1. Introduction

Buildings in the European Union represent 40% of final energy consumption, 36% of CO

2 emissions, 30% of consumption of raw materials, 12% of consumption of drinking water and are producers of 30% of the waste destined for landfill [

1]. The need to reduce energy consumption in Europe has led to the approval of Directives to achieve almost zero energy buildings in new constructions by 2020 [

2,

3,

4]. The reduction in energy consumption has mainly affected energy of use, also known as operational energy, which represents the highest percentage of the energy that the buildings will use throughout their life cycle (see Sartori and Hestnes [

5]). In recent years, there has been a progressive evolution towards low-energy buildings, passive buildings and buildings with almost zero consumption. The decrease in energy of use has also led to a decrease in the ratio between this energy and the total energy to be used throughout building’s lifespan. Consequently, the energy consumed in other stages of the life cycle, such as embodied energy, has gained importance. Karinpour et al. [

6] and Chastas et al. [

7] analysed cases to illustrate the embodied energy in the transition from conventional to nZEB, passive and low energy buildings, and realized that, despite the reduction in the total life cycle energy, the share of embodied energy takes an important role, mainly in nZEB and low-energy buildings. The need to understand the possibilities of reducing the embodied impacts has led to the “Annex 57” EBC (European Brain Council) project, a broad call for case studies launched with the aim of identifying design strategies to reduce the embodied energy and CO

2 emissions from buildings. Malmqvist et al. [

8] performed a systematic analysis of a collection of case studies in Annex 57, as well as of further scientific literature on this topic. Regarding passive houses, Stephan et al. [

9] studied the total life cycle energy demand of a typical Belgian single-family detached house, which comprises embodied, operational and transport energy, highlighting the importance of the manufacture of building materials, especially due to the large amount of insulation required to achieve high operational efficiencies.

Energies consumed in stages other than manufacturing and use, such as in maintenance, deconstruction and disposal or recycling, currently have a lower impact, as can be deduced from Morales et al. [

10] and Cuéllar-Franca and Azapagic [

11]. Therefore, manufacturing is the life cycle stage of the where interest is progressively gaining greater importance [

6,

9].

Sustainability assessment has been performed for diverse climates, but most of these refer to cold climatic regions, as in Takano et al. [

12], where buildings with different typologies were studied. Concerning mild and warm climates, Hanandeh [

13] analysed six construction systems in Jordan, a country with a Mediterranean climate with great variation in temperatures and rainfall. The role played by the envelope materials in the tropical climate of Indonesia was presented by Utama and Gheewala [

14]. Energy demands in different climatic regions of China were discussed by Luo et al. [

15] for various insulation thicknesses. There are also examples for hot desert climates in Qatar [

16] and for the tropical Lebanese climate [

17].

As regards the materials used to manufacture building envelopes, there are numerous studies covering those most commonly used: brick masonry [

18], laminated-timber [

19] and concrete [

20]. Wooden constructions are the most widely studied, since timber is a frequently used material due to its near zero impact in the production of greenhouse gases and its relatively low conductivity [

19]. However, there is a scarcity of data concerning buildings made of lightweight concrete, a material that admits a certain degree of recycling and has low conductivity [

21], being at the same time of great interest for its use in industrialized construction.

Previous studies have shown the importance of considering the embodied impacts of buildings for different materials and climates. However, particular case studies are required for housing typologies, especially for single-family houses. According to Eurostat [

22], in 2015 in the EU-28, more than 4 out of every 10 persons (42.0%) lived in flats, close to one quarter (24.1%) in semi-detached houses and one third (33.3%) in single-family houses. Therefore, single-family houses are important from the point of view of energy efficiency and environmental impacts.

As for the scenarios of sustainability and energy supply, recntly it is necessary to apply decarbonisation policies, both in general and in the production of electricity, in order to reduce climate change. Recently, Spain presented to the European Union the Integrated Energy and Climate National Plan for Spain [

23], which covers the objectives until 2030 and greatly increases electricity generation based on renewable sources. Therefore, in the near future an electricity-only scenario may become a highly appropriate option from a sustainability perspective, and that is the reason why it has been included as one of the scenarios to study in this paper. On the other hand, in Spain, particularly in the north, the use of heat pumps is gaining increasing interest, due to their performance and also in order to comply with the mandatory Spanish standards contained in the “Spanish Technical Building Code” [

24]. According to this code, part of the demand for domestic sanitary water must be covered by renewable energy. In this respect, the heat pump is a very good alternative to solar hot water panels in those regions where solar insolation is quite low, such as in northern Spain. For this reason, a heat pump installation has been chosen as the second power supply scenario. Finally, to take into account fossil fuels, a third energy supply scenario based on natural gas has been added, since: (i) it is a relatively clean fuel (it does not contain sulphur); (ii) its use to satisfy heating and domestic water demands is widespread; and (iii) the performance of natural gas boilers has improved substantially in recent decades.

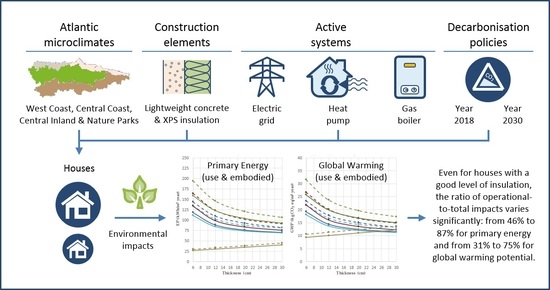

This paper analyses sustainability aspects obtained from life cycle assessment of a single-family house that has been designed to be built industrially using lightweight concrete panels with expanded clay. Two sizes of houses are considered that adapt to the needs of the potential users of single-family housing in northern Spain. The thermal behaviour and embodied impacts of the houses as the insulation thickness increases is analysed for different locations in the Principality of Asturias, located on Spain’s Atlantic coast. The set of considered locations presents a wide variety of climates, given that Asturias can be divided into sub-regions which, although geographically close, have very different weather conditions: the west and central coast, the central inland area and the mountains. The impacts on primary energy (embodied and use) and on greenhouse gas emissions (embodied and use) are analysed for various insulation thicknesses, taking into account that the two types of single-family houses have different shape factors and window-to-wall ratios. Regarding the impacts due to the energy used to cover the thermal demand, three supply scenarios are considered: (i) electricity only; (ii) heat pump plus electricity; and (iii) natural gas boiler. Finally, the influence on future impacts of the planned Spanish electricity mix in the 2030 horizon is analysed when using electricity only.

2. Materials and Methods

The information to calculate the life cycle assessment is provided in this section: thermal balance equations to calculate energy demand; geometric parameters (Design); materials, properties and inventory (Materials); climatic data (Climate); calculation of heating and cooling demands; and system boundaries.

Figure 1 shows a flow chart to illustrate the development of the study: (i) thermal energy consumption, which includes the calculation of balances, heating and domestic hot water (DHW) demands; (ii) definition of the thermal energy supply in three scenarios, in this case “only electric supply”, “with heat pump plus supplementary electric supply” and “natural gas boiler supply”); (iii) calculation of the building use impacts considering the Spanish passage factors [

25]; (iv) parallel calculation of the embodied impacts, in this case, primary energy (EP) and CO

2 equivalent emissions via Global Warming Potential (GWP); and (v) calculation of the use-to-total ratio of impacts for primary energy and CO

2 equivalent emissions.

2.1. Thermal Balances

Thermal balances are obtained using simplified expressions from EN (European Norm) ISO (International Organization for Standardization) 13790 [

26], which are used in [

19] and in the Passive House Planning Package (PHPP) standard [

27], which is the software used in the present study. The validity of the simulation model has been assessed in the literature. Recent papers discuss and compare the performance of buildings calculated under own country codes, using the widely employed software packages EnergyPlus and PHPP. An energy-efficient house built following Passive House design principles and equipped with extensive monitoring was compared to a reference house designed following the Romanian energy efficiency code in [

28]. Regarding the use of PHPP, the authors uphold the ability of this software to determine the energy performance of buildings according to European standards. Besides, four climatic regions of Portugal were also analysed in [

29] using EnergyPlus software and the Portuguese code, concluding that it is essential to adapt and detail the technical and constructive solutions for different regions.

The energy balance in Equation (1) considers heat inputs and outputs: transmission losses

), ventilation losses

, internal gains

and solar gains

. This overall balance in the building is performed in order to obtain the heating

and cooling

demands from Equations (2) and (3), respectively:

In the above equations, the building’s thermal inertia and the performance of the building in the unsteady state should be taken into account. In the quasi-stationary method according to EN ISO 13790 [

26], the heat gains are reduced by the utilization factor,

, which is introduced to calculate the heating demand in the following expressions:

where

are the heat losses,

are the heat gains and:

The solar gains

for the annual calculation are proportional to the window-to-wall ratio gross area

and the total solar insolation

during the period considered (heating or cooling):

where

r is the total shading reduction factor,

g is the solar factor (energy transmitted through the glazing normal to the irradiated surface) and

is the usable floor area. The solar gains diminish the heat demand during the heating period, but increase the cooling demand in the summer period. Therefore, the solar factor should be carefully chosen according to the location to minimize the sum of the annual energy demand for the heating and cooling periods. More detailed expressions consider insolation according to the four orientations (N, S, E and W). However, as the transmittance of the windows is higher than the transmittance of the opaque elements, a high window-to-wall ratio also increases losses by transmission through the windows and hence the importance of an appropriate selection of the windows. The transmission losses are a function of the areas of the construction elements:

where

is the area of the element of the envelope (roof, floor, wall, window),

is the transmittance of the element,

is the temperature reduction factor and

is the sum of the differences in temperature (exterior air temperature and base temperature), which is calculated on an hourly basis, i.e., degree hours for the period (heating or cooling).

2.2. Geometric Parameters

The type of housing and the living spaces were defined based on: the average income level of the potential users and the number of children per couple, as reported in [

30]. However, it is also very common for 5 occupants to live together in the house when considering a large family or when living with older relatives, so the study considers two sizes of single-family houses. The layout for both types of houses and the floor areas of the rooms is shown in

Figure 2. The one on the left corresponds to a four-bedroom building (referred to as 4BB), while the one on the right is for a three-bedroom building (3BB); the houses include a living room/kitchen, corridor and a facilities room. The usable floor areas are 121.27 and 67 m

2, respectively. The houses are on one level, with a 20-degree pitched roof and slate finish.

Table 1 shows parameters that define the thermal performance of the windows. The window-to-wall ratio (AWF) is defined in this paper as the ratio of the gross area of the windows facing south to the total area of the south facade. The solar gains depend on the glazing fraction (AGF), which is the glazing-to-wall area ratio for the south oriented facade. The buildings have a rectangular floor plan, with windows only on the north and south facades. Two cases were studied: large windows facing south and small windows facing north (LW-SOUTH), and small windows facing south and large windows facing north (SW-SOUTH). The average glass fraction (GFavg) considers the ratio of the overall glazing areas to the total wall area of the building. Similarly, the average frame fraction (FFavg) considers the ratio of the overall framed areas to the total wall area of the building. The transmittances are: Uf for the frame, Ug for the glazing and Uw_avg for the average of all windows. The values for both buildings are quite similar, the windows being somewhat larger for the 4BB. The windows use argon-filled triple glazing with a solar factor

g = 0.51. The window frames are made of aluminium, with thermal bridge breaking, absorptivity = 0.4 and infiltration class = 4.

Table 2 contains the characteristics of the opaque components and the geometric values of the buildings: Aref_net is the usable area; Agross is the outer projection area; Atot is the total outer area of the envelope (i.e., the sum of areas of opaque elements in contact with the surrounding air: wall, roof and floor). The table also shows the shape factor, Fc, which is the ratio of Atot to the inner heated volume of the building, Vint. The shape factor and the window-to-wall ratio, AWF, are the two parameters that are most often taken into account when studying the performance of buildings. A compact shape (associated with a low shape factor) is desirable to minimize transmission losses. Concerning the influence of this factor, Albatici and Passerini [

31] found it more important in cold localities and less important in mild and warm climates. The aspect ratio (L/W), which is the ratio of the building’s length to its width, is another parameter that is often considered to determine solar access to the building. In cold climates, the ideal L/W value for a rectangular shape ranges from 1.3 to 1.5, as cited in Premrov et al. (2016) [

19]. However, the influence of the L/W ratio for mild and warm climates is not so well defined [

12,

32]. Area ratios for the wall (Fwall) and the roof (Froof) help interpret transmission losses. The overall opaque transmittance of the building, Uop_avg, depends on the thickness of the insulation, and for the present study ranges from 0.14 to 0.33 W/m

2 K.

2.3. Materials and Properties

2.3.1. Construction Elements of the Building

Table 3 shows the life cycle inventory, with the areas of each constructive element, as well as the density, thickness and thermal conductivity of each layer of materials, all of which were obtained from the catalogue of construction elements [

33]. The thickness of the expanded polystyrene (XPS) insulation installed on the building’s exterior is studied parametrically for each location. When the thickness of the XPS insulation is increased, maintaining the rest of the building elements the same, the transmittance values decrease accordingly. PHPP requirements are met for a thickness of about 20 cm: 0.130 W/m

2 K for the floor and the external walls with internal lining, and 0.147 W/m

2 K for the roof.

2.3.2. Active Technical Systems

The characteristics of the active systems that are used by each of the three thermal energy supply scenarios are found in

Table 4. The energy systems are decentralized and the houses are equipped with a heat recovery ventilation unit. They include heat pumps, gas boilers, water heating tanks and pipes, as well as hydronic radiant floors that will be used with heat pumps or boilers. In the electricity-only scenario, the electricity is used as an energy source for: space heating by electric radiators (about 50 W/m

2), DHW and LED lights (about 4 W/m

2). The environmental behaviour depends on the embodied impacts (EP and GWP) of the materials that compose the active systems employed and therefore these impacts are included in the present study. Impact values for the active components were obtained from Ecoinvent v3.3 (2016) in SimaPro (aerothermal heat pump, gas boiler, hydronic floor, tank and ventilation unit) and Leskovar et al. [

34] (electric radiators, piping, electric cables and LED lights).

The active components that comprise each scenario are as follows: (i) the electricity-only scenario comprises electric radiators, a ventilation unit, pipes, electrical cables and LED lights; (ii) the heat pump plus electricity scenario comprises a heat pump, hydronic floor, ventilation unit, pipes, tank, electric cables and LED lights; and (iii) the natural gas boiler scenario comprises a boiler, hydronic floor, ventilation unit, pipes, tank, electric cables and LED lights.

2.4. Climate Data

Asturias is located in the central region of Spain’s Atlantic coast, where the climate is Atlantic with mild winters and cool summers. According to the Köppen–Geiger Classification [

35], part of the territory is Cfb (oceanic) and part is Csb (Mediterranean). The annual thermal oscillation is generally slight and there is abundant rainfall because of the proximity of the ocean. However, the orography is very rugged due to the presence of the Cantabrian Mountains. This context of coast and mountains so close together produces strong variations in altitude between locations and results in a variety of microclimates. In general terms, four main climatic sub-regions can be established: the coastal strip, highly influenced by the sea, with a more continental climate in the west; the central inland strip, with an oceanic climate, although not as influenced by the sea as the coast; and the mountain strip in the Cantabrian Mountains. The locations whose climatic data were studied are numbered from 1 to 11 in the map of

Figure 3. The classification of the points into sub-regions, location names, geographical coordinates and altitudes can be seen in

Table 5: Valdés, which is a typical tourist resort on the west coast; Gijón, also a tourist resort, which is located on the central coast and is the region’s largest city; Oviedo, the administrative capital, which is the second largest city in terms of inhabitants; and Ibias, a representative location in the mountains that comprise several areas listed as Nature Parks, which was chosen for its high altitude and very different climatic conditions.

Table 6 and

Table 7 present climatic data for a representative location from each sub-region studied here. The data were obtained using the Meteonorm software [

36].

Table 6 shows the following data for each period of thermal energy use (heating and cooling) and each sub-region: degree hours, solar insolation on the vertical planes (N, E, S and W) and global insolation on the horizontal plane. The degree hours are calculated as the sum over the period (heating or cooling) of temperature differences with respect to a reference temperature corresponding to each period (20 °C for the heating period and 25 °C for the cooling period). The heating period runs from the first day of October to the last day of May, and the rest is considered as the cooling period.

Table 7 presents monthly averaged data for outdoor air temperature (Tamb) and dew point (Tdew) for the representative location of each sub-region. These data were obtained for open field landscapes.

2.5. Calculation of Heating and Cooling Demands

The software used to assess the energy performance of the houses was the Passive House Planning Package PHPP [

27], in accordance with DIN EN ISO 13790 [

26].

The energy balances were analysed and the results compared for the four sub-regions of different microclimates. Subsequently, the effect of climatic variation was investigated, expanding the number of situations. Finally, to achieve the best sustainability conditions, the influence of the insulation thickness was studied for two possible orientations of the building: with the largest windows facing south (LW-SOUTH) and with the smallest windows facing south (SW- SOUTH). The results were obtained using a monthly steady-state computing method, implemented in PHPP. The set point temperature is 20 °C for winter and 25 °C for summer. The infiltration rate is 0.6 h−1 and the ventilation rate was calculated using PHPP software according to the number of occupants in the house: five people for 4BB and three people for 3BB. An air-to-air heat recovery unit with 82% efficiency was considered.

The domestic hot water energy needs include usable hot water and losses due to distribution and accumulation. The usable DHW is calculated considering 25 litres per person per day, which means 23.06 kWh/m2 year for 4BB and 24.90 kWh/m2 year for 3BB. The heat losses in the distribution and in the storage tanks are respectively: 4.29 and 1.47 kWh/m2 year for 4BB and 5.17 and 1.88 kWh/m2 year for 3BB. This calculation was performed considering the following heat loss coefficients: 0.11 W/m K per metre of length of a pipe with an interior diameter of 0.014 m and 0.45 W/m K per metre of height of a tank with an interior diameter of 0.220 m. These heat loss coefficients were calculated using an auxiliary calculation tool in PHPP, for an insulation of 0.034 W/m K, with a thickness of 30 mm for the pipes and 60 mm for the tank.

An electrical consumption of 2.7 kWh/m

2 year was added to the electrical energy needs for air conditioning and domestic hot water. This value, suggested in Leskovar et al. [

34], corresponds to the ventilation unit (including heat recovery equipment) and LED lights. As for the rest of the household appliances, their energy consumption was not considered strictly associated with the characteristics of the building, so it was excluded due to the difficulty in establishing accurate data and the variability of both its performance and the occupants’ usage habits.

The service life, characteristics and software used to calculate the active systems are given in

Section 2.3.2.

2.6. Life Cycle and System Boundaries

Concerns about environmental aspects have led to greater use of life cycle studies, with the impacts reflected in the environmental product declaration, EN 15804 [

37], and the environmental performance of buildings, EN 15978 [

38]. The life cycle assessment in this study is carried out from cradle–to-grave and focuses on the calculation of the following impacts: primary energy (EP) and global warming potential (GWP, i.e., CO

2 equivalent emissions). The stages considered are: (i) manufacturing of components (A1 + A2 + A3), where A1 is the supply of raw materials, A2 is the transportation of raw materials and A3 is the manufacturing of the product; (ii) construction of the building, which consists of the transport of materials to the factory (A4) and the on-site erection of the building (A5); (iii) replacement (B5) of the active systems at the end of their service life, but not of the opaque elements of the building envelope, nor of the windows or coatings, since the durability of the chosen materials is greater than the lifespan of the building (50 years); and (iv) operational energy use (B6). To obtain the embodied primary energy and the CO

2 equivalent emissions, the CypeCad “Archimedes” database [

39], which implements ISO 14040 and 14044 standards [

40,

41], was used for the materials of the passive elements of the buildings, which are those included in the inventory of materials in

Table 3.

The envelope as a whole is a 14 cm skin of lightweight concrete panel with expanded clay and includes the exterior walls, roof and floor. It is cladded with mineral wool and plasterboard on the inside and with expanded polystyrene (XPS) of different thicknesses on the outside. The walls that divide the interior spaces are 8 cm thick and are also made of lightweight concrete panels. The panels are reinforced with steel mesh during their manufacture.

As no data were found in the “Archimedes” database or in other sources on the impacts corresponding to the manufacture of lightweight reinforced concrete panels, or of other concretes that had a composition sufficiently similar to them, impact data were obtained from the composition of the panels, as explained below. The composition of lightweight expanded clay mortars was provided by the manufacturer Laterlite [

42], while data on the reinforcing steel, for a square mesh of 10 x 10 cm with 4 mm diameter wire, were provided by the manufacturer [

43]. The composition considered for the panels was: 22.0% Portland cement; 25.0% expanded clay; 83% water; 1.95% and 2.2% reinforcing steel for panels 8 and 14 cm thick, respectively; 1.4% hydrated lime; 0.2% organic chemicals; and the rest, up to 100%, of silica sand. The impacts for the 8 and 14 cm thick panels were obtained from these compositions using SimaPro and the Impact 2002+ method software (PRè Consultants, Amersfoort, The Netherlands), as well as the Ecoinvent v. 3.2 database. The resulting total impacts, per m

2 of panel, for a panel lifespan of 50 years, were: 102.3 and 178.9 kWh/m

2 for EP and 47.3 and 82.7 kg CO

2 eq/m

2 for GWP, for 8 and 14 cm thick panels, respectively.

The overall impacts were calculated taking into account the total amount of each material present in the building, and are expressed per m2 of usable floor area, which is the functional unit for all buildings.

All the products necessary to construct the building and their respective packaging are considered to be transported from the factory to the construction site by diesel trucks, with an average route of 80 km.

The calculation method and the service lives that were considered for the active systems are given in

Section 2.3.2. The demolition and disposal stages were not considered in the present study, as they are of much less relative importance.

4. Discussion

In the calculation of use demands, the importance of the demand for DHW was highlighted for the studied buildings, which have a high level of insulation. The demand for DHW is twice that of the demand for heating, a fact that has also been highlighted in Hassell for other buildings with a high level of insulation [

45]. The heating demands calculated in this paper for sub-regional Atlantic climates depend inversely on the shape factor, as observed for other buildings and climates in Premrov et al. (2016 and 2018) [

19,

20,

21,

22,

23,

24,

25,

26,

27] and Takano et al. [

12].

From the present study, it was found that the embodied primary energy depends on the insulation level and the shape factor, with values ranging from 26.8 kWh/m

2 year (4BB,

= 6 cm) to 47.4 kWh/m

2 year (3BB, to

= 30 cm). Data in the literature show dependence on lifespan, usable floor area and construction materials. Lifespan ranges from 40 to 100 years in previous papers, as reported in the review by Karinpour [

6]. Mithraratne and Vale [

47] studied an individual house in New Zealand with 90 m

2 of usable floor area, a 100-year lifespan and built in concrete, obtaining an embodied primary energy of 13 kWh/m

2 per year, a result that is not so far from that calculated in the current study, bearing in mind that the latter corresponds to a 50-year lifespan. Ramesh et al. [

48] carried out a life cycle energy analysis in different climatic zones of India for a residential building with 85.5 m

2 of usable floor area, a 75-year lifespan and built using aerated concrete for the envelope. They obtained a value of 27 kWh/m

2 year of embodied primary energy and an operational energy of 167 kWh/m

2 year.

In general, it is observed that, although the values of embodied energy may be more in agreement, this is not the case of those of energy use. This result is reasonable, seeing as the technologies for obtaining and manufacturing materials have similar efficiencies everywhere. However, energy use is highly dependent on the climate and the technology used for its supply. In addition to this, it depends on the country’s energy mix, which has a major influence on the results. As for CO2 equivalent emissions, this is an impact related to the system used for energy supply, which is strongly linked to the country’s mix in the case of electricity.

The average data (for all locations and thicknesses studied) obtained for primary energy and CO

2 equivalent emissions are in keeping with data reported in the literature for mild climates. Data normalized in kWh/m

2 year of embodied and operational energy were summarized from a literature review in Karinpour [

6] for several buildings with a usable net area from 50 to 130 m

2 and in a variety of climates and construction technologies. The ratio of embodied to total was found to be around 25% for primary energy and 35% for CO

2 eq emission in mild climates. The primary energy in [

6] falls within the range of the results obtained in the current study, in which the embodied energy varies on average from 25.80% to 44.60% of the total energy, as the energy use varies on average from 74.20% to 55.40% of the total energy, depending in both cases on the energy scenario (the extreme values corresponding to the electricity-only and heat pump plus electricity). Similarly, average CO

2 equivalent emissions range from 25.03% to 69.13%, when expressed as embodied-to-total ratio, and from 74.97% to 30.87%, when expressed as use-to-total ratio.

Moschetti et al. [

18] analysed the sustainability of buildings with different typologies and climates in Italy. In their paper, the lifespan was considered to be 50 years and the aspects of sustainability that were studied include total primary energy and climate change. Several energy supply systems were also analysed, including one with a natural gas boiler and another with electrical energy from the energy mix in Italy. Although various types of buildings were studied and the energy demands were established for insulation thicknesses lower than those of the present study, both the methodology and the global trends show similarities. The values of the total primary energy found in [

18] range from 69 to 121 kWh/m

2 year, the stage of energy of use representing 75% on average, while the values obtained in the present study range from 51.1 kWh/m

2 year (Spanish energy mix) to 88.7 kWh/m

2 year (gas boiler). The differences in values are related to the different types of buildings and the different levels of insulation used. Regarding the impact of climate change, the average value in [

18] is 34.2 kg CO

2 eq/m

2 year, while in the present study the values range from 41.4 kg CO

2 eq/m

2 year (Spanish energy mix) to 75.0 kg CO

2 eq/m

2 year (gas boiler). As in the present study, in [

18] it was found that the GWP values are greatly defined by the energy supply system.

For their part, Leskovar et al. [

34] carried out a study comparing several typologies of wooden buildings (cross-laminated timber) with similar construction characteristics, a high degree of insulation and different form factors. The buildings were located in a Dfb climate-classified region of Central Europe, with cold winters and hot summers. The active systems consisted of an air conditioning unit, the system for heating the domestic hot water not being clearly specified. The environmental study was carried out for a lifespan of the building of 50 and 100 years. Regarding the analysed impacts, non-renewable primary energy and global warming were evaluated, in addition to the potential for acidification. Although the materials are very different from those used in the present study, the overall trends regarding the effects of the form factor are similar when comparing the two buildings in this study (67.0 m

2 for 3BB and 121.3 m

2 for 4BB) with the two buildings in [

34] that have the closest size to them (42.3 and 84.5 m

2), the thermal behaviour and effect of impacts being better when the form factors are smaller (the case of the larger building). The total global warming potential for these buildings in [

34] is 23 and 29 kg CO

2 eq/m

2 year, respectively, the GWP impact of use representing 73% in both cases. These values are lower than those calculated in the present study due to the use of laminated wood in the structure of buildings in [

34], instead of lightweight concrete panels.

5. Conclusions

The relative importance of embodied and use impacts of buildings is increasingly changing because of the application of energy efficiency and environmental directives. In this paper, these impacts are investigated for single-family houses with lightweight concrete envelopes in sub-regions of northern Spain presenting different Atlantic microclimates. The effects of varying the insulation thickness, compactness, size of the windows and three scenarios of thermal energy supply (electricity only, heat pump plus electricity and gas boiler) are calculated.

The use of electricity only has impacts on primary energy and on climate change that almost triple those calculated for heat pumps and there is greater variation with the microclimate.

For the heat pump and for the gas boiler, the embodied impact can exceed the impacts of use, hence the interest in achieving insulation with less environmental impact and in using insulation thicknesses according to the climate.

The current Spanish electric energy mix does not have sufficient supply of renewable energy to compete in terms of environmental impacts with the use of the heat pump and natural gas. However, although the heat pump will continue to be a very sustainable system in the long term, natural gas may no longer have the environmental advantages it currently has if environmental policies planned for Spain are implemented by the 2030 horizon.

As future work, aimed at improving the life cycle analysis, it would be convenient to carry out a broader-reaching study that considers the variation in lifespan and the recycling of lightweight concrete. This would help in future decisions to select the most appropriate material for each microclimatic sub-region.