1. Introduction

Since the advent of automobiles, fossil fuels have seen growing demands, and they are set to peak in the upcoming years due to the transition to cleaner energy sources [

1]. According to a 2021 report by British Petroleum [

2], the proven global petroleum reserves stand at 244,400 million tonnes. The fuel price surge [

3] does not only correlate with a typical rise in consumer demand but also depends on geopolitical [

4] and economic factors [

5]. In addition, such rises in fuel costs are a huge problem for both businesses and individuals to overcome [

6]. Fossil-fueled vehicles are well known to have a detrimental effect on air quality [

7] and human health [

8]. When compared to results obtained during approval tests, diesel-powered cars were found to emit 4–7 times more nitrogen oxide (NO

X) emissions.

In 2013 [

9], the NO

X emissions from diesel-powered vehicles were attributed to the nearly 10,000 premature deaths from particulate matter (PM

2.5) and ozone in the adult population greater than 30 years of age. The combined issue of rising fuel demand, fuel costs, and air pollution motivates us to move ahead in search of better solutions for the long term. In this study, biofuels from numerous feedstocks [

10] are promoted to replace existing fossil fuels such as gasoline and diesel [

11]. However, not all feedstocks can be good candidates for commercial sale as transport fuel due to the limited availability of the feedstock itself [

12]. This stems from the fact that if large quantities of biodiesel were produced from edible oils, then it could lead to an edible oil shortage, thus affecting human consumption [

13] and cooking [

14]. So, newer generation biodiesels derived from non-edible natural sources such as algae are being studied [

15]. Malaysia [

16] and Indonesia [

17] are two of the largest palm oil producers in the world. Palm oil is an edible oil that can be used for both cooking and as a biodiesel feedstock [

18]. In a study by Chen et al. [

19], it was reported that elevated ischemic heart disease mortality rates could be attributed to higher palm oil consumption in developing countries. This effect can be a deviating factor in converting palm oil for biodiesel use only and relying on other edible oils for human consumption. According to a market research analyst [

20], the biofuel market is set to be worth

$51.47 billion by the year 2029. The proceeds from biodiesel sales could be invested in such a way that will lead to overcoming socio-economic woes [

21].

Recently, the experimental studies using ternary fuel blends on CI engines have been extensively investigated globally. In this regard, Prakash et al. [

22] used castor oil–diesel–ethanol-based ternary fuel blends in their experiment to study the characteristics of the Kirloskar TV1 compression ignition (CI) engine. They report that at full engine loading with B40D30E30 and diesel fueling, the brake thermal efficiency (BTE) was at 31.25 and 32.94%, brake-specific nitrogen oxide (BSNO

X) emission was at 6.11 and 8.17 g/kWh, smoke opacity (SM) was at 68% and 57%, brake-specific energy consumption (BSEC) was observed to be 11.87 and 10.38 MJ/kWh, and ignition delay (ID) was at 13 and 9 CAD, respectively. Waste cooking oil biodiesel–diesel–ethanol fuel blends were used by El-Sheekh et al. [

23] in their study on the characteristics of a Deutz FL511/W CI engine. Further, with B40D40E20 blend fueling, BTE increased and was observed to be 33% at full engine load when compared to operation with B50D50 blend at 27% BTE. The NO

X formation is significantly reduced with 10% ethanol enrichment, while 20% ethanol blending reduces hydrocarbon (HC) and carbon monoxide (CO) emissions.

Mukhtar et al. [

24] used palm oil–diesel–ethanol-based fuel blends in their experiment to study the characteristics of the Yanmar TF120 CI engine. The results show that at full engine loading conditions, the B5D90E5 blend exhibits an average indicated mean effective pressure (IMEP) of 6.14 bars, followed by diesel at 5.96 bar, and the B15D70E15 blend at 4.56 bar. The B5D90E5 attains the highest in-cylinder pressure (CP), followed by the B15D70E15 and diesel fuel. The ID is observed to be higher for ternary blends when compared to diesel fuel operations. The biodiesel-diesel-ethanol fuel blends were used by Bhurat et al. [

25] in their research on the characteristics of a CI engine. In addition, with ethanol blending, NO

X emissions are higher when compared to diesel fueling. Further, the HC and CO emissions were also reportedly higher for all engine loads with ternary blends. The brake specific fuel consumption (BSFC) increased for ethanol-blended operation but was comparable to diesel at medium-to-high engine load.

Kulanthaivel et al. [

26] used algae biodiesel-diesel-anhydrous ethanol-based ternary blends in their study on the characteristics of a Kirloskar CI engine and reported higher BSFC and lower BTE with ternary blend fueling when compared to pure diesel. Azadirachta indica biodiesel-diesel-ethanol fuel blends were used by Satish et al. [

27] in their study on the characteristics of a CI engine. The D60B20E20 fuel blend resulted in 4.25% and 4.43% higher BTE and NO

X emissions and 18% and 8.54% lower CO and HC emissions when compared to pure diesel fuel operation.

Zuo et al. [

28] used cotton seed oil-diesel–ethanol-based ternary fuel blends in their experiment to study the characteristics of the 4B28V16 CI engine. They report that ternary blends exhibit larger CO and HC emissions and lower SM than other tested fuels. Moringa seed oil Diesel–ethanol fuel blends were used by Jegadheesan et al. [

29] in their study on the characteristics of a CI engine. They report that when compared to diesel, higher BTE, CP, Heat Release Rate (HRR), and NO

X with ternary fuel engine operation. Kandasamy et al. [

30] used cotton seed oil–diesel–ethanol-based ternary fuel blends in their experiment to study the durability characteristics of the CI engine. In addition, after 500 h of durability testing, the cylinder pressure and lubricating oil consumption were higher for the B5D75E20 blend when compared to the B5D95 fuel. Further, within the entire engine speed range, both SM and CO were seen to be lower while HC and NO

X were reduced at lower and medium engine speeds, respectively.

Ghadikolaei et al. [

31] used waste cooking oil-diesel–propanol-based fuel blends in their experiment to study the characteristics of the Isuzu 4HF1 CI engine. They report that the highest CP for all tested fuels increased slightly. However, decreases in BSCO and BSCO

2 were observed with ternary blend base engine operation. Bencheikh et al. [

32] also used waste cooking oil–diesel–propanol-based fuel blends in their experiment to study the performance and emission characteristics of the Katana KM178FE CI engine. The results show that when compared to pure diesel fueling, using B5D80E15, B10D80E10, and B15D80E5 reduced SM by 2.85%, 2.56%, and 1.59%, reduced NO

X emissions by 3.56, 3.08, and 2.85 ppm, and CO emissions by 16.98%, 1.42%, and 15.09%, but increased BSFC by 8.33%, 8.07%, and 4.95%, respectively. Jatropha biodiesel-diesel-propanol fuel blends were used by Ahmed et al. [

33] in their research on the characteristics of a CI engine. The results showed that BSFC increased and power dropped when the engine was run on propanol-blend fuel. Similar findings were reported by Gad et al. [

34] in their study of a Deutz F1L511 CI engine fueled by a Mandarin essential oil–diesel–propanol fuel blend.

Motive of Work

The discussion in the former section reports numerous experiments on ternary fuel blends utilising a variety of biodiesel feedstocks. However, for better mass adoption, there is a need for further research on ternary fuel blends involving commercially marketed biodiesel. In this respect, palm biodiesel was seen as a prime candidate due to high feedstock availability, well established biodiesel production facilities, distribution infrastructure, and a readily available market for mass adoption. These scenarios hold true in countries such as Malaysia and Indonesia, where palm biodiesel blends are commercially available for the transportation sector [

35]. Almost a decade earlier, in 2011, Malaysia introduced diesel–palm biodiesel B5D95 blends. This was followed by the subsequent release of increased palm biodiesel blending in the year 2014 with a B7D93 blend and a B10D90 blend in the year 2018 [

36]. By the end of the year 2022, it also plans to make a B20D80 blend for consumers [

37]. Malaysia was planning to upgrade its refineries in order to turn out B30D30 blends and also had consultations with numerous associates [

38]. Indonesia, the neighbouring equatorial country, is a step ahead of Malaysia in terms of biodiesel implementation and currently markets palm-based B30D70 blends for its inland consumers. This was mandated in order to reduce its reliance on imported petro-diesel fuel [

39], and it also plans to raise it to B35D65 blending standards [

40]. As of the year 2022, the country is also testing B40D60 blends in six Toyota Innova cars. The vehicles will traverse the country, and test data will be studied for the feasibility of using high-concentrated biodiesel fuel in CI engines [

41].

In addition, with respect to the second fuel in the ternary blend, alcohols possessing a higher latent heat of vaporisation were the primary criteria for selection. This physiochemical property helps in lowering combustion temperatures and thus hindering NO

X formation. In this study, lower-order alcohols such as ethanol and propanol exhibit elevated standards of latent heat of evaporation compared to alcohols in the higher order. However, this preferred physiochemical property comes with a trade-off of a lowered cetane number (CN) in the respective alcohol [

42]. The higher-order alcohols possess CN values closer to those of diesel, but their lower latent heat of vaporization negates the purpose of their use in blended form, as the intended motive is to reduce NO

X formation. Another added advantage of alcohols such as ethanol [

43] and propanol [

44] is that they can be derived from biomass. The third fuel in the blend is petro-diesel, and here the common notion is to increase the volume concentration of biodiesel and alcohol in the ternary blend, thus lowering the need for fossil-based diesel.

Further, when reviewing prior literature, a study by Mukhtar et al. [

24] using palm biodiesel-diesel–ethanol blends B5D90E5 and B15D70E15 is identified as falling in line with the purpose of this work of using commercially available biodiesel feedstock in ternary blends. As earlier indicated, countries are planning to implement biodiesel blending rates as high as 40% to supplement diesel. In addition, no studies were found using palm biodiesel-diesel–propanol blends. So, this work will explore using palm biodiesel-diesel–ethanol blends and palm biodiesel–diesel–propanol blends, where palm biodiesel blends are kept at a constant 40% of the overall ternary blend volume. While volumetric concentrations of diesel-ethanol in the first batch and diesel-propanol in the second batch are varied in the ternary blend.

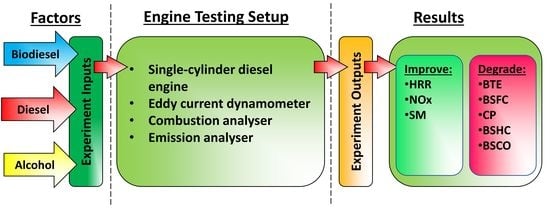

The task ahead is to identify the optimum blend concentration that exhibits elevated combustion, performance, and lower exhaust emission values when used in a CI engine. Standard diesel, pure palm biodiesel (B100), and palm biodiesel-diesel (B40D60)-based binary blends are also tested in order to serve as reference fuels, so the scope of operating a CI engine with ternary blends can be effectively judged. The structure of this article is defined in the following:

Section 1 emphasises the need for biofuels, summarises prior studies on ternary blends, and highlights the importance and novelty of this study. The description of fuel preparation and experimental setup is provided in

Section 2.

Section 3 describes the outcome of the test results in terms of various performance, emission, and combustion parameters, with illustrations. Finally, the study is concluded with key takeaways and a heat map for graphical comparison.

4. Conclusions

In this study, tests were carried out on a Kirloskar TV1 661 cc CI engine with reference fuels, namely diesel, B100, and B40D60. Then the experiments were continued with ethanol-based ternary blends, namely B40D50E10, B40D40E20, and B40D30E30, and propanol-based ternary blends, namely B40D50P10, B40D40P20, and B40D30P30. The test results were studied in terms of various performance, combustion, and emission parameters.

A heat map comparing the observed results is illustrated in

Figure 11. To select an optimum blend, ternary fuel blends exhibiting the highest BTE are considered the primary selection criteria. The engine operation using B40D50E10 and B40D50P10 exhibits superior BTE in terms of performance among other ternary blends tested. However, even though higher alcohol blending rates in ternary fuel blends showed a proportional increase in HRR, values of CP were seen to decrease. In this study, both the values of CP and HRR for B40D50E10 and B40D50P10 fuels are closer to the values obtained with diesel fuel. When comparing emission characteristics, both SM and BSNO

X are seen to lower with higher alcohol blending rates in ternary fuel blends, but BSHC and BSCO are observed to raise proportionally. Similarly, the ternary fuels B40D50E10 and B40D50P10 provide the best trade-off, with values for BSHC, BSCO, and BSNO

X lower than the results seen with diesel fuel engine operation. However, although the SM values obtained with B40D50E10 and B40D50P10 fuels are higher than diesel, they are lower when compared to the values obtained with B100 and B40D60. In this regard, ethanol and propanol-based ternary blends having alcohol at a 10% volumetric concentration are found to be most suitable for engine application.

The key takeaways from the study are as follows:

In terms of BTE, engine operation with diesel fuel, which had the highest CV among tested fuels, was observed to give the highest estimate at 29.9%, while the lowest BTE values were observed with ternary blends containing 30% volumetric concentration of alcohol.

The BSEC trend for tested fuels was observed to be the opposite of the trend seen with BTE. In this study, BSEC values were 13.7 MJ/kWh for B40D30P30 and 13.8 MJ/kWh for B40D30E30 due to lower CV in the fuel blends.

In terms of combustion parameters, the trend for CP observed was similar to that of BTE where the highest value was observed by 71.91 bars with diesel fuelling and was followed by other tested fuels. Meanwhile, for HRR, ternary blends showed faster combustion characteristics, which can be attributed to better mixture preparation timing that caused a longer ignition delay. Both B40D30E30 and B40D30P30 showed the highest HRR values at 78.46 J/CAD and 77.93 J/CAD, respectively while B100 reported the lowest value at 68.21 J/CAD.

BSHC and BSCO show similar trends among the tested fuels. For ternary blends, there is a visible increase in the respective emissions with increasing alcohol concentration. Both palm biodiesel-based fuels, B100 and B40D60, were observed to give lower BSHC at 0.069 g/kWh and 0.092 g/kWh, while BSCO were at 0.132 g/kWh and 0.102 g/kWh, respectively.

Physicochemical properties such as lower viscosity, lower density, and a higher latent heat of vaporization in alcohols are noticed to have a tremendous effect on both SM and BSNOX emissions. The respective emission values for ternary blends were observed to be lower than reference fuels. The SM values were observed to be lowest at 63.6% and 60.1%, while BSNOX was observed to be lowest at 4.504 g/kWh and 4.672 g/kWh for B40D30E30 and B40D30P30, respectively.

Further studies using B40D50E10 and B40D50P10 blends could be tested on CI--powered vehicles to study on-road vehicular emissions. The strategies such as water injection and exhaust gas recirculation could be utilised to lower emissions even further.