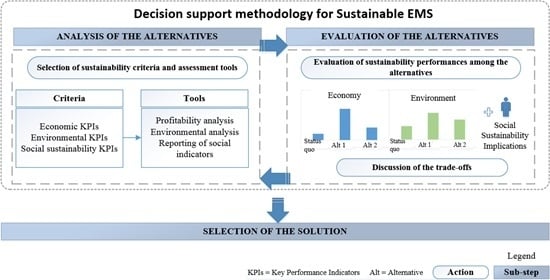

The decision support methodology served to support the decision of whether and how to integrate the new, automated sorting unit (represented by the e-grader demonstrator) within the current e-waste sorting plants, which normally have a high manual, human work content. To that end, the decision support methodology assessed the economic, environmental and social impacts that the demonstrator is expected to bring within an existing facility for e-waste sorting and recording adopted as a baseline for the case study.

Figure 4.

As-is sorting system versus the automated solution being proposed.

5.2.1. Setting Economic Criteria of the Demonstrator

Measurements to be employed in the economic assessment should be selected according to the metrics and the time horizon that the stakeholders deem reasonable to evaluate, and these can vary in different scenarios. The set of indicators used for the analysis of the demonstrator evaluates the impacts of the new technology adoption at two levels that are tightly connected: facility operations performances and economic performances. The operational indicators deemed suitable for the analysis are:

throughput (rate of items being processed),

lead time (from input storage to the end of the line),

utilization of the sorting unit.

The economic indicators deemed suitable for the analysis are:

income (revenues),

gross profit margin, which is the percentage of revenue remaining after the cost of goods sold,

return of investment (ROI), which measures the amount of return on an investment relative to the investment’s cost.

Among the operations management performances by which the facility can be economically evaluated, throughput is one of the most preferred indicators among top management. It is reasonable to assume that introducing the automatic sorting unit leads to higher overall system throughput, if this is properly utilized and placed within the facility. From the total input of WEEE items into the facility, the higher percentage of WEEE items suitable for processing by the sorting unit, the higher the total system throughput will be, which matches the throughput of items being sorted manually and the items being sorted by the equipment. Capturing the dynamic behavior of the system through DES gives an understanding of the variability embedded within any production system and helps decision makers visualize possible system behaviors.

Figure 5 shows a snapshot of the DES model being used in the case study.

Figure 5.

Snapshot of the DES model of the e-grader demonstrator in AnyLogic.

Figure 5.

Snapshot of the DES model of the e-grader demonstrator in AnyLogic.

A trend describing how system throughput increases when the percentage of input to the sorting unit increases can be drawn through interpolation techniques applied to the “experiment points”.

Interpolation functionalities are available in Microsoft Excel and MATLAB [

42], among other software packages.

In this case, the higher the throughput, the higher the possibility to sell the items straight away, resulting in higher revenue within a given time. The orange bars in

Figure 6 represent the possible increases of income from the adoption of the sorting unit when compared to the as-is case.

However, several sources of variability can affect the final throughput. When considering a constant input rate to the facility, the resulting average throughput will vary within a certain range because of the variabilityin operating conditions. For instance, average throughput of the as-is system varies according to the variability of the service time of operators and their available work time. Average throughput of the sole sorting unit varies according to the availability of the equipment.

Such variability is expressed by the dotted lines in

Figure 6 and should always be a matter for discussion when evaluating the robustness of the results from the economic assessment. Because the income is the result of the amount of product types multiplied by the selling price, the variability of the income reflects the same sources of variability depicted in

Figure 6 plus the variability of sellingprices themselves. This is an important aspect to be considered within a sensitivity analysis of the income.

Figure 6.

Graphical representation of an estimation of the trend of income from the e-grader demonstrator as the percentage of WEEE items being processed by the sorting unit increases.

Figure 6.

Graphical representation of an estimation of the trend of income from the e-grader demonstrator as the percentage of WEEE items being processed by the sorting unit increases.

Not only can the prices of metals contained in the WEEE vary significantly over time, but also the prices for the same items processed on the same shift might vary according to their condition: in fact, an item suitable for reuse purposes has a higher value than the same item sorted for recycling.

The authors have proposed a way to argue and value sorting unit impacts on throughput and income. Nevertheless, due to the use of confidential data,

Figure 6 will not be numerically fully solved in this study. The application on the demonstrator occurred at a specific percentage of input of WEEE items to the sorting unit and aimed at comparing the economic performance gained when this input “feeds” the as-is system (orange line in

Figure 6) with the e-grader system (blue line in

Figure 6).

As a result, the value of the three KPIs referring to operations management within the facility have been calculated and presented in

Table 3.

Table 3.

Economic assessment: operational outputs.

Table 3.

Economic assessment: operational outputs.

| Indicator | Unit | Mean | Standard Deviation |

|---|

| As-Is | E-Grader | As-Is | E-Grader |

|---|

| Throughput | items/h | 205 | 497 | NA | 40.2 |

| Lead time | workdays | 5 | 3.4 | NA | 0.31 |

| Utilization of e-grader | - | NA | 83% | NA | 6% |

Table 3 presents values of the as-is system from data collection and personal communications in the sorting facility and shall be used as an indication. Values of the e-grader system in

Table 3 stem from five DES runs of the factory model shown in

Figure 5, and each refers to one year of production time.

It can be seen that the throughput of the e-grader case numbers more than doubles the as-is case.

From this result, the question becomes: “is a higher throughput worthwhile when compared to the additional costs of acquisition and operation?” To reply accurately, benefits and costs need to be considered in parallel. In this application on the demonstrator, cost-benefit analysis must capture the differences in performance figuring when comparing the e-grader and as-is systems, because the latter represents a baseline. The gross-profit-margin KPI [

43] has been selected to this end. The formula is given by (1):

Revenue is the total amount of income generated by primary operations, which in this case coincides with recording and sorting, and the cost of goods sold (COGS) includes all expenses of purchasing and processing goods to be sold. Gross profit margin is used to compare a company’s current state to its past performance or with competitor performance, especially in markets where the price of goods can fluctuate significantly. This was therefore considered suitable for the demonstrator in this case. Equation (1) shows the gross profit margin is the percentage of revenue remaining after the COGS, as defined in [

44].

COGS for this demonstrator is expressed by Equation (2):

For the application on this demonstrator, the four costs eligible to be calculated by Equation (2) are those spent solely on operational activities and directly linkable to the processing of WEEE items (storing included). Under the hypothesis of using the e-grader as a product service, the sorting service cost in Equation (2) refers to the fee to be paid for its use.

Table 4 shows results from the simulation experiments.

Table 4.

Economic assessment: economic outputs. Components of the gross profit margin. Values are averaged over one year of production time.

Table 4.

Economic assessment: economic outputs. Components of the gross profit margin. Values are averaged over one year of production time.

| Indicator | Unit | Mean |

|---|

| As-is | E-Grader |

|---|

| Electricity costs | USD/year | 3 | 14 |

| Labor cost | USD/year | 138,847 | 138,847 |

| Inventory holding cost | USD/year | 2065 | 588 |

| Sorting service cost | USD/year | | 27,769 |

| Cost of goods sold | USD/year | 140,915 | 167,219 |

| Revenues | USD/year | 885,061 | 9,790,113 |

| Gross profit margin | USD/item | 0.84 | 0.98 |

Table 3 and

Table 4 report how the modelled e-grader system presented a 19% increase of COGS counterbalanced by more than a double throughput rate, when compared to the as-is case. Ultimately, the case demonstrated represented an increase of the gross profit margin by 17%.

Revenues were calculated on the basis of the yearly throughput, the selling prices of each WEEE item within the input mix and the percentages of each WEEE item within the input mix. These percentages were retrieved from Swedish recycling of WEEE data and were normalized afterwards.

Moreover, a 35% selling price free of hazardous items was considered within the WEEE input mix. Note that this case was simplified, and many hidden costs were not captured by the evaluation illustrated above. This could make the gross profit margin lower within a short timeframe.

In addition to this, evaluating the economic impact from a new technology or piece of equipment requires more than calculating variations of profit margins. Investment evaluation methods help stakeholders see the bigger picture and analyze impacts with a longer perspective. The ROI was proposed for such a purpose [

44]. The ROI formula is given by Equation (3):

Gain from the investment results from additional revenues and from the value of the benefits brought by the sorting unit. These benefits can be of a tangible or intangible nature. The following benefits have been identified in the case of the e-grader demonstrator:

improved facility scheduling thanks to the analysis of statistics,

social benefits for operators (reduced health hazards, more fulfilling work tasks),

economic and environmental benefits for downstream operations due to more accurate sorting,

improvement of product knowledge leading to a fairer price for the WEEE items.

Losses from the investment are the result of avoidable costs. Avoidable costs are expenses that can be avoided if a decision is made to alter the course of a project or business. They can also be calculated from

Table 4. Nevertheless, other monetary losses have to be estimated and considered. The following additional losses have been identified:

installation and maintenance costs of the equipment,

training costs for operators,

productivity losses for the start-up phase.

An arbitrary estimation of the value of benefits and costs being listed above is reported in

Table 5 over a horizon of five years. This estimation has been reached in accordance with a life-cycle thinking approach. This means that the values of this estimation represent the value of the economic, natural and social capital affected by the introduction of the e-grader. They refer not only to the facility being analyzed, but to the whole electronics supply chain.

Table 5.

Estimated benefits and additional costs from the installation and use of the e-grader. Values are in million US dollars (MUSD).

Table 5.

Estimated benefits and additional costs from the installation and use of the e-grader. Values are in million US dollars (MUSD).

| Estimated Value (MUSD) | Worst Case (WC) | Expected | Best Case (BC) |

|---|

| Benefits | 6 | 9 | 15 |

| Additional costs | 4 | 2 | 1 |

By coupling the values from

Table 5 with the revenues and costs from

Table 4, the values of ROI over a five-year evaluation period have been calculated for each scenario. The results are the following:

the estimated ROI is equal to 96%,

the worst case (WC)-ROI is equal to 91%,

the best case (BC)-ROI is equal to 98%.

Another increasingly common KPI, often due to increased kWh price, is the electricity cost. This cost is uniquely linkable to the usage of the e-grader and other equipment for WEEE sorting.

Electricity cost also correlates with environmental KPIs for the e-grader demonstrator due to the environmental impact from electricity usage.

5.2.2. Setting Environmental Criteria on the Demonstrator

Following a life-cycle thinking approach, two different components of environmental impact can be considered for a facility using the proposed e-grader:

- (1)

the impact from the production of the sorting unit (including the sorting unit’s bill of materials),

- (2)

the impact from the use phase of the sorter within the facility.

The second component does not have any particular relevance in the big picture of the environmental impact, which is mostly determined by its first component. In fact, the energy consumption from the use of the new sorting unit is produced by the electricity spent to run the electronic equipment and the conveyor belt. They demand low power in comparison to the power demanded by the technical building services (TBS) of a facility, such as cooling and ventilation.

With a hypothesis of 50% utilization of the conveyor for the as-is case and considering the 83% utilization for the e-grader demonstrator, average values of electricity consumption per item and CO

2 emissions per item are calculated and presented in

Table 6.

Table 6.

Electric energy consumptions and emissions per item being sorted.

Table 6.

Electric energy consumptions and emissions per item being sorted.

| Value | Unit | As-Is | E-Grader |

|---|

| Electricity consumption per item | kWh/item | 0.001 | 0.950 |

| CO2 emissions per item | kg/item | 0.0000065 | 0.009 |

The energy consumption for the e-grader demonstrator is 1333-times larger than the as-is case.

Nevertheless, the absolute amount of energy and emissions caused by sorting activities is relatively small if compared to the energy spent by TBS. An energy consumption of 250 MWh/month from TBS can be speculated and compared to an energy consumption of 45 MWh/month from the e-grader’s use phase (at the production rate being calculated).

An LCA analysis as defined from the standard ISO14044:2006 [

28] has been selected, because it fits well with the purpose of the decision support methodology in the evaluation of the environmental sustainability’s impact. The functional unit of the LCA is one unit of e-grader, and the goal of the LCA is to assess the environmental impact caused by the building of each component constituting the bill of material of the e-grader. The stages included in the analysis are raw material extraction and manufacturing of components (cradle-to-gate scope). The geographical system boundaries are global, and impacts from transportation have been included.

The LCA has been performed according to the impact assessment method of ReCiPe midpoint according to the hierarchist (H) perspective [

45].

Table 7 shows the main outputs from the LCA analysis.

Table 7.

LCIA ReCiPe midpoint (H) applied to the demonstrator. Characterization factors related to toxicity are expressed through the reference unit kg 1.4-dichlorobenzene equivalent (kg 1.4-DB eq).

Table 7.

LCIA ReCiPe midpoint (H) applied to the demonstrator. Characterization factors related to toxicity are expressed through the reference unit kg 1.4-dichlorobenzene equivalent (kg 1.4-DB eq).

| Life Cycle Impact Assessment (LCIA) Category | Reference Unit | Value |

|---|

| Climate change | kg CO2 eq | 9,039.502 |

| Fossil depletion | kg oil eq | 2,182.532 |

| Freshwater ecotoxicity | kg 1.4-DB eq | 0.193 |

| Freshwater eutrophication | kg P eq | 10,095.415 |

| Human toxicity | kg 1.4-DB eq | 706.066 |

| Metal depletion | kg Fe eq | 6,296.526 |

| Terrestrial ecotoxicity | kg 1.4-DB eq | 0.893 |

| Water depletion | m3 | 43,988.726 |

The indicators shown in

Table 7 represent a sub-set of the whole set of the impact categories included by the ReCiPe midpoint (H). The authors selected those indicators that were deemed most interesting for assessment with respect to the type of functional unit at issue. This choice also comes from discussions with the engineers of the company using the demonstrator. At this stage, these figures cannot be compared to any other type of technology for e-waste sorting, but can still be used as a baseline for future environmental analyses, which may be orientated toward reducing the impact in specific areas. Comments on the implications of the absolute values of

Table 6 and

Table 7 are to be performed by environmental engineers, as this exceeds the scope of this study. It is possible to argue that at this stage of the technology development, a reduction in environmental burdens or an increase in environmental benefits from the e-grader life cycle can be pursued. First, the e-grader might cause less environmental impact than that reported in the LCA analysis by two means: the use of materials that cause less “embedded” resource consumptions and emissions or less component weight. Moreover, if the components are acquired from local suppliers, then the impact from transporting this equipment from the vendor to the user will be reduced.

In conclusion, the more the WEEE input stream, that is sorted by the sorting unit, contains reusable items, the more the benefits from using the sorting unit for grading purposes increase when compared to the value provided by grading performed by operators (because in this case, uniformity of grading criteria is not guaranteed).

5.2.3. Reporting Social Considerations on the Demonstrator

The results from the social sustainability assessment within the system boundaries of the sorting facility have been reported by Taghavi

et al. in [

30], to which the authors of this paper contributed.

Taghavi

et al. used an established framework based on social sustainability indicators in order to assess the social implications for facility operators from the introduction of the e-grader within the sorting facility. These indicators range from labor codes of conduct (e.g., occupational health and safety), personal development, work design (e.g., participation), work-life balance, employee turnover and job security. Literature studies, on-site observations, semi- and un-structured interviews were used in order to collect initial data for the study. A structured interview with a company representative was carried out using the framework as a question guide. The results from [

30] showed that an overall benefit from the use of the e-grader exists for operators, because it may support some proactive aspects of social sustainability, such as competence development. Some additional conditions, which the sorting technology itself does not provide, need to be secured by the organization in order to ensure a socially-sustainable implementation:

Education and training must be provided to employees,

Workers must be made aware that they have new responsibilities.

These two conditions have been recognized as key to having employees willing to use the e-grader and an important contribution to a positive work environment.

Nevertheless, trade-offs between the number of job opportunities and meaningful work content must be managed by companies.

A stakeholder map was drawn to capture the three sustainability assessments from a life-cycle perspective. The influences occurring amongst the stakeholders of the electronics life cycle following the introduction of the e-grader are shown in

Figure 7. It summarizes the relationships between system boundaries of the different assessments being performed and the main stakeholders whose activities affect the use or will be affected by the use of the e-grader demonstrator.

Figure 7.

Stakeholder map: influences among stakeholders.

Figure 7.

Stakeholder map: influences among stakeholders.

In

Figure 7, connections represented by arrows were drawn according to the expertise of the authors and the outcome from discussions held with experts over the CIRP (College International pour la Recherche en Productique) Life Cycle Engineering Conference 2015 [

12]. Grey arrows represent influences acting within the e-waste facility, whereas orange arrows represent influences acting outside the e-waste facility, which may or may not affect its activities. The width of the arrows aims at qualitatively representing the strength of the influence from one actor towards another. From

Figure 7, two findings are extracted:

Operations carried out by recyclers, if connected to informal e-waste treatment activities, cause huge damage to the communities of developing countries affected by illegal e-waste dumping. More accurate sorting and higher reuse initiatives can indirectly reduce the amount of e-waste otherwise intended for informal e-waste recycling.

Policy makers can incentivize the adoption of the e-grader unit within sorting and recycling centers through several means, for instance monetary incentives (e.g., tax reductions).

From the results of the economic, environmental and social assessment and from the considerations being drawn from the stakeholder map, it can be concluded that the adoption of the e-grader in the facility used for the demonstrator will make it more economic and socially sustainable in comparison with the current state of the facility. Environmental sustainability performances of the facility grow worse when compared to the as-is state, when considering the system boundaries of the sorting facility.

However, this does not hold anymore when the system boundaries of the analysis are expanded and embrace the whole electronics supply chain, as the cost-benefit analysis showed. Therefore, it can be argued that with the introduction of the e-grader, to that facility, and later on within the market, positive impacts on sustainability’s triple-bottom line will ripple throughout the electronics supply chain.