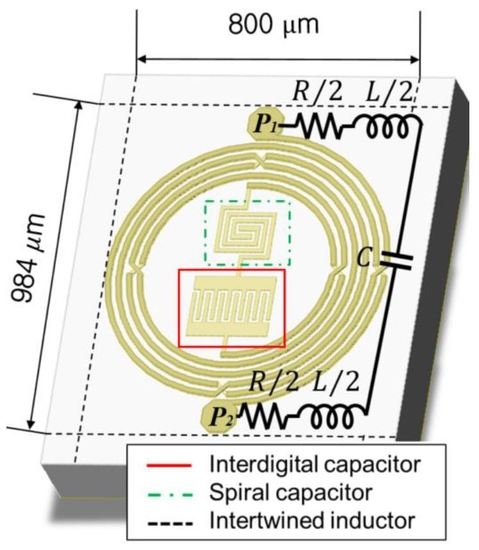

Design and Realization of a Compact High-Frequency Band-Pass Filter with Low Insertion Loss Based on a Combination of a Circular-Shaped Spiral Inductor, Spiral Capacitor and Interdigital Capacitor

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Results

3.2. Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yeung, L.K.; Wu, K.L. A Compact Second-Order LTCC Bandpass Filter With Two Finite Transmission Zeros. IEEE Trans. Microw. Theory Technol. 2003, 51, 337–341. [Google Scholar] [CrossRef]

- Zhang, S.; Rao, J.Y.; Hong, J.S.; Liu, F.L. A Novel Dual-Band Controllable Bandpass Filter Based on Fan-Shaped Substrate Integrated Waveguide. IEEE Microw. Wirel. Compon. Lett. 2018, 28, 308–310. [Google Scholar] [CrossRef]

- Xue, Q.; Jin, J.Y. Bandpass Filters Designed by Transmission Zero Resonator Pairs with Proximity Coupling. IEEE Trans. Microw. Theory Technol. 2017, 65, 4103–4110. [Google Scholar] [CrossRef]

- Wu, M.C.; Chung, S.J. A Small SiP Module Using LTCC 3D Circuitry for Dual Band WLAN 802.11a/b/g Front-End Solution. In Proceedings of the IEEE Topical Meeting on Silicon Monolithic Integrated Circuits in RF Systems, San Diego, CA, USA, 18–20 January 2006; pp. 174–177. [Google Scholar] [CrossRef]

- Ko, Y.J.; Park, J.Y.; Ryu, J.H.; Lee, K.H.; Bu, J.U. A Miniaturized LTCC Multi-layered Front-end Modulefor Dual Band WLAN (802.1 la/b/g) Applications. In Proceedings of the 2004 IEEE MTT-S International Microwave Symposium Digest, Fort Worth, TX, USA, 6–11 June 2004; pp. 563–566. [Google Scholar] [CrossRef]

- Kundu, A.; Mellen, N. Miniaturized Multilayer Bandpass Filter with Multiple Transmission Zeros. IEEE MTT-S Int. Microw. Symp. Dig. 2006, 760–763. [Google Scholar] [CrossRef]

- Swaminathan, M.; Bavisi, A.; Yun, W.; Sundaram, V.; Govind, V.; Monajemi, P. Design and Fabrication of Integrated RF Modules in Liquid Crystalline Polymer (LCP) Substrates. In Proceedings of the Conference of IEEE Industrial Electronics Society, Raleigh, NC, USA, 6–10 November 2005; pp. 2346–2351. [Google Scholar] [CrossRef]

- Sarkar, S.; Palazarri, V.; Wang, G.; Papageorgiou, N.; Thompson, D.; Lee, J.H.; Pinel, S.; Tentzeris, M.M.; Papapolymerou, J.; Laskar, J. RF and mm-wave SOP Module Platform using LCP and RF MEMS Technologies. In Proceedings of the Conference IEEE MTT-S International Microwave Symposium Digest, Fort Worth, TX, USA, 6–11 November 2004; pp. 567–570. [Google Scholar] [CrossRef]

- Yook, J.M.; Kim, K.M.; Kwon, Y.S. Suspended Spiral Inductor and Band-Pass Filter on Thick Anodized Aluminum Oxide. IEEE Microw. Wirel. Compon. Lett. 2009, 19, 620–622. [Google Scholar] [CrossRef]

- Chia, S.W.; Chiu, H.C.; Lin, Y.F. Microwave band-pass filter and passive devices using copper metal process on Al2O3 substrate. Microw. J. 2008, 19, 620–622. [Google Scholar]

- Wang, C.; Lee, W.S.; Zhang, F.; Kim, N.Y. A novel method for the fabrication of integrated passive devices on SI-GaAs substrate. Int. J. Adv. Manuf. Technol. 2011, 52, 1011–1018. [Google Scholar] [CrossRef]

- Kim, E.S.; Kim, N.Y. Micro-Fabricated Resonator Based on Inscribing a Meandered-Line Coupling Capacitor in an Air-Bridged Circular Spiral Inductor. Micromachines 2018, 9, 294. [Google Scholar] [CrossRef]

- Li, Y.; Wang, C.; Kim, N.Y. A high performance compact Wilkinson power divider using GaAs-based optimized integrated passive device fabrication process for LTE application. Solid-State Electron. 2014, 103, 147–153. [Google Scholar] [CrossRef]

- Chuluunbaatar, Z.; Adhikari, K.K.; Wang, C.; Kim, N.Y. Micro-fabricated bandpass filter using intertwined spiral inductor and interdigital capacitor. Electron. Lett. 2014, 50, 1296–1297. [Google Scholar] [CrossRef]

- Li, Y.; Wang, C.; Kim, N.Y. Design of Very Compact Bandpass Filters Based on Differential Transformers. IEEE Micrw. Wirel. Compon. Lett. 2015, 25, 439–441. [Google Scholar] [CrossRef]

- Mohan, S.S.; Hershenson, M.D.M.; Boyd, S.P.; Lee, T.H. Simple Accurate Expressions for Planar Spiral Inductances. IEEE J Solid State Circuits 1999, 34, 1419–1422. [Google Scholar] [CrossRef]

- Bryan, H.E. Printed inductors and capacitors. Tele-Tech Electron. Ind. 1955, 14, 68. [Google Scholar]

- Ong, K.G.; Grimes, C.A. A resonant printed-circuit sensor for remote query monitoring of environmental parameters. Smart Mater. Struct. 2000, 9, 421–428. [Google Scholar] [CrossRef]

- Liu, K.; Frye, R.; Emigh, R. Band-Pass-Filter with Balun Function from IPD Technology. In Proceedings of the IEEE Electronic Components and Technology Conference, Lake Buena Vista, FL, USA, 27–30 May 2008; pp. 718–723. [Google Scholar] [CrossRef]

- Li, N.; Li, X.Z.; Xing, M.J.; Chen, Q.; Yang, X.D. Design of Super Compact Bandpass Filter Using Silicon-Based Integrated Passive Device Technology. In Proceedings of the IEEE International Conference on Electronic Packaging Technology (ICEPT), Harbin, China, 16–19 August 2017; pp. 1069–1072. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Dai, X.; Kao, H.L.; Wei, B.H.; Cai, Z.Y.; Xue, Q. Compact LTCC Bandpass Filter With Wide Stopband Using Discriminating Coupling. IEEE Trans. Microw. Theory Technol. 2014, 4, 656–663. [Google Scholar] [CrossRef]

| Ref. | Technology | Cutoff Frequency (GHz) | Insertion Loss (dB) | Return Loss (dB) | Size (mm2) | Metal Layers |

|---|---|---|---|---|---|---|

| [19] | Silicon IPD | 2.45 | 2.2 | 30 | 1.5 × 1.5 | 3 |

| [20] | Silicon IPD | 1.7 | 2.0 | 25 | 1.0 × 0.5 | 3 |

| [21] | LTCC | 2.4 | 2.4 | 15 | 2.6 × 2.6 | 4 |

| [9] | Aluminum IPD | 2.45 | 2.8 | 14 | 2.2 × 1.8 | 4 |

| [10] | Al2O3 MMIC | 5.2 | 2.5 | 29.1 | 0.81 × 0.68 | 3 |

| [12] | GaAs IPD | 1.63 | 0.4 | 24.2 | 0.88 × 1.0 | 2 |

| [14] | GaAs IPD | 2.27 | 0.8 | 26.1 | 0.9 × 0.7 | 2 |

| This work | GaAs IPD | 1.96 | 0.27 | 26.8 | 0.8 × 9.8 | 2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, K.-H.; Kim, E.-S.; Liang, J.-G.; Kim, N.-Y. Design and Realization of a Compact High-Frequency Band-Pass Filter with Low Insertion Loss Based on a Combination of a Circular-Shaped Spiral Inductor, Spiral Capacitor and Interdigital Capacitor. Electronics 2018, 7, 195. https://0-doi-org.brum.beds.ac.uk/10.3390/electronics7090195

Lee K-H, Kim E-S, Liang J-G, Kim N-Y. Design and Realization of a Compact High-Frequency Band-Pass Filter with Low Insertion Loss Based on a Combination of a Circular-Shaped Spiral Inductor, Spiral Capacitor and Interdigital Capacitor. Electronics. 2018; 7(9):195. https://0-doi-org.brum.beds.ac.uk/10.3390/electronics7090195

Chicago/Turabian StyleLee, Ki-Hun, Eun-Seong Kim, Jun-Ge Liang, and Nam-Young Kim. 2018. "Design and Realization of a Compact High-Frequency Band-Pass Filter with Low Insertion Loss Based on a Combination of a Circular-Shaped Spiral Inductor, Spiral Capacitor and Interdigital Capacitor" Electronics 7, no. 9: 195. https://0-doi-org.brum.beds.ac.uk/10.3390/electronics7090195