Quasi-Active Thermal Imaging of Large Floating Covers Using Ambient Solar Energy

Abstract

:1. Introduction

- Scumbergs block the pathway of biogas and produce “whaleback” regions on the surface of the cover, affecting the movement and collection of biogases by the covers. Whaleback regions will generate regional strain and stress on the HDPE geomembrane material.

- The existence of scumbergs causes a vertical displacement of the membrane surface. When the wind blows over the cover, the cover will then be exposed to an increased lateral drag force, which can affect the structural integrity of the cover.

- If the scum has developed a hard crust, this may scratch the under-surface of the cover, if the scum moves horizontally and has not yet attached itself to the cover, and potentially result in the development of highly localized non-through cracks which have the potential to become a through-crack.

- Scumbergs can deform the covers in a vertical direction and have an impact on its structural integrity which might then be made even worse when the accumulated scum move under the cover, as any horizontal movement will also exert lateral drag on the covers if the scum has attached itself to the underside of the cover material.

2. Quasi-Active Thermographic Method

2.1. Preliminary Concept of Quasi-Active Thermography

2.2. Newton’s Law of Cooling for Quasi-Active Thermography

3. Proof of Concept (Quasi-Active Thermography)

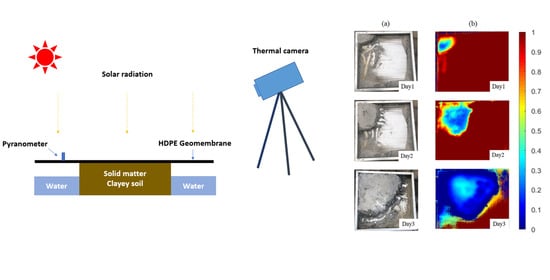

3.1. Experiment Setup

3.2. Cooling Constant Estimation Using Newton’s Law of Cooling

- (1)

- (2)

- the HDPE cover can absorb the heat radiated by the block of soil and air, and a portion of the absorbed heat can be re-emitted back to the soil and the air. The cover material acts like a reflective layer which partially reflects the heat back to the soil and air (absorb from soil and air and re-emitted back to soil and air). The thermal wave reflection coefficient [18] of air interface and soil interface is different, leading to efficiency of heat exchange different between the air/geomembrane medium and the soil/geomembrane medium.

3.3. Experiments to Verify the Consistency of the Quasi-Active Thermography Measurements

4. Quasi-Active Thermography Monitoring of Accumulation of Soil Buildup under the HDPE Membrane

5. Conclusions

- Solar radiation can be employed as the external heat source in thermography since the solar energy is economical and is uniformly applied over a large surface area. By monitoring the solar intensity via pyranometer, full transient cooling events can be determined starting when the solar intensity begins to decrease and ending at the time when solar intensity increases from zero.

- Single frame of thermal imaging can be used to show the thermal contrast at some particular time, however, it is influenced by other factors which include condition of the monitoring surface, angle of view of the camera and presence of wrinkles. By monitoring the entire cooling history of the cover, a map of cooling constant can be constructed which enhances the identification and definition of the objects attached underneath the HDPE covers. The results show that the map of cooling constants is more reliable than only relying on the thermal contrast based on a single frame of the thermal image.

- The cooling constants in different transient cooling events can be varied day to day, due to the weather conditions, ambient temperature, wind strength, cloud conditions and solar intensity. This is causing the temperature changes and lengths of cooling events of each day to be different. A multiple-day experiment was conducted to compare results in different days, and the result showed that the cooling constant (rate of cooling) is noted to be significantly different between the no-soil region and soil region in the map of cooling constants. The measurement consistency was verified by normalizing the cooling constant in two transient events. The results have evidence that the proposed monitoring technique is repeatable and reliable.

- The proposed quasi-active thermography inspection is also further examined to monitor the growth of the under-surface objects. The outcomes have demonstrated its potential for field trial to inspect the accumulation of scum at the anaerobic lagoon at the WTP and evaluate the extent and location of scum.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Scheirs, J. A Guide to Polymeric Geomembranes: A Practical Approach; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Ong, W.H.; Chiu, W.K.; Kuen, T.; Kodikara, J. Determination of the State of Strain of Large Floating Covers Using Unmanned Aerial Vehicle (UAV) Aided Photogrammetry. Sensors 2017, 17, 1731. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aldave, I.J.; Bosom, P.V.; González, L.V.; De Santiago, I.L.; Vollheim, B.; Krausz, L.; Georges, M.P. Review of thermal imaging systems in composite defect detection. Infrared Phys. Technol. 2013, 61, 167–175. [Google Scholar] [CrossRef]

- Wong, L.; Vien, B.S.; Ma, Y.; Kuen, T.; Courtney, F.; Kodikara, J.; Chiu, W.K. Remote Monitoring of Floating Covers Using UAV Photogrammetry. Remote Sens. 2020, 12, 1118. [Google Scholar] [CrossRef] [Green Version]

- Swiderski, W.; Vavilov, V.P. IR thermographic detection of defects in multi-layered composite materials used in military applications. In Proceedings of the 2007 Joint 32nd International Conference on Infrared and Millimeter Waves and the 15th International Conference on Terahertz Electronics, Cardiff, UK, 2–9 September 2007; pp. 553–556. [Google Scholar]

- Avdelidis, N.; Hawtin, B.; Almond, D. Transient thermography in the assessment of defects of aircraft composites. Ndt E Int. 2003, 36, 433–439. [Google Scholar] [CrossRef]

- Omar, M.A.; Hassan, M.; Donohue, K.; Saito, K.; Alloo, R. Infrared thermography for inspecting the adhesion integrity of plastic welded joints. Ndt E Int. 2006, 39, 1–7. [Google Scholar] [CrossRef]

- Flores-Bolarin, J.; Royo-Pastor, R. Infrared thermography: A good tool for nondestructive testing of plastic materials. In Proceedings of the 5th European Thermal-Sciences Conference, Eindhoven, The Netherlands, 18–22 May 2008. [Google Scholar]

- Dassisti, M.; Intini, F.; Chimienti, M.; Starace, G. Thermography-enhanced LCA (Life Cycle Assessment) for manufacturing sustainability assessment. The case study of an HDPE (High Density Polyethylene) net company in Italy. Energy 2016, 108, 7–18. [Google Scholar] [CrossRef]

- Steinberger, R.; Leitão, T.V.; Ladstätter, E.; Pinter, G.; Billinger, W.; Lang, R. Infrared thermographic techniques for non-destructive damage characterization of carbon fibre reinforced polymers during tensile fatigue testing. Int. J. Fatigue 2006, 28, 1340–1347. [Google Scholar] [CrossRef]

- Kafieh, R.; Lotfi, T.; Amirfattahi, R. Automatic detection of defects on polyethylene pipe welding using thermal infrared imaging. Infrared Phys. Technol. 2011, 54, 317–325. [Google Scholar] [CrossRef]

- Yang, R.; He, Y. Optically and non-optically excited thermography for composites: A review. Infrared Phys. Technol. 2016, 75, 26–50. [Google Scholar] [CrossRef]

- Bagavathiappan, S.; Lahiri, B.; Saravanan, T.; Philip, J.; Jayakumar, T. Infrared thermography for condition monitoring–A review. Infrared Phys. Technol. 2013, 60, 35–55. [Google Scholar] [CrossRef]

- Kylili, A.; Fokaides, P.A.; Christou, P.; Kalogirou, S.A. Infrared thermography (IRT) applications for building diagnostics: A review. Appl. Energy 2014, 134, 531–549. [Google Scholar] [CrossRef]

- Genest, M.; Martinez, M.; Mrad, N.; Renaud, G.; Fahr, A. Pulsed thermography for non-destructive evaluation and damage growth monitoring of bonded repairs. Compos. Struct. 2009, 88, 112–120. [Google Scholar] [CrossRef]

- Schroeder, J.; Ahmed, T.; Chaudhry, B.; Shepard, S. Non-destructive testing of structural composites and adhesively bonded composite joints: Pulsed thermography. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1511–1517. [Google Scholar] [CrossRef]

- Rajic, N.; Rowlands, D.; Tsoi, K. An Australian perspective on the application of infrared thermography to the inspection of military aircraft. In Proceedings of the 2nd International Symposium on NDT in Aerospace, Hamburg, Germany, 22–24 November 2010. [Google Scholar]

- Zeng, Z.; Li, C.; Tao, N.; Feng, L.; Zhang, C. Depth prediction of non-air interface defect using pulsed thermography. Ndt E Int. 2012, 48, 39–45. [Google Scholar] [CrossRef]

- Breitenstein, O.; Rakotoniaina, J.P.; Al Rifai, M.H. Quantitative evaluation of shunts in solar cells by lock-in thermography. Prog. Photovolt. Res. Appl. 2003, 11, 515–526. [Google Scholar] [CrossRef]

- Taole, R.; Falcon, R.; Bada, S. The impact of coal quality on the efficiency of a spreader stoker boiler. J. South. Afr. Inst. Min. Metall. 2015, 115, 1159–1165. [Google Scholar] [CrossRef]

- Kroll, A.; Baetz, W.; Peretzki, D. On autonomous detection of pressured air and gas leaks using passive IR-thermography for mobile robot application. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009. [Google Scholar]

- Brooke, C. Thermal imaging for the archaeological investigation of historic buildings. Remote Sens. 2018, 10, 1401. [Google Scholar] [CrossRef] [Green Version]

- Xiao, C.; Fu, B.; Shui, H.; Guo, Z.; Zhu, J. Detecting the Sources of Methane Emission from Oil Shale Mining and Processing Using Airborne Hyperspectral Data. Remote Sens. 2020, 12, 537. [Google Scholar] [CrossRef] [Green Version]

- Song, H.; Park, K.J.; Han, S.K.; Jung, H.S. Thermal conductivity characteristics of dewatered sewage sludge by thermal hydrolysis reaction. J. Air Waste Manag. Assoc. 2014, 64, 1384–1389. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.-S.; Tseng, C.-J.; Chiou, I.-J.; Shih, M.-H. The thermal conductivity mechanism of sewage sludge ash lightweight materials. Cem. Concr. Res. 2005, 35, 803–809. [Google Scholar] [CrossRef]

- Ding, H.-S.; Jiang, H. Self-heating co-pyrolysis of excessive activated sludge with waste biomass: Energy balance and sludge reduction. Bioresour. Technol. 2013, 133, 16–22. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Lu, Y.; Horton, R.; Ren, T. Specific heat capacity of soil solids: Influences of clay content, organic matter, and tightly bound water. Soil Sci. Soc. Am. J. 2019, 83, 1062–1066. [Google Scholar] [CrossRef]

- Zeri, M.; Álvala, R.C.S.; Carneiro, R.; Cunha-Zeri, G.; Costa, J.M.; Spatafora, L.R.; Urbano, D.; Vall·llossera, M.; Marengo, J.A. Tools for communicating agricultural drought over the Brazilian Semiarid using the soil moisture index. Water 2018, 10, 1421. [Google Scholar] [CrossRef] [Green Version]

- Balasubramanian, R.; Sircar, A.; Sivakumar, P.; Ashokkumar, V. Conversion of bio-solids (scum) from tannery effluent treatment plant into biodiesel. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 959–967. [Google Scholar]

- Bergman, T.L.; Incropera, F.P.; DeWitt, D.P.; Lavine, A.S. Fundamentals of Heat and Mass Transfer; Bergman, T.L., Lavine, A.S., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017. [Google Scholar]

- FLIR. User’s Manual FLIR A6xx Series; FLIR systems: Wilsonville, OR, USA, 2016. [Google Scholar]

- Apogee. Apogee Instruments Owner’s Manual Pyranometer Models SP-110 and SP-230; Apogee: Logan, UT, USA, 2020. [Google Scholar]

- Guo, X.; Zhang, F.; Liu, Y. Study on pulsed thermography for water ingress detection in composite honeycomb panels. Hangkong Xuebao Acta Aeronaut. Astronaut. Sin. 2012, 33, 1134–1146. [Google Scholar]

- Abu-Hamdeh, N.H. Thermal Properties of Soils as affected by Density and Water Content. Biosyst. Eng. 2003, 86, 97–102. [Google Scholar] [CrossRef]

| Region | Highest Temperature(°C) | Lowest Temperature(°C) | Fitted Cooling Constant, k | R-Squared | RMSE |

|---|---|---|---|---|---|

| No-soil region | 26.1 | 4.3 | 0.00925 | 0.9748 | 0.8675 |

| Soil region | 22.5 | 4.3 | 0.00484 | 0.9973 | 0.2608 |

| Region | Transient Events Start Points | Transient Events End Points | Initial Geomembrane Temperatures (°C) | Final Geomembrane Temperatures (°C) | |

|---|---|---|---|---|---|

| No-soil region | Day 1 | 16:32:15 | 07:07:55 | 17.84 | 0.31 |

| Day 2 | 16:14:35 | 06:30:17 | 19.29 | 3.57 | |

| Soil region | Day 1 | 16:32:15 | 07:07:55 | 13.72 | 1.60 |

| Day 2 | 16:14:15 | 06:30:17 | 16.41 | 2.81 |

| Day | Region | Fitted Cooling Constants | R-Squared | RMSE |

|---|---|---|---|---|

| 1 | No-Soil region | 0.01813 | 0.9004 | 0.9871 |

| 1 | Soil region | 0.00763 | 0.9888 | 0.3534 |

| 2 | No-soil region | 0.02163 | 0.8851 | 0.8283 |

| 2 | Soil region | 0.01081 | 0.9104 | 0.7507 |

| Day | No-Soil Region | Soil Region |

|---|---|---|

| 1 | 0.01813 | 0.00763 |

| 2 | 0.02163 | 0.01081 |

| Threshold | Geomembrane Condition (%) | |||||

|---|---|---|---|---|---|---|

| Soil Region | No-Soil Region | |||||

| Day 1 | Day 2 | Difference | Day 1 | Day 2 | Difference | |

| 0–0.75 | 27.13 | 29.09 | 1.96 | 72.87 | 70.91 | 1.96 |

| 0–0.7 | 24.03 | 25.14 | 1.11 | 75.97 | 74.86 | 1.11 |

| 0–0.65 | 20.97 | 20.71 | 0.26 | 79.03 | 79.29 | 0.26 |

| 0–0.6 | 17.17 | 11.99 | 5.18 | 82.83 | 88.01 | 5.18 |

| 0–0.55 | 11.21 | 5.00 | 6.21 | 88.79 | 95.00 | 6.21 |

| Mean | 20.10 | 18.39 | 2.94 | 79.90 | 81.61 | 2.94 |

| Standard deviation | 5.54 | 8.78 | 2.33 | 5.54 | 8.78 | 2.33 |

| Transient Events Start Points | Transient Events end Points | Initial Geomembrane Temperatures (°C) | Final Geomembrane Temperatures (°C) | |

|---|---|---|---|---|

| Day 1 | 13:31:05 | 6:48:00 | 17.84 | 9.07 |

| Day 2 | 11:59:33 | 6:30:17 | 19.29 | 2.97 |

| Day 3 | 15:43:00 | 6:14:24 | 13.72 | 7.23 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Wong, L.; Vien, B.S.; Kuen, T.; Kodikara, J.; Chiu, W.K. Quasi-Active Thermal Imaging of Large Floating Covers Using Ambient Solar Energy. Remote Sens. 2020, 12, 3455. https://0-doi-org.brum.beds.ac.uk/10.3390/rs12203455

Ma Y, Wong L, Vien BS, Kuen T, Kodikara J, Chiu WK. Quasi-Active Thermal Imaging of Large Floating Covers Using Ambient Solar Energy. Remote Sensing. 2020; 12(20):3455. https://0-doi-org.brum.beds.ac.uk/10.3390/rs12203455

Chicago/Turabian StyleMa, Yue, Leslie Wong, Benjamin Steven Vien, Thomas Kuen, Jayantha Kodikara, and Wing Kong Chiu. 2020. "Quasi-Active Thermal Imaging of Large Floating Covers Using Ambient Solar Energy" Remote Sensing 12, no. 20: 3455. https://0-doi-org.brum.beds.ac.uk/10.3390/rs12203455