Evaluation of Urban Tree Leaf Biomass-Potential, Physico-Mechanical and Chemical Parameters of Raw Material and Solid Biofuel

Abstract

:1. Introduction

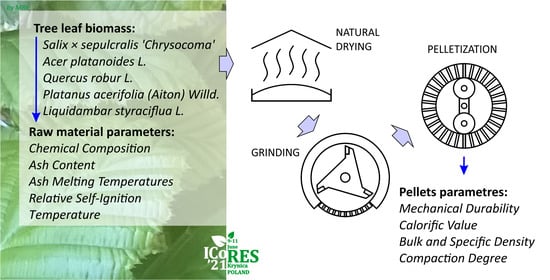

2. Materials and Methods

- Weeping golden willow (Salix × sepulcralis ‘Chrysocoma’)—code: Salix,

- Norway maple (Acer platanoides L.)—code: Acer,

- Common oak (Quercus robur L.)—code: Quercus,

- London plane (Platanus acerifolia (Aiton) Willd.)—code: Platanus,

- American sweetgum (Liquidambar styraciflua L.)—code: Liquidambar.

- determination of the chemical composition of the raw materials,

- determination of moisture content of the raw materials and the produced pellets,

- determination of characteristic densities of raw materials and pellets,

- pelletization tests (including raw material preparation),

- determination of ash content in the obtained pellets,

- determination of characteristic ash melting temperatures,

- determination of self-ignition temperature of the obtained pellets,

- determination of mechanical durability of the pellets,

- determination of calorific value of the obtained pellets.

2.1. Determination of the Chemical Composition of Raw Materials

2.2. Determination of Moisture Content

2.3. Determination of Bulk and Specific Density

- 50 dm3—for whole leaves,

- 5 dm3—for shredded raw materials and pellets,

- 0.1 dm3—for ash.

2.4. Process of Shredding and Pelletization of Tested Raw Materials

2.5. Determination of Ash Content and Melting Temperatures

2.6. Relative Self-Ignition Temperature

2.7. Mechanical Durability of Pellets

2.8. Calorific Value of Pellets

3. Results and Discussion

3.1. Chemical Analyses of the Investigated Materials

3.2. Characteristics of Raw Materials and Obtained Pellets

3.3. Relative Self-Ignition Temperature of Tested Sample

3.4. Characteristics of the Ashes

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lin, J. Developing a composite indicator to prioritize tree planting and protection locations. Sci. Total Environ. 2020, 717, 137269. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.; Wang, Q.; Li, X. Socioeconomic and spatial inequalities of street tree abundance, species diversity, and size structure in New York City. Landsc. Urban Plan. 2021, 206, 103992. [Google Scholar] [CrossRef]

- Speak, A.; Montagnani, L.; Wellstein, C.; Zerbe, S. The influence of tree traits on urban ground surface shade cooling. Landsc. Urban Plan. 2020, 197. [Google Scholar] [CrossRef]

- Fan, C.; Myint, S.W.; Zheng, B. Measuring the spatial arrangement of urban vegetation and its impacts on seasonal surface temperatures. Prog. Phys. Geogr. 2015, 39, 199–219. [Google Scholar] [CrossRef]

- Lin, B.-S.; Lin, Y.-J. Cooling effect of shade trees with different characteristics in a subtropical urban park. HortScience 2010, 45, 83–86. [Google Scholar] [CrossRef] [Green Version]

- Speak, A.; Escobedo, F.J.; Russo, A.; Zerbe, S. Total urban tree carbon storage and waste management emissions estimated using a combination of LiDAR, field measurements and an end-of-life wood approach. J. Clean. Prod. 2020, 256, 120420. [Google Scholar] [CrossRef]

- Armson, D.; Stringer, P.; Ennos, A.R. The effect of tree shade and grass on surface and globe temperatures in an urban area. Urban For. Urban Green. 2012, 11, 245–255. [Google Scholar] [CrossRef]

- Taraba, B.; Podstawka, T.; Mucha, M. Towards indication gases of spontaneous heating of biomass. Fuel 2018, 222, 610–616. [Google Scholar] [CrossRef]

- Selmi, W.; Weber, C.; Rivière, E.; Blond, N.; Mehdi, L.; Nowak, D. Air pollution removal by trees in public green spaces in Strasbourg City, France. Urban For. Urban Green. 2016, 17, 192–201. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.; Wang, D.; Wei, L.; Zhang, X.; Song, B. Bioaccumulation of heavy metals in plant leaves from yan[U+05F3]an city of the Loess Plateau, China. Ecotoxicol. Environ. Saf. 2014, 110, 82–88. [Google Scholar] [CrossRef] [PubMed]

- Jia, M.; Zhou, D.; Lu, S.; Yu, J. Assessment of foliar dust particle retention and toxic metal accumulation ability of fifteen roadside tree species: Relationship and mechanism. Atmos. Pollut. Res. 2020. [Google Scholar] [CrossRef]

- Vlek, P.L.G.; Khamzina, A.; Tamene, L. Land Degradation and the Sustainable Development Goals: Threats and Potential Remedies; CIAT Publication No. 440; CIAT: Nairobi, Kenya, 2017. [Google Scholar]

- Sharrock, S.; Jackson, P.W. Plant conservation and the sustainable development goals: A policy paper prepared for the global partnership for plant conservation. Ann. Mo. Bot. Gard. 2017, 102, 290–302. [Google Scholar] [CrossRef] [Green Version]

- Endreny, T.A. Strategically growing the urban forest will improve our world. Nat. Commun. 2018, 9, 1160. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Leaf & Yard Waste Collection—Collection & Recycling—Streets & Recycling—City of Madison, Wisconsin. Available online: https://www.cityofmadison.com/streets/yardwaste/leaf/ (accessed on 2 January 2021).

- Recycle Tree Leaves for Healthy Lawns, Gardens, and Water | UNL Water. Available online: https://water.unl.edu/article/lawns-gardens-landscapes/recycle-tree-leaves-healthy-lawns-gardens-and-water (accessed on 2 January 2021).

- Jordan, R.A.; Schulze, T.L. Artificial accumulation of leaf litter in forest edges on residential properties via leaf blowing is associated with increased numbers of host-seeking ixodes scapularis (Acari: Ixodidae) nymphs. J. Med. Entomol. 2020, 57, 1193–1198. [Google Scholar] [CrossRef] [Green Version]

- Nedveckytė, I.; Pečiulytė, D.; Būda, V. Fungi associated with horse-chestnut leaf miner moth cameraria ohridella mortality. Forests 2021, 12, 58. [Google Scholar] [CrossRef]

- Straw, N.A.; Bellett-Travers, M. Impact And Management Of The Horse Chestnut Leaf-Miner (Cameraria ohridella). Arboric. J. 2004, 28, 67–83. [Google Scholar] [CrossRef]

- Ramadhan, M.L.; Zarate, S.; Carrascal, J.; Osorio, A.F.; Hidalgo, J.P. Effect of fuel bed size and moisture on the flammability of eucalyptus saligna leaves in cone calorimeter testing. Fire Saf. J. 2020, 103016. [Google Scholar] [CrossRef]

- González, W.A.; Zimmermann, F.; Pérez, J.F. Thermodynamic assessment of the fixed-bed downdraft gasification process of fallen leaves pelletized with glycerol as binder. Case Stud. Therm. Eng. 2019, 14, 100480. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, J.; Huang, J.; He, W.; Li, G. Conversion of phoenix tree leaves into hydro-char by microwave-assisted hydrothermal carbonization. Bioresour. Technol. Rep. 2020, 9, 100353. [Google Scholar] [CrossRef]

- Gupta, A.; Siddiqui, H.; Rathi, S.; Mahajani, S. Intra-pellet transport limitations in the pyrolysis of raintree leaves litter. Energy 2020, 216, 119267. [Google Scholar] [CrossRef]

- Szufa, S.; Wielgosiński, G.; Piersa, P.; Czerwińska, J.; Dzikuć, M.; Adrian, Ł.; Lewandowska, W.; Marczak, M. Torrefaction of straw from oats and maize for use as a fuel and additive to organic fertilizers—TGA analysis, kinetics as products for agricultural purposes. Energies 2020, 13, 2064. [Google Scholar] [CrossRef] [Green Version]

- Szufa, S.; Piersa, P.; Adrian, Ł.; Sielski, J.; Grzesik, M.; Romanowska-Duda, Z.; Piotrowski, K.; Lewandowska, W. Acquisition of torrefied biomass from jerusalem artichoke grown in a closed circular system using biogas plant waste. Molecules 2020, 25, 3862. [Google Scholar] [CrossRef]

- Wróbel, M.; Frączek, J.; Jewiarz, M.; Mudryk, K.; Dziedzic, K. Impact of selected properties of raw material on quality features of granular fertilizers obtained from digestates and ASH mixtures. Agric. Eng. 2016. [Google Scholar] [CrossRef] [Green Version]

- Obidziński, S.; Dołżyńska, M.; Kowczyk-Sadowy, M.; Jadwisieńczak, K.; Sobczak, P. Densification and fuel properties of onion husks. Energies 2019, 12, 4687. [Google Scholar] [CrossRef] [Green Version]

- Obidziński, S.; Puchlik, M.; Dołżyńska, M. Pelletization of post-harvest tobacco waste and investigation of flue gas emissions from pellet combustion. Energies 2020, 13, 6002. [Google Scholar] [CrossRef]

- Larsson, S.H.; Thyrel, M.; Geladi, P.; Lestander, T.A. High quality biofuel pellet production from pre-compacted low density raw materials. Bioresour. Technol. 2008, 99, 7176–7182. [Google Scholar] [CrossRef]

- Ragland, K.W.; Aerts, D.J.; Baker, A.J. Properties of wood for combustion analysis. Bioresour. Technol. 1991, 37, 161–168. [Google Scholar] [CrossRef]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Pilot scale production of fuel pellets from waste biomass leaves: Effect of milling size on pelletization process and pellet quality. Fuel 2021, 285, 119145. [Google Scholar] [CrossRef]

- Sepúlveda, F.; Arranz, J.; Miranda, M.; Montero, I.; Rojas, C. Drying and pelletizing analysis of waste from cork granulated industry. Energies 2018, 11, 109. [Google Scholar] [CrossRef] [Green Version]

- Havrland, B.; Ivanova, T.; Lapczynska-Kordon, B.; Kolarikova, M. Comparative analysis of bio-raw materials and biofuels. In Engineering for Rural Development; Latvia University of Agriculture: Jelgava, Latvia, 2013; pp. 541–544. [Google Scholar]

- Francik, S.; Knapczyk, A.; Francik, R.; Ślipek, Z. Analysis of Possible Application of Olive Pomace as Biomass Source; Springer: Cham, Switzerland, 2018; pp. 583–592. [Google Scholar]

- Mudryk, K.; Fraczek, J.; Slipek, Z.; Francik, S.; Wrobel, M. Chosen physico-mechanical properties of cutleaf coneflower (Rudbeckia Laciniata L.) shoots. In Engineering for Rural Development; Latvia University of Agriculture: Jelgava, Latvia, 2013; pp. 658–662. [Google Scholar]

- Knapczyk, A.; Francik, S.; Fraczek, J.; Slipek, Z. Analysis of research trends in production of solid biofuels. In Engineering for Rural Development; Latvia University of Life Sciences and Technologies: Jelgava, Latvia, 2019; Volume 18, pp. 1503–1509. [Google Scholar]

- González, W.A.; López, D.; Pérez, J.F. Biofuel quality analysis of fallen leaf pellets: Effect of moisture and glycerol contents as binders. Renew. Energy 2020, 147, 1139–1150. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Vassileva, C.G. An overview of the behaviour of biomass during combustion: Part II. Ash fusion and ash formation mechanisms of biomass types. Fuel 2014, 117, 152–183. [Google Scholar] [CrossRef]

- Mlonka-Mędrala, A.; Magdziarz, A.; Gajek, M.; Nowińska, K.; Nowak, W. Alkali metals association in biomass and their impact on ash melting behaviour. Fuel 2020, 261, 116421. [Google Scholar] [CrossRef]

- Murri, A.N.; Medri, V.; Papa, E.; Laghi, L.; Mingazzini, C.; Landi, E. Porous geopolymer insulating core from a metakaolin/biomass ash composite. Environments 2017, 4, 86. [Google Scholar] [CrossRef] [Green Version]

- Obraniak, A.; Orczykowska, M.; Olejnik, T.P. The effects of viscoelastic properties of the wetting liquid on the kinetics of the disc granulation process. Powder Technol. 2019, 342, 328–334. [Google Scholar] [CrossRef]

- Łapczyńska-Kordon, B.; Krzysztofik, B.; Sobol, Z. Quality of dried cauliflower according to the methods and drying parameters. BIO Web Conf. 2018, 10, 02017. [Google Scholar] [CrossRef] [Green Version]

- Wójcik, A.; Frączek, J.; Niemczewska-Wójcik, M. The relationship between static and kinetic friction for plant granular materials. Powder Technol. 2020, 361, 739–747. [Google Scholar] [CrossRef]

- Tursunov, O.; Dobrowolski, J.; Zubek, K.; Czerski, G.; Grzywacz, P.; Dubert, F.; Lapczynska-Kordon, B.; Klima, K.; Handke, B. Kinetic study of the pyrolysis and gasification of Rosa multiflora and Miscanthus giganteus biomasses via thermogravimetric analysis. Therm. Sci. 2018, 22, 3057–3071. [Google Scholar] [CrossRef]

- Wąsik, R.; Michalec, K.; Mudryk, K. Research reports variability in static bending strength of the “Tabórz” Scots pine wood (Pinus Sylvestris L.). Drewno 2016, 59. [Google Scholar] [CrossRef]

- Łapczyńska-Kordon, B. Sterowanie procesem mikrofalowego suszenia wybranych owoców i warzyw. Przegląd Elektrotechniczny 2019, 1, 76–79. [Google Scholar] [CrossRef]

- Francik, S.; Knapczyk, A.; Knapczyk, A.; Francik, R. Decision support system for the production of miscanthus and willow briquettes. Energies 2020, 13, 1364. [Google Scholar] [CrossRef] [Green Version]

- Knapczyk, A.; Francik, S.; Wójcik, A.; Bednarz, G. Influence of Storing Miscanthus x Gigantheus on Its Mechanical and Energetic Properties; Springer: Cham, Switzerland, 2018; pp. 651–660. [Google Scholar]

- International Organization for Standardization. Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 3: Moisture in General Analysis Simple; EN ISO 18134-3:2015; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- International Organization for Standardization. Solid Biofuels—Determination of Bulk Density; EN ISO 17828:2016-02; International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- Wróbel, M.; Jewiarz, M.; Mudryk, K.; Knapczyk, A. Influence of raw material drying temperature on the Scots pine (Pinus Sylvestris L.) biomass agglomeration process—A preliminary study. Energies 2020. [Google Scholar] [CrossRef] [Green Version]

- International Organization for Standardization. Solid Biofuels—Determination of Ash Content; EN ISO 18122:2015; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- PKN Polish Committee for Standardization. Solid Fuels—Determination of the Fusibility of Ashes at High Temperature Using a Tubular Method; PN ISO 540:2001; PKN Polish Committee for Standardization: Warsaw, Poland, 2001. [Google Scholar]

- European Union. Council Regulation (EC) No 440/2008 of 30 May 2008. Laying down Test Methods Pursuant to Regulation (EC) No 1907/2006 of the European Parliament and of the Council on the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH). Off. J. Eur. Union 2008, 136. [Google Scholar]

- International Organization for Standardization. Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes—Part 1: Pellets; EN ISO 17831-1:2015; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- International Organization for Standardization. Solid Biofuels—Determination of Calorific Value; EN ISO 18125:2017; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- Cao, W.; Li, J.; Lin, L.; Zhang, X. Release of potassium in association with structural evolution during biomass combustion. Fuel 2020, 287, 119524. [Google Scholar] [CrossRef]

- Tian, X.; Wang, Y.; Zeng, Z.; Dai, L.; Peng, Y.; Jiang, L.; Yang, X.; Yue, L.; Liu, Y.; Ruan, R. Study on the mechanism of co-catalyzed pyrolysis of biomass by potassium and calcium. Bioresour. Technol. 2021, 320, 124415. [Google Scholar] [CrossRef]

- Devi, G.S.; Vaishnavi, S.; Srinath, S.; Dutt, B.; Rajmohan, K.S. Energy recovery from biomass using gasification. In Current Developments in Biotechnology and Bioengineering: Resource Recovery from Wastes; Elsevier: Amsterdam, Netherlands, 2020; pp. 363–382. ISBN 978-0-444-64321-6. [Google Scholar]

- Bridgwater, A.V. The technical and economic feasibility of biomass gasification for power generation. Fuel 1995, 74, 631–653. [Google Scholar] [CrossRef]

- Jagustyn, B.; Kmieć, M.; Smędowski, Ł.; Sajdak, M. The content and emission factors of heavy metals in biomass used for energy purposes in the context of the requirements of international standards. J. Energy Inst. 2017, 90, 704–714. [Google Scholar] [CrossRef]

- García-Maraver, A.; Terron, L.C.; Ramos-Ridao, A.; Zamorano, M. Effects of mineral contamination on the ash content of olive tree residual biomass. Biosyst. Eng. 2014, 118, 167–173. [Google Scholar] [CrossRef]

- Tortosa Masiá, A.A.; Buhre, B.J.P.; Gupta, R.P.; Wall, T.F. Characterising ash of biomass and waste. Fuel Process. Technol. 2007, 88, 1071–1081. [Google Scholar] [CrossRef]

- Mudryk, K.; Hutsol, T.; Wrobel, M.; Jewiarz, M.; Dziedzic, B. Determination of friction coefficients of fast-growing tree biomass. In Engineering for Rural Development; Latvia University of Life Sciences and Technologies: Jelgava, Latvia, 2019; Volume 18, pp. 1568–1573. [Google Scholar] [CrossRef]

- Masto, R.E.; Pandit, A.; Kumar, S.; Datta, S.; Mukhopadhyay, S.; Selvi, V.A.; Dutta, P.; Sarkar, P. Comparative evaluation of aquatic biomass feedstocks for energy application and potential for extraction of plant nutrients from their ash. Biomass Bioenergy 2020, 142, 105783. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Krzyżaniak, M.; Warmiński, K.; Załuski, D.; Olba-Zięty, E. Willow biomass as energy feedstock: The effect of habitat, genotype and harvest rotation on thermophysical properties and elemental composition. Energies 2020, 13, 4130. [Google Scholar] [CrossRef]

- Lanzerstorfer, C. Combustion of miscanthus: Composition of the ash by particle size. Energies 2019, 12, 178. [Google Scholar] [CrossRef] [Green Version]

- Jewiarz, M.; Wróbel, M.; Mudryk, K.; Szufa, S. Impact of the drying temperature and grinding technique on biomass grindability. Energies 2020, 13, 3392. [Google Scholar] [CrossRef]

- Monedero, E.; Hernández, J.; Collado, R. Combustion-related properties of poplar, willow and black locust to be used as fuels in power plants. Energies 2017, 10, 997. [Google Scholar] [CrossRef] [Green Version]

- Mudryk, K.; Fraczek, J.; Wrobel, M.; Jewiarz, M. Pressure agglomeration herbaceous raw materials intended for consumer purposes. In Engineering for Rural Development; Latvia University of Life Sciences and Technologies: Jelgava, Latvia, 2018; Volume 17. [Google Scholar]

- Moliner, C.; Bove, D.; Arato, E. Co-incineration of rice straw-wood pellets: a sustainable strategy for the valorisation of rice waste. Energies 2020, 13, 5750. [Google Scholar] [CrossRef]

- Picchio, R.; Latterini, F.; Venanzi, R.; Stefanoni, W.; Suardi, A.; Tocci, D.; Pari, L. Pellet production from woody and non-woody feedstocks: A review on biomass quality evaluation. Energies 2020, 13, 2937. [Google Scholar] [CrossRef]

- Drach, K.L.; Kuzyk, A.D.; Tovarianskyi, V.I.; Yemelianenko, S.O. Fire dangerous properties of the most common plants of grass ecosystems in Ukraine. Ecol. Balk. 2020, 12, 147–154. [Google Scholar]

- Jones, J.M.; Saddawi, A.; Dooley, B.; Mitchell, E.J.S.; Werner, J.; Waldron, D.J.; Weatherstone, S.; Williams, A. Low temperature ignition of biomass. Fuel Process. Technol. 2015, 134. [Google Scholar] [CrossRef] [Green Version]

- Magalhães, D.; Kazanç, F.; Ferreira, A.; Rabaçal, M.; Costa, M. Ignition behavior of Turkish biomass and lignite fuels at low and high heating rates. Fuel 2017, 207. [Google Scholar] [CrossRef]

- Półka, M. Analysis of susceptibility of peat on its spontaneous heating and self-ignition properties. MATEC Web Conf. 2018, 247. [Google Scholar] [CrossRef] [Green Version]

- Schwarzer, L.; Jensen, P.A.; Glarborg, P.; Holm, J.K.; Dam-Johansen, K. General Rights Biomass Ignition in Mills and Storages-Is It Explained by Conventional Thermal Ignition Theory? Technical University of Denmark: Lyngby, Denmark, 2018. [Google Scholar]

- Schwarzer, L.; Jensen, P.A.; Glarborg, P.; Holm, J.K.; Dam-Johansen, K. The role of inorganic matter in biomass self-ignition. In Proceedings of the European Biomass Conference and Exhibition, Copenhagen, Denmark, 18 May 2018; Volume 2018. [Google Scholar]

- Villacorta, E.; Haraldseid, I.; Mikalsen, R.F.; Hagen, B.C.; Erland, S.; Kleppe, G.; Krause, U.; Frette, V. Onset of smoldering fires in storage silos: Susceptibility to design, scenario, and material parameters. Fuel 2021, 284. [Google Scholar] [CrossRef]

- Tang, Y.; Zhou, J. Laboratory investigation on the spontaneous combustion of a lignocellulosic biomass and its suppression by chemical inhibitors. Energy Fuels 2020, 34. [Google Scholar] [CrossRef]

- Toscano, G.; Feliciangeli, G.; Rossini, G.; Fabrizi, S.; Foppa Pedretti, E.; Duca, D. Engineered solid biofuel from herbaceous biomass mixed with inorganic additives. Fuel 2019, 256. [Google Scholar] [CrossRef]

- Wang, Q.; Han, K.; Wang, P.; Li, S.; Zhang, M. Influence of additive on ash and combustion characteristics during biomass combustion under O2/CO2 Atmosphere. Energy 2020, 195. [Google Scholar] [CrossRef]

| Parameters | Wavelengths (nm) | Limit Detection (mg∙dm−3) | Content in Cert. Material (mg∙kg−1) | Measured (mg∙kg−1) | Recovery (%) |

|---|---|---|---|---|---|

| Ca | 317.933 | 0.01 | 21,600 | 20,896 | 97 |

| Cd | 228.802 | 0.0027 | 0.03 | 0.0305 | 102 |

| Cr | 267.707 | 0.0071 | 6.5 | 6.860 | 106 |

| Cu | 327.393 | 0.0097 | 9.4 | 10.01 | 106 |

| Fe | 238.204 | 0.0046 | 185 | 168.5 | 91 |

| K | 766.490 | - | 21,000 | 20,740 | 99 |

| Mg | 285.208 | 0.0016 | 1360 | 1423 | 105 |

| Mn | 257.608 | 0.0014 | 47 | 44.83 | 95 |

| Na | 589.592 | 0.069 | 500 | 472.4 | 94 |

| Ni | 231.604 | 0.0151 | 4 | 4.359 | 109 |

| P | 213.617 | 0.076 | 2300 | 2248 | 98 |

| Pb | 220.353 | 0.0425 | 1.6 | 1.508 | 94 |

| Zn | 206.200 | 0.0059 | 24 | 25.32 | 106 |

| Salix | Acer | Quercus | Platanus | Liquidambar | |

|---|---|---|---|---|---|

| Ca | 15,435.7 | 12,678.5 | 14,407.9 | 11,613.5 | 9720.8 |

| ± | 1722.5 | 996.5 | 1098.6 | 896.8 | 1102.5 |

| Cd | 0.9426 | 0.1947 | 0.1254 | 0.1988 | 0.3612 |

| ± | 0.0723 | 0.0282 | 0.0663 | 0.0234 | 0.0411 |

| Cr | 20.231 | 10.742 | 8.332 | 13.342 | 5.250 |

| ± | 1.5226 | 2.492 | 1.729 | 1.509 | 0.729 |

| Cu | 4.640 | 4.189 | 4.021 | 2.886 | 2.172 |

| ± | 0.753 | 0.581 | 0.277 | 0.439 | 0.128 |

| Fe | 854.1 | 395.8 | 426.3 | 446.1 | 330.1 |

| ± | 125.5 | 28.4 | 58.63 | 27.62 | 38.53 |

| K | 6574.2 | 6317.1 | 3967.6 | 3924.0 | 2713.9 |

| ± | 483.5 | 594.7 | 411.9 | 272.9 | 496.7 |

| Mg | 904.4 | 1021.7 | 1292.1 | 1175.5 | 1473.0 |

| ± | 192.6 | 138.7 | 100.9 | 168.2 | 211.6 |

| Mn | 81.47 | 312.57 | 93.36 | 73.49 | 220.03 |

| ± | 14.77 | 48.23 | 9.16 | 14.91 | 36.8 |

| Na | 36.235 | 21.330 | 35.614 | 29.918 | 18.488 |

| ± | 2.893 | 1.728 | 2.83 | 3.628 | 2.466 |

| Ni | 1.2529 | 0.5845 | 0.6754 | 0.6386 | 1.4686 |

| ± | 0.096 | 0.0709 | 0.0842 | 0.0859 | 0.1163 |

| P | 1038.3 | 1479.1 | 1185.12 | 801.9 | 653.6 |

| ± | 121.8 | 163.4 | 96.85 | 66.82 | 94.11 |

| Pb | 3.352 | 2.272 | 2.029 | 1.590 | 1.488 |

| ± | 0.427 | 0.339 | 0.173 | 0.186 | 0.118 |

| Zn | 120.36 | 87.98 | 38.22 | 31.58 | 59.23 |

| ± | 9.419 | 11.62 | 6.73 | 4.48 | 9.16 |

| Material Properties | Salix | Acer | Quercus | Platanus | Liquidambar |

|---|---|---|---|---|---|

| Moisture after harvesting Mar (%) | 32.8 ± 0.3 | 25.4 ± 0.2 | 23.2 ± 0.2 | 23.4 ± 0.2 | 26.3 ± 0.2 |

| Moisture after grinding Mar (%) | 13.6 ± 0.2 | 12.6 ± 0.2 | 13.1 ± 0.2 | 14.2 ± 0.2 | 13.8 ± 0.2 |

| Bulk density of whole tree leaves BDar (kg·m−3) | 46.1 ± 2.6 | 11.5 ± 0.6 | 28.2 ± 1.4 | 12.2 ± 0.8 | 22.4 ± 1.3 |

| Bulk density after grinding BDar (kg·m−3) | 115.7 ± 7.1 | 98.4 ± 5.1 | 121.1 ± 7.3 | 93.4 ± 5.5 | 144.9 ± 8.6 |

| Compaction degree after grinding IDm (-) | 2.51 ± 0.28 | 8.55 ± 0.39 | 4.29 ± 0.34 | 7.65 ± 0.42 | 6.47 ± 0.38 |

| Pelet Properties | Salix | Acer | Quercus | Platanus | Liquidambar |

| Ash content (as received) Aar (%) | 20.12 ± 0.31 | 11.95 ± 0.08 | 11.62 ± 0.09 | 9.79 ± 0.11 | 10.27 ± 0.04 |

| Moisture content Mar (%) | 11.8 ± 0.1 | 10.3 ± 0.1 | 10.9 ± 0.2 | 12.2 ± 0.1 | 12.4 ± 0.2 |

| Ash content (dry) Ad (%) | 22.81 ± 0.32 | 13.32 ± 0.10 | 13.04 ± 0.11 | 11.15 ± 0.12 | 11.72 ± 0.06 |

| LHV qp. net. ar (J·g−1) | 14,502 ± 293 | 15,233 ± 274 | 15,495 ± 281 | 14,990 ± 312 | 15,567 ± 265 |

| Bulk density BDar (kg·m−3) | 658.9 ± 12.5 | 603.4 ± 15.4 | 650.2 ± 18.4 | 611.6 ± 14.4 | 665.8 ± 10.3 |

| Compaction degree pelletizing IDp (-) | 5.69 ± 0.28 | 6.13 ± 0.32 | 5.37 ± 0.21 | 6.55 ± 0.18 | 4.59 ± 0.16 |

| Absolute compaction degree IDa (-) | 14.29 ± 0.54 | 52.47 ± 1.22 | 23.06 ± 0.38 | 50.13 ± 1.85 | 29.72 ± 0.58 |

| Specific density of the particle DE (kg·m−3) | 1249 ± 68 | 1114 ± 38 | 1243 ± 56 | 1176 ± 46 | 1267 ± 43 |

| Mechanical durability DU (%) | 90.30 ± 0.25 | 91.70 ± 0.59 | 95.99 ± 0.67 | 92.58 ± 0.61 | 96.56 ± 0.37 |

| Sample | RSIT (°C) | SD (°C) |

|---|---|---|

| Salix | 221.0 | 3.6 |

| Acer | 231.6 | 3.5 |

| Quercus | 232.0 | 5.2 |

| Platanus | 228.3 | 3.5 |

| Liquidambar | 239.0 | 3.0 |

| Characteristic Melting Temperatures of Ash: | Salix | Acer | Quercus | Platanus | Liquidambar |

|---|---|---|---|---|---|

| DT deformation temp. (°C) | 1045 ± 10 | 980 ± 17 | 1045 ± 15 | 1140 ± 13 | 1080 ± 15 |

| ST ball temp. (°C) | 1250 ± 12 | 1160 ± 14 | 1250 ± 11 | 1270 ± 15 | 1180 ± 17 |

| HT hemisphere temp. (°C) | 1260 ± 9 | 1350 ± 12 | 1260 ± 8 | 1350 ± 7 | 1330 ± 9 |

| FT flow temp. (°C) | 1310 ± 11 | 1460 ± 13 | 1330 ± 14 | 1430 ± 11 | 1370 ± 16 |

| Bulk density BDd (kg·m−3) | 445.5 ± 10.2 | 216.7 ± 8.6 | 261.3 ± 15.2 | 229.3 ± 2.2 | 263.7 ± 11.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mudryk, K.; Jewiarz, M.; Wróbel, M.; Niemiec, M.; Dyjakon, A. Evaluation of Urban Tree Leaf Biomass-Potential, Physico-Mechanical and Chemical Parameters of Raw Material and Solid Biofuel. Energies 2021, 14, 818. https://0-doi-org.brum.beds.ac.uk/10.3390/en14040818

Mudryk K, Jewiarz M, Wróbel M, Niemiec M, Dyjakon A. Evaluation of Urban Tree Leaf Biomass-Potential, Physico-Mechanical and Chemical Parameters of Raw Material and Solid Biofuel. Energies. 2021; 14(4):818. https://0-doi-org.brum.beds.ac.uk/10.3390/en14040818

Chicago/Turabian StyleMudryk, Krzysztof, Marcin Jewiarz, Marek Wróbel, Marcin Niemiec, and Arkadiusz Dyjakon. 2021. "Evaluation of Urban Tree Leaf Biomass-Potential, Physico-Mechanical and Chemical Parameters of Raw Material and Solid Biofuel" Energies 14, no. 4: 818. https://0-doi-org.brum.beds.ac.uk/10.3390/en14040818