3.6.1. Major Contributors to Fermented Dairy Flavor

Fermented soy, oat, and coconut bases were screened for targeted VOCs by GC-FID, and results are shown in

Table 8. When all fermented bases were compared, diacetyl, acetoin, acetaldehyde, acetone, and ethanol levels were significantly different in all three bases. Ethyl acetate, an ester that is found in lactobacilli fermented products [

71] and in dairy cheese [

72], was targeted but not identified in any of them by GC-FID.

Diacetyl, acetoin, and acetaldehyde play a key role in dairy flavor perception [

73] and are products of pyruvate degradation. Pyruvate can be metabolized through two main pathways. The first one converts pyruvate into

-acetolactate, which is decarboxylated to diacetyl in aerobic conditions without any enzymatic activity. Diacetyl can then be reduced to acetoin, and acetoin to 2-3-butanediol. The second one transforms pyruvate into acetaldehyde through acetyl-coenzyme A (acetyl-CoA) [

74]. The effect LGG

® can cause on the levels of these pyruvate breakdown products can be relevant for the sensory perception of fermented samples. Acetoin and diacetyl provide buttery odors that are responsible for caramel and sweet flavors, respectively [

34]. Acetoin is generally produced in higher amounts than diacetyl through citrate metabolism, which was reflected in all three fermented bases (

Table 8). Both compounds were significantly higher in fermented oat samples, followed by coconut and soy. This could be explained by a higher fermentable carbohydrate content in oat samples. LGG

®-containing samples reflected higher acetoin levels in all three bases in comparison to samples that were fermented with culture combinations without LGG

®. Consequently, it could be assumed that LGG

® has high diacetyl-reductase activity to transform diacetyl into acetoin compared to the starter cultures. Acetoin was produced in lower quantities in soy samples by BY-01+LGG

® and YF-L01+LGG

® in comparison to YF-L02+LGG

®. LGG

® increased diacetyl levels in oat and coconut when it was combined with YF-L01 and BY-01. In contrast, LGG

® decreased them in combination with YF-L02 in all three bases. Kaneko et al. reported a relationship between excessive amounts of diacetyl and unpleasant odors [

74]. This suggests that YF-L02 without LGG

® would not be an appropriate candidate to ferment the oat matrix investigated in this study due to the high diacetyl levels that were identified in this sample. One of the main principal components of fermentation aroma in yogurt is acetaldehyde [

74]. Samples that were fermented with LGG

®-containing culture combinations showed significantly lower acetaldehyde content in all three bases. This could be due to a low ability of

L. rhamnosus to produce it from this specific matrix, or due to a high enzymatic activity to convert it into ethanol. Acetaldehyde is a product of pyruvate degradation by acetyl-coenzyme A, but it can also be produced through other metabolic pathways from citrate by

S. thermophilus (strain present in YF-L01, YF-L02, and BY-01). Acetone content was significantly higher in soy samples. It is a compound that confers apple and solvent flavor and has been identified in dairy products, such as kefir [

71]. Previous studies reported its presence in fermented soy and considered it as another main contributor to the flavor and aroma in yogurt [

75]. However, LGG

® did not show any significant effect on its production in any of the three bases. Ethanol levels were significantly higher in coconut samples, but different culture combinations did not have a significant effect on its content. In contrast, LGG

® significantly reduced ethanol levels in fermented oat samples when it was combined with YF-L01, but increased them when it was combined with BY-01. Kpodo et al. detected ethanol in their fermented matrix containing peanut and soy, but not in their dairy yogurt control [

57]. They attributed its presence to glucose breakdown and amino acid catabolism. Nevertheless, they remarked that it is not a relevant contributor to dairy flavor profiles, but probably a complementary one. Ethanol can also react with free fatty acids and be further converted into ethyl esters, which would provide floral and fruity odors [

34].

3-methyl-butanal was found in all fermented oat samples and in nonsignificant amounts in the other two fermented bases. Yan Chun et al. identified it in soy milk, although it had a low flavor dilution factor and, therefore, was not considered a major flavor component [

76]. This compound derives from an enzymatic reaction of leucine [

77] and has been already identified in oat samples by Salmenkallio–Marttila [

78] and by Lee et al. [

79] as a product of amino acid degradation by

L. paracasei. Natrella et al. characterized it as the most relevant volatile compound in mozzarella cheese, providing a nutty and fresh cheese odor [

80]. Dan et al. reported higher 3-methyl-butanal content when dairy milk was fermented by a mixed culture of

L. bulgaricus and

S. thermophilus when the rates of the latter one were higher [

81]. This supports the results of this study, where oat samples fermented with YF-L01 without LGG

® (pure

S. thermophilus) reflected higher levels of 3-methyl-butanal than the one fermented with YF-L01+LGG

®. 1-Butanol was not identified in sufficiently high amounts, and therefore it was not reported in

Table 8.

3.6.2. Characteristic VOCs of Soy, Oat, and Coconut (Reported as Signal-to-Noise)

Fifty-four untargeted volatile compounds were identified by GC-MS in all three fermented bases (data not shown). They comprised ketones, esters, acids, aldehydes, alcohol, furans, sulfurs, lactones, terpenes, benzenes, and aromatic compounds. Twelve of them (ethyl acetate, 2,3-pentanedione, hexanal, ethyl decanoate,

-pinene, benzaldehyde, 3-carene, acetoin,

-decalactone,

-octalactone, dimethyl disulfide, and 2-heptanone) were present in the three fermented bases. Previous studies were taken as references for predominant volatiles of soy [

76,

82,

83], oat [

27,

79], and coconut [

84,

85]. Compounds identified in this study (

Table A3–

Table A5 in

Appendix C) were compared to their results. Two compounds were present in all fermented samples, namely, hexanal and benzaldehyde. Hexanal is mainly produced through linoleic acid oxidation, and it can be further oxidized to hexanoic acid and reduced to 1-hexanol by dehydrogenase enzymes during fermentation processes [

79]. Since linoleic acid is the primary fatty acid in oat [

79] and soybeans [

86], detection of hexanal in fermented soy and oat samples was expected in this study. Hexanal content was significantly higher in these two fermented bases in comparison to fermented coconut samples, where it was found in very low quantities, as previous studies suggested [

85]. Achouri et al. detected its presence in soy milk and in soy blends and observed changes in its levels during storage, attributing them to further lipid oxidation [

82]. Hexanal is associated with green and beany odors [

83], but also related to rancidity [

28]. Nevertheless, Sides et al. stated that, since hexanal is present in oat samples with acceptable flavors, perception of rancidity is not directly linked to the presence of hexanal, but to its concentration [

87]. Regarding benzaldehyde, a compound found in Camembert cheese [

88], it was significantly different in all three bases and higher in fermented oat samples, followed by coconut and soy samples. Achouri et al. and Kaczmarska et al. reported its presence in soy milk products and in germinated soy, but stated its minor contribution to the soybean aroma [

82,

83]. Salmenkallio [

78], McGorrin [

27], and Lee [

79] detected benzaldehyde in uncooked and cooked oatmeal and attributed it to an almond odor. Its presence could be associated with reducing sugars and amino acids interactions [

87]. Wang et al. identified benzaldehyde in coconut milk [

89], and fermented coconut samples in this study were the only ones showing significantly different benzaldehyde content between the different culture combinations (

Table 8). However, LGG

® had no significant effect on its production.

The main contributors to soy flavor (in addition to hexanal and benzaldehyde) are nonanal, heptanal, octanal, acetic acid, 1-hexanol, 1-pentanol, 1-octen-3-ol, heptanol, 2-pentyl furan, 2-ethyl furan, 1-octen-3-one [

76,

82,

83]. From this list, only hexanal, 2-pentyl furan and benzaldehyde were identified in fermented soy samples in this study, and none of the different culture combinations had an effect on their quantity. Nevertheless, other volatile compounds were found in fermented soy samples, and those whose production was affected by LGG

® are shown in

Table A3 in

Appendix C. The sample fermented with YF-L01 was not included due to a lack of reliable replicates for the statistical analysis of VOCs. 3-Methyl-butanal, dimethyl trisulfide, 2-undecenal, and

-dodecalactone were identified with values under the level of detection, and therefore, it was not possible to properly quantify their presence.

-Nonalactone was only detected in samples fermented with BY-L01+LGG

® at a signal-to-noise value of 12. 2,3-Pentanedione is considered a dairy yogurt flavor contributor [

90] and was detected in high levels in fermented soy samples, in line with the findings of Kaneko et al. [

74] and Ahmad et al. [

91]. A combination of LGG

® with BY-01 significantly increased the levels of this compound. Ethyl octanoate and ethyl decanoate were detected in all fermented soy samples, but the former was under the levels of detection in the sample fermented with BY-01. A combination of LGG

® with YF-L02 significantly decreased their production, but it was significantly enhanced when combined with BY-01. Ahmad et al. found both compounds in cheddar cheese, but only the former in soy cheese [

91]. They also identified lactones in dairy cheese, but not in soy cheese. In contrast, soy samples in this study fermented with YF-L02 and BY-01+LGG

® contained remarkable levels of

-decalactone and

-octalactone. This would be a positive aspect of soy fermentation with the culture combinations used in this study for dairy alternatives. However, there was no significant effect of the cultures on their production, and it was not possible to quantify lactones in other fermented samples because the values were between levels of detection and levels of quantification. Regarding terpenes, there was a significant decreasing effect of LGG

® in limonene levels when combined with YF-L02. Moreover,

-pinene levels decreased when LGG

® was combined with YF-L02, but increased in combination with BY-01. In the case of hexanal, its content was significantly decreased when LGG

® was combined with YF-L01, but significantly increased in combination with BY-01. The lowest levels of this compound were found in samples fermented with BY-01 and with YF-L01+LGG

®, which would suggest these combinations as appropriate to remove one of the main responsible compounds for beany flavor [

19]. 2-pentyl-furan, a product of the degradation of fatty acids, also contributes to soy flavor, and was found in high amounts in all fermented samples, but significantly decreased when LGG

® was combined with YF-L02.

According to McGorrin [

27] and Lee et al. [

79], the key volatile compounds of oat flavor are hexanal, nonanal, benzaldehyde, 3- methyl-butanal, octanal, 1-hexanol, 1-pentanol, 1-octen-3-ol, 3-methyl-1-butanol, 2-ethylfuran, 2- heptanone, 3-hydroxy-2-butanone, and 3,5-octadien-2-one. However, only hexanal, benzaldehyde, 3-methyl-butanal, octanal, 2-ethyl-furan, and 1-hexanol were found in fermented oat samples of this study. Previous literature reported variations in volatile compounds with fermentation time in oats [

79]. Initial fermentation stages were associated with aldehydes and later stages with acids, alcohols, ketones, and furans.

Table A4 in

Appendix C shows VOCs in whose content LGG

® had a significant effect. 2-3-Pentanedione was previously identified in oats [

92], and it is one of the main flavor components of fermented dairy milk [

93]. Its presence in fermented oat samples in higher levels than in fermented soy and coconut samples may suggest oat’s potential for fermented dairy alternatives. However, 2-3-Pentanedione levels decreased when the culture combination contained LGG

®. Although previous studies did not find ethyl acetate in dairy yogurt, Beshkova et al. detected its presence in kefir [

71] and it was also detected by GC-MS in the fermented oat samples in this study. Lee et al. identified nonanal, hexanal, 2-pentylfuran, 1-octen-3-ol, and 2-nonenal as lipid degradation products [

79]. They observed that hexanal content decreased during fermentation of oats, while 1-hexanol levels increased. This could explain the presence of the latter compound in fermented oat samples. Toluene, ethanol, and 2-propanol were the VOCs that were found in higher amounts in fermented oat. Toluene did not vary among culture combinations and, therefore, was not reported in the table, but it has been found in dairy yogurts [

90] and also in fermented oats [

94]. In regard to alcohol levels, 2-propanol drastically decreased when YF-L01 was combined with LGG

®. In samples where YF-L02 was supplemented with LGG

®, 2-3-pentanedione levels increased and limonene levels decreased. The combination of BY-01 with LGG

® increased ethyl acetate content, but decreased the amount of 2-3-pentanedione and furfural.

The predominant compounds of coconut flavor according to the literature [

84,

85] are hexanal, 2-heptanone, nonanal, acetic acid, 2-ethylfuran, 2-pentanone, ethyl lactate, ethyl acetate,

-octalactone,

-decalactone, dodecanoic acid, octanoic acid, 1-hexanol, phenyl ethyl alcohol, 2-methyl tetrahydrofuran, tetradecanone, hexadecanone, ethyl octanoate, ethyl acetate, and ethyl decanoate. From all of them, only the first 10 compounds were identified in fermented coconut samples in this study. Ethyl lactate, previously characterized as the main flavor component in coconut variety

neera [

84], was detected in all samples. Furthermore, phenylacetaldehyde was also found in all samples at low levels. It is a derivative compound from phenyl ethyl alcohol, another key aroma contributor in coconut [

84], which would explain its presence.

-octalactone and

-decalactone were also present in all fermented coconut samples, as well as butyrolactone. This was expected since they are major contributors to the coconut flavor derived from hydroxy acids [

95].

Table A5 in

Appendix B shows untargeted VOCs in fermented coconut samples whose content was affected by LGG

®. LGG

® increased the content of 2-pentanone and decreased the content of 2-3-pentanedione when it was combined with YF-L01. In combination with YF-L02, LGG

® increased 2-pentanone and

-pinene production, but decreased that of 2-3-pentanedione. BY-01 supplemented with LGG

® increased 2-pentanone,

-nonalactone, and butyrolactone levels, but decreased 2-3-pentanedione content.

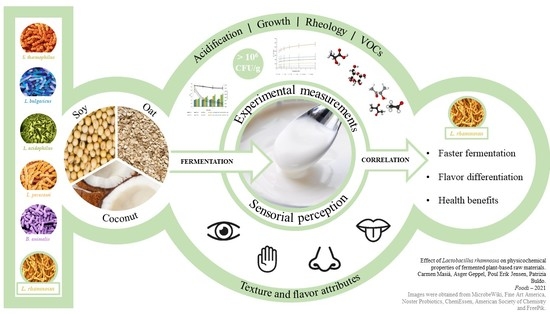

3.6.3. Correlation between Instrumental Measurements and Flavor Perception

PCA correlated VOCs and perception of sensorial attributes identified in each fermented sample (

Figure 6). VOCs and flavor attributes showing significant differences between culture combinations in each base were selected for the analysis. Hexanal was included in all three analyses due to its contribution to off-flavors in plant-based products [

83].

PCA of fermented soy samples explains 87.9% of the total variance, comprising 59.5% of the first PC and 28.4% of the second PC. YF-L01 was not included in the PCA of soy samples due to a lack of reliable replicates in VOCs analysis, as mentioned above. Samples fermented with YF-L02 were far from those fermented with YF-L02+LGG® along PC2 axis. In contrast, BY-01 and BY-01+LGG® were located remarkably close to each other. Therefore, an effect of LGG® when combined with YF-L02, but not when combined with BY-01 was observed in soy samples. Perception of sourness was negatively correlated (R = −0.9) with -pinene, 2-pentyl-furan, hexanal, diacetyl, ethyl-decanoate, ethyl-octanoate, and limonene. Simultaneously, -pinene, 2-pentyl-furan, hexanal, and diacetyl were positively correlated (R = 0.9) with ethyl-decanoate, ethyl-octanoate, and limonene. Lemon flavor was better perceived when acetone and ethanol were produced (R = 0.9). BY-01 and BY-01+LGG® clustered together around these components, which would point at a contribution of BY-01 and not LGG® to their production. PCA of fermented oat samples explained 89% of the total variance, comprising 63% of the first PC and 26% of the second PC. All culture combinations containing LGG® clustered together far from their respective cultures without LGG®, which indicated that LGG® had an effect on fermented oat flavor. They were close to the attribute sourness and to lemon and fruity flavors. A positive correlation between them and the presence of diacetyl and acetoin (R = 0.9–1) was found. Sweetness and cereal flavor were related with the presence of acetaldehyde (R = 0.7) and acetone (R = 0.4–0.5), although the association was not significantly strong. Samples including LGG® in the culture were plotted far from these components, reflecting higher acidification. YF-L01 was found close to ethanol and 2-propanol, and these compounds were negatively correlated to diacetyl and acetoin (R = −0.9), which is supported by the results obtained by GC-FID. PCA of fermented coconut samples explained 96% of the total variance, comprising 55% of the first PC and 41% of the second PC. Sweetness and fattiness were positively correlated with ethanol (R = 0.9) and diacetyl (R = 1), but negatively correlated with the presence of 2,3-pentanedione (R = 9). The presence of acetoin was positively correlated (R = 1) with -nonalactone, butyrolactone, -pinene, and 2-pentanone. The sample fermented with YF-L02 clustered with all culture combinations containing LGG® around the previously mentioned attributes. This indicates that LGG® did not have any effect on fermented coconut flavor when added to YF-L02. Samples fermented with BY-01 were associated with acetaldehyde, which is supported by the results obtained by GC-FID.