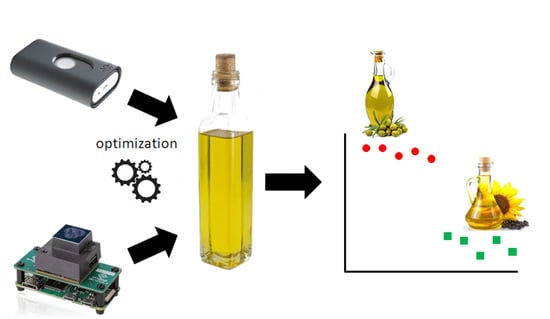

Measurement Strategies for the Classification of Edible Oils Using Low-Cost Miniaturised Portable NIR Instruments

Abstract

:1. Introduction

2. Materials and Methods

2.1. Instrumentation

2.2. Samples

2.3. Materials and Instruments

2.4. Statistical Data Analysis

3. Results and Discussion

3.1. Optimisation of the Instrumental Setup

3.1.1. SCiO

3.1.2. NeoSpectra Micro Development Kit

- -

- A drop of oil was deposited on a borosilicate cover slip directly above the NeoSpectra, but the information obtained in the spectra was mainly noise.

- -

- The same configuration (drop on a borosilicate cover slip directly above the NeoSpectra) was tried but with an object covered with aluminium foil a few millimetres placed above the drop to enhance the transflectance. This strategy gave a good spectral signal. However, this option was discarded, as the position and shape of the oil droplets were not totally reproducible, greatly affecting the quality of the signal, even trying to optimise different volumes of the droplet (from 25 to 200 μL). The position of the droplet was important since the maximum instrumental signal was obtained for droplets deposited on the centre of the optical window.

- -

- Quartz cuvettes were also tested. Although the goal is developing a cuvette-cleaning free method, we tried using cuvettes to obtain reference spectra with our instruments. Two cuvettes with optical path lengths of 1 mm and 10 mm were used. In both cases, it was necessary to use aluminium foil at the back of the cuvette to enhance the transflectance; otherwise, only noise was obtained. For the 1 mm cuvette, a foil-covered object was used on the back of the cuvette, and the spectral signal obtained was very similar to that obtained with the droplet. As previously pointed out, this method is unfeasible due to the difficulty of cleaning this cuvette and the possible cross-contamination between samples. When using the 10 mm cuvette with aluminium foil at the back side, the spectra were only obtained in the 1350–1700 nm range: for higher wavelengths, the instrumental signal dramatically decreased to practically 0. Because of this, the possibility of using a borosilicate glass vial with a certain volume of olive oil over the optical window of the NeoSpectra was discarded.

3.2. Spectroscopic Signals

3.3. Multivariate Statistical Analysis

3.3.1. Exploratory Data Analysis

3.3.2. Classification of Oils

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- U.S. Department of Agriculture—Food Data Central. Available online: https://fdc.nal.usda.gov/fdc-app.html#/food-details/171413/nutrientsa.gov (accessed on 16 October 2021).

- Australian Olive Oil—An Overview 2019. Available online: https://australianolives.com.au/australian-olive-oil-an-overview-2019/ (accessed on 16 October 2021).

- European Commission Committee for the Common Organisation of the Agricultural Markets. Arable Crops and Olive Oil—Market Situation in the Olive Oil and Table Olives Sectors; European Commission: Brussels, Belgium, 2021; pp. 1–27. [Google Scholar]

- International Olive Council—Designations and Definitions of Olive Oils. Available online: https://www.internationaloliveoil.org/olive-world/olive-oil/ (accessed on 16 October 2021).

- IOC (International Olive Council). Trade Standard Applying to Olive Oils and Olive Pomace Oils; COI/T.15/NC No 3/Rev. 13; IOC: Madrid, Spain, 2019. [Google Scholar]

- International Olive Council—IOC Standards, Methods and Guides. Available online: https://www.internationaloliveoil.org/what-we-do/chemistry-standardisation-unit/standards-and-methods/ (accessed on 16 October 2021).

- Zaroual, H.; Chénè, C.; El Hadrami, E.M.; Karoui, R. Application of new emerging techniques in combination with classical methods for the determination of the quality and authenticity of olive oil: A review. Crit. Rev. Food Sci. Nutr. 2021, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhang, L.; Zhang, Y.; Wang, D.; Wang, X.; Yu, L.; Zhang, W.; Li, P. Review of NIR spectroscopy methods for nondestructive quality analysis of oilseeds and edible oils. Trends Food Sci. Technol. 2020, 101, 172–181. [Google Scholar] [CrossRef]

- Beć, K.B.; Grabska, J.; Huck, C.W. Principles and Applications of Miniaturized Near-Infrared (NIR) Spectrometers. Chem.-A Eur. J. 2021, 27, 1514–1532. [Google Scholar] [CrossRef] [PubMed]

- Crocombe, R.A. Portable Spectroscopy. Appl. Spectrosc. 2018, 72, 1701–1751. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; van Stuijvenberg, L.; van Ruth, S.M. Handheld Near-Infrared Spectroscopy for Distinction of Extra Virgin Olive Oil from Other Olive Oil Grades Substantiated by Compositional Data. Eur. J. Lipid Sci. Technol. 2019, 121, 1900031. [Google Scholar] [CrossRef] [Green Version]

- Borghi, F.T.; Santos, P.C.; Santos, F.D.; Nascimento, M.H.C.; Corrêa, T.; Cesconetto, M.; Pires, A.A.; Ribeiro, A.V.F.N.; Lacerda, V.; Romão, W.; et al. Quantification and classification of vegetable oils in extra virgin olive oil samples using a portable near-infrared spectrometer associated with chemometrics. Microchem. J. 2020, 159, 105544. [Google Scholar] [CrossRef]

- Karunathilaka, S.R.; Fardin-Kia, A.R.; Srigley, C.; Chung, J.K.; Mossoba, M.M. Rapid screening of commercial extra virgin olive oil products for authenticity: Performance of a handheld NIR device. NIR News 2017, 28, 9–14. [Google Scholar] [CrossRef]

- Weesepoel, Y.; Alewijn, M.; Wijtten, M.; Müller-Maatsch, J. Detecting Food Fraud in Extra Virgin Olive Oil Using a Prototype Portable Hyphenated Photonics Sensor. J. AOAC Int. 2021, 104, 7–15. [Google Scholar] [CrossRef] [PubMed]

- Riu, J.; Gorla, G.; Chakif, D.; Boqué, R.; Giussani, B. Rapid analysis of milk using low-cost pocket-size NIR spectrometers and multivariate analysis. Foods 2020, 9, 1090. [Google Scholar] [CrossRef] [PubMed]

- Mustorgi, E.; Malegori, C.; Oliveri, P.; Hooshyary, M.; Bounneche, H.; Mondello, L.; Oteri, M.; Casale, M. A chemometric strategy to evaluate the comparability of PLS models obtained from quartz cuvettes and disposable glass vials in the determination of extra virgin olive oil quality parameters by NIR spectroscopy. Chemom. Intell. Lab. Syst. 2020, 199, 103974. [Google Scholar] [CrossRef]

- Jolayemi, O.S.; Tokatli, F.; Buratti, S.; Alamprese, C. Discriminative capacities of infrared spectroscopy and e-nose on Turkish olive oils. Eur. Food Res. Technol. 2017, 243, 2035–2042. [Google Scholar] [CrossRef]

- Ballabio, D.; Grisoni, F.; Todeschini, R. Multivariate comparison of classification performance measures. Chemom. Intell. Lab. Syst. 2018, 174, 33–44. [Google Scholar] [CrossRef]

- Gonzalez Viejo, C.; Fuentes, S.; Torrico, D.; Howell, K.; Dunshea, F.R. Assessment of beer quality based on foamability and chemical composition using computer vision algorithms, near infrared spectroscopy and machine learning algorithms. J. Sci. Food Agric. 2018, 98, 618–627. [Google Scholar] [CrossRef] [PubMed]

- Cayuela Sánchez, J.A.; Moreda, W.; García, J.M. Rapid determination of olive oil oxidative stability and its major quality parameters using vis/NIR transmittance spectroscopy. J. Agric. Food Chem. 2013, 61, 8056–8062. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Sánchez, N.; Gómez-Del-Campo, M. From NIR spectra to singular wavelengths for the estimation of the oil and water contents in olive fruits. Grasas Aceites 2018, 69, e278. [Google Scholar] [CrossRef] [Green Version]

- Sinelli, N.; Casale, M.; Di Egidio, V.; Oliveri, P.; Bassi, D.; Tura, D.; Casiraghi, E. Varietal discrimination of extra virgin olive oils by near and mid infrared spectroscopy. Food Res. Int. 2010, 43, 2126–2131. [Google Scholar] [CrossRef]

- Woodcock, T.; Downey, G.; O’Donnell, C.P. Confirmation of declared provenance of European extra virgin olive oil samples by NIR spectroscopy. J. Agric. Food Chem. 2008, 56, 11520–11525. [Google Scholar] [CrossRef] [PubMed]

- Downey, G.; McIntyre, P.; Davies, A.N. Detecting and quantifying sunflower oil adulteration in extra virgin olive oils from the Eastern Mediterranean by visible and near-infrared spectroscopy. J. Agric. Food Chem. 2002, 50, 5520–5525. [Google Scholar] [CrossRef] [PubMed]

- Vieira, L.S.; Assis, C.; de Queiroz, M.E.L.R.; Neves, A.A.; de Oliveira, A.F. Building robust models for identification of adulteration in olive oil using FT-NIR, PLS-DA and variable selection. Food Chem. 2021, 345, 128866. [Google Scholar] [CrossRef] [PubMed]

- Garrido-Varo, A.; Sánchez, M.T.; De la Haba, M.J.; Torres, I.; Pérez-Marín, D. Fast, low-cost and non-destructive physico-chemical analysis of virgin olive oils using near-infrared reflectance spectroscopy. Sensors 2017, 17, 2642. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Training Set Sensitivity | Training Set Specificity | Test Set Sensitivity | Test Set Specificity | ||

|---|---|---|---|---|---|

| SCiO | Extra virgin olive oil | 1 | 1 | 1 | 0.88 |

| Pomace olive oil | 1 | 1 | 1 | 1 | |

| Refined olive oil | 1 | 1 | 0.80 | 1 | |

| Virgin olive oil | 1 | 1 | 1 | 1 | |

| NeoSpectra method 1 (home-made cells) | Extra virgin olive oil | 1 | 1 | 1 | 0.88 |

| Pomace olive oil | 1 | 1 | 1 | 1 | |

| Refined olive oil | 1 | 1 | 0.60 | 1 | |

| Virgin olive oil | 1 | 1 | 1 | 0.94 | |

| NeoSpectra method 2 (paper) | Extra virgin olive oil | 1 | 1 | 0.60 | 0.63 |

| Pomace olive oil | 1 | 1 | 0 | 1 | |

| Refined olive oil | 1 | 1 | 0.40 | 0.85 | |

| Virgin olive oil | 1 | 1 | 1 | 0.76 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giussani, B.; Escalante-Quiceno, A.T.; Boqué, R.; Riu, J. Measurement Strategies for the Classification of Edible Oils Using Low-Cost Miniaturised Portable NIR Instruments. Foods 2021, 10, 2856. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10112856

Giussani B, Escalante-Quiceno AT, Boqué R, Riu J. Measurement Strategies for the Classification of Edible Oils Using Low-Cost Miniaturised Portable NIR Instruments. Foods. 2021; 10(11):2856. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10112856

Chicago/Turabian StyleGiussani, Barbara, Alix Tatiana Escalante-Quiceno, Ricard Boqué, and Jordi Riu. 2021. "Measurement Strategies for the Classification of Edible Oils Using Low-Cost Miniaturised Portable NIR Instruments" Foods 10, no. 11: 2856. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10112856