2.1. Mechanics of Welding Distortion

Arc welding uses thermal energy that is converted from electrical energy. Once the molten wire is placed on a base metal, its heat is transferred to the base, and the weld pool cools down, with the base metal undergoing both heating and cooling. The shrinkage of the weld pool is determined by subtracting the tensile plastic strain that is induced by surrounding constraints from the thermal strain during cooling. On the other hand, the shrinkage of the base metal is determined by subtracting the tensile plastic strain that is caused by cooling from the compressive plastic strain induced by surrounding constraints during heating. The constraining effect disappears if the elastic region is removed from the cooled welding joint, and the final contracted strain in the pure plasticity region, known as inherent strain [

18], can be obtained. Physically, the inherent strain corresponds to subtracting the elastic strain from the total strain and it equals the sum of the plastic strain and thermal strain if the strain due to phase transformation is negligible, as in low-carbon steel. As the inherent strain at the welding joint includes plasticity, the plastic region is identical to the region where the inherent strain is distributed, and the inherent strain region can be considered as the plastic region.

Angular distortion occurs by the inconsistency between the location of contraction and the neutral axis of the plate. In this study, we aimed to predict angular distortion under constraints due to a connection to surrounding structures. Therefore, a mathematical model for the contraction of the welding joint was devised and experimentally verified.

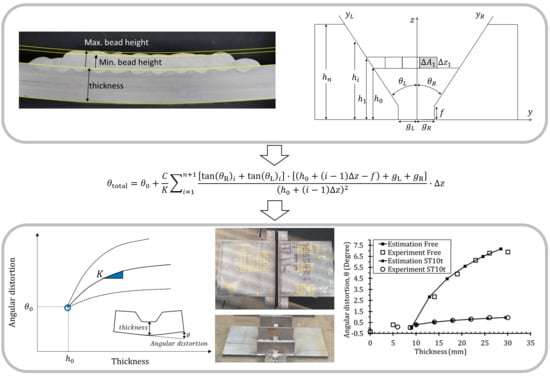

Figure 1 shows the free body diagram of the area where bending occurs due to weld-induced contraction. The figure depicts the force that is caused by contraction in the plastic region, reaction force, and geometrical dimensions. The inherent strain that causes contraction in the bead and base metal is assumed to have a rectangular shape with a uniform distribution. Force

represents the force by contraction,

is its reaction force and

is the reaction moment by self-equilibrium of the plate without any constraint or external force. When the target structure is connected to other structures and both ends are constrained,

is the resulting reaction moment. Thus, the reaction moment that is caused by the equilibrium of force due to the contraction of the welding joint is expressed as the sum of

and

. As we address angular distortion, only the constraints that are caused by the moment in the out-of-plane direction are considered, disregarding the compressive and tensile loads in the in-plane direction. Although the in-plane reaction force at the constraining sides might affect the angular distortion of the welding joint, it is negligible with respect to out-of-plane moment

. If no constraint by surrounding structures exists,

becomes zero, and only the reaction moment by the self-equilibrium,

, should be considered.

From

Figure 1, the equilibrium equations can be expressed, as follows:

The load due to shrinkage and the reaction force against the plastic region beyond the yield strength are in equilibrium. Weighting factor is adopted for the yield strength of the welding joint. The inherent strain that is generated by welding is inhomogeneous in terms of distribution and size due to heat transfer distribution, strain hardening, dilution with welding materials, degree of constraint, and residual stress, but it is higher than the yield strength of the material. Therefore, we introduce the weighting factor to quantify these uncertainties. The ratio of the reaction moment by constraints, , to the pure reaction moment by the plate, , is defined as . When equals 1, the constraints are removed, because becomes zero and, when is above 1, the degree of constraint increases.

Equation (3) can be obtained by calculating Equations (1) and (2) for the elastic and plastic regions.

,

,

,

and

Solving the integral of Equation (3), we obtain

Geometrically, this can be expressed as the angular distortion that is given by

,

.

We assume that the plate is much thicker than the size of the plastic region. Thus,

is much smaller than the square of thickness

and Equation (5) can be expressed as

, which indicates that the angular distortion is proportional to the area of the plastic region and inversely proportional to the square of thickness. The direct relationship between plastic region and angular distortion has been determined in studies on welding and laser forming [

2,

18,

19]. The plasticity of a material is likely to occur at high temperatures between 500 and 800 °C, which produce a sharp stiffness drop. Therefore, the plastic region can be estimated from the distribution of the peak temperature field inside the material during heating and cooling. As we consider a thick plate, the equation of the peak temperature field by the point heat source on the semi-infinite plate is defined, as follows, according to the derivation in [

20]:

,

,

, with

representing the area within an isotherm, because it is the distance from the center of the heat source to a specific temperature. If plasticity occurs at a specific temperature between 500 and 800 °C, the area of plastic region

is proportional to the heat input, according to Equation (7).

The wire melting rate is expressed as the sum of the wire resistance heating and the arc heat, which also originate from electrical energy. Thus, for typical arc welding, the bead area is proportional to the heat input. As the plastic region and bead area are determined by the heat input, the angular distortion can be obtained from the bead area, as follows:

,

.

Equation (8) indicates that the angular distortion by welding is proportional to the bead area and inversely proportional to the square of thickness and degree of constraint only for materials with sufficient thickness when compared to the heated part. Here, the degree of constraint must be 1 or above, and constant C depends on the material properties of the base metal and wire, the wire diameter, and the welding process. This constant includes errors while deriving Equations (1) through (8), and its value can be experimentally obtained through bead-on-plate welding for without the external constraints. In this study, we maintain the same material and welding process to keep the constant C unchanged.

2.2. Bead-on-Plate Welding Experiment

We conducted an experiment of bead-on-plate welding to verify the validity of Equations (1) to (8) while considering various assumptions. Low-carbon steel AH32 was used as the base metal, and E81T1-K2C flux cored wire with 1.2 mm in diameter and meeting the American Welding Society (AWS) Standards was used as welding material. The shielding gas was 100% CO

2. Welding was performed at two trisection lines in a 1500 × 1000 mm specimen with different thicknesses without constraints, as shown in

Figure 2. The thicknesses of the bead-on-plate welding specimen were determined in consideration of the bead-formed thickness generated during the multilayer welding. The width was larger than the length along the welding direction to minimize the influence of longitudinal distortion. The specimen size and measurement method were adopted, as in the previous study [

10]. Constant current and voltage were maintained, but the welding speed was varied to achieve different heat input conditions.

Table 1 lists the experimental conditions.

We performed multi-pass welding up to two layers to increase the measurement accuracy of the bead cross-sectional area and height. Welding was performed twice per condition, and the angular distortion was measured for each pass of the first layer. For angular distortion, the average values were obtained at three points (A1, A2, A3 or B1, B2, B3 in

Figure 2) while using a digital angle gauge. Metal cubes were used to facilitate measurements.

Figure 3 shows the bead cross-section after welding. The bead cross-sectional area stacked on the base metal was obtained by calculating the number of pixels. The maximum and minimum bead heights were obtained by creating curves parallel to the deformed geometry of the base metal, with their average being considered to be the bead height.

Figure 4 shows the measured angular distortion for varying thicknesses of the base metal. In a base metal with constant thickness, the angular distortion linearly increases with the number of passes. As the base metal thickness increases, the angular distortion reduces and, hence, the angular distortion per pass is constant at a given thickness.

Figure 5 shows the measured bead cross-sectional area and square of bead height per pass, according to the heat input. As the heat input increases, the bead area and height proportionally increase. We assumed that the bead heights that were obtained during multilayer welding were the same as those measured in this experiment under the same conditions.

Figure 6 shows the relationship between the ratio of bead area to the square of base metal thickness and angular distortion. The angular distortion increases proportionally to the ratio, but decreases after a threshold, which was found to be approximately 0.375. The threshold seems to occur as the center position of the contracted load becomes closer to the neutral axis. The data above the threshold produce low measurement accuracy of angular distortion due to in-plane shrinkage, and they exhibit nonlinearity [

2,

3]. If the center position of the shrinkage load agrees with the neutral axis, the angular distortion becomes zero, and shrinkage reaches its maximum. Reverse angular distortion might occur if it is located below the neutral axis. The reason is that if the thickness under the beads is not sufficient, the temperature gradient can be reversed, depending on the ambient cooling conditions. In addition, the reverse distorted shape generated during heating might be maintained until being completely cooled down. Xie et al. [

21] has reported that the distortion direction can be affected by the asymmetry of the cross-sectional profile along the thickness direction and even pores generated by insufficient flow of the molten pool. Consequently, it is almost impossible to quantitatively predict the amount and direction of deformation above the threshold. Therefore, we only address cases in which the distance between the load position and neutral axis is sufficiently long, as assumed in Equation (6). Thus, we used data that were below the threshold (dashed line in

Figure 6). When all of the the welding passes are completed at the same heat input, the third layer or beyond results in welding within this range.

Without external constraint, the calculated value of

in the linear section below the threshold was 4.75 from

Figure 6. Hence, we verified the relationship between bead area and angular distortion in Equation (8). The relationship between heat input, bead area, and angular distortion, as shown in

Figure 5 and

Figure 6, implies that heat input is proportional to plastic area as in Equation (7), which is proportional to angular distortion shown in Equation (6).

2.3. Multilayer Welding Considering Degree of Constraint

We derived the relationship between the bead area and angular distortion through a mechanical approach and experiments, as shown in the previous sections. We also aimed to obtain the analytic solutions for practical butt welding joints. As multilayer welding is a repetitive process, the welding conditions do not notably change across layers and, hence, we assumed a uniform amount of weld deposition. As the accumulation of beads increases the thickness, it complicates distortion across layers. The bead area and thickness for a heat input can be calculated while using the relation that is shown in

Figure 5. Thus, the angular distortion can be predicted if the geometry of the welding joint is known. The total angular distortion at a layer can be obtained from the total bead area, as the angular distortion linearly increases with the number of passes at a given thickness (

Figure 4). Equation (9) is obtained by applying Equation (8) to a V groove welding joint, as shown in

Figure 7.

,

,

,

,

,

,

,

,

.

In Equation (9) with

Figure 7,

and

are the initial angular distortion and initial thickness, respectively. The initial angular distortion is the angle at the initial thickness, and the values should be determined after welding at least two layers. In typical weld groove joints, rather than welding onto the base material, the accumulation of beads (layers) creates the thickness. The angular distortion at the first and second layers cannot be accurately predicted, because the layers belong to conditions above the threshold, as shown in

Figure 6. In addition, some distortions occur during initial setting and fit-up. Hence, the initial thickness and its angular distortion should be considered to include these errors, but the purely predicted angular distortion excludes the initial angular distortion.

Layer number

is zero at the initial angular distortion, and

denotes the total number of layers stacked up to the thickness of the base material. This thickness is obtained by subtracting the initial one from that of the base material and dividing it by the bead height.

was set by adding a layer, as the surface of the final bead layer must be higher than the base metal thickness. The width of a layer,

, represents the length from the left to right bevel surfaces, as shown in

Figure 7. The width can be geometrically obtained from the linear equation of each bevel surface in the

y–z plane. The bead area of layer

is then obtained by multiplying the width by layer height

.

The angular distortion after the initial one can be calculated, as follows:

,

,

,

.

Substituting Equation (10) into Equation (9), the total angular distortion of a V groove can be obtained, as follows:

.

Equation (11) represents the sum of the initial measured angular distortion and the predicted angular distortions at all subsequent layers. Angular distortion decreases as constant

C, root gap, and bevel angle decrease, and the degree of constraint

, initial thickness, and root face increase. The angular distortion during V groove welding depends on geometric parameters, except for two factors, namely, bead height

, which is determined by the heat input (

Figure 5), and constant

, which is experimentally determined (

Figure 6).

Figure 8 shows the angular distortion prediction curves that were obtained from Equation (11). The position of the starting point of the curve and its slope must be determined for a prediction curve to be determined. The starting point is obtained from initial thickness

and initial angular distortion

, whereas the slope is obtained from degree of constraint

, which requires another point after the starting point. In

Figure 8, the initial thicknesses of curves A and B are

x2 and

x1, and their initial angular distortions are

y1 and

y2, respectively. Although curves A and B have different initial angular distortions and thicknesses, they are almost parallel with the initial and final differences in angular distortion being the same. In practice, this results from the distortion by fit-up, presetting, and welding up to the second layer. Curves B and C have the same starting point, but different slopes. The slope of the curve becomes steeper as the degree of constrain reduces and the root gap or bevel angle increases with decreasing root face. Under the same geometry, curve C has a lower degree of constraint

than curve A or B.

In addition, we considered that the angular distortion of each layer reduces the bevel angle. Hence, the amount of deposition decreases at the subsequent layer, which further decreases the angular distortion. The predicted angular distortion and bevel angle at the previous layer must be subtracted to obtain the bevel angle at a layer, as shown in Equation (12). This is used as the bevel angle term in Equation (11).

,

,

,

.

Equation (11) for predicting the angular distortion has three unknown variables, namely,

,

, and

. Initial thickness

and corresponding angular distortion

can be determined from measurements at the desired layer, but at least two layers should be stacked. The degree of constraint

can be obtained by measuring the angular distortion of the additionally accumulated layer after the first measurement (the starting point in

Figure 8). For calculation, we increase

by 0.01 from 1.0 and adopt the value that agrees with the measurement after two or more layers have been accumulated after the first measurement. Alternatively, it can be directly obtained when the angular distortion is known after only one layer is stacked at the first measurement, by using

in Equation (11) and the following expression for

:

Once is determined, it can be used to predict the angular distortion at all subsequent layers. However, must be recalculated following the abovementioned procedure if the constraint condition changes during welding.