Alignment of the Safety Assessment Method with New Zealand Legislative Responsibilities

Abstract

:1. Introduction

2. Background to Health and Safety Legislation in NZ

2.1. Health and Safety Legislation in NZ

2.2. Intent of Legislative Frameworks for Self-Management—The International Context

2.3. Challenges to Management Systems

2.4. Need for More Systematic Methods

2.5. Standardised Methods

2.6. Specific Needs for New Zealand

- ‘Insignificant—no injuries,

- Moderate—first aid and/or medical treatment,

- Major—extensive injuries,

- Catastrophic—fatalities’ [41].

- Minor

- Moderate—first aid required

- Serious harm occurs

- Major harm—permanent injury

- Death—loss of life

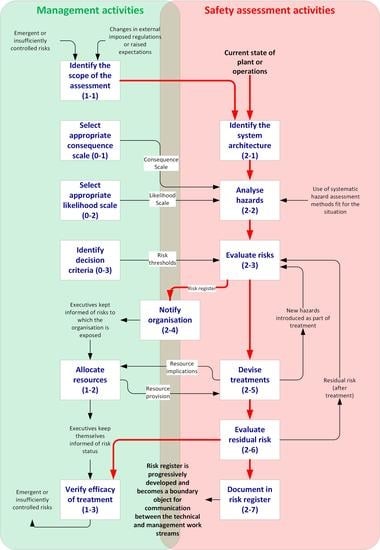

3. Method

3.1. Purpose

- Provide an instrument which has a clear and unambiguous definition for the various legal categories of harm. This is necessary for consistency of application.

- Accommodate the particular definitions of harm used in the jurisdiction (NZ in this case).

- Accommodate health considerations (chronic, long-term harm).

- Accommodate the non-linearity of catastrophic harm incidents.

- Accommodate the fact that the Act’s legal penalties and liabilities increase disproportionately with the scale.

- Define clear expectations regarding treatment. In contrast existing methods leave this to each organisation to set, without guidance.

- Integrate preventative and recovery treatments, by providing a means whereby both may be brought to mind. In contrast existing methods focus overly on prevention at the expense of recovery.

- Offer a systematic way to structure the hazard assessment without overburdening it with the need for specialised knowledge.

3.2. Approach

4. Results

4.1. A Harm to NZ Legislation

- 1.

- Hazard present but existing controls prevent progression (hazard is controlled by existing treatments and if it materialises the effects are expected to be inconsequential)

- 2.

- Incident occurs with no harm (near-accident)

- 3.

- Incident occurs and Minor harm results

- 4.

- Incident occurs and exposure to serious harm but no actual harm (‘notifiable incident’)

- 5.

- Serious harm Occurs (‘notifiable injury or illnesses)

- 8.

- Death

- 10.

- Catastrophe (recovery systems fail, multiple deaths occur)

- 6.

- Almost certain

- 5.

- Likely

- 4.

- Possible

- 3.

- Unlikely

- 2.

- Rare

- 1.

- Almost incredible

4.2. Identification of System Architecture

- Workplace Location: The work may be done by different people in separate physical locations. For example a company printing a newspaper has different risks for the reporters, pre-print layup, printing engineers, and delivery people.

- Zones: Another type of location is where there are different technical systems in different physical zones, irrespective of whether there are people there or not. For example, an aircraft fuselage has a cockpit, galley, passenger seating zone, cargo hold, toilets, and avionics bays. Each of these have different types of hazards. A specialised form of this is called Zonal Analysis.

- Hardware Sub-System or Type of Equipment: This is similar to above except the analysis is for each piece of plant or equipment. An example is a construction site, and the analysis could be by the type of machine: excavator, roller, dump truck, laser based surveying equipment, etc.

- Task: In this case, a worker is performing multiple different types of task. For example, a garden service worker could be mowing lawns (dust, cuts), trimming hedges (hand injury, eyes), spreading compost (Legionnaires disease), or lifting and loading (back injury).

- Work-Flow: In most manufacturing plants, there is a sequence of operating procedures that determine the work-flow. In which case, the hazard would be determined for each stage in the work-flow. For example, in an injection moulding firm there are hazards involved with lifting plastic granules into hoppers (falls, working at height dust), heating and drying of feedstock (fire), injection moulding (burns, fluid lancing by blast of hydraulic oil, slipping on floors, fumes, fire), part removal from press (burns, crushing), or deburring (cuts, contact dermatitis, repetitive strain injury).

4.3. Decision Criteria

4.4. Treatment Options

4.5. Adjustments to the Method for Safety Assessment

5. Discussion

5.1. Outcomes

5.2. Implications for Practitioners

5.3. Limitations of the Work

5.4. Implications for Future Research

6. Conclusions

Funding

Conflicts of Interest

Appendix A. Example Application of the Method

| Risks of System in its CURRENT STATE, with Its Existing Controls. | Angle Grinder with Operator Wearing Eye Protection and Hearing Protection | ||||

|---|---|---|---|---|---|

| Architecture level: Work-stream, project phase, hardware category, workstation | Specific hazard | Consequence (C), as per ‘Severity of harm’ scale | Likelihood (L) of that consequence arising | Risk | Treatment? Consider Preventative and Recovery mechanisms. (Controls) |

| (C × L) | |||||

| 1. Hazard occurred | 6 Almost certain | 30 or higher Unacceptable risk. | |||

| 2. Incident with no harm | 5 Likely | 18 or higher Urgent treatment. | |||

| 3. Incident and Minor harm | 4 Possible | 8 or higher Consider treatment | |||

| 4. Incident and exposure to serious harm | 3 Unlikely | 7 or less No intervention necessary. | |||

| 5. Serious harm Occurs | 2 Rare | ||||

| 8. Death | 1 Almost incredible | ||||

| 10. Catastrophe | |||||

| 1 Cutting disk | Fixation fails | 5 | 3 | 15 | Design review to check reliability of fixation between tool and cutting disk. |

| Warning in User instructions: Stop operation if disk develops eccentricity. | |||||

| Disk breaks free | 5 | 2 | 10 | Manufacturing defect of disk. | |

| Warning in User instructions: Do not use cracked or partially broken disks. | |||||

| Disk fails and breaks up | 5 | 4 | 20 | Poor quality of disk. Warning in User instructions: Do not use cracked or partially broken disks. | |

| operator roll or yaw of disk | 5 | 4 | 20 | Operator error. Warning in User instructions: hold tool steady and avoid bending the disk in the cutting slot | |

| Pieces of substrate material break free | 4 | 2 | 8 | Situational error. Warning in User instructions: No suitable for substrates that have risk of breaking up. | |

| wrong type disk for substrate | 4 | 4 | 16 | Situational error. Warning in User instructions: Use disk appropriate for substrate | |

| wrong size or speed | 3 | 4 | 12 | Operator error. Warning in User instructions: Use disk maximum outer diameter 120 mm. | |

| dust particles | 5 | 5 | 25 | Warning in User instructions: Use respirator protection if dust or fumes are produced. | |

| sharp abraded edge | 3 | 5 | 15 | Warning in User instructions: Take care when handling cutting disks as these may have sharp edges or splinters. | |

| splinters of reinforcement | 3 | 5 | 15 | Warning in User instructions: Take care when handling cutting disks as these may have sharp edges or splinters | |

| heat | 3 | 5 | 15 | Warning in User instructions: Take care when handling cutting disks as these may be hot. | |

| 2 Front handle | 2.1 vibration | 3 | 5 | 15 | Warning in User instructions: Use gloves. |

| 2.2 comes loose | 4 | 3 | 12 | Warning in User instructions: Ensure handle is tight before using. | |

| 2.3 Hand slides medially, contacts disk | 5 | 5 | 25 | Design handle with medial flange to prevent hand migration. | |

| 3 Guard fails to protect eyes | 3.1 not fitted | 4 | 3 | 12 | Warning in User instructions: Not recommended to use without guard fitted. |

| 3.2.1 wrong position due to operator error | 4 | 3 | 12 | Warning in User instructions: Ensure guard is positioned to protect against flying debris, and also not interfere with the substrate. | |

| 3.2.2 wrong position because too difficult to adjust | 4 | 5 | 20 | Design guard to be easy to adjust and reposition securely, without tool. | |

| 3. loose | 4 | 4 | 16 | Ibid (design solution) | |

| 3.3.3 interferes with substrate | 2 | 6 | 12 | Ibid (warning to secure) | |

| 4 Gearbox | 4.1 noise | 3 | 4 | 12 | Already prevented with hearing protection |

| 4.2 vibration | 3 | 4 | 12 | Ibid (use gloves) | |

| 5 Motor body and trigger handle | 5.1 noise | 4 | 4 | 16 | Ibid (hearing protection) |

| 5.2 heat | 3 | 2 | 6 | Ibid (use gloves) | |

| 5.3 electric shock | 5 | 2 | 10 | ||

| 5.4 fracture | 4 | 3 | 12 | Design housing for robustness | |

| 6 Trigger | 6.1 command error | 5 | 5 | 25 | Design trigger for usability. Include safety interlock |

| 6.2 ergonomics | 4 | 3 | 12 | Design padding into handle. | |

| Ibid (use gloves) | |||||

| 7 Battery Power supply | 7.1 fire | 5 | 3 | 15 | Design thermal cut-out into battery electronics |

| 7.2 heat | 3 | 6 | 18 | Design thermal cut-out into battery electronics | |

| 7.3 electric shock | 8 | 2 | 16 | Design tool to operate on less than 30VDC | |

| 7.4 reverse polarity | 2 | 3 | 6 | Design electronics so that assembly errors are physically prevented. | |

| 8 Charging station | 8.1 fire | 8 | 5 | 30 | Design thermal cut-out into charger electronics |

| 8.2 electric shock | 8 | 4 | 24 | Design double insulated charging station, no external metal parts that are easily accessible, charging pins to be difficult to reach even accidentally | |

| 9 Disk changing tool | 9.1 left attached and flung off | 5 | 3 | 15 | Design tool to be loose fit so it will not stay attached. |

| 9.2 lost so disk not attached properly | 4 | 5 | 20 | Design tool out altogether. Alternatively provide a means to retain it with the tool. | |

References

- ISO 31000. Risk Management—Principles and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- SAA/SNZ HB436. Risk Management Guidelines; Australian/New Zealand Standard, Standards Australia: Sydney, Australia, 2004. [Google Scholar]

- AS/NZS 3931. Risk Analysis of Technological Systems—Application Guide; Joint Technical Committee MB/2, Risk Management; Standards Australia International Ltd.: Homebush, Australia, 1998. [Google Scholar]

- NZ Govt. Health and Safety at Work Act 2015. Public Act 2015, Act No 70. Available online: http://www.legislation.govt.nz/act/public/2015/0070/latest/whole.html#DLM5976660 (accessed on 23 August 2019).

- Pons, D.J. Pike River Mine Disaster: Systems-Engineering and Organisational Contributions. Safety 2016, 2, 21. [Google Scholar] [CrossRef]

- NZ Govt. Royal Commission Report. Royal Commission on the Pike River Coal Mine Tragedy 2012. Available online: http://pikeriver.royalcommission.govt.nz/Final-Report (accessed on 23 August 2019).

- ALLI, B.O. Fundamental Principles of Occupational Health and Safety, 2nd ed.; International Labour Organization: Geneva, Switzerland, 2008. [Google Scholar]

- Kerin, T. The evolution of process safety standards and legislation following landmark events-what have we learnt? Process Saf. Prog. 2016, 35, 165–170. [Google Scholar] [CrossRef]

- ILO. Guidelines on Occupational Safety and Health Management Systems, ILO-OSH 2001, 2nd ed.; International Labour Organization: Geneva, Switzerland, 2009. [Google Scholar]

- Niu, S. Ergonomics and occupational safety and health: An ILO perspective. Appl. Ergon. 2010, 41, 744–753. [Google Scholar] [CrossRef] [PubMed]

- Hellebust, C.R.; Braut, G.S. Regulated self-regulation or external control? A study of the effects of different legislative approaches in the petroleum sector in Norway and Brazil. In Proceedings of the SPE International Conference on Health, Safety and Environment in Oil and Gas Exploration and Production 2010, Rio de Janeiro, Brazil, 12–14 April 2010; pp. 416–421. [Google Scholar]

- Arntz-Gray, J. Plan, Do, Check, Act: The need for independent audit of the internal responsibility system in occupational health and safety. Saf. Sci. 2016, 84, 12–23. [Google Scholar] [CrossRef]

- Gee, N.; Rogers, J.H. The impact of the Kelly Barnes Dam failure on the development of dam safety legislation and policy in the 1970s. J. Dam Saf. 2018, 15, 9–18. [Google Scholar]

- Adeyemo, O.; Smallwood, J. Impact of Occupational Health and Safety Legislation on Performance Improvement in the Nigerian Construction Industry. In Proceedings of the Creative Construction Conference, CCC 2017, Primosten, Croatia, 19–22 June 2017; pp. 785–791. [Google Scholar]

- Adeyemo, O.; Smallwood, J.J. Barriers to the implementation of occupational health and safety legislation in the Nigerian construction industry. In Proceedings of the 22nd International Conference on Advancement of Construction Management and Real Estate, CRIOCM 2017, Melbourne, Australia, 20–23 November 2017; pp. 1163–1170. [Google Scholar]

- Anderson, J. Health and safety—The language of UK law. Available online: https://0-doi-org.brum.beds.ac.uk/10.1680/mpal.10.00038 (accessed on 23 August 2019).

- Bluff, E. How SMEs respond to legal requirements to provide information, training, instruction and supervision to workers about work health and safety matters. Saf. Sci. 2019, 116, 45–57. [Google Scholar] [CrossRef]

- Comberti, L.; Demichela, M.; Baldissone, G.; Luzzi, R.; Fois, G. The impact of regulation on occupational safety—A regional study for Italian food industry. Chem. Eng. Trans. 2018, 67, 397–402. [Google Scholar] [CrossRef]

- Hamid, A.R.A.; Razak, A.R.A.; Yusof, A.M.; Jaya, R.P.; Zakaria, R.; Aminudin, E.; Anuar, M.A.S.K.; Yahya, K.; Haron, Z.; Yunus, R.; et al. Noncompliance of the occupational safety and health legislation in the Malaysian construction industry. In Proceedings of the 12th International Civil Engineering Post Graduate Conference, SEPKA 2018 and 3rd International Symposium on Expertise of Engineering Design (ISEED 2018), Johor, Malaysia, 27–28 August 2018. [Google Scholar]

- Simukonda, W. Occupational health and safety practices among contractors in Malawi: A generic overview. Proc. Inst. Civ. Eng. Manag. Procure. Law 2019, 172, 118–124. [Google Scholar] [CrossRef]

- Mustapha, Z.; Aigbavboa, C.; Thwala, W. Health and safety regulation and its compliance among small and medium-sized enterprises contractors in Ghana. In Proceedings of the International Conference on Safety Management and Human Factors, Walt Disney World, FL, USA, 27–31 July 2016; pp. 243–249. [Google Scholar]

- Colombo, S.; Golzio, L.E.; Bianchi, G. The evolution of health-, safety- and environment-related competencies in Italy: From HSE technicians, to HSE professionals and, eventually, to HSE managers. Saf. Sci. 2019, 118, 724–739. [Google Scholar] [CrossRef]

- Lawrenson, A.J.; Braithwaite, G.R. Regulation or criminalisation: What determines legal standards of safety culture in commercial aviation? Saf. Sci. 2018, 102, 251–262. [Google Scholar] [CrossRef]

- Lingard, H.; Warmerdam, A.; Shooshtarian, S. Getting the balance right: Regulating occupational health and safety planning and coordination in the Australian construction industry. Eng. Constr. Archit. Manag. 2019, 26, 599–617. [Google Scholar] [CrossRef]

- Oswald, D.; Sherratt, F.; Smith, S.D.; Hallowell, M.R. Exploring safety management challenges for multi-national construction workforces: A UK case study. Constr. Manag. Econ. 2018, 36, 291–301. [Google Scholar] [CrossRef]

- Dempsey, P.S. A comparative analysis of national laws governing launch safety. In Proceedings of the 66th International Astronautical Congress 2015: Space—The Gateway for Mankind’s Future, IAC 2015, Jerusalem, Israel, 12–16 October 2015; pp. 9862–9891. [Google Scholar]

- Freeland, J. Occupational Regulations; Elsevier: Amsterdam, The Netherlands, 2015; pp. 637–672. [Google Scholar]

- Drew, C.A.; Clydesdale, F.M. New Food Safety Law: Effectiveness on the Ground. Crit. Rev. Food Sci. Nutr. 2015, 55, 689–700. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Bai, L.; Gong, S. Government regulations and voluntary certifications in food safety in China: A review. Trends Food Sci. Technol. 2019, 90, 160–165. [Google Scholar] [CrossRef]

- Niskanen, T. Results of Finnish national survey in the chemical industry on EU legislation concerned with risk assessment and safety compliance climate. J. Loss Prev. Process Ind. 2012, 25, 535–543. [Google Scholar] [CrossRef]

- Iavicoli, S.; Leka, S.; Jain, A.; Persechino, B.; Rondinone, B.M.; Ronchetti, M.; Valenti, A. Hard and soft law approaches to addressing psychosocial risks in Europe: Lessons learned in the development of the Italian approach. J. Risk Res. 2014, 17, 855–869. [Google Scholar] [CrossRef]

- Potter, R.E.; Dollard, M.F.; Owen, M.S.; O’Keeffe, V.; Bailey, T.; Leka, S. Assessing a national work health and safety policy intervention using the psychosocial safety climate framework. Saf. Sci. 2017, 100, 91–102. [Google Scholar] [CrossRef]

- ISO 45001. Occupational Health and Safety Management Systems—Requirements with Guidance for Use, 2018th ed.; International Organization for Standardization, 2018; Available online: https://www.iso.org/iso-45001-occupational-health-and-safety.html (accessed on 23 August 2019).

- Niskanen, T.; Naumanen, P.; Hirvonen, M.L. An evaluation of EU legislation concerning risk assessment and preventive measures in occupational safety and health. Appl. Ergon. 2012, 43, 829–842. [Google Scholar] [CrossRef]

- Niskanen, T.; Naumanen, P.; Hirvonen, M.L. Safety compliance climate concerning risk assessment and preventive measures in EU legislation: A Finnish survey. Saf. Sci. 2012, 50, 1929–1937. [Google Scholar] [CrossRef]

- Yranheikki, E.; Savolainen, H. Occupational Safety and Health in Finland. J. Saf. Res. 2000, 31, 177–183. [Google Scholar] [CrossRef]

- Audiffren, T.; Rallo, J.-M.; Guarnieri, F. The contribution of case law to compliance management in Occupational Health and Safety (OHS) in france. In Proceedings of the 11th International Probabilistic Safety Assessment and Management Conference and the Annual European Safety and Reliability Conference 2012, PSAM11 ESREL 2012, Helsinki, Finland, 25–29 June 2012; pp. 1320–1328. [Google Scholar]

- Darabont, D.; Gheorghe, M.; Funar, S.; Tudorel, M.E. Method for evaluation of compliance with Occupational health and safety legislation. In Proceedings of the International Conference on Risk Management, Assessment and Mitigation (RIMA’10), Algarve, Portugal, 13–15 September 2010; pp. 529–531. [Google Scholar]

- Zhang, B.; Chu, Z.; Cheng, L.; Zou, N. A quantitative safety regulation compliance level evaluation method. Saf. Sci. 2019, 112, 81–89. [Google Scholar] [CrossRef]

- Darabont, D.C.; Antonov, A.E.; Bejinariu, C. Key elements on implementing an occupational health and safety management system using ISO 45001 standard. In Proceedings of the 8th International Conference on Manufacturing Science and Education: Trends in New Industrial Revolution (MSE 2017), Sibiu, Romania, 7–9 June 2017. [Google Scholar]

- Worksafe NZ. Safe Use of Machinery; Worksafe: Wellington, New Zealand, 2014; pp. 1–119. [Google Scholar]

- WHO. Measuring Health and Disability—Manual for WHO Disability Assessment Schedule WHODAS 2.0; World Health Organization: Geneva, Switzerland, 2010. [Google Scholar]

- Ji, Z.; Pons, D.; Pearse, J. Measuring Industrial Health Using a Diminished Quality of Life Instrument. Safety 2018, 4, 55. [Google Scholar] [CrossRef]

- Worksafe NZ. General Risk and Workplace Management; Worksafe: Wellington, New Zealand, 2019; Volume 2, pp. 1–32. [Google Scholar]

- Worksafe NZ. Identifying, Assessing and Managing Work Risks; Worksafe: Wellington, New Zealand, 2019; Volume 2, pp. 1–26. [Google Scholar]

- Worksafe NZ. How to Manage Work Risks. Available online: https://worksafe.govt.nz/managing-health-and-safety/managing-risks/how-to-manage-work-risks/ (accessed on 10 August 2019).

| Level | Harm | Actions | Legal Obligation of Managers, Engineers, and Workers |

|---|---|---|---|

| 1 | Hazard present but existing controls prevent progression | Periodically check the efficacy of existing controls. Be alert to the possibility that the addition of new hardware or changed routines may add new hazards. Repeat the hazard assessment periodically. | Be aware of the hazards: ignorance is an offence in its own right. |

| 2 | Incident occurs with no harm (near-accident) | Collect incident reports, review them, and look for trends. Are some risks increasing? Are you seeing new hazards? Are the existing controls effective? Investigate the more significant incidents. | Make sure that a system exists for reporting incidents and that it is actually used, as lack of systems is an offense. |

| 3 | Incident occurs and Minor harm results | As above | As above |

| 4 | Incident occurs and exposure to serious harm but no actual harm (‘notifiable incident’) | Something slipped: what was it? Interestingly this is just as much notifiable as when serious harm does occur. | The organisation has to report the event to the regulator ‘immediately’ (s51) [4], preserve the site for inspection until authorised by an inspector (s53), and keep records for 5 years (s52). |

| 5 | Serious harm Occurs (‘notifiable injury or illness’) | Notifiable event | |

| 8 | Death | Notifiable event | |

| 10 | Catastrophe (recovery systems fail, multiple deaths occur) | Often organisations are slow to recognise the problem, unwilling to admit that a mistake has happened, and tardy in calling for help. Their risk treatment is focussed on prevention, and their limited emergency plans are overwhelmed when catastrophe occurs. They may be paralysed by incapacitation, indecision, or denial as the disaster unfolds. Better recovery systems are needed, but may be difficult to improvise at the time. The fact that catastrophe occurred indicates that the barriers were overwhelmed and the recovery systems failed. Why? |

| Risk, R = C × L | Corresponding Colour in Risk Map | Description | Principle of Action | Authority for Continued Operation | Reporting |

|---|---|---|---|---|---|

| 30 or higher | Purple | Unacceptable risk. | Operations to cease until risk reduction is achieved. Ensure provenance of Disaster Recovery mechanisms in addition to Preventative means. | Board | CEO to advise Board as soon as practicable. |

| 18 or higher | Red | Urgent treatment. | Urgent implementation of treatment required. Operations proceed with caution and ongoing monitoring of risk | CEO | Technical manager to advise CEO as soon as practicable, and report regularly on status of the risk and its treatment. |

| 8 or higher | Yellow | Consider treatment | Implement treatment in a reasonable time period. Operations proceed, with monitoring to detect if risk becomes worse or persistent | Technical manager | Team leader to report periodically to Technical manager on the risk and the progress of the treatment plan. |

| 7 or less | Green | No intervention necessary. | No further treatment required. Operations continue, with ongoing monitoring to check the efficacy of existing controls/barriers/procedures. Conduct periodic (e.g., annual) re-assessment of the risk. | Team leader | Staff to report periodically to Team leader on the state of this risk. |

| Risks of System in its CURRENT STATE, with Its Existing Controls. | Risks of System in its FUTURE STATE after these Treatments. Insert Any New Threats Caused by the Treatments. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Architecture level: Work-stream, project phase, hardware category, workstation | Specific hazard | Consequence (C), as per ‘Severity of harm’ scale | Likelihood (L) of that consequence arising | Risk = (C × L) | Treatment? Consider Preventative and Recovery mechanisms. | Action required by who? Resources required? | Monitoring required of efficacy of treatment? | Treated Consequence (C*) | Treated Likelihood (L*) | Residual Risk (C* × L*) | Is this acceptable? What further action is required? |

| 30 or higher Unacceptable risk. | |||||||||||

| 1. Hazard occurred | 6 Almost certain | 18 or higher Urgent treatment. | |||||||||

| 2. Incident with no harm | 5 Likely | 8 or higher Consider treatment | |||||||||

| 3. Incident and Minor harm | 4 Possible | 7 or less No intervention necessary. | |||||||||

| 4. Incident and exposure to serious harm | 3 Unlikely | ||||||||||

| 5. Serious harm Occurs | 2 Rare | ||||||||||

| 8. Death | 1 Almost incredible | ||||||||||

| 10. Catastrophe | |||||||||||

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pons, D.J. Alignment of the Safety Assessment Method with New Zealand Legislative Responsibilities. Safety 2019, 5, 59. https://0-doi-org.brum.beds.ac.uk/10.3390/safety5030059

Pons DJ. Alignment of the Safety Assessment Method with New Zealand Legislative Responsibilities. Safety. 2019; 5(3):59. https://0-doi-org.brum.beds.ac.uk/10.3390/safety5030059

Chicago/Turabian StylePons, Dirk J. 2019. "Alignment of the Safety Assessment Method with New Zealand Legislative Responsibilities" Safety 5, no. 3: 59. https://0-doi-org.brum.beds.ac.uk/10.3390/safety5030059