1. Introduction

The strawberry (

Fragaria ×

ananassa) is one of the world’s most popular fruit due to its excellent organoleptic and nutritional properties. The fruit has a very thin and fragile epidermis that makes it highly susceptible to mechanical damage during harvest and storage. This often results in a deterioration in quality, rapid loss of weight and firmness, and a loss of antioxidant capacity. In addition, the rate of respiration increases and there are changes in color [

1]. The activity of enzymes such as polyphenol oxidase and peroxidase cause the degradation of anthocyanins and other polyphenols that lead to discoloration and increased darkening of the surface of the fruit [

2]. The rate of deterioration of the fruit is proportional to the speed at which respiration occurs, approximately 15 mg kg

−1 h

−1 at 0 °C, increasing by 4–5 times when the temperature rises to 10 °C. This means that the fruit are highly perishable [

3,

4,

5].

Edible coatings can retard the process of ripening, extend the shelf life, and prevent the loss of important components such as antioxidants in both fruit and vegetables [

4]. For instance, chitosan (CS) has been used to improve the quality and extend the shelf life among others, of bananas, mango, guava, carambola, and figs [

5,

6,

7,

8,

9]. However, it has been reported that a greater interaction on the surface area of the fruit can occur with the incorporation of chitosan nanoparticles into the coatings. In addition, the desired characteristics of the fruit, including, the quality attributes and the antioxidant capacity, also improved [

10,

11,

12]. On this subject, Divya et al. (2018) [

13] evaluated a coating containing chitosan nanoparticles at 5% in tomato and chilli pepper, and reported less weight (0.21% and 3.3% respectively). Also, Mohammadi et al. (2015) [

14] evaluated chitosan nanoparticles at 0.15% in cucumber and found that the treated fruit had lower weight loss (9%) and CO

2 production (215 µg kg

−1 s

−1), and higher firmness (55 N) compared to the control group (12%, 230 µg kg

−1 s

−1, and 49 N, respectively). On this same line, Eshghi et al. (2014) [

15] evaluated coatings with chitosan nanoparticles (0.25%) on various physicochemical characteristics and the functional profile on strawberries at 4 ºC. The authors reported that, after eight days of storage, the coated strawberries showed lower weight (1.5%), firmness (27%), and respiration (33 mg kg

−1 h

−1) than the remaining treatments. Chitosan can be combined with other hydrophobic compounds such as oils, waxes, and resins in order to improve the characteristics of the fresh, treated product [

16]. For example, propolis extract is another natural product used to preserve the quality of fruit and vegetables. Barrera et al. (2012) [

17] reported that papaya fruit covered with a commercial wax and propolis extract (5% w/v) had higher firmness (6.28 N) than fruit without propolis (5.4 N). In the same line, Ali et al. (2013) [

18] found that a coating with propolis (5%

v/v), gum arabic (5%

p/v), and cinnamon oil (0.1%

v/v) reduced the percentage of weight loss in chilli compared with the untreated vegetables (27% and 92%, respectively), and had the highest firmness (13 and 2 N, respectively). Also, Siripatrawan and Vitchayakitti (2016) [

19] tested chitosan coatings combined with propolis extract (0, 2.5, 5, 10, and 20%

w/w) and found that the total phenolic content and 1,1-diphenyl-2-picrilhydrazil (DPPH) in chitosan films increased due to the addition of propolis.

Although compounds such as chitosan and propolis have been shown to be effective in preserving the quality of various agricultural products, the combination of these compounds could show a synergic effect and improve the quality of the strawberries. Therefore, the objectives of this research were to evaluate the effect of coatings with CS, CSNP, and P on the ripening behavior and the antioxidant capacity of strawberries stored for a given time.

2. Materials and Methods

2.1. Materials

Strawberries cv. Camarosa were obtained from an orchard located in Tepoztlán, México (18°59′07″N 99°05′59″W). The fruit were harvested when 75% of the surface was red in accordance with NMX-FF-062-SCFI-2002 (Secretaría de Economía, 2002). Fruit with physical damage, irregular shapes, and the presence of microorganisms were discarded. A medium molecular weight chitosan Sigma Aldrich® (deacetylation degree 75%–85%) was used. The propolis extracts (10%, 20%, and 30%) were donated by the Laboratorio de Microbiología de la Unidad de Investigación Multidisciplinaria de la Facultad de Estudios Superiores (FES)-Cuautitlán, Universidad Autónoma de México. The ethanol was acquired from Hycel, Mexico, and the glacial acetic acid from Fermont Chemicals Inc, Mexico. The glycerol was purchased from J.T. Baker® (Randor, PA, USA)and Tween 20 from Meyer® (Tlahuac, Distrito Federal, Mexico).

2.2. Synthesis of Chitosan Nanoparticles

To obtain the CSNPs, the nanoprecipitation method reported by Correa-Pacheco [

20] was followed. A CS solution (0.05%

w/v) was dissolved in glacial acetic acid (1%

v/v) and distilled water to form the aqueous phase. Then, 2.5 mL of this phase was added to 40 mL of the organic phase (ethanol) with 10 μL of Tween 20, using a peristaltic pump under constant magnetic stirring. The solution was placed in a rotary evaporator at 40 °C for solvent evaporation. The mean size of the CSNPs in ethanol was approximately 28.42 ± 7.43 nm, while the size of the CSNPs in propolis was 31.50 ± 7.77 nm, according to the results published previously by our research group [

20]. Later, the obtained nanoparticles were stored under refrigeration at 4 °C and the concentration used in the coating was 33%.

2.3. Formulations and Application of Coatings

Five coatings were prepared: (1) CS, (2) CS + CSNPs, (3) CS + CSNPs + P10%), (4) CS + CSNPs + P20%, and (5) CS + CSNPs + P30%. The control consisted of dipping the fruit in water. The solution was homogenized with 1% chitosan (w/v), 1% acetic acid (v/v), and 0.3% glycerol (v/v), and the propolis extract was added by dripping using a peristaltic pump. The formulation was kept at 40 °C under constant stirring for 10 min and allowed to cool at room temperature. CSNPs were added to the formulation and stirring continued for another 5 min. The solution was then homogenized at 10,000 rpm for 1 min. The formulations were stored in amber colored bottles prior to use.

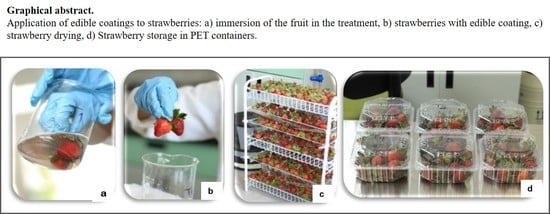

Strawberries were quickly washed with running water to remove excess dirt or garbage and allowed to dry, following which they were immersed for 30 s in each formulation, dried at room temperature, and stored in PET containers under refrigeration at 4 ± 1 °C for 8 days.

2.4. Determination of Weight Loss, Firmness, TSS, and Color

The fruit were weighed daily. Weight loss was determined by gravimetry with the help of a scale (OHAUS, Tokyo, Japan). This involved calculating the difference between the initial and final weight of each experimental unit, dividing this by the initial weight, and then multiplying the outcome by 100. The result was expressed as a percentage. Firmness was determined using an analogous penetrometer (KANDPI, Tokyo, Japan). A cylindrical tip 8 mm in diameter was used and both sides of the fruit were penetrated to a depth of 10 mm. Firmness was assessed at the beginning and end of the experiment. The values were reported as the force required to cross the membrane of the fruit in Newtons (N). To determine the TSS, a drop of strawberry juice was extracted and analyzed in a refractometer (ATAGO, Tokyo, Japan). The results were expressed in °Brix. The color of the fruit was determined daily using a colorimeter (Konica, Tokyo, Japan) for a period of 8 days. The CIEL * a * b * system values were evaluated. Measurements were made on both sides of the equatorial part of the fruit. Color values were reported in terms of the coordinate’s luminosity (L *), hue angle (H * = tan − 1 b * / a *), and chromaticity (C * = √ (a *) 2 + (b *) 2). The CIELAB data were transformed to RGB values, using the nix color sensor converter.

2.5. Total Phenolic Compounds

The quantification of total phenolic compounds was evaluated every third day and analyzed using the Folin–Ciocalteau colorimetric method described by Singleton and Rossi (1965) [

21]. Subsequently, 150 μL of the sample was mixed with 3.85 mL of distilled water, 250 μL of Folin–Ciocalteau phenol, and 750 μL of NaCO

3. These were allowed to react for 2 h in the dark at room temperature. Absorbance was measured at 760 nm with a spectrophotometer (Thermo scientific Genesys, Shanghai, China) and the concentration of total phenolic compounds in the samples was expressed as mg of gallic acid equivalents.

2.6. Total Flavonoids

To quantify the flavonoid content, the methodology by Chougui et al. (2013) [

22] was followed. Briefly, Two g of strawberry were macerated with 5 mL of an 80% methanol solution and centrifuged at 8000 rpm for 12 min. Then, 1.5 mL of supernatant was then added, which reacted with 1.5 mL of AlCl

3. After 30 min, the absorbance of the sample was read at 430 nm with a spectrophotometer (Thermo scientific Genesys, China). Flavonoid content was quantified using a standard quercetin curve (20–110 µg quercetin) and evaluated every third day.

2.7. Antioxidant Capacity

The isolation and determination of extracts rich in bioactive compounds, enables the identification of the antioxidant properties, and this information can be considered as an indicator of the antioxidant properties of a food matrix. (Durazo and Lucarini, 2019) [

23]. To quantify the antioxidant capacity, the methodology employed by Brand-Williams (1995) [

24] was followed. Here, 0.01g of DPPH was weighed and added to 25 mL with methanol. Then, 10 mL with methanol was then added to 1.3 mL of the solution to prepare the daily solution. Subsequently, 0.5 g of the strawberry sample were weighed, following which 5 mL of methanol was added, macerated with a ceramic mortar, and centrifuged (Labnet International, New York, NJ, USA) at 800 rpm for 10 min. 250 μL of the sample was then taken and added to 750 μL of DPPH (133µM). For the blank, 750 µL of DPPH was added to 250 µL of methanol. The sample was incubated in the dark at room temperature for 30 min. Absorbance at 517 nm was then measured (Thermo scientific Genesys, Shanghai, China). Radical uptake activity was expressed as a percentage of DPPH inhibition and was calculated according to the following formula:

where Abs0* denotes blank absorbance and Absm**, sample absorbance.

2.8. Sensory Evaluation

The sensory evaluation was carried out on strawberries covered with the five different treatments. Five strawberries were used per treatment, including the control. Covered strawberries were cut in half and those coded with random digits were then placed in white plastic cups. The glasses were closed for 20 min. 30 untrained judges evaluated two random samples in which aroma, color, and flavor were rated on a scale from 1 to 9, whereby 1 means “I extremely dislike it” and 9 “I extremely like it”. The judges ate a salty cookie between each sample so that the first sample did not influence the second.

2.9. Statistical Analysis

An analysis of variance (ANOVA) and a Tukey means test (p ≤ 0.05) were then performed, using the statistical package InfoStat student version 2018. Fifteen treated strawberries with 3 repetitions were used in the variables of weight, firmness, TSS, color, total phenols, total flavonoids and antioxidant capacity, while 10 samples per treatment were used in the sensory evaluation.

3. Results and Discussion

For all treated and non-treated fruit, there was a continuous loss of weight during the eight days of storage (

Table 1). The strawberries with the lowest weight at the end of the storage period were those coated with CS + CSNPs + P10% (9.7 and 10.2%, respectively) followed by the coatings CS + CSNPs + P30% and CS + CSNPs + P20% (10.9 and 11.0%, respectively). There was a significant difference (

p ≤ 0.05) between these and the controls (14.9%). These results aligned with those reported by Gol et al. (2013) [

25]. A lower percentage of weight loss (4.0%) in strawberries coated with Hydroxypropylmethylcellulose 1% (HPMC) and CS 1% was obtained with respect to the control (14.3%) after eight days of storage. This may have occurred because the edible coatings served as a semipermeable barrier between the oxygen, carbon dioxide, and moisture loss, which reduced respiration, water loss, and oxidation reactions [

26].

After eight days storage, the strawberries coated with CS + CSNPs + P20% and CS + CSNPs + P10% showed the greatest firmness (4.96 N and 4.87 N, respectively). These two values were statistically similar to the rest of the treatments but significantly different (

p ≤ 0.05) from the control (3.83 N) (

Table 2). These results align with those of Restrepo et al. (2010) [

27] who reported greater firmness in strawberries covered with mucilaginous gel of aloe penca and carnauba wax. They also reported the lowest firmness and highest weight loss in non-coated strawberries. Ventura-Aguilar et al. (2018) [

28] evaluated the effect of a chitosan and cinnamon essential oil coating applied to strawberries at 5 °C and 20 °C. The results indicated that weight loss was reduced by 15 times and firmness was 33% higher in the fruit treated with the coating compared with the control. By contrast, studies carried out by Pilon et al. (2014) [

29] reported no significant differences in firmness values between freshly cut apples covered with chitosan nanoparticles and uncovered apples. The coatings with CSNPs and the control group showed statistical differences among the storage days.

In this research, the values obtained for the weight and firmness of the strawberries could be due to the combination of propolis and chitosan extract. For instance, Bodini et al. (2013) [

30] found that incorporating propolis extract (5%) significantly reduced the permeability of water vapor in relation to a control film (2.4 and 3.2 g mm/h cm

2 Pa, respectively). Similarly, Siripatrawan and Vitchayakitti (2016) [

19] studied the effect of propolis (2%) on the functional properties of chitosan films and found that this reduced the permeability of water vapor in the films (0.5 g mm Pa

−1 d

−1 m

2). This was because the polyphenolic compounds of the propolis stuck to the chitosan matrix and engaged in hydrogen or covalent bonding with chitosan reactive groups. This limited the availability of hydrogen atoms needed to form a hydrophilic bond with water. This eventually led to a decrease in the affinity of chitosan films towards water, and thus reduced the water vapor permeability of the coatings.

With respect to the TSS, there were no significant statistical differences between the treatments (

Table 3). This aligns with the findings of Pastor et al. (2010) [

31], who tested an edible coating made of HPMC (5%) and propolis extract (0.5%, 1%, and 1.5%) on grapes cv. Muscatel and found no significant differences. Similarly, Barrera et al. (2012) [

17] applied propolis extract (5%

w/v) to papaya fruit and found no significant differences with respect to the TTS. In general, statistical differences were not observed between the storage days of the evaluated fruit.

Regarding luminosity, chromaticity, and hue angle, no significant statistical differences (

p ≤ 0.05) were observed between the treatments (

Figure 1).

Trejo et al. (2007) [

32] reported that the application of an edible coating using 1% and 2% gelatin did not affect the luminosity of strawberries stored in refrigeration for 10 days. Similarly, Del Valle et al. (2005) [

33] reported no changes in color parameters for strawberries coated with cactus mucilage and glycerol stored for 10 days at 5 °C. The color of the strawberry is a very important attribute in the acceptance of the product by the consumer, and the edible coatings applied in this study did not modify the original color.

The total phenol content decreased during the storage period for all treatments. However, strawberries coated with formulations containing chitosan and propolis exhibited the highest phenolic content on each day of storage (

Table 4). On the first day, the corresponding values were 69.98, 67.15, and 66.46 mg GAE g

−1 strawberry, respectively. On the third day of storage, the fruit coated with CS + CSNPs + P20% showed the highest content of total phenolic compounds (45.49 mg GAE g

−1 strawberry) compared with the control and the remaining treatments. During the following two sampling periods, the highest content was in the fruit coated with CS + CSNPs + P10% (34.75 mg GAE g

−1 and 28.49 mg GAE g

−1 strawberry, respectively), which was significantly different (

p ≤ 0.05) from the control (18.13 mg GAE g

−1 strawberry). However, it was statistically similar to the other coatings tested. In all treatments, significant differences were observed and a decrease of phenol content was observed at the end of the storage time.

The total flavonoid content was generally reduced during storage (

Table 5). For each storage evaluation, fruit from the treatments CS + CSNPs and CS + CSNPs + P20% showed the highest flavonoid content. The corresponding values were in the range of 954 to 554.6 μg quercetin g

−1 and were significantly different (

p ≤ 0.05) from those of the other treatments. In all treatments, significant differences were observed and a decrease of flavonoids content was observed at the end of the storage.

The percentage of DPPH inhibition was higher in the coated strawberries compared with the control regardless of the applied treatment (

Table 6). In general, strawberries coated with CS, CSNPs, and P at different concentrations had the highest percentage of DPPH inhibition with values of 87.5, 90.2%, 79.8%, and 92.4%, respectively. These results are consistent with those reported by Wang and Gao (2013) [

34] who demonstrated that the ability to sequester free radicals in chitosan-coated strawberries cv Earliglow was higher than that of uncoated fruit at the end of nine days of storage at 5 °C. Similarly, López et al. (2012) [

35] evaluated the effect of a coating of CS (1%) and cinnamon essential oil (0.03%) on preserving the quality, antioxidant capacity, and phenolic content of strawberries stored at 5 °C. They found that the coating was effective for maintaining the total phenolic content (170 mg GAE g

−1) and antioxidant capacity (inhibition 85% DPPH) for up to 15 days. Zahid et al. (2013) [

36] also reported an increase in the biosynthesis of antioxidants and total flavonoids following the application of 0.5% propolis extract. According to Thomas et al. (2016) [

37] and Anjum et al. (2013) [

38], the propolis has high biological activity, including antioxidant activity, due to its high phenolic and flavonoid content. In all treatments, significant statistical differences were observed and a decrease in DPPH inhibition was observed at the end of the storage.

Chitosan and propolis have separately proven to be effective in increasing antioxidant capacity. However, in this research, a synergistic effect was also observed between CSNPs and P as the highest concentrations of phenols, flavonoids and % DPPH were obtained using these coatings. Currently, there is little information on the effect of combining these compounds on the antioxidant activity on fruit, although some studies have demonstrated the synergism of nanoparticles with other compounds in edible coatings. For example, Yang et al. (2016) [

39] found that using lignin nanoparticles in polylactic acid-based films was highly efficient in terms of antioxidant capacity and, in combination with cellulose nanocrystals, a positive synergistic effect was generated in the antioxidant response of the films in vitro. In other work, Yang et al. (2016) [

40] observed an increased antioxidant capacity through the addition of lignin nanoparticles to films based on polyvinyl alcohol-chitosan.

The synergism between the chitosan and the nanoparticles can be explained by the ability of the first compound to eliminate chelated ions and free radicals, thus avoiding hydrogen donation and resulting in greater antioxidant capacity. Their small size and low molecular weight means that the nanoparticles contribute to significant changes in the functional properties due to an increase in the surface area in relation to the volume. Therefore, they are more biologically active, improving the bioavailability of active ingredients and controlled release, and contributing to preserving the antioxidant capacity of the fruit [

41,

42].

With respect to the sensory evaluation, the coatings were evaluated satisfactorily and no statistical differences were observed between the treatments (

Table 7). The coatings did not modify the taste or cause any bad odors. These data align with those of Marquez et al. (2009) [

43] who evaluated a coating based on chitosan 0.6% and sucroester fatty acids (1%), and observed that its application to loquat fruit did not modify its flavor, aroma, or appearance.