Functional Analysis in Long-Term Operation of High Power UV-LEDs in Continuous Fluoro-Sensing Systems for Hydrocarbon Pollution

Abstract

:1. Introduction

2. Materials and Method

2.1. Materials

- Gasoline 95 and 98 octanes.

- Diesel types A and A Plus, B, and C.

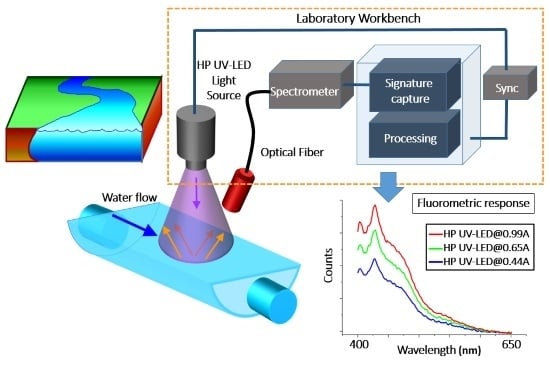

2.2. Laboratory Workbench Instrumentation

- UV light source, HP UV-LED. A 3W 365 nm LED was chosen for its simplicity and better beam light concentration than a circuit with several LEDs. The HP UV-LED is placed perpendicular at water surface at a distance of 8 cm, the view angle of the UV-LEDs is 2θ1/2 = 70°. The optical fiber has an angle of 30° with respect UV-LED perpendicular line, and a 6 cm distance to water surface.

- Spectrometer and optical fiber. Fluorescence detection systems based on compact CCD spectrometer are emerging as a tool in research field applications [2,3,4,20]. In this work two compact spectrometers (Avantes® Ava-Spec 2048-USB2-UA, and Mightex® HRS-BD1-025) have been used, the first one for workbench instrumentation in signature readout, and the second one for analysis of UV-LED temperature ALT [24,25]. The spectra readout is obtained via a specific optical fiber of 0.6 mm Ø, solid angle Ω = 0.15 sr, numerical aperture NA = 0.22 (Figure 2a). Considering the perpendicular distance to the water is 6 cm, the measurement area of fluorescence is 6.73 cm2. The wavelengths range of Avantes® Ava-Spec 2048-USB2-UA is 200–1100 nm, and the Mightex® HRS-BD1-025 with wavelengths range 300–1050 nm, proprietary measurement software, power supply, and PC connection by USB cable. This element is the only significant system cost, around 2500$.

- Processor block. This element is implemented in a Windows laptop computer under the software proprietary of Avantes® integrated in MATLAB® (MathWorks®, Natick, MA, USA). The micro-spectrometer readout is loaded in a MATLAB® application, which processes the signal for pollutant identification. The objective of this work is to make a qualitative identifications of hydrocarbons in an early warning system, therefore the measurements of the time-dependent decay of fluorescence have not been developed.

3. Results

3.1. Wavelength Analysis for Hydrocarbon Identification

3.2. Viscosity and Temperature Influence in Hydrocarbon Identification

- In the case of Diesel A, the response at 35 °C is different from the others at lower temperatures because the fluorescence peak at 425 nm is lower at 35 °C. This difference cannot be corrected with a normalization of the signal because it depends on the wavelength, in this case a different master signature for low, medium, and high temperatures are required, and furthermore, a real-time measured temperature is needed for a correct identification of the signature [12,28].

- In the case of Diesel A Plus and Gasoline 98 octane, the difference in the optical power between the high and low temperatures is much greater than for the other hydrocarbons.

3.3. Processing of Spectra Readout

3.4. Influence of HP UV-LED Parameters in the Spectrometer Readout

- The variations in the initial optical outputs of power of the new LEDs identified earlier.

- The optical output power degradation during the life of the LED, and the additional optical output power losses during real operation due to a dirty lens or dust.

- A 30% optical output power degradation with respect to the initial optical output power value is the standard definition of degradation failure in white illumination LEDs [36]. The reliability datasheets of the LEDs that include the standard report IES-LM-80-08 (Approved Method for Measuring Lumen Maintenance of LED Light Sources) [37] also select this failure limit evaluating the MTTF(L70) (Mean Time to Failure assuming failure when optical output power decays below 70% of the initial optical output power). The other, less frequent failure modes of the LED are the catastrophic failures due to short or open circuit. During temperature ALT, no catastrophic failures have been observed, all detected failures are due to light output degradation over 30%.

- In Figure 8d, the normalized signatures in the worst fluorescence signature case (Gasoline 98), for different currents have been represented. The signature at 220 mA (violet) has been observed to have higher noise than the fluorescence curve at nominal current (650 mA black line), the 330 mA (cyan) fluorescence signature (with a 54.4% of the optical output power with respect to the nominal current) has significantly less noise and therefore, we will consider that 220 mA is not a functional power at which to identify Gasoline 98. Therefore, although 50% or 60% of the initial optical output power would suffice, considering the other possible factors of optical output power that have been explained in the prior paragraph, we conservatively selected 70% of the initial optical output power, which is the standard value [36] and it is contemplated in the reliability datasheet of the commercial LEDs.

3.5. Long Life UV-LED Test for Hydrocarbons Detection

- For the continuous working mode HP UV-LEDs MTTF life of eight-and-a-half months, is better than or similar to continuously working spectrometric lamps.

- For the cycled mode, the MTTF life of more than seven years for one type of the HP-UV-LEDs and four years for the other type, are considerably better than that of the conventional spectrometric lamps in the continuous operation mode. It must be considered that the conventional UV-lamps cannot operate in the cycled (1 min) mode, due to the great stabilization times.

- The continuous working mode has a short life compared with the cycled working condition, where for 30 s of each minute the water pollutants are not sensed. A partial solution will be to switch the power supply every 30 s to two different LEDs to excite the fluorescence, and although the time for stabilizing the optical output power is over 7 s and the cost of each 3W HP UV-LEDs is roughly $35.

4. Conclusions

- The materials, process, and laboratory equipment workbench used have been discussed. The detection system proposed has been performed without any contact with the fluent water, which offers several advantages, as it avoids soiling of the intermediate elements (glass, lens) of UV-LED while it analyzes a large area. The sensitivity and detection area could be improved by reducing optical losses and increasing the solid angle for fluorescence detection, using a lens or lens system.

- The absorbance and fluorescence signature of the different hydrocarbons have been analyzed using the selected HP UV-LED, and the influence of temperature and viscosity in the signature have been studied.

- After testing several types of signal processing, it has been proposed that a Savitzky-Golay filter and signal normalization in the range of 400 to 650 were the best method to obtain a repetitive signature under different conditions of the parameters, including the possible optical output power degradation of the HP UV-LED.

- The influence of HP UV-LED long-term output optical power degradation by current supply emulation, in fluorescence signature detection error was analyzed and the degradation limit of 30% was noted. Then maintaining 70% of the initial optical output power of the HP UV-LED was selected as the conservative limit for the repetitive identification of all the hydrocarbon signatures. Degraded LEDs in the ALT with optical output power degradations below 30% value show an optimum fluorescence signature.

- In order to validate the long-term life of the HP UV-LEDs, temperature ALTs have been developed. The complete setup of the parameters in this test are explained in [24,25], and it has been assessed and extrapolation of failure distribution is shown (Figure 9). From these data, it can be concluded that the MTTF(L70) for the cycled working mode (30 s ON & 30 s OFF) is several times better than that obtained for the continuous working mode.

- For long term operation, the HP UV-LEDS with continuous working mode has an estimated MTTF(L70) ≈ 6200 h working, and for cycled working it depends on the type technology of LED, MTTF(L70) ≈ 66,000 h for HP UV-LED with long life type. In all cases, the results of MTTF(L70) are very promising, mainly for the cycled 30s ON & 30s OFF working condition.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- O’Toole, M.; Diamond, D. Absorbance Based Light Emitting Diode Optical Sensors and Sensing Devices. Sensors 2008, 8, 2453–2479. [Google Scholar] [CrossRef] [Green Version]

- Puiu, A.; Fiorani, L.; Menicucci, I.; Pistilli, M.; Lai, A. Submersible Spectrofluorometer for Real-Time Sensing of Water Quality. Sensors 2015, 15, 14415–14434. [Google Scholar] [CrossRef] [PubMed]

- Ng, C.-L.; Teo, W.-K.; Cai, H.-T.; Hemond, H.F. Characterization and Field Test of an in Situ Multi-Platform Optical Sensor. Limnol. Oceanogr. Methods 2014, 12, 484–497. [Google Scholar] [CrossRef]

- Ng, C.-L.; Senft-Grupp, S.; Hemond, H.F. A Multi-Platform Optical Sensor for in Situ Sensing of Water Chemistry. Limnol. Oceanogr. Methods 2012, 10, 978–990. [Google Scholar] [CrossRef]

- Maraver Abad, P.; Vassal'lo Sanz, J.; Gutiérrez Ríos, J.; Esteban Orobio, A.; Soto Macía, I.; Vassal'lo Sanz, J.; Gallego García, E.; Medrano Gil, A. Detector a distancia de sustancias fluorescentes. Utility model. No ES1075980 U, 19-Jan-2012. Available online: http://digital.csic.es/handle/10261/53851 (accessed on 18 January 2016).

- Ibañez, G.A.; Escandar, G.M. Luminescence Sensors Applied to Water Analysis of Organic Pollutants—An Update. Sensors 2011, 11, 11081–11102. [Google Scholar] [CrossRef] [PubMed]

- Leeuw, T.; Boss, E.; Wright, D. In Situ Measurements of Phytoplankton Fluorescence Using Low Cost Electronics. Sensors 2013, 13, 7872–7883. [Google Scholar] [CrossRef] [PubMed]

- Kissinger, J.; Wilson, D. Portable Fluorescence Lifetime Detection for Chlorophyll Analysis in Marine Environments. IEEE Sens. J. 2011, 11, 288–295. [Google Scholar] [CrossRef]

- Ji, J.W.; Xu, M.H.; Li, Z.M. Research and application on chlorophyll fluorescence on-line monitoring technology. Adv. Mater. Res. 2010, 139, 2550–2555. [Google Scholar] [CrossRef]

- Fernandez-Jaramillo, A.A.; Duarte-Galvan, C.; Contreras-Medina, L.M.; Torres-Pacheco, I.; Romero-Troncoso, R.J.; Guevara-Gonzalez, R.G.; Millan-Almaraz, J.R. Instrumentation in Developing Chlorophyll Fluorescence Biosensing: A Review. Sensors 2012, 12, 11853–11869. [Google Scholar] [CrossRef] [PubMed]

- Sighicelli, M.; Iocola, I.; Pittalis, D.; Luglié, A.; Padedda, B.M.; Pulina, S.; Iannetta, M.; Menicucci, I.; Fiorani, L.; Palucci, A. An Innovative and High-Speed Technology for Seawater Monitoring of Asinara Gulf (Sardinia-Italy). Open J. Mar. Sci. 2014, 4, 31–41. [Google Scholar] [CrossRef]

- Hur, J.; Hwang, S.-J.; Shin, J.-K. Using Synchronous Fluorescence Technique as a Water Quality Monitoring Tool for an Urban River. Water Air Soil Pollut. 2008, 191, 231–243. [Google Scholar] [CrossRef]

- Lakowicz, J.R. Principles of Fluorescence Spectroscopy, 3rd ed.; Springer-Verlag: New York, NY, USA, 2006; pp. 623–673. [Google Scholar]

- Measurement of Environmental Contaminant Hydrocarbons by Fluorescence Spectroscopy. Princenton Instrumets. Available online: http://www.princetoninstruments.com/Uploads/Princeton/Documents/Library/UpdatedLibrary/EEM_for_Environmental_contaminant_hydrocarbons.pdf (accessed on 18 January 2016).

- Jones, R.N. The Spectrographic Analysis of Carcinogenic Hydrocarbons and Metabolites. III. Distribution of 1,2,5,6-Dibenzanthracene in Rats Following Subcutaneous Injection in Olive Oil. Cancer Res. 1942, 2, 252–255. [Google Scholar]

- Van Duuren, B.L. Identification of some polynuclear aromatic hydrocarbons in cigarette-smoke condensate. J. Natl. Cancer Inst. 1958, 21, 1–16. [Google Scholar] [PubMed]

- Northrop, D.C.; Simpson, O. Electronic Properties of aromatic hydrocarbons. II. Fluorescence transfer in solid solutions. Proc. R. Soc. London A Math. Phys. Eng. Sci. 1956, 234, 136–149. [Google Scholar] [CrossRef]

- Muramoto, Y.; Kimura, M.; Nouda, S. Development and Future of Ultraviolet Light-Emitting Diodes: UV-LED Will Replace the UV Lamp. Semicond. Sci. Technol. 2014, 29, 84004–84011. [Google Scholar] [CrossRef]

- Venugopalan, H. UVC LEDs enable cost-effective spectroscopic instruments. Laser Focus World 2015, 51, 81–85. [Google Scholar]

- Arques Orobon, F.J.; Gonzalez Posadas, V.; Jimenez Martin, J.L.; Gutierrez Rios, J.; Esteban Orobio, A. Fluoro-sensing applied to detection and identification of hydrocarbons in inland waters. In Proceedings of the 10th IEEE International Conference on Networking, Sensing and Control (ICNSC), Evry, France, 10–12 April 2013; pp. 193–198.

- Montes-Hugo, M.; Fiorani, L.; Marullo, S.; Roy, S.; Gagné, J.-P.; Borelli, R.; Demers, S.; Palucci, A. A Comparison between Local and Global Spaceborne Chlorophyll Indices in the St. Lawrence Estuary. Remote Sens. 2012, 4, 3666–3688. [Google Scholar] [CrossRef]

- Tagus Hydrographic Confederation, Spanish Ministry of Agriculture, Food and Environment Minister. Available online: http://hispagua.cedex.es/en/instituciones/confederaciones/tajo (accessed on 18 January 2016).

- Tagus Hydrographic Confederation, (Confederación hidrográfica del Tajo). Red SAICA (Sistema Automático de Información de Calidad de las Aguas—Automatic Information System Water Quality). Available online: http://www.chtajo.es/Informacion%20Ciudadano/Calidad/AguasSup/Paginas/RedSAICA.aspx (accessed on 18 January 2016). (In Spanish)

- Arques-Orobon, F.J.; Nuñez, N.; Vazquez, M.; González-Posadas, V. UV LEDs Reliability Tests for Fluoro-Sensing Sensor Application. Microelectron. Reliabil. 2014, 54, 2154–2158. [Google Scholar] [CrossRef]

- Arques-Orobon, F.J.; Nuñez, N.; Vazquez, M.; Segura-Antunez, C.; González-Posadas, V. High-Power UV-LED Degradation: Continuous and Cycled Working Condition Influence. Solid-State Electron. 2015, 111, 111–117. [Google Scholar] [CrossRef]

- Jimenez Martin, J.L.; Gonzalez-Posadas, V.; Gonzalez-Garcia, J.E.; Arques-Orobon, F.J.; Garcia Munoz, L.E.; Segovia-Vargas, D. Dual Band High Efficiency Class Ce Power Amplifier Based on Crlh Diplexer. Prog. Electromag. Res. 2009, 97, 217–240. [Google Scholar] [CrossRef]

- Jiménez-Martín, V.; Gonzalez-Posadas, F.J.; Arques-Orobon, L.E.; Garcia-Muñoz, D. Dual Band High Efficiency Power Amplifier Based on CRLH Lines. Radioengineering 2009, 18, 567–578. [Google Scholar]

- Pajares, G. Sensors in collaboration increase individual potentialities. Sensors 2012, 12, 4892–4896. [Google Scholar] [CrossRef] [PubMed]

- Boniewicz-Szmyt, K.; Pogorzelski, S.; Mazurek, A. Hydrocarbons on sea water: Steady-state spreading signatures determined by an optical method. Oceanologia 2007, 49, 413–437. [Google Scholar]

- Hirayama, H. Building brighter and cheaper UV LEDs. Semicond. Compd. 2013, 19, 43–48. [Google Scholar]

- Melendez-Pastor, I.; Navarro-Pedreño, J.; Gómez, I.; Koch, M. Identifying Optimal Spectral Bands to Assess Soil Properties with VNIR Radiometry in Semi-Arid Soils. Geoderma 2008, 147, 126–132. [Google Scholar] [CrossRef]

- Savitzky, A.; Golay, M.J.E. Smoothing and Differentiation of Data by Simplified Least Squares Procedures. Anal. Chem. 1964, 36, 1627–1639. [Google Scholar] [CrossRef]

- Schafer, R.W. What is a Savitzky-Golay filter? [lecture notes]. IEEE Signal Process. Mag. 2011, 28, 111–117. [Google Scholar] [CrossRef]

- Melendez-Pastor, I.; Almendro-Candel, M.; Navarro-Pedreño, J.; Gómez, I.; Lillo, M.; Hernández, E. Monitoring Urban Wastewaters’ Characteristics by Visible and Short Wave near-Infrared Spectroscopy. Water 2013, 5, 2026–2036. [Google Scholar] [CrossRef]

- Slade, W.H.; Boss, E. Spectral Attenuation and Backscattering as Indicators of Average Particle Size. Appl. Opt. 2015, 54, 7264. [Google Scholar] [CrossRef] [PubMed]

- Taylor, J. Industry Alliance Proposes Standard Definition for LED Life. LED’s Mag. 2005, 2, 9–11. [Google Scholar]

- Approved Method for Lumen Maintenance Testing of LED Light Source; Illuminating Enginering Society: New York, NY, USA, 2008.

- Arrhenius, S. Über die Reaktionsgeschwindigkeit bei der Inversion von Rohrzucker durch Säuren. Z. Physikal. Chem. 1889, 4, 226–248. [Google Scholar]

- Philips Lumileds. Luxeon reliability, Reliability Datasheet RD25, Section: Estimating Failure Rates over Temperature 2006. Available online: https://www.olino.org/wp-content/uploads/2008/articles/thousand_lumen_led_Luxeon_RD25.pdf (accessed on 18 January 2016).

- Packard, H. Reliability of Precision Optical Performance AlInGaP LED Lamps in Traffic Signals and Variable Message Signs. Application Brief I-004. 1999. Available online: www.semiconductor.agilent.com (accessed on 18 January 2016).

- IES-TM-21-11. In Standard. Projecting Long Term Lumen Maintenance of LED Light Sources; Illuminating Engineering Society: New York, NY, USA, 2011.

- Glaab, J.; Ploch, C.; Kelz, R.; Stölmacker, C.; Lapeyrade, M.; Ploch, N.L.; Rass, J.; Kolbe, T.; Einfeldt, S.; Mehnke, F.; et al. Degradation of (InAlGa)n-Based UV-B Light Emitting Diodes Stressed by Current and Temperature. J. Appl. Phys. 2015, 118, 094504. [Google Scholar] [CrossRef]

- Vázquez, M.; Núñez, N.; Nogueira, E.; Borreguero, A. Degradation of AlInGaP Red LEDs under Drive Current and Temperature Accelerated Life Tests. Microelectron. Reliabil. 2010, 50, 1559–1562. [Google Scholar] [CrossRef]

- Chang, M.-H.; Das, D.; Varde, P.V.; Pecht, M. Light Emitting Diodes Reliability Review. Microelectron. Reliabil. 2012, 52, 762–782. [Google Scholar] [CrossRef]

- Mukai, T.; Morita, D.; Yamamoto, M.; Akaishi, K.; Matoba, K.; Yasutomo, K.; Kasai, Y.; Sano, M.; Nagahama, S. Investigation of Optical-Output-Power Degradation in 365-Nm UV-LEDs. Phys. Status Solidi 2006, 3, 2211–2214. [Google Scholar] [CrossRef]

- Núñez, N.; González, J.R.; Vázquez, M.; Algora, C.; Espinet, P. Evaluation of the Reliability of High Concentrator GaAs Solar Cells by Means of Temperature Accelerated Aging Tests. Prog. Photovol. Res. Appl. 2013, 21, 1104–1113. [Google Scholar] [CrossRef]

- ReliaSoft Corporation, Weibull++ and ALTA PRO, Software Packages, Tucson, AZ. Available online: www.ReliaSoft.com (accessed on 18 January 2016).

| HP UV-LED Type | Nominal Electrical/Optical Power (W) | Electrical/Optical Power at 600 mA (W) | Irradiance at 8 cm & 600 mA (mW/cm2) |

|---|---|---|---|

| A | ≈3/0.8 | ≈2.4/0.65 | 9.11 |

| B | ≈2.8/1 | ≈2.25/0.75 | 10.40 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arques-Orobon, F.J.; Nuñez, N.; Vazquez, M.; Gonzalez-Posadas, V. Functional Analysis in Long-Term Operation of High Power UV-LEDs in Continuous Fluoro-Sensing Systems for Hydrocarbon Pollution. Sensors 2016, 16, 293. https://0-doi-org.brum.beds.ac.uk/10.3390/s16030293

Arques-Orobon FJ, Nuñez N, Vazquez M, Gonzalez-Posadas V. Functional Analysis in Long-Term Operation of High Power UV-LEDs in Continuous Fluoro-Sensing Systems for Hydrocarbon Pollution. Sensors. 2016; 16(3):293. https://0-doi-org.brum.beds.ac.uk/10.3390/s16030293

Chicago/Turabian StyleArques-Orobon, Francisco Jose, Neftali Nuñez, Manuel Vazquez, and Vicente Gonzalez-Posadas. 2016. "Functional Analysis in Long-Term Operation of High Power UV-LEDs in Continuous Fluoro-Sensing Systems for Hydrocarbon Pollution" Sensors 16, no. 3: 293. https://0-doi-org.brum.beds.ac.uk/10.3390/s16030293