Microstructure and Piezoelectricity of (Na,K,Li)(Nb,Sb)O3–(Bi,Na)(Sr)ZrO3–BaZrO3 Ceramics

Abstract

:1. Introduction

2. Experiments

3. Results and Discussions

4. Conclusions

- All the specimens exhibited pure perovskite phase, and no second phases were observed;

- An average grain size of the specimen slowly reduced with the increase of the lithium substitution;

- When Li substitution was added to the ceramics, d33 and kp were slowly reduced;

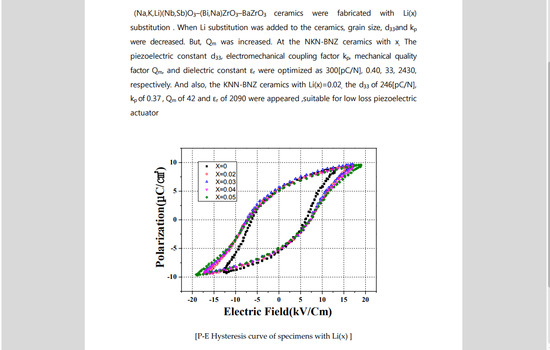

- With increasing Li substitution, the remnant polarization (Pr) decreased from 5.47 μC/cm2 to 4.98 μC/cm2, and coercive field (Ec) gradually showed the trend of increment;

- The KNN-BNZ ceramics with Li(x) = 0.02, the d33 of 246 [pC/N], kp of 0.37, Qm of 42 and εr of 2090 appeared to be suitable for low-loss piezoelectric actuator application;

- The KNN-BNZ ceramics with Li(x) = 0, and the best physical properties of d33 = 300 [pC/N], kp = 0.40, Qm = 33 and εr = 2430 were shown, respectively.

Author Contributions

Funding

Conflicts of Interest

References

- Minho, P.; Juhyun, Y. Piezoelectric and Dielectric Properties of Nonstoichiometric (Na0.5K0.5)0.97(Nb0.90Ta0.1)O3 Ceramics Doped with MnO2. J. Electron. Mater. 2012, 41, 3095–3099. [Google Scholar]

- Kim, S.G. Recent Trend of Electronic Speaker. Electric. Electron. Mater. 2006, 19, 33. [Google Scholar]

- Juhyun, Y. High Dielectric and Piezoelectric Properties of Low-Temperature Sintering PNNPMN-PZT Ceramics for Low-Loss Piezoelectric Actuator Application. Trans. Electr. Electron. Mater. 2018, 19, 249–253. [Google Scholar]

- Bomlai, P.; Muensit, N.; Milne, S.J. Structural and electrical properties of (1−x)(Na0.465K0.465Li0.07)NbO3−x CaTiO3 lead-free piezoelectric ceramics with high Curie temperature. Procedia Eng. 2012, 32, 814–820. [Google Scholar] [CrossRef] [Green Version]

- Gou, Q.; Zhu, J.; Wu, J.; Li, F.; Jiang, L.; Xiao, D. Microstructure and electrical properties of (1−x)K0.5Na0.5NbO3–xBi0.5Na0.5Zr0.85Sn0.15O3 lead-free ceramics. J. Alloys Compd. 2018, 730, 311–317. [Google Scholar] [CrossRef]

- Zheng, T.; Zu, Y.; Wu, J. Composition dependence of phase structure and electrical properties in lead-free (1−x)(K0.42Na0.585)(Nb1−ySby) O3−xBi0.5K0.5ZrO3 piezoceramics. J. Alloys Compd. 2015, 647, 927–934. [Google Scholar] [CrossRef]

- Sunmin, B.; Juhyun, Y. Dielectric and Piezoelectric Properties of [Li0.04(Na0.54K0.46)0.96](Nb0.84Ta0.10Sb0.06)O3 Lead-Free Ceramics as a Function of (Bi,Na)TiO3 Substitution. Ferroelectrics 2012, 437, 55. [Google Scholar]

- Yiping, G.; Ken-ichi, K.; Hitoshi, O. Dielectric and piezoelectric properties of lead-free (Na0.5K0.5)NbO3–SrTiO3 ceramics. Solid State Commun. 2004, 129, 279–284. [Google Scholar]

- Juhyun, Y. Effect of sintering temperature on the dielectric and piezoelectric properties of (Na0.525K0.443Li0.037)(Nb0.883Sb0.08Ta0.037)O3 Pb-free ceramics for actuator. Ferroelectrics 2017, 507, 12–18. [Google Scholar]

- Jungrae, N.; Juhyun, Y. Dielectric and piezoelectric properties of KCT added Li0.02(Na0.56 K0.46)0.98(Nb0.81Ta0.15Sb0.04)O3 ceramics. J. Electroceramics 2013, 30, 139–144. [Google Scholar]

- Sang-Hoon, S.; Juhyun, Y.; Sang-Don, L. Dielectric and piezoelectric properties of (Ba0.85Ca0.15)(Ti1−xZrx)O3 + 0.004 CuO ceramics for piezoelectric actuator. Ferroelectr. Lett. 2014, 41, 56. [Google Scholar]

- Sungjin, C.; Juhyun, Y. Dielectric and Piezoelectric Properties of 0.97(Na0.52K0.443Li0.037)(Nb0.96−xSb0.04Tax)O3–0.03(Bi0.5Na0.5)0.9(Sr)0.1ZrO3 Ceramics for Pizoelectric Actuator. Trans. Electr. Electron. Mater. 2019, 20, 328–333. [Google Scholar]

- Zhang, B.; Zhu, J. Lead-free Piezoelectrics Based on Potassium–Sodium Niobate with Giant d33. ACS Appl. Mater. Interfaces 2013, 5, 7718–7725. [Google Scholar] [CrossRef] [PubMed]

- Shi, H.; Chen, J.; Wang, R.; Dong, S. Full set of material constants of (Na0.5K0.5)NbO3–BaZrO3–(Bi0.5Li0.5)TiO3 lead-free piezoelectric ceramics at the morphotropic phase boundary. J. Alloys Compd. 2016, 655, 290–295. [Google Scholar] [CrossRef]

- Zhou, C.; Zhang, J.; Yao, W. Remarkably strong piezoelectricity, rhombohedral-orthorhombic-tetragonal phase coexistence and domain structure of (K,Na)(Nb,Sb)O3–(Bi,Na)ZrO3–BaZrO3 ceramics. J. Alloys Compd. 2020, 820, 153411. [Google Scholar] [CrossRef]

| Sinter. Temp. (°C) | X (= Li) | Density [g/cm3] | kp | Dielectric Constant | d33 (pC/N) | Qm |

|---|---|---|---|---|---|---|

| 1070 | 0 | 4.321 | 0.400 | 2430 | 300 | 33 |

| 0.02 | 4.372 | 0.370 | 2090 | 246 | 42 | |

| 0.03 | 4.379 | 0.351 | 2072 | 240 | 47 | |

| 0.04 | 4.444 | 0.327 | 1957 | 203 | 52 | |

| 0.05 | 4.502 | 0.287 | 1827 | 161 | 54 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoo, J.; Lee, J. Microstructure and Piezoelectricity of (Na,K,Li)(Nb,Sb)O3–(Bi,Na)(Sr)ZrO3–BaZrO3 Ceramics. Crystals 2020, 10, 868. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst10100868

Yoo J, Lee J. Microstructure and Piezoelectricity of (Na,K,Li)(Nb,Sb)O3–(Bi,Na)(Sr)ZrO3–BaZrO3 Ceramics. Crystals. 2020; 10(10):868. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst10100868

Chicago/Turabian StyleYoo, Juhyun, and Jonghyun Lee. 2020. "Microstructure and Piezoelectricity of (Na,K,Li)(Nb,Sb)O3–(Bi,Na)(Sr)ZrO3–BaZrO3 Ceramics" Crystals 10, no. 10: 868. https://0-doi-org.brum.beds.ac.uk/10.3390/cryst10100868