Design and Evaluation of Uniform LED Illumination Based on Double Linear Fresnel Lenses

Abstract

:1. Introduction

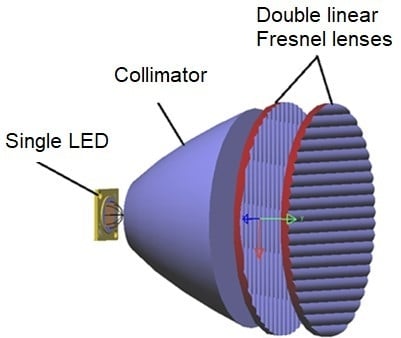

2. Module Design and Simulation

2.1. Module Design

2.2. Simulation: Illumination Performance and Tolerance Analyses

3. Experiment

3.1. Manufacturing Process of Double Fresnel Lenses

3.2. Prototype Test

3.3. Outdoor Test

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Giang, D.T.; La, T.L.; Tien, T.Q.; Duong, P.H.; Tong, Q.C. A simple designed lens for human centric lighting using LEDs. Appl. Sci. 2020, 10, 1–9. [Google Scholar]

- Giang, D.T.; Pham, T.S.; Ngo, Q.M.; Nguyen, V.T.; Tien, T.Q.; Duong, P.H. An Alternative Approach for High Uniformity Distribution of Indoor Lighting LED. IEEE Photonics J. 2020, 12. [Google Scholar] [CrossRef]

- E. Fred Schubert Light-Emitting Diodes, 2nd editio; Cambridge University Press: Cambridge, UK, 2006.

- Ding, Y.; Liu, X.; Zheng, Z.; Gu, P. Freeform LED lens for uniform illumination. Opt. Express 2008, 16, 12958. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, K.; Chen, F.; Liu, Z.; Luo, X.; Liu, S. Design of compact freeform lens for application specific light-emitting diode packaging. Opt. Express 2010, 18, 413. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Benı´tez, P. Simultaneous multiple surface optical design method in three dimensions. Opt. Eng. 2004, 43, 1489. [Google Scholar] [CrossRef]

- Miñano, J.C.; Benítez, P.; Liu, J.; Infante, J.; Chaves, J.; Wang, L. Applications of the SMS method to the design of compact optics. Opt. Model. Des. 2010, 7717, 77170I. [Google Scholar]

- Wang, G.; Wang, L.; Li, F.; Kong, D. Design of optical element combining Fresnel lens with microlens array for uniform light-emitting diode lighting. J. Opt. Soc. Am. A 2012, 29, 1877. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Wei, X.; Zhang, O.; Zhang, X. Research on illumination uniformity of high-power LED array light source. AIP Conf. Proc. 2018, 1971. [Google Scholar] [CrossRef] [Green Version]

- Vu, N.H.; Pham, T.T.; Shin, S. LED uniform illumination using double linear fresnel lenses for energy saving. Energies 2017, 10, 2091. [Google Scholar] [CrossRef] [Green Version]

- Ries, H.; Rabl, A. Edge-ray principle of nonimaging optics. J. Opt. Soc. Am. A 1994, 11, 2627. [Google Scholar] [CrossRef]

- Shimomachi, T. Effect of Night Break Treatment on Growth and Flowering in. Metab. Clin. Exp. 2011, 8521, 303–308. [Google Scholar]

- Lens by LED. Available online: https://www.ledlink-optics.com/lens/ (accessed on 6 March 2020).

- High Speed CNC Milling. Available online: https://www.proxxon.com/en/micromot/27110.php (accessed on 6 March 2020).

- Blalock, T.; Medicus, K.; DeGroote Nelson, J. Fabrication of freeform optics. Opt. Manuf. Test. XI 2015, 9575, 95750H. [Google Scholar]

- BPW 21-Photodiode. Available online: https://www.osram.com/ecat/Metal Can® TO39 Ambient Light Sensor BPW 21/com/en/class_pim_web_catalog_103489/global/prd_pim_device_2219533/ (accessed on 18 April 2020).

- Higuchi, Y. Florigen and anti-florigen: Flowering regulation in horticultural crops. Breed. Sci. 2018, 68, 109–118. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tripathi, S.; Hoang, Q.T.N.; Han, Y.J.; Kim, J. Il Regulation of photomorphogenic development by plant phytochromes. Int. J. Mol. Sci. 2019, 20, 6165. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Design Parameters | |

|---|---|

| Type of LED | COB |

| Type of collimator | TIR |

| Refractive index of the Fresnel lens | 1.49 |

| Thickness of the Fresnel lens | 5 mm |

| Number of grooves of the Fresnel lens | 20 |

| Diameter of the Fresnel lens | 100 mm |

| Parameter | LED with Double Fresnel Lenses | LED with Parabolic Reflector |

|---|---|---|

| Number of stems surveyed Rate of early flowering | 216 4.2% | 207 5.9% |

| Lowest height of the stems | 75 cm | 58 cm |

| Highest height of the stems | 84 cm | 80 cm |

| Average height of the stems | 82 cm | 72 cm |

| Average diameter of the flower | 7.8 cm | 7.3 cm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vu, H.; Kieu, N.M.; Gam, D.T.; Shin, S.; Tien, T.Q.; Vu, N.H. Design and Evaluation of Uniform LED Illumination Based on Double Linear Fresnel Lenses. Appl. Sci. 2020, 10, 3257. https://0-doi-org.brum.beds.ac.uk/10.3390/app10093257

Vu H, Kieu NM, Gam DT, Shin S, Tien TQ, Vu NH. Design and Evaluation of Uniform LED Illumination Based on Double Linear Fresnel Lenses. Applied Sciences. 2020; 10(9):3257. https://0-doi-org.brum.beds.ac.uk/10.3390/app10093257

Chicago/Turabian StyleVu, Hoang, Ngoc Minh Kieu, Do Thi Gam, Seoyong Shin, Tran Quoc Tien, and Ngoc Hai Vu. 2020. "Design and Evaluation of Uniform LED Illumination Based on Double Linear Fresnel Lenses" Applied Sciences 10, no. 9: 3257. https://0-doi-org.brum.beds.ac.uk/10.3390/app10093257