Selected Aspects of Indoor Climate in a Passive Office Building with a Thermally Activated Building System: A Case Study from Poland

Abstract

:1. Introduction

2. Materials and Methods

2.1. Case Object

2.2. Measurements

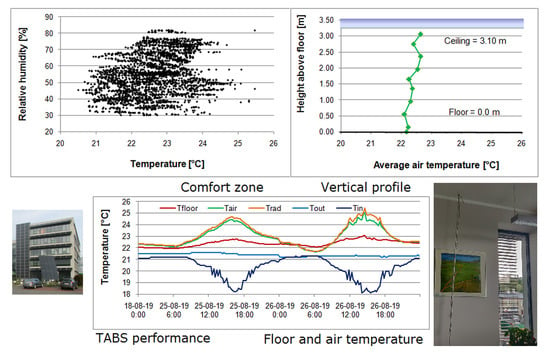

3. Indoor Environment in the Office Room

3.1. Floor Temperature

3.2. Vertical Temperature Profile

3.3. Internal Air Temperature and Relative Humidity

3.4. Thermal Comfort According to EN ISO 7730

3.5. PMV and PPD

4. Thermal Performance of the TABS

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dołęga, W. Selected aspects of national economy energy efficiency. Energy Policy J. 2019, 22, 19–32. [Google Scholar] [CrossRef]

- Kozik, R.; Karasińska—Jaśkowiec, I. Green public procurement—Legal base and instruments supporting sustainable development in the construction industry in Poland. E3S Web Conf. 2016, 00044. [Google Scholar] [CrossRef] [Green Version]

- Ramczyk, M. Legal bases and economic conditions of applying renewable energy resources in construction industry. MATEC Web Conf. 2018, 174, 04004. [Google Scholar] [CrossRef]

- Building Performance Institute Europe (BPIE). Financing Building Energy Performance Improvement in Poland; BPIE: Brussels, Belgium, 2016; Available online: http://bpie.eu/wpcontent/uploads/2016/01/BPIE_Financing-building-energy-in-Poland_EN.pdf (accessed on 4 February 2021).

- The European Parliament and The Council. Directive 2002/91/EC of the European Parliament and of the Council of 16 December 2002 on the energy performance of buildings, 4.1.2003. Off. J. Eur. Communities 2002, L 1, 65–71. [Google Scholar]

- The European Parliament and The Council. Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the energy performance of buildings (recast), L 153/16. Off. J. Eur. Union 2010, L 153, 13–35. [Google Scholar]

- Deja, B.M.; Tyburski, J. Selected aspects of designing and realization of low energy single-family houses according to the NF15 and NF40 standards. Tech. Sci. 2015, 18, 103–114. Available online: http://uwm.edu.pl/wnt/technicalsc/tech_18_2/deja.pdf (accessed on 5 February 2021).

- PN- EN ISO 13790. Energy Performance of Buildings—Calculation of Energy Use for Space Heating and Coolin; Polish Standardization Committee: Warsaw, Poland, 2008. [Google Scholar]

- Pineau, D.; Rivière, P.; Stabat, P.; Hoang, P.; Archambault, V. Performance analysis of heating systems for low energy houses. Energy Build. 2013, 65, 45–54. [Google Scholar] [CrossRef]

- Martinopoulos, G.; Papakostas, K.T.; Papadopoulos, A.M. Comparative analysis of various heating systems for residential buildings in Mediterranean climate. Energy Build. 2016, 124, 79–87. [Google Scholar] [CrossRef]

- Milwicz, R.; Pasławski, J. Comparative analysis of heating systems in terms of flexibility in sustainable buildings. Procedia Eng. 2017, 82–89. [Google Scholar] [CrossRef]

- Sandvall, A.F.; Ahlgren, E.O.; Ekvall, T. Cost-efficiency of urban heating strategies—Modelling scale effects of low-energy building heat supply. Energy Strategy Rev. 2017, 18, 212–223. [Google Scholar] [CrossRef]

- Kumar, N.M.; Mathew, M. Comparative life-cycle cost and GHG emission analysis of five different water heating systems for residential buildings in Australia. Beni. Suef. Univ. J. Basic Appl. Sci. 2018, 7, 748–751. [Google Scholar] [CrossRef]

- Dec, K.; Broniewicz, E.; Broniewicz, M. The Possibility Analysis of Adapting a Public Building to the Standard of a Building with a Zero Energy Balance. Energies 2020, 13, 6389. [Google Scholar] [CrossRef]

- Vadiee, A.; Dodoo, A.; Jalilzadehazhari, E. Heat Supply Comparison in a Single-Family House with Radiator and Floor Heating Systems. Buildings 2020, 10, 5. [Google Scholar] [CrossRef] [Green Version]

- Romaní, J.; Gracia, A.; Cabeza, L.F. Simulation and control of thermally activated building systems (TABS). Energy Build. 2016, 22–42. [Google Scholar] [CrossRef] [Green Version]

- Chung, W.J.; Park, S.H.; Yeo, M.S.; Kim, K.W. Control of Thermally Activated Building System Considering Zone Load Characteristics. Sustainability 2017, 9, 586. [Google Scholar] [CrossRef] [Green Version]

- Guerrero, M.C.; Sánchez, J.; Álvarez, S.; Tenorio, J.A.; Cabeza, L.F.; Bartolomé, C.; Pavón, M. Evaluation of the behavior of an innovative thermally activated building system (TABS) with PCM for an efficient design. E3S Web Conf. 2019, 111, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Behrendt, B. Possibilities and Limitations of Thermally Activated Building Systems: Simply TABS and a Climate Classification for TABS. Ph.D. Thesis, Technical University of Denmark, Copenhagen, Denmark, 2016. Rapport, No. R-361. Available online: https://orbit.dtu.dk/en/publications/possibilities-and-limitations-of-thermally-activated-building-sys (accessed on 5 February 2021).

- Chung, W.J.; Lim, J. Improved Thermally Activated Building System Design Method Considering Integration of Air Systems. Adv. Civ. Eng. 2018, 4928746. [Google Scholar] [CrossRef]

- Boccardo, L.B.; Kazanci, O.B. Economic comparison of TABS, PCM ceiling panels and all-air systems for cooling offices. Energy Build. 2019, 205, 109527. [Google Scholar] [CrossRef]

- Manfren, M.; Nastasi, B.; Piana, E.; Tronchin, L. On the link between energy performance of building and thermal comfort: An example. AIP Conf. Proc. 2019, 2123, 020066. [Google Scholar] [CrossRef]

- Blaszczok, M.; Baranowski, A. Thermal improvement in residential buildings in view of the indoor air quality—case study for Polish dwelling. Arch. Civ. Eng. Environ. 2018, 11, 121–130. [Google Scholar] [CrossRef] [Green Version]

- Suszanowicz, D.; Pietkun-Greber, I. The effectiveness of various types of ventilation on air quality in multi-family building. Ecol. Chem. Eng. A 2017, 24, 33–41. [Google Scholar] [CrossRef]

- Lis, A. The efficiency of energy saving activities in the process of thermal modernization of multifamily buildings. BoZPE 2019, 8, 107–116. [Google Scholar] [CrossRef]

- Podawca, K.; Pawłat-Zawrzykraj, A.; Dohojda, M. Analysis of the possibilities for improvement of thermal comfort of living quarters located in multi-family large-panel prefabricated buildings. E3S Web Conf. 2018, 44, 00145. [Google Scholar] [CrossRef]

- Sowa, J. Air Quality and Ventilation Rates in Schools in Poland—Requirements, Reality and Possible Improvements. Proceedings: Indoor Air 2002, Monterey, CA, USA. Volume III, pp. 68–73. Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.1080.8791&rep=rep1&type=pdf (accessed on 5 February 2021).

- Sowa, J.; Karaś, A. Whole Year Simulation of Natural and Hybrid Ventilation Performance and Estimation Indoor Air Quality for Modernized School Building. Proceedings of Clima 2007 WellBeing Indoors. Available online: http://www.inive.org/members_area/medias/pdf/Inive/clima2007/B06/B06F1566.pdf (accessed on 5 February 2021).

- Albatayneh, A.; Alterman, D.; Page, A.; Moghtaderi, B. The Significance of the Adaptive Thermal Comfort Limits on the Air-Conditioning Loads in a Temperate Climate. Sustainability 2019, 11, 328. [Google Scholar] [CrossRef] [Green Version]

- PN-EN ISO 7730: 2006. Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using the Calculation of PMV and PPD Indicators and Criteria of Local Thermal Comfort; Polish Standardization Committee: Warsaw, Poland, 2006. [Google Scholar]

- PN-EN ISO 7726: 2001. Ergonomics of the Thermal Environment. Instruments for Measuring Physical Quantities; Polish Standardization Committee: Warsaw, Poland, 2001. [Google Scholar]

- PN-EN 15251:2012. Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics; Polish Committee for Standardization: Warsaw, Poland, 2012. [Google Scholar]

- Fedorczak-Cisak, M.; Kowalska-Koczwara, A.; Nering, K.; Pachla, F.; Radziszewska-Zielina, E.; Sladowski, G.; Tatara, T.; Ziarko, B. Evaluation of the Criteria for Selecting Proposed Variants of Utility Functions in the Adaptation of Historic Regional Architecture. Sustainability 2019, 11, 1094. [Google Scholar] [CrossRef] [Green Version]

- Grygierek, K.; Ferdyn-Grygierek, J. Multi-Objective optimization of Envelope Building with Natural Ventilation. Energies 2018, 11, 1383. [Google Scholar] [CrossRef] [Green Version]

- Nowak-Dzieszko, K.; Rojewska-Warchał, M. Thermal comfort of the individual flats of multi-family panel building. Tech. Trans. Civ. Eng. 2014, 201–206. [Google Scholar] [CrossRef]

- Antczak-Jarząbska, R.; Krzaczek, M. Assessment of Natural Ventilation System for a Typical Residential House in Poland. CEER 2016, 22, 025–044. [Google Scholar] [CrossRef] [Green Version]

- Zygmunt, M.; Gawin, D. Analysis of energy efficiency and thermal comfort for an office building complex located in Poland—a case study. IOP Conf. Ser. Mater. Sci. Eng. 2018, 415, 012023. [Google Scholar] [CrossRef]

- Nowak, K.; Rojewska-Warchał, M. Thermal comfort of office rooms with a large area of glazing. Tech. Trans. Civ. Eng. 2014, 335–342. [Google Scholar] [CrossRef]

- Saelens, D.; Parys, W.; Baetens, R. Energy and comfort performance of thermally activated building systems including occupant behavior. Build. Environ. 2011, 46, 835–848. [Google Scholar] [CrossRef]

- Sigg, F.; Krause, H. Occupant comfort in Nearly Zero Energy Buildings (nZEB) by using the building structure for demand side management (DMS). E3S Web Conf. 2020, 172, 6011. [Google Scholar] [CrossRef]

- Drgoňa, J.; Picard, D.; Helsen, L. Cloud-based implementation of white-box model predictive control for a GEOTABS office building: A field test demonstration. J. Process. Control 2020, 88, 63–77. [Google Scholar] [CrossRef]

- Pałaszyńska, K.; Bandurski, K.; Porowski, M. Energy demand and thermal comfort of HVAC systems with thermally activated building systems as a function of user profile. E3S Web Conf. 2017, 22, 00130. [Google Scholar] [CrossRef] [Green Version]

- Gantiez, C.; Lemort, V.; Hoogmartens, J.; Bockelmann, F.; Kipry, H. Energy and Comfort Performance Analysis of Monitored Thermally Activated Building Systems Combined with Geothermal Heat Pumps. Int. High. Perform. Build. Conf. 2020. Available online: http://docs.lib.purdue.edu/ihpbc/82 (accessed on 5 February 2021).

- Raimondo, D.; Olesen, B.W.; Corgnati, S.P. Field test of a thermal active building system (tabs) in an office building in Denmark. In Proceedings of the 13th Conference of International Building Performance Simulation Association (IBPSA; BS2013), Kogens Lyngby, Denmark, 26–28 August 2013; pp. 2527–2534. [Google Scholar]

- Zhang, C.; Yu, T.; Heiselberg, P.; Pomianowski, M.Z. Experimental Study of an Integrated System with Diffuse Ceiling Ventilation and Thermally Activated Building Constructions. Department of Civil Engineering, Aalborg University DCE Technical Reports No. 182. , 2014. Available online: https://vbn.aau.dk/ws/portalfiles/portal/207597383/Experimental_Study_of_an_Integrated_System_with_Diffuse_Ceiling_Ventilation_and_Thermally_Activated_Building_Constructions.pdf (accessed on 5 February 2021).

- Rey Martínez, F.J.; Chicote, M.A. Villanueva Peñalver, A.; Tejero Gónzalez, A.; Velasco Gómez, E. Indoor air quality and thermal comfort evaluation in a Spanish modern low-energy office with thermally activated building systems. Sci. Technol. Built Environ. 2015, 21, 1091–1099. [Google Scholar] [CrossRef]

- Piasecki, M.; Fedorczak-Cisak, M.; Furtak, M.; Biskupski, J. Experimental Confirmation of the Reliability of Fanger’s Thermal Comfort Model—Case Study of a Near-Zero Energy Building (NZEB) Office Building. Sustainability 2019, 11, 2461. [Google Scholar] [CrossRef] [Green Version]

- Piasecki, M.; Kostyrko, K.; Fedorczak-Cisak, M.; Nowak, K. Air Enthalpy as an IAQ Indicator in Hot and Humid Environment—Experimental Evaluation. Energies 2020, 13, 1481. [Google Scholar] [CrossRef] [Green Version]

- Sinacka, J.; Szczechowiak, E. Heat Flow Modelling in a Building with Thermally Activated Building Systems [in Polish]. District. Heat Heat Vent. 2018, 49, 271–278. [Google Scholar] [CrossRef]

- Gil, S.; Rozpondek, M.; Grychowski, T. The analysis of indoor environment parameters in office buildings. Acta Mech. Slovaca 2012, 16, 74–81. [Google Scholar] [CrossRef]

- Szpytma, M.; Rybka, A. Ecological ideas in Polish architecture—environmental impact. J. Civ. Eng. Environ. Arch. 2016, XXXIII, 321–328. [Google Scholar] [CrossRef] [Green Version]

- Kontes, G.D.; Giannakis, G.I.; Horn, P.; Steiger, S.; Rovas, D.V. Using Thermostats for Indoor Climate Control in Office Buildings: The Effect on Thermal Comfort. Energies 2017, 10, 1368. [Google Scholar] [CrossRef] [Green Version]

- Michalak, P.; Grygierczyk, S. Heat pumps in the passive office building: First exploitation results. District. Heat Heat Vent. 2015, 46, 396–398. (In Polish) [Google Scholar] [CrossRef]

- Michalak, P.; Grygierczyk, S. Temperature efficiency of the heat recovery in an air-handling unit with a rotary heat exchanger. District. Heat Heat Vent. 2018, 49, 183–187. (In Polish) [Google Scholar] [CrossRef]

- Michalak, P.; Grygierczyk, S. Temperature Efficiency of Heat Exchangers in Air Handling Units. J. Mech. Energy Eng. 2019, 3, 267–272. [Google Scholar] [CrossRef] [Green Version]

- Domínguez Lacarte, L.M.; Fan, J. Modelling of a thermally activated building system (TABS) combined with free-hanging acoustic ceiling units using computational fluid dynamics (CFD). Build. Simul. 2018, 11, 315–324. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Kvols Heiselberg, P.; Chen, Q.; Pomianowski, M. Numerical analysis of diffuse ceiling ventilation and its integration with a radiant ceiling system. Build. Simul. 2017, 10, 203–218. [Google Scholar] [CrossRef] [Green Version]

- Digital Relative Humidity & Temperature Sensor DHT11. Aosong Electronics Co., Ltd. Available online: https://www.electronicoscaldas.com/datasheet/DHT11_Aosong.pdf (accessed on 28 December 2020).

- DS18B20 Programmable Resolution 1-Wire Digital Thermometer. Maxim Integrated Products, Inc. Available online: https://datasheets.maximintegrated.com/en/ds/DS18B20.pdf (accessed on 28 December 2020).

- Seidel, D.S.; Field, T.C.; Schinckel, A.P.; Stwalley, C.S.; Stwalley, R.M. Effects of temperature probe orientation on the Purdue hog cooling pad data acquisition. Comput. Electron. Agric. 2020, 175, 105609. [Google Scholar] [CrossRef]

- Nasruddin, A.N.; Tee, B.T.; Mustafah, M.T.; Jasman, M.E.S.M. Ambient data analytic on indoor environment monitoring for office buildings in hot and humid climates. Data Brief 2019, 27, 104534. [Google Scholar] [CrossRef] [PubMed]

- Doolan Fernandes, J.; Carvalho Souza, F.E.; Cipriano Maniçoba, G.G.; Salazar, A.O.; De Paiva, J.A. Wireless Monitoring of Induction Machine Rotor Physical Variables. Sensors 2017, 17, 2660. [Google Scholar] [CrossRef] [Green Version]

- Obando Vega, F.A.; Montoya Ríos, A.P.; Osorio Saraz, J.A.; Vargas Quiroz, L.G.; Alves Damasceno, F. Assessment of black globe thermometers employing various sensors and alternative materials. Agric. For. Meteorol. 2020, 284, 107891. [Google Scholar] [CrossRef]

- Walikewitz, N.; Janicke, B.; Langner, M.; Meier, F.; Endlicher, W. The difference between the mean radiant temperature and the air temperature within indoor environments: A case study during summer conditions. Build. Environ. 2015, 84, 151–161. [Google Scholar] [CrossRef]

- PN EN 12831-1: 2017. Energy Performance of Buildings—Method for Calculation of the Design Heat Load; Polish Committee of Standardisation: Warsaw, Poland, 2017. [Google Scholar]

- Nowak, S. Management of Heat Energy Consumption in Poland For The Purpose of Buildings’ Heating and Preparation Of Useable, Hot Water. Ann. Univ. Apulensis Ser. Oeconomica 2009, 11, 895–901. Available online: http://www.oeconomica.uab.ro/upload/lucrari/1120092/33.pdf (accessed on 5 February 2021).

- Dylewski, R.; Adamczyk, J. The environmental impacts of thermal insulation of buildings including the categories of damage: A Polish case study. J. Clean. Prod. 2016, 137, 878–887. [Google Scholar] [CrossRef]

- GIG Institute Meteo Station. Available online: http://meteo.gig.eu (accessed on 28 December 2020).

- PN-EN ISO 11855-1:2015. Building Environment Design—Design, Dimensioning, Installation and Control of Embedded Radiant Heating and Cooling Systems—Part 1: Definition, Symbols, and Comfort Criteria; Polish Standardization Committee: Warsaw, Poland, 2015. [Google Scholar]

- Potter, S.E.; Underwood, C.P. SE Potter and CP Underwood, A modelling method for conjugate heat transfer and fluid flow in building spaces. Build. Serv. Eng. Res. Technol. 2004, 25, 111. [Google Scholar] [CrossRef]

- Lastovets, N.; Kosonen, R.; Mustakallio, P.; Jokisalo, J.; Li, A. Modelling of room air temperature profile with displacement ventilation. Int. J. Vent. 2020, 19, 112–126. [Google Scholar] [CrossRef]

- Gao, R.; Li, A.; Zhang, O.; Zhang, H. Comparison of indoor air temperatures of different under-floor heating pipe layouts. Energy Convers. Manag. 2011, 52, 1295–1304. [Google Scholar] [CrossRef]

- Jia, H.; Pang, X.; Haves, P. Experimentally-determined characteristics of radiant systems for office buildings. Appl. Energy 2018, 221, 41–54. [Google Scholar] [CrossRef] [Green Version]

- Novoselac, A.; Burley, B.J.; Srebric, J. New Convection Correlations for Cooled Ceiling Panels in Room with Mixed and Stratified Airflow. HVAC&R Res. 2006, 12, 279–294. [Google Scholar] [CrossRef]

- Shin, M.S.; Rhee, K.N.; Park, S.H.; Yeo, M.S.; Kim, K.W. Enhancement of cooling capacity through open-type installation of cooling radiant ceiling panel systems. Build. Environ. 2019, 148, 417–432. [Google Scholar] [CrossRef]

- Fikru, M.G.; Gautier, L. The impact of weather variation on energy consumption in residential houses. Appl. Energy 2015, 144, 19–30. [Google Scholar] [CrossRef]

- Spinoni, J.; Vogt, J.; Barbosa, P. European degree-day climatologies and trends for the period 1951–2011. Int. J. Climatol. 2015, 35, 25–36. [Google Scholar] [CrossRef] [Green Version]

- Heating and Cooling Degree Days, European Environment Agency. Available online: https://www.eea.europa.eu/data-and-maps/indicators/heating-degree-days-2 (accessed on 28 December 2020).

- Fabrizio, E.; Corgnati, S.P.; Causone, F.; Filippi, M. Numerical comparison between energy and comfort performances of radiant heating and cooling systems versus air systems. HVAC&R Res. 2012, 18, 692–708. [Google Scholar] [CrossRef]

- Olesen, B. Radiant floor heating in theory and practice. ASHRAE J. 2002, 44, 19–26. [Google Scholar]

- Hasan, A.; Kurnitski, J.; Jokiranta, K. A combined low temperature water heating system consisting of radiators and floor heating. Energy Build. 2009, 41, 470–479. [Google Scholar] [CrossRef]

- Catalina, T.; Virgone, J.; Kuznik, F. CFD and experimentation study in a test room equipped with a cooling ceiling. Build. Environ. 2009, 44, 1740–1750. [Google Scholar] [CrossRef]

- Leo Samuel, D.G.; Shiva Nagendra, S.M.; Maiya, M.P. A sensitivity analysis of the design parameters for thermal comfort of thermally activated building system. Sådhanå 2019, 44, 48. [Google Scholar] [CrossRef] [Green Version]

- Klein, O.; Schlenger, J. Basics Room Conditioning; Birkhäuser Verlag: Basel, Switerland, 2008. [Google Scholar]

- Dalheimer, M. Energiemanagement für Mietwohnungen mit Open-Source Smart Metern (EMOS), Fraunhofer IRB Verlag, Stuttgart. 2015. Available online: https://www.irbnet.de/daten/rswb/15109001837.pdf (accessed on 5 February 2021).

- Czernecki, B.; Miętus, M. The thermal seasons variability in Poland, 1951–2010. Theor. Appl. Climatol. 2017, 127, 481–493. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Parkinson, T.; Brager, G.; Schiavon, S.; Cheung, T.C.T.; Froese, T. A data-driven approach to defining acceptable temperature ranges in buildings. Build. Environ. 2019, 153, 302–312. [Google Scholar] [CrossRef] [Green Version]

- Baharum, M.A.; Surat, M.; Tawil, N.M.; Che-Ani, A.I. Modern Housing Tranquillity in Malaysia from the Aspect of Thermal Comfort for Humid Hot Climate Zone. E3S Web Conf. 2014, 01008. [Google Scholar] [CrossRef] [Green Version]

- Shaharon, M.N.; Jalaludin, J. Thermal Comfort Assessment-A Study Toward Workers’ Satisfaction in a Low Energy Office Building. Am. J. Appl. Sci. 2012, 9, 1037–1045. [Google Scholar] [CrossRef] [Green Version]

- Lai, A.; Maing, M.; Ng, E. Observational studies of mean radiant temperature across different outdoor spaces under shaded conditions in densely built environment. Build. Environ. 2017, 114, 397–409. [Google Scholar] [CrossRef]

- Guo, H.; Teitelbaum, E.; Houchois, N.; Bozlar, M.; Meggers, F. Revisiting the use of globe thermometers to estimate radiant temperature in studies of heating and ventilation. Energy Build. 2018, 180, 83–94. [Google Scholar] [CrossRef]

- D’Orazio, M.; Maracchini, G. An experimental investigation on the indoor hygrothermal environment of a reinforced-EPS based temporary housing solution. Energy Build. 2019, 204, 109500. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Wang, X.; Sanjayan, J.; Wilson, J. Thermal performance of buildings integrated with phase change, materials to reduce heat stress risks during extreme heatwave events. Appl. Energy 2017, 194, 410–421. [Google Scholar] [CrossRef]

- Ioannou, A.; Itard, L.; Agarwal, T. In-situ real time measurements of thermal comfort and comparison with the adaptive comfort theory in dutch residential dwellings. Energy Build. 2018, 170, 229–241. [Google Scholar] [CrossRef]

- Khatoon, S.; Kim, M.-H. Thermal Comfort in the Passenger Compartment Using a 3-D Numerical Analysis and Comparison with Fanger’s Comfort Models. Energies 2020, 13, 690. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.-H.; Kim, Y.-K.; Kim, K.-S.; Kim, S. Estimating Clothing Thermal Insulation Using an Infrared Camera. Sensors 2016, 16, 341. [Google Scholar] [CrossRef] [Green Version]

- Palladino, D.; Nardi, I.; Buratti, C. Artificial Neural Network for the Thermal Comfort Index Prediction: Development of a New Simplified Algorithm. Energies 2020, 13, 4500. [Google Scholar] [CrossRef]

- Cowie, A.R. Numerical Optimisation of Building Thermal and Energy Performance in Hospitals. The University of Leeds, 2017. Available online: https://core.ac.uk/download/pdf/80689144.pdf (accessed on 5 February 2021).

- Grassi, B.; Piana, E.A.; Beretta, G.P.; Pilotelli, M. Dynamic Approach to Evaluate the Effect of Reducing District Heating Temperature on Indoor Thermal Comfort. Energies 2021, 14, 25. [Google Scholar] [CrossRef]

- D’Ambrosio Alfano, F.R.; Olesen, B.W.; Palella, B.I.; Pepe, D.; Riccio, G. Fifty Years of PMV Model: Reliability, Implementation and Design of Software for Its Calculation. Atmosphere 2020, 11, 49. [Google Scholar] [CrossRef] [Green Version]

- Ning, B.; Schiavon, S.; Bauman, F.S. A novel classification scheme for design and control of radiant system based on thermal response time. Energy Build. 2017, 137, 38–45. [Google Scholar] [CrossRef] [Green Version]

- Rhee, K.N.; Olesen, B.W.; Kim, K.W. Ten questions about radiant heating and cooling systems. Build. Environ. 2017, 112, 367–381. [Google Scholar] [CrossRef] [Green Version]

- Feng, J.D.; Schiavon, S.; Bauman, F. Cooling load differences between radiant and air systems. Energy Build. 2013, 65, 310–321. [Google Scholar] [CrossRef] [Green Version]

- Oravec, J.; Šikula, O.; Krajčík, M.; Arıcıc, M.; Mohapl, M. A comparative study on the applicability of six radiant floor, wall, and ceiling heating systems based on thermal performance analysis. J. Build. Eng. 2021, 36, 102133. [Google Scholar] [CrossRef]

- Gwerder, M.; Tödtli, J.; Lehmann, B.; Dorer, V.; Güntensperger, W.; Renggli, F. Control of thermally activated building systems (TABS) in intermittent operation with pulse width modulation. Appl. Energy 2009, 86, 1606–1616. [Google Scholar] [CrossRef]

- De Wit, A.K.; Wisse, C.J. Hydronic circuit topologies for thermally activated building systems—design questions and case study. Energy Build. 2012, 52, 56–67. [Google Scholar] [CrossRef]

- PN-EN ISO 11855-2:2015. Building Environment Design—Design, Dimensioning, Installation and Control of Embedded Radiant Heating and Cooling Systems—Part 2: Determination of the Design Heating and Cooling Capacity; Polish Standardization Committee: Warsaw, Poland, 2015. [Google Scholar]

- Sourbron, M. Dynamic Thermal Behaviour of Buildings with Concrete Core Activation. Ph.D. Thesis, Katholieke Universiteit Leuven—Faculty of Engineering, Leuven, Belgium, 2012. Available online: https://limo.libis.be/primo-explore/fulldisplay?docid=LIRIAS1672631&context=L&vid=Lirias&search_scope=Lirias&tab=default_tab&lang=en_US&fromSitemap=1 (accessed on 5 February 2021).

- Krajčík, M.; Šikula, O. The possibilities and limitations of using radiant wall cooling in new and retrofitted existing buildings. Appl. Therm. Eng. 2020, 164, 114490. [Google Scholar] [CrossRef]

- Krajčík, M.; Šikula, O. Heat storage efficiency and effective thermal output: Indicators of thermal response and output of radiant heating and cooling systems. Energy Build. 2020, 229, 110524. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michalak, P. Selected Aspects of Indoor Climate in a Passive Office Building with a Thermally Activated Building System: A Case Study from Poland. Energies 2021, 14, 860. https://0-doi-org.brum.beds.ac.uk/10.3390/en14040860

Michalak P. Selected Aspects of Indoor Climate in a Passive Office Building with a Thermally Activated Building System: A Case Study from Poland. Energies. 2021; 14(4):860. https://0-doi-org.brum.beds.ac.uk/10.3390/en14040860

Chicago/Turabian StyleMichalak, Piotr. 2021. "Selected Aspects of Indoor Climate in a Passive Office Building with a Thermally Activated Building System: A Case Study from Poland" Energies 14, no. 4: 860. https://0-doi-org.brum.beds.ac.uk/10.3390/en14040860