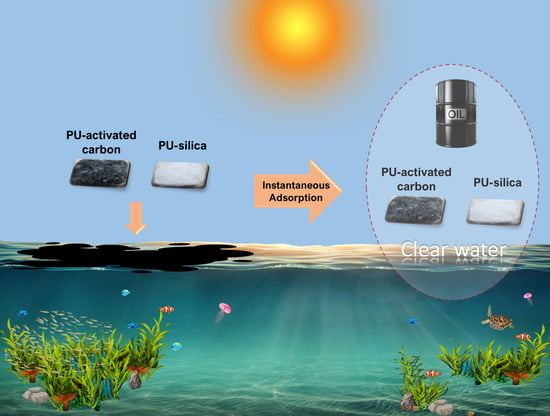

Efficient and Fast Removal of Oils from Water Surfaces via Highly Oleophilic Polyurethane Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Synthesis of Polyurethane 1

2.2.1. Prepolymer Synthesis

2.2.2. Chain Extension

2.3. Preparation of Composites 2 and 3

2.4. Adsorption Capacity Test in Oil Phase

2.5. Adsorption Capacity Test in Oil/Fresh Water System

2.6. Adsorption Capacity Test in Oil/Sea Water System

2.7. Adsorption Isotherms

2.8. FT-IR and SEM Characterization

3. Results and Discussion

3.1. Characterization of the Materials Used in this Study

3.1.1. FT-IR Spectra

3.1.2. SEM Analysis

3.2. Regeneration and Reuse in Diesel

3.3. Adsorption Capacity Using Different Oil Phases

3.4. Effect of Initial Concentration in Diesel/Fresh Water System

3.5. Adsorption Isotherms in Diesel/Fresh Water System

3.6. Adsorption Capacity in Diesel/Seawater System

3.7. Video Recording

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Garcia, M.R.; Cattani, A.P.; Lana, P.C.; Figueira, R.C.S.; Martins, C.C. Petroleum biomarkers as tracers of low-level chronic oil contamination of coastal environments: A systematic approach in a subtropical mangrove. Environ. Pollut. 2019, 249, 1060–1070. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, Z.; Lee, K.; Owens, E.; Boufadel, M.C.; An, C.; Taylor, E. Decision support tools for oil spill response (OSR-DSTs): Approaches, challenges, and future research perspectives. Mar. Pollut. Bull. 2021, 167, 112313–112328. [Google Scholar] [CrossRef]

- Gizatullin, B.; Papmahl, E.; Mattea, C.; Stapf, S. Quantifying Crude Oil Contamination in Sand and Soil by EPR Spectroscopy. Appl. Magn. Reson. 2021, 52, 633–648. [Google Scholar] [CrossRef]

- Naz, S.; Iqbal, M.F.; Mahmood, I.; Allam, M. Marine oil spill detection using Synthetic Aperture Radar over Indian Ocean. Mar. Pollut. Bull. 2021, 162, 111921–111943. [Google Scholar] [CrossRef] [PubMed]

- Xiaoju, N.; Tongqian, Z.; Yanyan, S. Fossil fuel carbon contamination impacts soil organic carbon estimation in cropland. Catena 2021, 196, 104889–104898. [Google Scholar]

- Lim, Z.S.; Wong, R.R.; Wong, C.-Y.; Zulkharnain, A.; Shaharuddin, N.A.; Ahmad, S.A. Bibliometric Analysis of Research on Diesel Pollution in Antarctica and a Review on Remediation Techniques. Appl. Sci. 2021, 11, 1123. [Google Scholar] [CrossRef]

- Zahri, K.N.M.; Zulkharnian, A.; Sabri, S.; Gomez-Fuentes, C.; Ahmad, S.A. Research Trends of Biodegradation of Cooking Oil in Antarctica from 2001 to 2021: A Bibliometric Analysis Based on the Scopus Database. Int. J. Environ. Res. Public Health 2021, 18, 2050. [Google Scholar] [CrossRef]

- Sun, K.; Song, Y.; He, F.; Jing, M.; Tang, J.; Liu, R. A review of human and animals exposure to polycyclic aromatic hydrocarbons: Health risk and adverse effects, photo-induced toxicity. Sci. Total Environ. 2021, 773, 145403–145421. [Google Scholar] [CrossRef]

- Almeida, K.A.; Garcia, E.M.; Penteado, J.O.; Tavella, R.A.; Fernandes, C.L.F.; Ramires, P.F.; Junior, O.V.R.; Muccillo-Baisch, A.L.; Mathias, M.L.; Dias, D.; et al. Multimarker approach to assess the exposure of the wild rodent Calomys laucha to a simulated crude oil spill. Environ. Sci. Pollut. Res. 2021, 28, 2236–2244. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Ren, H.; Li, X.; Chen, H.; Ju, Z.; Xiong, D. Sex-Specific Differences in the Toxic Effects of Heavy Fuel Oil on Sea Urchin (Strongylocentrotus intermedius). Int. J. Environ. Res. Public Health 2021, 18, 499. [Google Scholar] [CrossRef] [PubMed]

- Encinar, J.M.; Nogales-Delgado, S.; Sanchez, N.; Gonzalez, J.F. Biolubricants from Rapeseed and Castor Oil Transesterification by Using Titanium Isopropoxide as a Catalyst: Production and Characterization. Catalysts 2020, 10, 366. [Google Scholar] [CrossRef] [Green Version]

- Tsakona, S.; Papadaki, A.; Kopsahelis, N.; Kachrimanidou, V.; Papanikolaou, S.; Koutinas, A. Development of a Circular Oriented Bioprocess for Microbial Oil Production Using Diversified Mixed Confectionery Side-Streams. Foods 2019, 8, 300. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bhardwaj, N.; Bhaskarwar, A.N. A review on sorbent devices for oil-spill control. Environ. Pollut. 2018, 243, 1758–1771. [Google Scholar] [CrossRef]

- Shah, M.U.H.; Moniruzzaman, M.; Sivapragasam, M.; Talukder, M.M.R.; Yusup, S.B.; Goto, M. A binary mixture of a biosurfactant and an ionic liquid surfactant as a green dispersant for oil spill remediation. J. Mol. Liq. 2019, 280, 111–119. [Google Scholar] [CrossRef]

- Rojas-Alva, U.; Andersen, B.S.; Jomaas, G. Chemical herding of weathered crude oils for in-situ burning. J. Environ. Manag. 2019, 250, 109470–109480. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, D.C.; Bui, T.T.; Cho, Y.B.; Kim, Y.S. Highly Hydrophobic Polydimethylsiloxane-Coated Expanded Vermiculite Sorbents for Selective Oil Removal from Water. Nanomaterials 2021, 11, 367. [Google Scholar] [CrossRef]

- Piekutin, J. The Identification of Fouling in Reverse Osmosis in the Treatment of Water with Petroleum Substances. Water 2021, 13, 1092. [Google Scholar] [CrossRef]

- Li, J.; Xu, C.; Zhang, Y.; Tang, X.; Qi, W.; Wang, Q. Gravity-directed separation of both immiscible and emulsified oil/water mixtures utilizing coconut shell layer. J. Colloid Interface Sci. 2018, 511, 233–242. [Google Scholar] [CrossRef]

- Bian, Y.; Ge, Z.; Albano, C.; Lobo, F.L.; Ren, Z.J. Oily bilge water treatment using DC/AC powered electrocoagulation. Environ. Sci. Water Res. Technol. 2019, 5, 1654–1660. [Google Scholar] [CrossRef]

- Mirshafiee, A.; Rezaee, A.; Mamoory, R.S. A clean production process for edible oil removal from wastewater using an electroflotation with horizontal arrangement of mesh electrodes. J. Clean. Prod. 2018, 198, 71–79. [Google Scholar] [CrossRef]

- Della Pina, C.; De Gregorio, M.A.; Dellavedova, P.; Falletta, E. Polyanilines as New Sorbents for Hydrocarbons Removal from Aqueous Solutions. Materials 2020, 13, 2161. [Google Scholar] [CrossRef] [PubMed]

- Izevbekhai, O.U.; Gitari, W.M.; Tavengwa, N.T.; Ayinde, W.B.; Mudzielwana, R. Response Surface Optimization of Oil Removal Using Synthesized Polypyrrole-Silica Polymer Composite. Molecules 2020, 25, 4628. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.-J.; Yuen, A.C.Y.; Li, A.; Lin, B.; Chen, T.B.Y.; Yang, W.; Lu, H.-D.; Yeoh, G.H. Recent progress in bio-based aerogel absorbents for oil/water separation. Cellulose 2019, 26, 6449–6476. [Google Scholar] [CrossRef]

- Chen, X.; Xu, R.; Xu, Y.; Hu, H.; Pan, S.; Pan, H. Natural adsorbent based on sawdust for removing impurities in waste lubricants. J. Hazard. Mater. 2018, 350, 38–45. [Google Scholar] [CrossRef] [PubMed]

- Navarathna, C.M.; Dewage, N.B.; Keeton, C.; Pennisson, J.; Henderson, R.; Lashley, B.; Zhang, X.; Hassan, E.B.; Perez, F.; Mohan, D.; et al. Biochar Adsorbents with Enhanced Hydrophobicity for Oil Spill Removal. ACS Appl. Mater. Interfaces 2020, 12, 9248–9260. [Google Scholar] [CrossRef]

- Sabzehmeidani, M.M.; Mahnaee, S.; Ghaedi, M.; Heidari, H.; Roy, V.A.L. Carbon based materials: A review of adsorbents for inorganic and organic compounds. Mater. Adv. 2021, 2, 598–627. [Google Scholar] [CrossRef]

- Gu, J.; Fan, H.; Li, C.; Caro, J.; Meng, H. Robust Superhydrophobic/Superoleophilic Wrinkled Microspherical MOF@rGO Composites for Efficient Oil–Water Separation. Angew. Chem. Int. Ed. 2019, 58, 5297–5301. [Google Scholar] [CrossRef]

- Dalapati, R.; Nandi, S.; Gogoi, C.; Shome, A.; Biswas, S. Metal−Organic Framework (MOF) Derived Recyclable, Superhydrophobic Composite of Cotton Fabrics for the Facile Removal of Oil Spills. ACS Appl. Mater. Interfaces 2021, 13, 8563–8573. [Google Scholar] [CrossRef]

- Saleh, T.A.; Baig, N.; Alghunaimi, F.I.; Aljuryyed, N.W. A flexible biomimetic superhydrophobic and superoleophilic 3D macroporous polymer-based robust network for the efficient separation of oil-contaminated water. RSC Adv. 2020, 10, 5088–5097. [Google Scholar] [CrossRef] [Green Version]

- Zulfiqar, M.; Lee, S.Y.; Mafiz, A.A.; Kahar, N.A.M.A.; Johari, K.; Rabat, N.E. Efficient Removal of Pb(II) from Aqueous Solutions by Using Oil Palm Bio-Waste/MWCNTs Reinforced PVA Hydrogel Composites: Kinetic, Isotherm and Thermodynamic Modeling. Polymers 2020, 12, 430. [Google Scholar] [CrossRef] [Green Version]

- Zango, Z.U.; Sambudi, N.S.; Jumbri, K.; Ramli, A.; Bakar, N.H.H.A.; Saad, B.; Rozaini, M.N.H.; Isiyaka, H.A.; Osman, A.M.; Sulieman, A. An Overview and Evaluation of Highly Porous Adsorbent Materials for Polycyclic Aromatic Hydrocarbons and Phenols Removal from Wastewater. Water 2020, 12, 2921. [Google Scholar] [CrossRef]

- Yu, P.; Wang, X.; Zhang, K.; Wu, M.; Wu, Q.; Liu, J.; Yang, J.; Zhang, J. Continuous purification of simulated wastewater based on rice straw composites for oil/water separation and removal of heavy metal ions. Cellulose 2020, 27, 5223–5239. [Google Scholar] [CrossRef]

- Sittinum, A.; Pisitsak, P.; Ummartyotin, S. Improving the oil sorption capability of porous polyurethane composites by the incorporation of cellulose fibers extracted from water hyacinth. Compos. Commun. 2020, 20, 100351–100356. [Google Scholar] [CrossRef]

- Santamaria-Echart, A.; Fernandes, I.; Barreiro, F.; Corcuera, M.A.; Eceiza, A. Advances in Waterborne Polyurethane and Polyurethane-Urea Dispersions and Their Eco-friendly Derivatives: A Review. Polymers 2021, 13, 409. [Google Scholar] [CrossRef] [PubMed]

- Luo, Q.; Chen, J.; Gnanasekar, P.; Ma, X.; Qin, D.; Na, H.; Zhu, J.; Yan, N. A facile preparation strategy of polycaprolactone (PCL)-based biodegradable polyurethane elastomer with a highly efficient shape memory effect. New J. Chem. 2020, 44, 658–662. [Google Scholar] [CrossRef]

- Wang, X.-Z.; Lu, M.-S.; Zeng, J.-B.; Weng, Y.; Li, Y.-D. Malleable and thermally recyclable polyurethane foam. Green Chem. 2021, 23, 307–313. [Google Scholar] [CrossRef]

- Hai, T.A.P.; Neelakantan, N.; Tessman, M.; Sherman, S.D.; Griffin, G.; Pomeroy, R.; Mayfield, S.P.; Burkart, M.D. Flexible polyurethanes, renewable fuels, and flavorings from a microalgae oil waste stream. Green Chem. 2020, 22, 3088–3094. [Google Scholar]

- Mudri, N.H.; Abdullah, L.C.; Aung, M.M.; Salleh, M.Z.; Biak, D.R.A.; Rayung, M. Comparative Study of Aromatic and Cycloaliphatic Isocyanate E_ects on Physico-Chemical Properties of Bio-Based Polyurethane Acrylate Coatings. Polymers 2020, 12, 1494. [Google Scholar] [CrossRef] [PubMed]

- Černá, T.; Pražanová, K.; Beneš, H.; Titov, I.; Klubalová, K.; Filipová, A.; Klusoň, P.; Cajthaml, T. Polycyclic aromatic hydrocarbon accumulation in aged and unaged polyurethane microplastics in contaminated soil. Sci. Total Environ. 2021, 770, 145254–145261. [Google Scholar] [CrossRef] [PubMed]

- Maiuolo, L.; Olivito, F.; Ponte, F.; Algieri, V.; Tallarida, M.A.; Tursi, A.; Chidichimo, G.; Sicilia, E.; De Nino, A. Novel Catalytic Two-Step Process for Preparation of Rigid Polyurethane Foams: Synthesis, Mechanism and Computational Studies. React. Chem. Eng. 2021, 6, 1238–1245. [Google Scholar] [CrossRef]

- Beneš, H.; Vlčková, V.; Paruzel, A.; Trhlíková, O.; Chalupa, J.; Kanizsová, L.; Skleničková, K.; Halecký, M. Multifunctional and fully aliphatic biodegradable polyurethane foam as porous biomass carrier for biofiltration. Polym. Degrad. Stab. 2020, 176, 109156–109166. [Google Scholar] [CrossRef]

- Olszewski, A.; Kosmela, P.; Mielewczyk-Gryń, A.; Piszczyk, Ł. Bio-Based Polyurethane Composites and Hybrid Composites Containing a New Type of Bio-Polyol and Addition of Natural and Synthetic Fibers. Materials 2020, 13, 2028. [Google Scholar] [CrossRef]

- Xie, W.; Yan, F.; Pakdel, E.; Sharp, J.; Liu, D.; Wang, X.; Zhan, S.; Su, L. Natural Melanin/Polyurethane Composites as Highly Efficient Near-Infrared-Photoresponsive Shape Memory Implants. ACS Biomater. Sci. Eng. 2020, 6, 5305–5314. [Google Scholar] [CrossRef]

- Zhou, K.; Gong, K.; Zhou, Q.; Zhao, S.; Guo, H.; Qian, X. Estimating the feasibility of using industrial solid wastes as raw material for polyurethane composites with low fire hazards. J. Clean. Prod. 2020, 257, 120606–120615. [Google Scholar] [CrossRef]

- Vassalini, I.; Gjipalaj, J.; Crespi, S.; Gianoncelli, A.; Mella, M.; Ferroni, M.; Alessandri, I. Alginate-Derived Active Blend Enhances Adsorption and Photocatalytic Removal of Organic Pollutants in Water. Adv. Sustain. Syst. 2020, 4, 1900112–1900122. [Google Scholar] [CrossRef]

- Bravo, I.; Figueroa, F.; Swasy, M.I.; Attia, M.F.; Ateia, M.; Encalada, D.; Vizuete, K.; Galeas, S.; Guerrero, V.H.; Debut, A.; et al. particles capture aldehyde VOC pollutants. RSC Adv. 2020, 10, 7967–7975. [Google Scholar] [CrossRef]

- Spiridon, I.; Anghel, N.; Dinu, M.V.; Vlad, S.; Bele, A.; Ciubotaru, B.I.; Verestiuc, L.; Pamfil, D. Development and Performance of Bioactive Compounds-Loaded Cellulose/Collagen/Polyurethane Materials. Polymers 2020, 12, 1191. [Google Scholar] [CrossRef] [PubMed]

- Członka, S.; Kairytė, A.; Miedzińka, K.; Strąkowska, A. Polyurethane Hybrid Composites Reinforced with Lavender Residue Functionalized with Kaolinite and Hydroxyapatite. Materials 2021, 14, 415. [Google Scholar] [CrossRef] [PubMed]

- El Bouraie, M.; Abdelghany, A. Sorption Features of Polyurethane Foam Functionalized with Salicylate for Chlorpyrifos: Equilibrium, Kinetic Models and Thermodynamic Studies. Polymers 2020, 12, 2036. [Google Scholar] [CrossRef]

- Hernández-Martínez, A.R.; Molina, G.A.; Jiménez-Hernández, L.F.; Oskam, A.H.; Fonseca, G.; Estevez, M. Evaluation of Inulin Replacing Chitosan in a Polyurethane/Polysaccharide Material for Pb2+ Removal. Molecules 2017, 22, 2093. [Google Scholar] [CrossRef] [Green Version]

- Bidgoli, H.; Mortazavi, Y.; Khodadadi, A.A. A functionalized nano-structured cellulosic sorbent aerogel for oil spillcleanup: Synthesis and characterization. J. Hazard. Mater. 2019, 366, 229–239. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Liu, L.; Yang, F. Hydrophobic modification of polyurethane foam for oil spill cleanup. Mar. Pollut. Bull. 2012, 64, 1648–1653. [Google Scholar] [CrossRef] [PubMed]

- Hassanajili, S.; Sajedi, M.T. Fumed silica/polyurethane nanocomposites: Effect of silica concentration and its surface modification on rheology and mechanical properties. Iran. Polym. J. 2016, 25, 697–710. [Google Scholar] [CrossRef]

- Keshavarz, A.; Zilouei, H.; Abdolmaleki, A.; Asadinezhad, A.; Nikkhah, A.A. Impregnation of polyurethane foam with activated carbon for enhancing oil removal from water. Int. J. Environ. Sci. Technol. 2016, 13, 699–710. [Google Scholar] [CrossRef] [Green Version]

- Keshavarz, A.; Zilouei, H.; Abdolmaleki, A.; Asadinezhad, A. Enhancing oil removal from water by immobilizing multi-wall carbon nanotubes on the surface of polyurethane foam. J. Environ. Manag. 2015, 157, 279–286. [Google Scholar] [CrossRef]

- Nikkhah, A.A.; Zilouei, H.; Asadinezhad, A.; Keshavarz, A. Removal of oil from water using polyurethane foam modified with nanoclay. Chem. Eng. J. 2015, 262, 278–285. [Google Scholar] [CrossRef]

- Martins, L.S.; Zanini, N.C.; Maia, L.S.; Souza, A.G.; Barbosa, R.F.S.; Rosa, D.S.; Mulinari, D.R. Crude oil and S500 diesel removal from seawater by polyurethane composites reinforced with palm fiber residues. Chemosphere 2021, 267, 129288–129300. [Google Scholar] [CrossRef]

- Zhang, T.; Xiao, C.; Zhao, J.; Liu, X.; Huang, Y.; Ji, D. Graphite powder coated polyurethane sponge hollow tube as a high-efficiency and cost-effective oil-removal materials for continuous oil collection from water surface. J. Appl. Polym. Sci. 2020, 137, 48921. [Google Scholar] [CrossRef]

- Santosa, O.S.H.; Coelho da Silva, M.; Silva, V.R.; Mussel, W.N.; Yoshida, M.I. Polyurethane foam impregnated with lignin as a filler for the removalof crude oil from contaminated water. J. Hazard. Mater. 2017, 324, 406–413. [Google Scholar] [CrossRef]

- De Gisi, S.; Lofrano, G.; Grassi, M.; Notarnicola, M. Characteristics and adsorption capacities of low-cost sorbents for waste water treatment: A review. Sustain. Mater. Technol. 2016, 9, 10–40. [Google Scholar]

- Xiea, W.; Shiub, W.; Mackay, D. A review of the effect of salts on the solubility of organic compounds in seawater. Mar. Environ. Res. 1997, 44, 429–444. [Google Scholar] [CrossRef]

- Kumari, S.; Chauhan, G.S.; Ahn, J.H. Novel cellulose nanowhiskers-based polyurethane foam for rapid and persistent removal of methylene blue from its aqueous solutions. Chem. Eng. J. 2016, 304, 728–736. [Google Scholar] [CrossRef]

| Composite | Oil | Adsorption Capacity (g/g) | Preparation | Reference |

|---|---|---|---|---|

| PU-MWCNT | Crude oil | 23.0 | Chemical functionalization | [55] |

| PU-nanoclay | Crude oil | 21.5 | Inclusion in reaction mixture | [56] |

| PU-palm fiber | Diesel | 28.9 | Inclusion in reaction mixture | [57] |

| Crude oil | 19.3 | |||

| PU-graphite | Diesel | 20.0 | Surface coating | [58] |

| Motor oil | 26.0 | |||

| PU-lignin | Crude oil | 28.0 | Chemical functionalization | [59] |

| PU-Si 2 | Diesel | 25.5 | Surface coating | Our study |

| Gasoline | 24.0 | |||

| Motor oil | 38.5 | |||

| PU-ac 3 | Diesel | 32.5 | Surface coating | Our study |

| Gasoline | 32.0 | |||

| Motor oil | 42.5 |

| Isotherm | Parameter | PU | PU-Si | PU-ac |

|---|---|---|---|---|

| Langmuir | KL | 1.6 | 0.74 | 1.13 |

| qm | 15.63 | 26.95 | 29.50 | |

| R2 | 0.997 | 0.999 | 0.998 | |

| Freundlich | KF | 2.83 | 3.26 | 3.37 |

| n | 8.18 | 4.91 | 4.47 | |

| R2 | 0.765 | 0.522 | 0.474 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Nino, A.; Olivito, F.; Algieri, V.; Costanzo, P.; Jiritano, A.; Tallarida, M.A.; Maiuolo, L. Efficient and Fast Removal of Oils from Water Surfaces via Highly Oleophilic Polyurethane Composites. Toxics 2021, 9, 186. https://0-doi-org.brum.beds.ac.uk/10.3390/toxics9080186

De Nino A, Olivito F, Algieri V, Costanzo P, Jiritano A, Tallarida MA, Maiuolo L. Efficient and Fast Removal of Oils from Water Surfaces via Highly Oleophilic Polyurethane Composites. Toxics. 2021; 9(8):186. https://0-doi-org.brum.beds.ac.uk/10.3390/toxics9080186

Chicago/Turabian StyleDe Nino, Antonio, Fabrizio Olivito, Vincenzo Algieri, Paola Costanzo, Antonio Jiritano, Matteo Antonio Tallarida, and Loredana Maiuolo. 2021. "Efficient and Fast Removal of Oils from Water Surfaces via Highly Oleophilic Polyurethane Composites" Toxics 9, no. 8: 186. https://0-doi-org.brum.beds.ac.uk/10.3390/toxics9080186