Effect of Soy Protein Isolate on Textural Properties, Cooking Properties and Flavor of Whole-Grain Flat Rice Noodles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

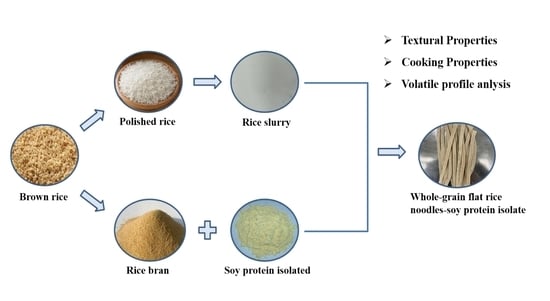

2.2. Preparation of Flat Rice Noodles

2.3. Textural Properties

2.4. Cooking Properties

2.5. Scanning Electron Microscope (SEM)

2.6. Electronic Nose Analysis

2.7. SPME/GC-MS Analysis

2.8. Sensory Evaluation

2.9. Statistical Analysis

3. Results and Discussion

3.1. Textural Properties

3.2. Cooking Properties

3.3. SEM

3.4. Electronic Nose Analysis

3.5. Volatile Compound Analysis

3.6. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gong, E.S.; Luo, S.; Li, T.; Liu, C.; Zhang, G.; Chen, J.; Zeng, Z.; Liu, R.H. Phytochemical profiles and antioxidant activity of processed brown rice products. Food Chem. 2017, 232, 67–78. [Google Scholar] [CrossRef]

- Xue, J.; Tong, L.; Hai, L.R. 2α-Hydroxyursolic Acid Inhibited Cell Proliferation and Induced Apoptosis in MDA-MB-231 Human Breast Cancer Cells through the p38/MAPK Signal Transduction Pathway. J. Agric. Food Chem. 2016, 64, 1806–1816. [Google Scholar]

- Okarter, N.; Liu, R.H. Health Benefits of Whole Grain Phytochemicals. Crit. Rev. Food Sci. 2010, 50, 193–208. [Google Scholar] [CrossRef]

- Xi, P.; Liu, R.H. Whole food approach for type 2 diabetes prevention. Mol. Nutr. Food Res. 2016, 60, 1819–1836. [Google Scholar] [CrossRef] [PubMed]

- Ilowefah, M.; Chinma, C.; Bakar, J.; Ghazali, H.; Muhammad, K.; Makeri, M. Fermented Brown Rice Flour as Functional Food Ingredient. Foods 2014, 3, 149–159. [Google Scholar] [CrossRef] [PubMed]

- Geng, D.H.; Zhou, S.; Wang, L.; Zhou, X.; Liu, L.; Lin, Z.; Qin, W.; Liu, L.; Tong, L.T. Effects of slight milling combined with cellulase enzymatic treatment on the textural and nutritional properties of brown rice noodles. LWT-Food Sci. Technol. 2020, 128, 109520. [Google Scholar] [CrossRef]

- Chung, H.-J.; Cho, A.; Lim, S.-T. Effect of heat-moisture treatment for utilization of germinated brown rice in wheat noodle. LWT-Food Sci. Technol. 2012, 47, 342–347. [Google Scholar] [CrossRef]

- Silva, E.M.M.d.; Ascheri, J.L.R.; Ascheri, D.P.R. Quality assessment of gluten-free pasta prepared with a brown rice and corn meal blend via thermoplastic extrusion. LWT-Food Sci. Technol. 2016, 68, 698–706. [Google Scholar] [CrossRef]

- Wu, X.C. Health effects of soy protein and isoflavones in humans. J. Nutr. 2008, 138, 1244S–1249S. [Google Scholar]

- De Angelis, D.; Kaleda, A.; Pasqualone, A.; Vaikma, H.; Tamm, M.; Tammik, M.-L.; SQUEO, G.; Summo, C. Physicochemical and Sensorial Evaluation of Meat Analogues Produced from Dry-Fractionated Pea and Oat Proteins. Foods 2020, 9, 1754. [Google Scholar] [CrossRef]

- Shao, S.; Duncan, A.M.; Yang, R.; Marcone, M.F.; Rajcan, I.; Tsao, R. Tracking isoflavones: From soybean to soy flour, soy protein isolates to functional soy bread. J. Funct. Foods 2008, 1, 119–127. [Google Scholar] [CrossRef]

- Rachman, A.; A Brennan, M.; Morton, J.; Brennan, C.S. Effect of Egg White Protein and Soy Protein Isolate Addition on Nutritional Properties and In-Vitro Digestibility of Gluten-Free Pasta Based on Banana Flour. Foods 2020, 9, 589. [Google Scholar] [CrossRef] [PubMed]

- Srikanlaya, C.; Therdthai, N.; Ritthiruangdej, P.; Zhou, W. Effect of hydroxypropyl methylcellulose, whey protein concentrate and soy protein isolate enrichment on characteristics of gluten-free rice dough and bread. Int. J. Food Sci. Technol. 2018, 53, 1760–1770. [Google Scholar] [CrossRef]

- Maga, J.A. Rice product volatiles: A review. J. Agric. Food Chem. 1984, 5, 964–970. [Google Scholar] [CrossRef]

- Hong, X.; Wang, J. Detection of adulteration in cherry tomato juices based on electronic nose and tongue: Comparison of different data fusion approaches. J. Food Eng. 2014, 126, 89–97. [Google Scholar] [CrossRef]

- Yang, W.; Yu, J.; Pei, F.; Mariga, A.M.; Ma, N.; Fang, Y.; Hu, Q. Effect of hot air drying on volatile compounds of Flammulina velutipes detected by HS-SPME–GC–MS and electronic nose. Food Chem. 2016, 196, 860–866. [Google Scholar] [CrossRef]

- Geng, D.-H.; Liang, T.; Yang, M.; Wang, L.; Zhou, X.; Sun, X.; Liu, L.; Zhou, S.; Tong, L.-T. Effects of Lactobacillus combined with semidry flour milling on the quality and flavor of fermented rice noodles. Food Res. Int. 2019, 126, 108612. [Google Scholar] [CrossRef] [PubMed]

- AACC. Approved Methods of the American Association of Cereal Chemists; AACC: Washington, DC, USA, 2000. [Google Scholar]

- Li, Q.; Liu, S.; Obadi, M.; Jiang, Y.; Zhao, F.; Jiang, S.; Xu, B. The impact of starch degradation induced by pre-gelatinization treatment on the quality of noodles. Food Chem. 2020, 302, 125267. [Google Scholar] [CrossRef]

- Chen, Q.; Song, J.; Bi, J.; Meng, X.; Wu, X. Characterization of volatile profile from ten different varieties of Chinese jujubes by HS-SPME/GC–MS coupled with E-nose. Food Res. Int. 2018, 105, 605–615. [Google Scholar] [CrossRef]

- Yi, C.; Zhu, H.; Yang, R.; Bao, J.; He, H.; Niu, M. Links between microbial compositions and volatile profiles of rice noodle fermentation liquid evaluated by 16S rRNA sequencing and GC-MS. LWT-Food Sci. Technol. 2020, 118, 108774. [Google Scholar] [CrossRef]

- Cocci, E.; Sacchetti, G.; Vallicelli, M.; Angioloni, A.; Dalla Rosa, M. Spaghetti cooking by microwave oven: Cooking kinetics and product quality. J. Food Eng. 2007, 85, 537–546. [Google Scholar] [CrossRef]

- Kong, S.; Kim, D.J.; Oh, S.K.; Choi, I.S.; Jeong, H.S.; Lee, J. Black Rice Bran as an Ingredient in Noodles: Chemical and Functional Evaluation. J. Food Sci. 2012, 77, C303–C307. [Google Scholar] [CrossRef]

- Qazi, I.M.; Rakshit, S.K.; Tran, T. Effect of physico-chemical properties of tropical starches and hydrocolloids on rice gels texture and noodles water retention ability. Starch-Stärke 2011, 9, 558–569. [Google Scholar] [CrossRef]

- Martins, V.B.; Netto, F.M. Physicochemical and functional properties of soy protein isolate as a function of water activity and storage. Food Res. Int. 2005, 39, 145–153. [Google Scholar] [CrossRef]

- Song, X.; Zhu, W.; Pei, Y.; Ai, Z.; Chen, J. Effects of wheat bran with different colors on the qualities of dry noodles. J. Cereal Sci. 2013, 58, 400–407. [Google Scholar] [CrossRef]

- Aravind, N.; Sissons, M.J.; Fellows, C.M.; Blazek, J.; Gilbert, E.P. Effect of inulin soluble dietary fibre addition on technological, sensory, and structural properties of durum wheat spaghetti. Food Chem. 2012, 132, 993–1002. [Google Scholar] [CrossRef]

- Kim, Y.; Kee, J.I.; Lee, S.; Yoo, S.-H. Quality improvement of rice noodle restructured with rice protein isolate and transglutaminase. Food Chem. 2014, 145, 409–416. [Google Scholar] [CrossRef]

- Li, X.; Liu, C.; Diao, E.; Dong, H.; Qiao, J. Effect of soybean protein isolate on dough characteristics and dried noodle quality. J. Chin. Cereal Oils Assoc. 2009, 24, 19–22. [Google Scholar]

- Kang, M.J.; Bae, I.Y.; Lee, H.G. Rice noodle enriched with okara: Cooking property, texture, and in vitro starch digestibility. Food Biosci. 2018, 22, 178–183. [Google Scholar] [CrossRef]

- Detchewa, P.; Thongngam, M.; Jane, J.L.; Naivikul, O. Preparation of gluten-free rice spaghetti with soy protein isolate using twin-screw extrusion. J. Food Sci. Technol. 2016, 53, 3485–3494. [Google Scholar] [CrossRef] [Green Version]

- Moses, O.; Shun, T.J.; Mat, E.A. Cooking, textural, and mechanical properties of rice flour-soy protein isolate noodles prepared using combined treatments of microbial transglutaminase and glucono-δ-lactone. J. Food Sci. 2020, 85, 2720–2727. [Google Scholar]

- Zheng, M.; Xiao, Y.; Yang, S.; Liu, M.; Feng, L.; Ren, Y.; Yang, X.; Lin, N.; Liu, J. Effect of adding zein, soy protein isolate and whey protein isolate on the physicochemical and in vitro digestion of proso millet starch. Int. J. Food Sci. Technol. 2020, 55, 776–784. [Google Scholar] [CrossRef]

- Fan, Z.; Yi, C.; Zhu, H.; Tong, L.; Zhou, S.; Yu, J. Quality of Fresh Rice Noodles Fermented with Lactobacillus Plantarum: II. Eating Quality. J. Chin. Cereals Oils Assoc. 2018, 33, 7–12. [Google Scholar]

- Miao, J.; Su, H.; Zhang, M. Analysis of the Key Flavor Compounds in Cooked Rice. Food Sci. 2016, 37, 82–86. [Google Scholar]

- Raczyk, M.; Kmiecik, D.; Schieberle, P.; Przybylski, R.; Jeleń, H.; Rudzińska, M. Model studies on the formation of volatile compounds generated by a thermal treatment of steryl esters with different fatty acid moieties. Food Res. Int. 2017, 97, 87–94. [Google Scholar] [CrossRef] [PubMed]

- Widjaja, R.; Craske, J.D.; Wootton, M. Changes in Volatile Components of Paddy, Brown and White Fragrant Rice during Storage. J. Sci. Food Agric. 1996, 71, 218–224. [Google Scholar] [CrossRef]

- Mahattanatawee, K.; Rouseff, R.L. Comparison of aroma active and sulfur volatiles in three fragrant rice cultivars using GC–Olfactometry and GC–PFPD. Food Chem. 2014, 154, 1–6. [Google Scholar] [CrossRef]

- Calingacion, M.N.; Boualaphanh, C.; Daygon, V.D.; Anacleto, R.; Hamilton, R.S.; Biais, B.; Deborde, C.; Maucourt, M.; Moing, A.; Mumm, R.; et al. A genomics and multi-platform metabolomics approach to identify new traits of rice quality in traditional and improved varieties. Metabolomics 2012, 8, 771–783. [Google Scholar] [CrossRef]

- Concepcion, J.C.T.; Ouk, S.; Riedel, A.; Calingacion, M.; Zhao, D.; Ouk, M.; Garson, M.J.; Fitzgerald, M.A. Quality evaluation, fatty acid analysis and untargeted profiling of volatiles in Cambodian rice. Food Chem. 2018, 240, 1014–1021. [Google Scholar] [CrossRef]

- Zeng, Z.; Zhang, H.; Chen, J.; Zhang, T.; Matsunaga, R. Flavor Volatiles of Rice During Cooking Analyzed by Modified Headspace SPME/GC-MS. Cereal Chem. 2008, 2, 140–145. [Google Scholar] [CrossRef]

- Wang, K.; Ma, C.; Gong, G.; Chang, C. Fermentation parameters, antioxidant capacities, and volatile flavor compounds of tomato juice-skim milk mixtures fermented by Lactobacillus plantarum ST-III. Food Sci. Biotechnol. 2019, 4, 1147–1154. [Google Scholar] [CrossRef] [PubMed]

| Cohesiveness | Adhesiveness (N·s) | Resilience | Springiness | Hardness (N) | Chewiness(N) | |

|---|---|---|---|---|---|---|

| FRN | 0.76 ± 0.03 b | −2.23 ± 0.55 b | 0.507 ± 0.01 b | 0.96 ± 0.01 b | 51.30 ± 4.85 a | 37.37 ± 3.26 a |

| WBRN | 0.71 ± 0.03 a | −1.57 ± 0.23 a | 0.390 ± 0.01 a | 0.91 ± 0.01 a | 47.93 ± 6.11 a | 32.17 ± 5.08 ab |

| WBRN -SPI | 0.74 ± 0.04 b | −1.87 ± 0.24 a | 0.437 ± 0.01 ab | 0.95 ± 0.01 b | 35.42 ± 3.94 b | 24.52 ± 3.17 b |

| Compounds | Relative Content (%) | ||

|---|---|---|---|

| FRN | WFRN | WFRN-SPI | |

| Alcohols | |||

| 2-Undecen-1-ol, (2E)- | 36.40 a | 0.49 b | - |

| Dihydroterpineol | 2.02 b | 3.94 a | 3.73 a |

| isomenthol | 0.18 | - | - |

| 1-Pentanol | - | 6.37 a | 3.27 b |

| 1-Octen-3-ol | - | 0.44 b | 1.74 a |

| 2-Decyn-1-ol | - | 1.95 | - |

| 3,5-Octadien-2-ol | - | 0.09 b | 0.43 a |

| 1-Octanol | - | 2.05 a | 0.18 b |

| (2Z)-2-Octene-1-ol | - | - | 0.13 |

| 2-Pentadecyn-1-ol | - | - | 0.24 |

| Linalool | 0.20 a | 0.22a | - |

| 2-Decen-1-ol, (2E)- | - | - | 0.15 |

| alpha-Terpineol | - | - | 0.18 |

| Aldehydes | |||

| 1-Nonanal | 23.87 b | 31.18 a | 20.73 c |

| Hexanal | - | 25.26 b | 30.96 a |

| 2-Nonenal, (2E)- | 1.25b | 1.62 a | 1.27 b |

| Decanal | 4.67 a | 2.90 b | 2.85 b |

| Octanal | 3.83 c | 5.80 a | 4.24 b |

| Heptanal | - | 2.72 b | 3.63 a |

| Dodecanal | 0.28 a | 0.30 a | 0.31 a |

| (E)-2-Octenal | - | 1.04 b | 2.69 a |

| 2,4-nonadienal | - | 0.22 a | 0.23 a |

| trans-2-Decenal | - | 0.27 b | 0.51 a |

| 2,4-decadienal | - | - | 2.81 |

| 4-Nonenal, (4E)- | - | - | 0.18 |

| Dodecyl aldehyde | - | - | 0.39 |

| Ketones | |||

| (1R)-trans-p-menthan-3-one | 9.04 a | 1.07 c | 2.58 b |

| Geranylacetone | 1.47 a | 0.98 b | 0.99 b |

| 2-Dodecanone | - | 0.43 a | 0.31 b |

| 2-Heptanone | - | - | 2.96 |

| 3,5-Octadien-2-one,(3E,5E)- | - | - | 1.12 |

| 1-(3-Butyloxiranyl)ethanone | - | - | 0.44 |

| 4-Nonenal, (4E)- | - | - | 0.17 |

| 6-Methyl-5-hepten-2-one | 1.75 | - | - |

| 2-Nonanone | - | 0.26 | - |

| 5-methyl-2-(1-methylethylidene)-Cyclohexanone | 0.50 | - | - |

| Hydrocarbons | |||

| Tridecane | 1.29 b | 1.62 a | 1.04 c |

| Cyclopropane, pentyl- | - | 2.44 a | 1.25 b |

| Dodecane, 4,6-dimethyl- | - | 0.57 a | 0.45 b |

| Decane,6-ethyl-2-methyl- | - | 0.33 b | 0.62 a |

| Undecane, 3,5-dimethyl- | 0.8 | - | - |

| Heptadecane, 2,6-dimethyl- | 0.74 | - | - |

| Heptadecane,2,6,10,14-tetramethyl- | - | 0.88 b | 2.31 a |

| 2,6,8-Trimethyldecane | - | - | 0.55 |

| Esters | |||

| Phenacyl thiocyanate | 2.08 a | 0.12 b | 0.12 b |

| Formic acid, heptylester | 2.54 a | 1.23 b | 1.29 b |

| Arecaidine methyl ester | 0.82 | - | - |

| Acetic acid, trichloro-, nonyl ester | 0.47 | - | - |

| Nonyl chloroformate | 0.32 | - | - |

| Others | |||

| 2,4-Di-tert-butylphenol | 3.66 a | 1.58 b | 1.55 b |

| 1,3-Dioxolane,4-methyl-2-pentyl- | - | 0.45 b | 0.59 a |

| (E)-2-Dodecene | - | 0.26 b | 0.48 a |

| Naphthalene | - | 0.62 a | 0.33 b |

| Indole | 0.81 a | 0.30 b | - |

| Azulene | 1.01 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Z.; Liu, Y.; Zhu, H.; Li, Y.; Xiao, Q.; Yi, C. Effect of Soy Protein Isolate on Textural Properties, Cooking Properties and Flavor of Whole-Grain Flat Rice Noodles. Foods 2021, 10, 1085. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10051085

Cao Z, Liu Y, Zhu H, Li Y, Xiao Q, Yi C. Effect of Soy Protein Isolate on Textural Properties, Cooking Properties and Flavor of Whole-Grain Flat Rice Noodles. Foods. 2021; 10(5):1085. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10051085

Chicago/Turabian StyleCao, Zhongfu, Yang Liu, Hong Zhu, Yisi Li, Qian Xiao, and Cuiping Yi. 2021. "Effect of Soy Protein Isolate on Textural Properties, Cooking Properties and Flavor of Whole-Grain Flat Rice Noodles" Foods 10, no. 5: 1085. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10051085