Output Properties of Transparent Submount Packaged FlipChip Light-Emitting Diode Modules

Abstract

:1. Introduction

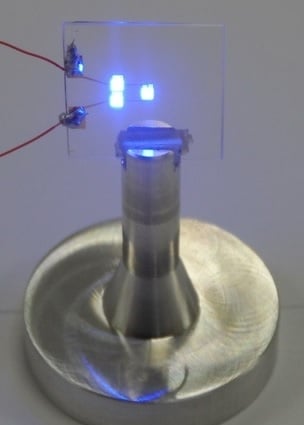

2. Experimental and Simulation

3. Results and Discussions

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chang, L.B.; Yeh, D.H.; Hsieh, L.Z.; Zeng, S.H. Enhanced modulation rate in platinum-diffused resonant-cavity light-emitting diodes. J. Appl. Phys. 2005. [Google Scholar] [CrossRef]

- Leem, Y.-C.; Seo, O.; Jo, Y.-R.; Kim, J.H.; Chun, J.; Kim, B.-J.; Noh, D.Y.; Lim, W.; Kim, Y.-I.; Park, S.-J. Titanium oxide nanotube arrays for high light extraction efficiency of GaN-based vertical light-emitting diodes. Nanoscale 2016, 8, 10138–10144. [Google Scholar] [CrossRef] [PubMed]

- Zhu, P.; Tansu, N. Effect of packing density and packing geometry on light extraction of III-nitride light-emitting diodes with microsphere arrays. Photon. Res. 2015, 3, 184–191. [Google Scholar] [CrossRef]

- Zhu, P.; Tansu, N. Resonant cavity effect optimization of III-nitride thin-film flip-chip light-emitting diodes with microsphere arrays. Appl. Opt. 2015, 54, 6305–6316. [Google Scholar] [CrossRef] [PubMed]

- Zhu, P.; Tan, C.-K.; Sun, W.; Tansu, N. Aspect ratio engineering of micro lens arrays in thin-film flip-chip light-emitting diodes. Appl. Opt. 2015, 54, 10299–10303. [Google Scholar] [CrossRef] [PubMed]

- Tsai, M.Y.; Tang, C.Y.; Yen, C.Y.; Chang, L.B. Bump and under fill effects on thermal behaviors of flip-chip LED packages: Measurement and modeling. IEEE Trans. Device Mater. Reliab. 2014, 14, 161–168. [Google Scholar] [CrossRef]

- Chang, L.B.; Chiang, K.L.; Chang, H.Y.; Jeng, M.J.; Yen, C.Y. Electrostatic reliability characteristics of GaN flip-chip power light-emitting diodes with metal-oxide-silicon submount. IEEE Trans. Electron. Devices 2010, 57, 119–124. [Google Scholar] [CrossRef]

- Chang, L.B.; Shiue, C.C.; Jeng, M.J. The reflectivity enhancement of Ni/Ag/(Ti or Mo)/Au ohmic contact for flip-chip LED application. In Proceedings of the 15th IEEE International Conference on Advanced Thermal, Catania, Italy, 2 October 2007.

- Ju, L.Y.; Chiu, C.H.; Ke, C.C.; Lin, P.C.; Lu, T.C.; Kuo, H.C.; Wang, S.C. Study of the excitation power dependent internal quantum efficiency in InGaN/GaN LEDs grown on patterned sapphire substrate. IEEE J. Sel. Top. Quantum Electron. 2009, 15, 1137–1143. [Google Scholar]

- Fujii, T.; Gao, Y.; Sharma, R.; Hu, E.L.; DenBaars, S.P.; Nakamura, S. Increase in the extraction efficiency of GaN-based light-emitting diodes via surface roughening. Appl. Phys. Lett. 2004, 84, 855–857. [Google Scholar] [CrossRef]

- Lee, S. Optimum design and selection of heat sinks. IEEE Trans. Compon. Packag. Manuf. Technol. 1995, 18, 812–817. [Google Scholar] [CrossRef]

- Mashford, B.S.; Stevenson, M.; Popovic, Z.; Hamilton, C.; Zhou, Z.; Breen, C.; Steckel, J.; Bulovic, V.; Bawendi, M.; Sullivan, S.C.; et al. High-efficiency quantum-dot light-emitting devices with enhanced charge injection. Nat. Photonics 2013, 7, 407–412. [Google Scholar] [CrossRef]

- Arik, M.; Petroski, J.; Weaver, S. Thermal challenges in the future generation solid state lighting applications: Light emitting diodes. Int. Soc. Conf. Ther. Phenom. 2002. [Google Scholar] [CrossRef]

- Chen, S.H.; Tan, C.M.; Tan, E.; Kong, J. Effects of carbon loading on the performance of functionalized carbon nanotube polymer heat sink for ultra high power light-emitting diode. In Proceedings of the 2013 IEEE 5th International on Nanoelectronics Conference, Singapore, 2–4 January 2013; pp. 81–84.

- Pan, C.-C.; Koslow, I.; Sonoda, J.; Ohta, H.; Ha, J.-S.; Nakamura, S.; DenBaars, S.P. Vertical stand transparent light-emitting diode architecture for high-efficiency and high-power light-emitting diodes. Jpn. J. Appl. Phys. 2010. [Google Scholar] [CrossRef]

- Kim, J.Y.; Na, S.I.; Ha, G.Y.; Kwon, M.K.; Park, I.K.; Lim, J.H.; Park, S.J. Thermally stable and highly reflective AgAl alloy for enhancing light extraction efficiency in GaN light-emitting diodes. Appl. Phys. Lett. 2006. [Google Scholar] [CrossRef]

- Peng, W.C.; Wu, Y.C.S. Enhanced performance of an InGaN-GaN light-emitting diode by roughening the undoped-GaN surface and applying a mirror coating to the sapphire substrate. Appl. Phys. Lett. 2006. [Google Scholar] [CrossRef]

- Katona, T.M.; Speck, J.S.; Denbaars, S.P. Effect of the nucleation layer on stress during cantilever epitaxy of GaN on Si (111). Phys. Stat. Sol. 2002, 194, 550–553. [Google Scholar] [CrossRef]

- Krost, A.; Dadgar, A. GaN-based optoelectronics on silicon substrates. Mater. Sci. Eng. B 2002, 93, 77–84. [Google Scholar] [CrossRef]

- Zhang, B.; Liang, H.; Wang, Y.; Feng, Z.; Ng, K.W.; Lau, K.M.J. High-performance III-nitride blue LEDs grown and fabricated on patterned Si substrates. Cryst. Growth 2007, 298, 725–730. [Google Scholar] [CrossRef]

- Dadgar, A.; Clos, R.; Strassburger, G.; Schulze, F.; Veit, P.; Hempel, T.; Bläsing, J.; Krtschil, A.; Daumiller, I.; Kunze, M.; et al. Strains and Stresses in GaN Heteroepitaxy—Sources and Control. Adv. Solid State Phys. 2004, 44, 313–325. [Google Scholar]

- Feltin, E.; Dalmasso, S.; Mierry, P.D.; Beaumont, B.; Lahrèche, H.; Bouillé, A.; Haas, H.; Leroux, M.; Gibart, P. Green InGaN light-emitting diodes grown on silicon (111) by metal organic vapor phase epitaxy. Jpn. J. Appl. Phys. 2001, 40, L738–L740. [Google Scholar] [CrossRef]

- Shih, C.F.; Chen, N.C.; Chang, C.A.; Liu, K.S. Blue, green and white InGaN light-emitting diodes grown on Si. Jpn. J. Appl. Phys. 2005, 44, L140–L143. [Google Scholar] [CrossRef]

- Egawa, T.; Zhang, B.; Ishikawa, H. High performance of InGaN LEDs on (111) silicon substrates grown by MOCVD. IEEE Electron Device Lett. 2005, 26, 169–171. [Google Scholar] [CrossRef]

- Li, J.; Lin, J.Y.; Jiang, H.X. Growth of III-nitride photonic structures on large area silicon substrates. Appl. Phys. Lett. 2006. [Google Scholar] [CrossRef]

- Wierer, J.J.; Steigerwald, D.A.; Krames, M.R.; O’Shea, J.J.; Ludowise, M.J.; Christenson, G.; Shen, Y.-C.; Lowery, C.; Martin, P.S.; Subramanya, S.; et al. High-power AlGaInN flip-chip light-emitting diodes. Appl. Phys. Lett. 2001, 78, 3379–3381. [Google Scholar] [CrossRef]

- Mukai, T.; Yamada, M.; Nakamura, S. Current and temperature dependences of electroluminescence of InGaN-based UV/Blue/Green light-emitting diodes. Jpn. J. Appl. Phys. 1998, 37, L1358–L1361. [Google Scholar] [CrossRef]

- Ding, L.Z.; Chen, H.; He, M.; Jiang, Y.; Lu, T.P.; Deng, Z.; Chen, F.S.; Yang, F.; Yang, Q.; Zhang, Y.; et al. Improved photoluminescence in InGaN/GaN strained quantum wells. Chin. Phys. Lett. 2014. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, P.; Yeh, D.-H.; Tan, C.-M.; Lai, C.-S.; Hou, C.-T.; Chao, T.-Y.; Chang, L.-B. Output Properties of Transparent Submount Packaged FlipChip Light-Emitting Diode Modules. Appl. Sci. 2016, 6, 179. https://0-doi-org.brum.beds.ac.uk/10.3390/app6060179

Singh P, Yeh D-H, Tan C-M, Lai C-S, Hou C-T, Chao T-Y, Chang L-B. Output Properties of Transparent Submount Packaged FlipChip Light-Emitting Diode Modules. Applied Sciences. 2016; 6(6):179. https://0-doi-org.brum.beds.ac.uk/10.3390/app6060179

Chicago/Turabian StyleSingh, Preetpal, Der-Hwa Yeh, Cher-Ming Tan, Chao-Sung Lai, Chih-Teng Hou, Ting-Yu Chao, and Liann-Be Chang. 2016. "Output Properties of Transparent Submount Packaged FlipChip Light-Emitting Diode Modules" Applied Sciences 6, no. 6: 179. https://0-doi-org.brum.beds.ac.uk/10.3390/app6060179