Baking Quality Assessment of Twenty Whole Grain Oat Cultivar Samples

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Oat Flour Analyses

2.2.2. Dough Yield Optimisation

2.2.3. Baking Trials with Storage Tests

2.2.4. Statistical Analyses

3. Results

3.1. Oat Flour Analyses

3.2. Baking Trials

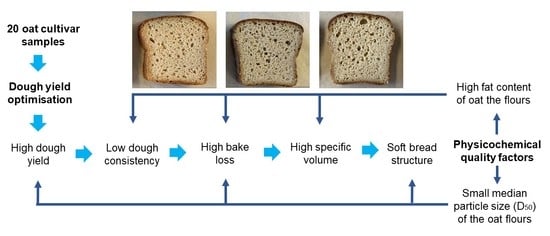

3.2.1. Dough Yield Optimisation

3.2.2. Baking Quality at Optimised Dough Yields

3.2.3. Quality Evaluation of the Oat Breads

3.3. Statistical Analyses

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Sample | Crumb Structure | Bread Shape | Taste | Mouthfeel |

|---|---|---|---|---|

| F11 | 3 | 2 | 3 | 3 |

| F12 | 2 | 1 | 2 | 1 |

| F13 | 1 | 1 | 2 | 2 |

| F14 | 2 | 1 | 3 | 3 |

| F15 | 2 | 2 | 3 | 3 |

| F16 | 1 | 2 | 2 | 1 |

| F17 | 3 | 2 | 3 | 3 |

| F18 | 3 | 2 | 2 | 3 |

| F19 | 1 | 1 | 3 | 2 |

| F20 | 2 | 1 | 2 | 1 |

| F21 | 2 | 1 | 1 | 1 |

| F22 | 1 | 1 | 1 | 3 |

| F23 | 1 | 1 | 1 | 1 |

| F24 | 2 | 1 | 2 | 1 |

| F25 | 2 | 1 | 2 | 1 |

| F26 | 3 | 3 | 1 | 1 |

| F27 | 1 | 2 | 2 | 2 |

| F28 | 3 | 3 | 2 | 3 |

| F29 | 1 | 1 | 3 | 3 |

| F30 | 2 | 1 | 2 | 2 |

References

- Jokinen, I.; Pihlava, J.-M.; Puganen, A.; Sontag-Strohm, T.; Linderborg, K.M.; Holopainen-Mantila, U.; Nordlund, E. Predicting the Properties of Industrially Produced Oat Flours by Characteristics of Native Oat Grains or Non-Heat-Treated Groats. Foods 2020, 10, 1552. [Google Scholar] [CrossRef] [PubMed]

- European Food Safety Authority. Commission Regulation (EU) No 432/2012 establishing a list of permitted health claims made on foods, other than those referring to the reduction of disease risk and to children’s development and health. Off. J. Eur. Union 2012, OJ L 136, 1–40. [Google Scholar]

- Food and Drug Administration. Department of Health and Human Services (HHS). Food Labeling: Health Claims; Oats and Coronary Heart Disease Final Rule. Fed. Regist. 1997, 62, 3584–3601. [Google Scholar]

- Lapveteläinen, A.; Rannikko, H. Quantitative sensory profiling of cooked oatmeal. LWT-Food Sci. Technol. 2000, 33, 374–379. [Google Scholar] [CrossRef]

- Lapveteläinen, A.; Alho-Lehto, P.; Sinn, L.; Laukkanen, T.; Lindman, T.; Kallio, H.; Kaitaranta, J.; Katajisto, J. Relationships of selected physical, chemical, and sensory parameters in oat grain, rolled oats, and cooked oatmeal—A three-year study with eight cultivars. Cereal Chem. 2001, 78, 322–329. [Google Scholar] [CrossRef]

- Rhymer, C.; Ames, N.; Malcolmson, L.; Brown, D.; Duguid, S. Effects of genotype and environment on the starch properties and end-product quality of oats. Cereal Chem. 2005, 82, 197–203. [Google Scholar] [CrossRef]

- Haque, A.; Morris, E.R. Combined use of ispaghula and HPMC to replace or augment gluten in breadmaking. Food Res. Int. 1994, 27, 379–393. [Google Scholar] [CrossRef]

- Eliasson, A.; Larsson, K. Cereals in Breadmaking: A Molecular Colloidal Approach; Marcel Dekker, Inc.: New York, NY, USA, 1993. [Google Scholar]

- de la Hera, E.; Talegón, M.; Caballero, P.; Gómez, M. Influence of maize flour particle size on gluten-free breadmaking. J. Sci. Food Agric. 2013, 93, 924–932. [Google Scholar] [CrossRef]

- Ronda, F.; Pérez-Quirce, S.; Lazaridou, A.; Biliaderis, C.G. Effect of barley and oat β-glucan concentrates on gluten-free rice-based doughs and bread characteristics. Food Hydrocoll. 2015, 48, 197–207. [Google Scholar] [CrossRef]

- Flander, L.; Salmenkallio-Marttila, M.; Suortti, T.; Autio, K. Optimization of ingredients and baking process for improved wholemeal oat bread quality. LWT-Food Sci. Technol. 2007, 40, 860–870. [Google Scholar] [CrossRef]

- Zhang, D.; Moore, W.R.; Doehlert, D.C. Effects of oat grain hydrothermal treatments on wheat-oat flour dough properties and breadbaking quality. Cereal Chem. 1998, 75, 602–605. [Google Scholar] [CrossRef]

- D’Appolonia, B.L.; Youngs, V.L. Effect of bran and high-protein concentrate from oats on dough properties and bread quality. Cereal Chem. 1978, 55, 736–743. [Google Scholar]

- AACC Method 44-15A. Moisture-Air Oven Methods. Approved Methods of the AACC, 10th ed.; MN American Association of Cereal Chemists: St Paul, MN, USA, 2000. [Google Scholar]

- AACC Method 56-30. Water Hydration Capacity of Protein Materials. Approved Methods of the AACC, 10th ed.; MN American Association of Cereal Chemists: St Paul, MN, USA, 2000. [Google Scholar]

- Hüttner, E.K.; Bello, F.D.; Arendt, E.K. Rheological properties and bread making performance of commercial wholegrain oat flours. J. Cereal Sci. 2010, 52, 65–71. [Google Scholar] [CrossRef]

- Hüttner, E.K.; Bello, F.D.; Zannini, E.; Titze, J.; Beuch, S.; Arendt, E.K. Physicochemical properties of oat varieties and their potential for breadmaking. Cereal Chem. 2011, 88, 602–608. [Google Scholar] [CrossRef]

- Ganßmann, W.; Vorwerck, K. Oat milling, processing and storage. In The Oat Crop: Production and Utilization; Welch, R.W., Ed.; Springer: Dordrecht, The Netherlands, 1995; pp. 369–408. [Google Scholar]

- Salovaara, H.; Anttila, H.; Gates, F.; Sontag-Strohm, T. Employing technology for oat pala bread. New Food 2003, 6, 10–11. [Google Scholar]

- MacRitchie, F.; Gras, P.W. The Role of Flour Lipids. Am. Assoc. Cereal Chem. 1973, 50, 292–302. [Google Scholar]

- Cappa, C.; Lucisano, M.; Mariotti, M. Influence of Psyllium, sugar beet fibre and water on gluten-free dough properties and bread quality. Carbohydr. Polym. 2013, 98, 1657–1666. [Google Scholar] [CrossRef]

- Pérez-Quirce, S.; Lazaridou, A.; Biliaderis, C.G.; Ronda, F. Effect of β-glucan molecular weight on rice flour dough rheology, quality parameters of breads and in vitro starch digestibility. LWT-Food Sci. Technol. 2017, 82, 446–453. [Google Scholar] [CrossRef] [Green Version]

- Bloksma, A.H. Rheological aspects of structural changes during baking. In Chemistry and Physics of Baking: Materials, Processes, And Products, Proceedings of an International Symposium Held at the School of Agric, Sutton Bonington, UK, 10–12 April 1985; Blanshard, J.M.V., Frazier, P.J., Galliard, T., Eds.; The Royal Society of Chemistry: Bristol, UK, 1986; pp. 170–178. [Google Scholar]

- Lazaridou, A.; Duta, D.; Papageorgiou, M.; Belc, N.; Biliaderis, C.G. Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J. Food Eng. 2007, 79, 1033–1047. [Google Scholar] [CrossRef]

- Bloksma, A.H. Rheology of the breadmaking process. Cereal Foods World 1990, 35, 228. [Google Scholar]

- Forssell, P.; Shamekh, S.; Härkönen, H.; Poutanen, K. Effects of native and enzymatically hydrolysed soya and oat lecithins in starch phase transitions and bread baking. J. Sci. Food Agric. 1998, 76, 31–38. [Google Scholar] [CrossRef]

- Erazo-Castrejón, S.V.; Doehlert, D.C.; D’Appolonia, B.L. Application of oat oil in breadbaking. Cereal Chem. 2001, 78, 243–248. [Google Scholar] [CrossRef]

- Kaukonen, O.; Sontag-Strohm, T.; Salovaara, H.; Lampi, A.M.; Sibakov, J.; Loponen, J. Foaming of differently processed oats: Role of nonpolar lipids and tryptophanin proteins. Cereal Chem. 2011, 88, 239–244. [Google Scholar] [CrossRef]

- Janssen, F.; Wouters, A.G.; Pauly, A.; Delcour, J.A. Relating the composition and air/water interfacial properties of wheat, rye, barley, and oat dough liquor. Food Chem. 2018, 264, 126–134. [Google Scholar] [CrossRef] [PubMed]

- Janssen, F.; Wouters, A.G.; Linclau, L.; Waelkens, E.; Derua, R.; Dehairs, J.; Moldenaers, P.; Vermant, J.; Delcour, J.A. The role of lipids in determining the air-water interfacial properties of wheat, rye, and oat dough liquor constituents. Food Chem. 2020, 319, 126565. [Google Scholar] [CrossRef]

- Gan, Z.; Ellis, P.R.; Schofield, J.D. Gas cell stabilisation and gas retention in wheat bread dough. J. Cereal Sci. 1995, 21, 215–230. [Google Scholar] [CrossRef]

- Trappey, E.F.; Khouryieh, H.; Aramouni, F.; Herald, T. Effect of sorghum flour composition and particle size on quality properties of gluten-free bread. Food Sci. Technol. Int. 2015, 21, 188–202. [Google Scholar] [CrossRef]

| Sample | D50 (µm), n = 3 | D4,3 (µm), n = 3 | D90 (µm), n = 3 | WHC (mL/g), n = 3 |

|---|---|---|---|---|

| F11 | 119 ± 2 | 229 ± 3 | 606 ± 8 | 1.08 ± 0.00 |

| F12 | 116 ± 1 | 239 ± 2 | 642 ± 5 | 1.11 ± 0.05 |

| F13 | 203 ± 6 | 325 ± 1 | 823 ± 7 | 1.32 ± 0.06 |

| F14 | 112 ± 4 | 236 ± 4 | 641 ± 7 | 1.24 ± 0.05 |

| F15 | 135 ± 2 | 252 ± 1 | 667 ± 4 | 1.45 ± 0.00 |

| F16 | 159 ± 4 | 260 ± 4 | 668 ± 10 | 1.34 ± 0.06 |

| F17 | 158 ± 5 | 292 ± 4 | 767 ± 5 | 1.16 ± 0.00 |

| F18 | 167 ± 2 | 300 ± 2 | 784 ± 8 | 1.19 ± 0.00 |

| F19 | 146 ± 1 | 259 ± 3 | 671 ± 9 | 1.21 ± 0.00 |

| F20 | 170 ± 5 | 277 ± 3 | 712 ± 4 | 1.29 ± 0.00 |

| F21 | 204 ± 1 | 316 ± 2 | 796 ± 7 | 1.25 ± 0.06 |

| F22 | 146 ± 3 | 252 ± 4 | 656 ± 11 | 1.19 ± 0.00 |

| F23 | 143 ± 4 | 270 ± 5 | 714 ± 12 | 1.09 ± 0.06 |

| F24 | 119 ± 1 | 257 ± 6 | 704 ± 23 | 1.19 ± 0.00 |

| F25 | 147 ± 4 | 284 ± 7 | 761 ± 17 | 1.19 ± 0.00 |

| F26 | 154 ± 6 | 260 ± 6 | 675 ± 12 | 1.13 ± 0.00 |

| F27 | 174 ± 5 | 314 ± 4 | 826 ± 9 | 1.20 ± 0.00 |

| F28 | 159 ± 1 | 268 ± 3 | 691 ± 9 | 1.25 ± 0.07 |

| F29 | 192 ± 6 | 304 ± 4 | 764 ± 12 | 1.14 ± 0.00 |

| F30 | 148 ± 2 | 278 ± 3 | 748 ± 13 | 1.08 ± 0.00 |

| Min−Max | 112–204 | 229–316 | 606–826 | 1.08–1.45 |

| Average | 153 | 274 | 716 | 1.20 |

| Sample | Optimised Dough Yield 1 | Dough Consistency (N∙s), n = 5 | Bake Loss (%), n = 3 | Specific Volume (mL/g), n = 3 | Staling Rate (N), n = 3 |

|---|---|---|---|---|---|

| F11 | 205 | 135 ± 3 i | 17.3 ± 0.3 ab | 1.9 ± 0.03 ab | 0 |

| F12 | 195 | 218 ± 5 ef | 16.2 ± 0.2 cde | 1.71 ± 0.02 c | 0 |

| F13 | 198 | 234 ± 5 de | 15.4 ± 0.2 efg | 1.58 ± 0.02 de | 7.1 ± 0.6 |

| F14 | 200 | 156 ± 5 i | 17.6 ± 0.1 a | 1.91 ± 0.02 ab | 0 |

| F15 | 205 | 162 ± 4 hi | 17.3 ± 0.2 ab | 1.93 ± 0.01 ab | 0 |

| F16 | 195 | 292 ± 8 b | 15.9 ± 0.2 def | 1.63 ± 0.02 cde | 5.9 ± 0.7 |

| F17 | 205 | 136 ± 4 i | 17.4 ± 0.1 ab | 1.92 ± 0.01 ab | 3.2 ± 0.4 |

| F18 | 195 | 194 ± 3 fg | 17.0 ± 0.1 abc | 1.85 ± 0.01 b | 1.1 ± 0.5 |

| F19 | 198 | 267 ± 6 bc | 15.9 ± 0.1 def | 1.57 ± 0.02 de | 5.1 ± 0.7 |

| F20 | 190 | 359 ± 7 a | 14.9 ± 0.1 g | 1.45 ± 0.01 f | 8.1 ± 1.2 |

| F21 | 192 | 255 ± 7 cd | 15.6 ± 0.1 defg | 1.59 ± 0.02 de | 3.8 ± 0.8 |

| F22 | 190 | 262 ± 8 c | 15.2 ± 0.1 fg | 1.56 ± 0.01 def | 1.5 ± 0.8 |

| F23 | 185 | 215 ± 5 ef | 16.4 ± 0.1 cd | 1.98 ± 0.05 a 2 | 1.8 ± 0.9 |

| F24 | 200 | 207 ± 3 efg | 16.2 ± 0.2 cdef | 1.60 ± 0.02 de | 0 |

| F25 | 197 | 231 ± 7 de | 15.6 ± 0.2 defg | 1.52 ± 0.01 def | 6.0 ± 2 |

| F26 | 197 | 192 ± 4 fg | 16.7 ± 0.1 bcd | 1.84 ± 0.01 b | 0 |

| F27 | 192 | 230 ± 3 de | 15.8 ± 0.2 defhg | 1.65 ± 0.01 cd | 5.9 ± 0.9 |

| F28 | 197 | 225 ± 5 e | 16.3 ± 0.2 cde | 1.83 ± 0.02 b | 7.0 ± 2 |

| F29 | 192 | 220 ± 5 ef | 15.5 ± 0.1 defg | 1.54 ± 0.01 def | 7.0 ± 3 |

| F30 | 197 | 184 ± 5 gh | 15.9 ± 0.2 def | 1.57 ± 0.01 de | 8.4 ± 1.3 |

| Min−Max | 185–205 | 135–359 | 14.9–17.6 | 1.45–1.93 | 0–8.4 |

| Average | 196 | 219 | 16.2 | 1.71 | 3.6 |

| Dough Yield | Dough Consistency | Bake Loss | Specific Volume | Crumb Hardness, Day 1 | Crumb Hardness, Day 3 | Staling Rate | |

|---|---|---|---|---|---|---|---|

| Baking Quality Parameter | |||||||

| Dough yield | 1 | −0.765 *** | 0.791 *** | 0.697 *** | −0.674 ** | −0.708 *** | - |

| Dough consistency | 1 | −0.845 *** | −0.780 *** | 0.786 *** | 0.849 *** | 0.542 * | |

| Bake loss | 1 | 0.949 *** | −0.731 *** | −0.858 *** | −0.674 ** | ||

| Specific volume | 1 | −0.607 ** | −0.746 *** | −0.644 ** | |||

| Crumb hardness, day 1 | 1 | 0.925 *** | - | ||||

| Crumb hardness, day 3 | 1 | 0.639 ** | |||||

| Staling rate | 1 | ||||||

| Physicochemical Quality Parameter | |||||||

| Protein a | - | - | - | - | - | - | - |

| Fat a | - | −0.474 * | 0.632 ** | 0.629 ** | - | - | - |

| Starch a | - | - | - | - | - | - | - |

| Ash a | - | - | - | - | - | - | - |

| TDF a | - | - | - | - | - | - | - |

| β-glucan a | - | - | - | - | 0.492 * | - | - |

| WHC | - | - | - | - | - | - | - |

| D50 | −0.496 * | - | −0.532 * | - | 0.609 ** | 0.726 *** | 0.592 ** |

| D4,3 | - | - | - | - | - | 0.530 * | 0.555 * |

| D90 | - | - | - | - | - | - | 0.516 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sammalisto, S.; Laitinen, M.; Sontag-Strohm, T. Baking Quality Assessment of Twenty Whole Grain Oat Cultivar Samples. Foods 2021, 10, 2461. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10102461

Sammalisto S, Laitinen M, Sontag-Strohm T. Baking Quality Assessment of Twenty Whole Grain Oat Cultivar Samples. Foods. 2021; 10(10):2461. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10102461

Chicago/Turabian StyleSammalisto, Saara, Miikka Laitinen, and Tuula Sontag-Strohm. 2021. "Baking Quality Assessment of Twenty Whole Grain Oat Cultivar Samples" Foods 10, no. 10: 2461. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10102461