Z.; Jia, L. Highly flexible heparin-modified chitosan/graphene oxide hybrid hydrogel as a super bilirubin adsorbent with excellent hemocompatibility. J. Mater. Chem. B 2015, 3, 1646–1654. [Google Scholar] [CrossRef]

- Zhang, E.; Wang, T.; Zhao, L.; Sun, W.; Liu, X.; Tong, Z. Fast self-healing of graphene oxide-hectorite clay-poly(N,N-dimethylacrylamide) hybrid hydrogels realized by near-infrared irradiation. ACS Appl. Mater. Interfaces 2014, 6, 22855–22861. [Google Scholar] [CrossRef] [PubMed]

- Katiyar, R.; Bag, D.S.; Nigam, I. Fullerene (C60) Containing Poly(N-isopropylacrylamide) Thermo-responsive Smart Hydrogels and their Swelling Behavior. J. Polym. Mater. 2013, 30, 15–26. [Google Scholar]

- Katiyar, R.; Bag, D.S.; Nigam, I. Synthesis and evaluation of swelling characteristics of fullerene (C60) containing cross-linked poly(2-hydroxyethyl methacrylate) hydrogels. Adv. Mater. Lett. 2014, 5, 214–222. [Google Scholar]

- Kim, S.; Lee, D.J.; Kwag, D.S.; Lee, U.Y.; Youn, Y.S.; Lee, E.S. Acid pH-activated glycol chitosan/fullerene nanogels for efficient tumor therapy. Carbohydr. Polym. 2014, 101, 692–698. [Google Scholar] [CrossRef] [PubMed]

- Hoppe, A.; Güldal, N.S.; Boccaccini, A.R. A review of the biological response to ionic dissolution products from bioactive glasses and glassceramics. Biomaterials 2011, 32, 2757–2774. [Google Scholar] [CrossRef] [PubMed]

- Song, W.; Markel, D.C.; Jin, X.; Shi, T.; Ren, W. Poly(vinyl alcohol)/collagen/hydroxyapatite hydrogel: Properties and in vitro cellular response. J. Biomed. Mater. Res. A 2012, 100, 3071–3079. [Google Scholar] [CrossRef] [PubMed]

- Kokubo, T.; Takadama, H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 2006, 27, 2907–2915. [Google Scholar] [CrossRef] [PubMed]

- Gaharwar, A.K.; Mihaila, S.M.; Swami, A.; Patel, A.; Sant, S.; Reis, R.L.; Marques, A.P.; Gomes, M.E.; Khademhosseini, A. Bioactive silicate nanoplatelets for osteogenic diffrentiation of human human mesenchymal stem cells. Adv. Mater. 2013, 25, 3329–3336. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Weir, M.D.; Xu, H.H. An injectable calcium phosphate-alginate hydrogelumbilical cord mesenchymal stem cell paste for bone tissue engineering. Biomaterials 2010, 31, 6502–6510. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; El-Fiqi, A.; Han, C.M.; Kim, H.W. Physically-strengthened collagen bioactive nanocomposite gels for bone: A feasibility study. Tissue Eng. Regen. Med. 2015, 12, 90–97. [Google Scholar] [CrossRef]

- Aguzzi, C.; Capra, P.; Bonferoni, C.; Cerezo, P.; Salcedo, I.; Sánchez, R.; Caramella, C.; Viseras, C. Chitosan-silicate biocomposites to be used in modified drug release of 5-aminosalicylic acid (5-ASA). Appl. Clay Sci. 2010, 50, 106–111. [Google Scholar] [CrossRef]

- Kawachi, Y.; Kugimiya, S.; Kato, K. Preparation of silica hydrogels using a synthetic peptide for application as carriers for controlled drug release and mesoporous oxides. J. Ceram. Soc. Jpn. 2014, 122, 134–140. [Google Scholar] [CrossRef]

- Karnik, S.; Hines, K.; Mills, D.K. Nanoenhanced hydrogel system with sustained release capabilities. J. Biomed. Mater. Res. A 2015, 103, 2416–2426. [Google Scholar] [CrossRef] [PubMed]

- Ayyub, O.B.; Kofinas, P. Enzyme Induced stiffening of nanoparticle-hydrogel composites with structural color. ACS Nano 2015, 9, 8004–8011. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Yang, X.; Wang, K.; Wang, Q.; Ji, H.; Wu, C.; Li, J.; He, X.; Tang, J.; Huang, J. Combining physical embedding and covalent bonding for stable encapsulation of quantum dots into agarose hydrogels. J. Mater. Chem. 2012, 22, 495–501. [Google Scholar] [CrossRef]

- Yuan, J.; Wen, D.; Gaponik, N.; Eychmuller, A. Enzyme-encapsulating quantum dot hydrogels and xerogels as biosensors: Multifunctional platforms for both biocatalysis and fluorescent probing. Angew. Chem. Int. Ed. Engl. 2013, 52, 976–979. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhang, Y.; Zhang, J.; Huang, L.; Liu, J.; Li, Y.; Zhang, G.; Kundu, S.C.; Wang, L. Exploring natural silk protein sericin for regenerative medicine: An injectable, photoluminescent, cell-adhesive 3D hydrogel. Sci. Rep. 2014, 4. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Hong, X.; Liu, Y.; Li, D.; Wang, Y.W.; Li, J.H.; Bai, Y.B.; Li, T.J. Highly photoluminescent cdte/poly(n-isopropylacrylamide) temperature-sensitive gels. Adv. Mater. 2005, 17, 163–166. [Google Scholar] [CrossRef]

- Amdursky, N.; Gazit, E.; Rosenman, G. Quantum confinement in self-assembled bioinspired peptide hydrogels. Adv. Mater. 2010, 22, 2311–2315. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Yang, J.; Bao, S.; Wu, Q.; Wang, Q. Semiconductor nanoparticle-based hydrogels prepared via self-initiated polymerization under sunlight, even visible light. Sci. Rep. 2013, 3. [Google Scholar] [CrossRef] [PubMed]

- Guo, M.; Jiang, M. Supramolecular hydrogels with CdS quantum dots incorporated by host-guest interactions. Macromol. Rapid Commun. 2010, 31, 1736–1739. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.S.; Li, C.M. Quantum dot-based nanocomposites for biomedical applications. Curr. Med. Chem. 2011, 18, 3516–3528. [Google Scholar] [CrossRef] [PubMed]

- Biju, V.; Itoh, T.; Ishikawa, M. Delivering quantum dots to cells: Bioconjugated quantum dots for targeted and nonspecific extracellular and intracellular imaging. Chem. Soc. Rev. 2010, 39, 3031–3056. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Zhang, F. Thermo-sensitive and photoluminescent hydrogels: Synthesis, characterization, and their drug-release property. Mater. Sci. Eng. C Mater. Biol. Appl. 2011, 31, 1429–1435. [Google Scholar] [CrossRef]

- Kim, J.H.; Lim, S.Y.; Nam, D.H.; Ryu, J.; Ku, S.H.; Park, C.B. Self-assembled, photoluminescent peptide hydrogel as a versatile platform for enzyme-based optical biosensors. Biosens. Bioelectron. 2011, 26, 1860–1865. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; He, X.W.; Li, W.Y.; Zhang, Y.K. Thermo-sensitive imprinted polymer coating CdTe quantum dots for target protein specific recognition. Chem. Commun. 2012, 48, 1757–1759. [Google Scholar] [CrossRef] [PubMed]