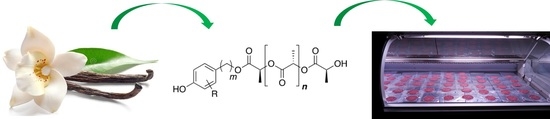

Synthesis of Polylactic Acid Initiated through Biobased Antioxidants: Towards Intrinsically Active Food Packaging

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Phenol-functionalised PLA Samples

2.3. Characterization

2.3.1. Determination of Antioxidant Capacity of Polymers In Vitro

2.3.2. Size Exclusion Chromatography (SEC)

2.3.3. Thermal Analysis

- Heating from 25 °C to 200 °C at 10 °C/min;

- 5 min isotherm at 200 °C;

- Cooling from 200 °C to 25 °C at 10 °C/min;

- 2 min isotherm at 25 °C;

- Heating from 25 °C to 200 °C at 10 °C/min;

2.3.4. Thermogravimetric Analysis (TGA)

2.3.5. Film Casting

2.3.6. H NMR Analysis

2.4. Evaluation of Antioxidant Capacity of Films In Vivo

2.4.1. Sample Preparation

2.4.2. Water Activity and pH Analysis

2.4.3. Color Measurements

2.4.4. Lipid Oxidation Analysis

2.4.5. Statistical Analysis

3. Results

3.1. SEC Results

3.2. DPPH Test Results

3.3. H NMR Analysis

3.4. Thermal Analyses

3.4.1. Differential Scanning Calorimetry (DSC)

3.4.2. Thermogravimetric Analysis (TGA)

3.5. Validation of Antioxidant Capacity of Films in vivo

3.5.1. Water Activity and pH

3.5.2. Color Measurements

3.5.3. Lipid Oxidation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Soroka, W. Illustrated Glossary of Packaging Terms. Institute of Packaging Professionals, 2nd ed.; Institute of Packaging Professionals: Naperville, IL, USA, 2008; p. 3. ISBN 1-930268-27-0. [Google Scholar]

- Farris, S.; Introzzi, L.; Fuentes-Alventosa, J.M.; Santo, N.; Rocca, R.; Piergiovanni, L. Self-Assembled Pullulan–Silica Oxygen Barrier Hybrid Coatings for Food Packaging Applications. J. Agric. Food Chem. 2012, 60, 782–790. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, F.; Biagioni, P.; Bollani, M.; Maccagnan, A.; Piergiovanni, L. Multi-functional coating of cellulose nanocrystals for flexible packaging applications. Cellulose 2013, 20, 2491–2504. [Google Scholar] [CrossRef] [Green Version]

- Lagaron, J.; Sanchez, G.M. Thermoplastic nanobiocomposites for rigid and flexible food packaging application. In Environmentally Compatible Food Packaging; Chiellini, E., Ed.; Woodhead Publishing: Cambridge, UK, 2008; pp. 63–89. [Google Scholar]

- Fabra, M.J.; Mayorga, J.L.C.; Randazzo, W.; Lagaron, J.M.; López-Rubio, A.; Aznar, R.; Sánchez, G. Efficacy of Cinnamaldehyde Against Enteric Viruses and Its Activity After Incorporation into Biodegradable Multilayer Systems of Interest in Food Packaging. Food Environ. Virol. 2016, 8, 125–132. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gazzotti, S.; Todisco, S.A.; Picozzi, C.; Ortenzi, M.A.; Farina, H.; Lesma, G.; Silvani, A. Eugenol-grafted aliphatic polyesters: Towards inherently antimicrobial PLA-based materials exploiting OCAs chemistry. Eur. Polym. J. 2019, 114, 369–379. [Google Scholar] [CrossRef]

- Wang, H.; Yang, C.; Wang, J.; Chen, M.; Luan, D.; Li, L. EVOH Films Containing Antimicrobials Geraniol and α-Terpilenol Extend the Shelf Life of Snakehead Slices. Packag. Technol. Sci. 2017, 30, 587–600. [Google Scholar] [CrossRef]

- Dias, M.V.; De Medeiros, H.S.; Soares, N.D.F.F.; De Melo, N.R.; Borges, S.V.; Carneiro, J.D.D.S.; Pereira, J.M.T.D.A.K. Development of low-density polyethylene films with lemon aroma. LWT 2013, 50, 167–171. [Google Scholar] [CrossRef] [Green Version]

- Souza, R.; Peruch, G.; Pires, A.C.D.S. Oxygen Scavengers: An Approach on Food Preservation. In Structure and Function of Food Engineering; IntechOpen: London, UK, 2012. [Google Scholar]

- Wang, Q.; Tian, F.; Feng, Z.; Fan, X.; Pan, Z.; Zhou, J. Antioxidant activity and physicochemical properties of chitosan films incorporated withLycium barbarumfruit extract for active food packaging. Int. J. Food Sci. Technol. 2014, 50, 458–464. [Google Scholar] [CrossRef]

- Bai, R.; Zhang, X.; Yong, H.; Wang, X.; Liu, Y.; Liu, J. Development and characterization of antioxidant active packaging and intelligent Al3+-sensing films based on carboxymethyl chitosan and quercetin. Int. J. Boil. Macromol. 2019, 126, 1074–1084. [Google Scholar] [CrossRef]

- Chen, C.; Tang, Z.; Ma, Y.; Qiu, W.; Yang, F.; Mei, J.; Xie, J. Physicochemical, microstructural, antioxidant and antimicrobial properties of active packaging films based on poly(vinyl alcohol)/clay nanocomposite incorporated with tea polyphenols. Prog. Org. Coat. 2018, 123, 176–184. [Google Scholar] [CrossRef]

- Olejar, K.; Ray, S.; Ricci, A.; Kilmartin, P.A. Superior antioxidant polymer films created through the incorporation of grape tannins in ethyl cellulose. Cellulose 2014, 21, 4545–4556. [Google Scholar] [CrossRef]

- Soto-Valdez, H.; Graciano-Verdugo, A.Z.; Peralta, E.; Yuridia, C. Active Packaging with Controlled Release of Tocopherol. U.S. Patent US2012/0276357, 1 November 2012. [Google Scholar]

- Bastarrachea, R.A.; Wong, D.E.; Roman, M.J.; Lin, Z.; Goddard, J.M. Active Packaging Coatings. Coatings 2015, 5, 771–791. [Google Scholar] [CrossRef]

- Fang, X.; Vitrac, O. Predicting Diffusion Coefficients of Chemicals in and through Packaging Materials. Crit. Rev. Food Sci. Nutr. 2015, 57, 275–312. [Google Scholar] [CrossRef] [PubMed]

- Biswas, M.C.; Tiimob, B.J.; Abdela, W.; Jeelani, S.; Rangari, V.K. Nano silica-carbon-silver ternary hybrid induced antimicrobial composite films for food packaging application. Food Packag. Shelf Life 2019, 19, 104–113. [Google Scholar] [CrossRef]

- Marcos, B.; Sárraga, C.; Castellari, M.; Kappen, F.; Schennink, G.; Arnau, J. Development of biodegradable films with antioxidant properties based on polyesters containing α-tocopherol and olive leaf extract for food packaging applications. Food Packag. Shelf Life 2014, 1, 140–150. [Google Scholar] [CrossRef] [Green Version]

- Olejar, K.; Ray, S.; Kilmartin, P.A. Enhanced antioxidant activity of polyolefin films integrated with grape tannins. J. Sci. Food Agric. 2015, 96, 2825–2831. [Google Scholar] [CrossRef]

- Boragno, L.; Stagnaro, P.; Losio, S.; Sacchi, M.C.; Menichetti, S.; Viglianisi, C.; Piergiovanni, L.; Limbo, S. LDPE-based blends and films stabilized with nonreleasing polymeric antioxidants for safer food packaging. J. Appl. Polym. Sci. 2011, 124, 3912–3920. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Wadhwa, P.; Hong, J.W.; Hong, Y.G.; Jeon, J.-M.; Lee, E.S.; Yang, Y.-H. Lipase mediated functionalization of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) with ascorbic acid into an antioxidant active biomaterial. Int. J. Boil. Macromol. 2019, 123, 117–123. [Google Scholar] [CrossRef]

- Van Lith, R.; Gregory, E.K.; Yang, J.; Kibbe, M.R.; Ameer, G.A. Engineering biodegradable polyester elastomers with antioxidant properties to attenuate oxidative stress in tissues. Biomaterials 2014, 35, 8113–8122. [Google Scholar] [CrossRef] [Green Version]

- Ge, F.; Ding, Y.; Yang, L.; Huang, Y.; Jiang, L.; Dan, Y. Effect of the content and distribution of ultraviolet absorbing groups on the UV protection and degradation of polylactide films. RSC Adv. 2015, 5, 70473–70481. [Google Scholar] [CrossRef]

- Trombino, S.; Cassano, R.; Ferrarelli, T.; Leta, S.; Puoci, F.; Picci, N. Preparation, Characterization and Efficacy Evaluation of Synthetic Biocompatible Polymers Linking Natural Antioxidants. Molecules 2012, 17, 12734–12745. [Google Scholar] [CrossRef] [Green Version]

- Righetti, M.C.; Gazzano, M.; Di Lorenzo, M.L.; Androsch, R. Enthalpy of melting of a- and a’-crystals of poly(l-lactic acid). Eur. Polym. J. 2015, 70, 215–220. [Google Scholar] [CrossRef]

- Buege, J.A.; Aust, S.D. Microsomal lipid peroxidation. Method Enzymol. 1978, 52, 302–310. [Google Scholar]

- Thomas, C.; Peruch, F.; Deffieux, A.; Milet, A.; Desvergne, J.-P.; Bibal, B. Phenols and Tertiary Amines: An Amazingly Simple Hydrogen-Bonding Organocatalytic System Promoting Ring Opening Polymerization. Adv. Synth. Catal. 2011, 353, 1049–1054. [Google Scholar] [CrossRef]

- Zhang, Y.; Thakur, V.; Li, Y.; Garrison, T.F.; Gao, Z.; Gu, J.; Kessler, M.R. Soybean-Oil-Based Thermosetting Resins with Methacrylated Vanillyl Alcohol as Bio-Based, Low-Viscosity Comonomer. Macromol. Mater. Eng. 2017, 303, 1700278. [Google Scholar] [CrossRef] [Green Version]

- Gazzotti, S.; Rampazzo, R.; Hakkarainen, M.; Bussini, D.; Ortenzi, M.A.; Farina, H.; Lesma, G.; Silvani, A. Cellulose nanofibrils as reinforcing agents for PLA-based nanocomposites: An in situ approach. Compos. Sci. Technol. 2019, 171, 94–102. [Google Scholar] [CrossRef]

- Andersen, H.J.; Skibsted, L.H. Kinetics and mechanism of thermal oxidation and photooxidation of nitrosylmyoglobin in aqueous solution. J. Agric. Food Chem. 1992, 40, 1741–1750. [Google Scholar] [CrossRef]

- Martín, M.J.; Andrés, A.I.; Sanabria, M.C. Colour stability during prolonged storage of dry fermented sausages from Iberian pork. In Options Méditerranéennes: Série A. Séminaires Méditerranéens; de Pedro, E.J., Cabezas, A.B., Eds.; CIHEAM: Zaragoza, Spain, 2012; Volume 101, pp. 355–359. [Google Scholar]

- Navikaite-Snipaitiene, V.; Ivanauskas, L.; Jakstas, V.; Rüegg, N.; Rutkaite, R.; Wolfram, E.; Yildirim, S.; Yıldırım, S. Development of antioxidant food packaging materials containing eugenol for extending display life of fresh beef. Meat Sci. 2018, 145, 9–15. [Google Scholar] [CrossRef]

- Domínguez, R.; Barba, F.; Gómez, B.; Putnik, P.; Kovačević, D.B.; Pateiro, M.; Santos, E.M.; Lorenzo, J. Active packaging films with natural antioxidants to be used in meat industry: A review. Food Res. Int. 2018, 113, 93–101. [Google Scholar] [CrossRef]

- Yang, H.-J.; Lee, J.-H.; Won, M.; Bin Song, K. Antioxidant activities of distiller dried grains with solubles as protein films containing tea extracts and their application in the packaging of pork meat. Food Chem. 2016, 196, 174–179. [Google Scholar] [CrossRef]

| Sample | Initiator | Initiator Quantity (mg) | |

|---|---|---|---|

| PLA-Tyr | Tyrosol |  | 47.9 |

| PLA-Pyr | Pyridoxine |  | 58.6 |

| PLA-DBA | 3,4-dihydroxy Benzyl Alcohol |  | 63.4 |

| PLA-AA | Ascorbic Acid Monoethyl Ether |  | 70.7 |

| PLA-VA | Vanillyl alcohol |  | 53.4 |

| Sample | Đ | Coloration | ||

|---|---|---|---|---|

| PLA-VA | 62,000 | 120,800 | 2.0 | White |

| 4043D | 71,300 | 127,300 | 1.8 | White |

| PLA-Tyr | 57,200 | 90,000 | 1.6 | White |

| PLA-Pyr | 27,500 | 54,600 | 2.0 | Dark brown |

| PLA-DBA | 47,000 | 91,400 | 1.9 | Brownish |

| PLA-AA | 90,800 | 474,000 | 5.2 | Brownish |

| Sample | PI * (%) |

|---|---|

| Tyr | 7.6 ± 0.2 |

| VA | 91.0 ± 1.4 |

| 4043D | 1.0 ± 0.2 |

| PLA-Tyr | 4.3 ± 4.3 |

| PLA-VA | 12.4 ± 1.5 |

| Sample | Tg (°C) | Tcc (°C) | ΔHcc (J g−1) | Tm (°C) | ΔHm (J g−1) | χc |

|---|---|---|---|---|---|---|

| PLA-VA | 52.7 | 108.3 | 55.3 | 167.4 | 58.3 | 3.2 |

| 4043D | 59.1 | - | - | 155.3 | 1.1 | 1.2 |

| Sample | T1% (°C) | T5% (°C) | T50% (°C) | T95% (°C) | ΔT1%–95% (°C) |

|---|---|---|---|---|---|

| PLA-VA | 274 | 302 | 353 | 381 | 107 |

| 4043D | 320 | 351 | 380 | 395 | 75 |

| Batch | Sampling Time | RMSE | P | |||||

|---|---|---|---|---|---|---|---|---|

| t0 | t7 | t14 | t43 | t51 | ||||

| L* | Control | 54.47a | 55.03a | 54.50a | 52.50b | 52.04b | 0.47 | <0.001 |

| PLA-VA | 54.47 | 53.99 | 53.84 | 54.56 | 54.53 | 0.49 | NS | |

| RMSE | 0.57 | 0.26 | 0.49 | 0.77 | ||||

| p | NS | <0.05 | <0.01 | <0.05 | ||||

| a* | Control | 34.19a | 32.63b | 32.65b | 29.27c | 29.38c | 0.39 | <0.001 |

| PLA-VA | 34.19a | 32.70b | 32.00b | 31.45c | 30.65c | 0.35 | <0.001 | |

| RMSE | 0.51 | 0.11 | 0.38 | 0.47 | ||||

| p | NS | NS | <0.01 | <0.05 | ||||

| b* | Control | 9.27a | 9.10a | 8.49a | 5.78b | 5.24b | 0.29 | <0.001 |

| PLA-VA | 9.27a | 8.89ab | 8.31b | 7.28c | 6.80c | 0.28 | <0.001 | |

| RMSE | 0.31 | 0.17 | 0.32 | 0.41 | ||||

| p | NS | NS | <0.01 | <0.01 | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortenzi, M.A.; Gazzotti, S.; Marcos, B.; Antenucci, S.; Camazzola, S.; Piergiovanni, L.; Farina, H.; Di Silvestro, G.; Verotta, L. Synthesis of Polylactic Acid Initiated through Biobased Antioxidants: Towards Intrinsically Active Food Packaging. Polymers 2020, 12, 1183. https://0-doi-org.brum.beds.ac.uk/10.3390/polym12051183

Ortenzi MA, Gazzotti S, Marcos B, Antenucci S, Camazzola S, Piergiovanni L, Farina H, Di Silvestro G, Verotta L. Synthesis of Polylactic Acid Initiated through Biobased Antioxidants: Towards Intrinsically Active Food Packaging. Polymers. 2020; 12(5):1183. https://0-doi-org.brum.beds.ac.uk/10.3390/polym12051183

Chicago/Turabian StyleOrtenzi, Marco Aldo, Stefano Gazzotti, Begonya Marcos, Stefano Antenucci, Stefano Camazzola, Luciano Piergiovanni, Hermes Farina, Giuseppe Di Silvestro, and Luisella Verotta. 2020. "Synthesis of Polylactic Acid Initiated through Biobased Antioxidants: Towards Intrinsically Active Food Packaging" Polymers 12, no. 5: 1183. https://0-doi-org.brum.beds.ac.uk/10.3390/polym12051183