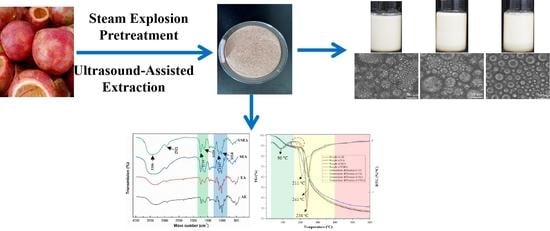

Extraction of Pectin from Passion Fruit Peel: Composition, Structural Characterization and Emulsion Stability

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pectin Extraction

2.2.1. Acid Extraction (AE)

2.2.2. Ultrasonic-Assisted Acid Extraction (UA)

2.2.3. Steam Explosion Pretreatment Combined with Acid Extraction (SEA)

2.2.4. Ultrasonic-Assisted Steam Explosion Pretreatment Combined with Acid Extraction (USEA)

2.3. Yield

2.4. Protein Content and TPC

2.5. Structure Analysis of Pectin

2.5.1. Scanning Electron Microscopy (SEM)

2.5.2. Determination of Degree of Esterification (DE) Value

2.5.3. Monosaccharides Composition

2.5.4. Molecular Weight (Mw)

2.5.5. FT-IR Spectroscopy

2.5.6. XRD Measurement

2.6. Thermal Analysis

2.7. Emulsifying Properties

2.8. Statistical Analysis

3. Results and Discussion

3.1. Effect of Extraction Method on Yield

3.2. Protein Content and TPC

3.3. Structural Characteristics of Pectin

3.3.1. Morphology

3.3.2. DE

3.3.3. Monosaccharide Composition and Mw

3.3.4. FT-IR and XRD Analysis

3.4. Thermal Analysis of Pectin

3.5. Emulsifying Properties of Pectin

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Corrêa, R.C.G.; Peralta, R.M.; Haminiuk, C.W.I.; Maciel, G.M.; Bracht, A.; Ferreira, I.C.F.R. The past decade findings related with nutritional composition, bioactive molecules and biotechnological applications of Passiflora spp. (passion fruit). Trends Food Sci. Technol. 2016, 58, 79–95. [Google Scholar] [CrossRef]

- My-Thao Nguyen, T.; Anh-Thu Nguyen, T.; Tuong-Van Pham, N.; Ly, Q.-V.; Thuy-Quynh Tran, T.; Thach, T.-D.; Nguyen, C.-L.; Banh, K.-S.; Le, V.-D.; Nguyen, L.-P.; et al. Biosynthesis of metallic nanoparticles from waste Passiflora edulis peels for their antibacterial effect and catalytic activity. Arab. J. Chem. 2021, 14, 103096. [Google Scholar] [CrossRef]

- Fonseca, A.M.A.; Geraldi, M.V.; Junior, M.R.M.; Silvestre, A.J.D.; Rocha, S.M. Purple passion fruit (Passiflora edulis f. edulis): A comprehensive review on the nutritional value, phytochemical profile and associated health effects. Food Res. Int. 2022, 160, 111665. [Google Scholar] [CrossRef]

- Delvar, A.; de Caro, P.; Candy, L.; Caro, Y.; Sing, A.S.C.; Raynaud, C. Integrated process for extraction and formulation in emulsions of active molecules from fresh passion fruits (Passiflora edulis Sims). J. Food Eng. 2019, 263, 388–397. [Google Scholar] [CrossRef] [Green Version]

- Adetunji, L.R.; Adekunle, A.; Orsat, V.; Raghavan, V. Advances in the pectin production process using novel extraction techniques: A review. Food Hydrocoll. 2017, 62, 239–250. [Google Scholar] [CrossRef]

- Yang, J.S.; Mu, T.H.; Ma, M.M. Extraction, structure, and emulsifying properties of pectin from potato pulp. Food Chem. 2018, 244, 197–205. [Google Scholar] [CrossRef]

- Klinchongkon, K.; Khuwijitjaru, P.; Adachi, S. Properties of subcritical water-hydrolyzed passion fruit (Passiflora edulis) pectin. Food Hydrocoll. 2018, 74, 72–77. [Google Scholar] [CrossRef]

- De Oliveira, C.F.; Giordani, D.; Gurak, P.D.; Cladera-Olivera, F.; Marczak, L.D.F. Extraction of pectin from passion fruit peel using moderate electric field and conventional heating extraction methods. Innov. Food Sci. Emerg. Technol. 2015, 29, 201–208. [Google Scholar] [CrossRef]

- De Oliveira, C.F.; Gurak, P.D.; Cladera-Olivera, F.; Marczak, L.D.F.; Karwe, M. Combined Effect of High-Pressure and Conventional Heating on Pectin Extraction from Passion Fruit Peel. Food Bioprocess Technol. 2016, 9, 1021–1030. [Google Scholar] [CrossRef]

- De Oliveira, C.F.; Giordani, D.; Lutckemier, R.; Gurak, P.D.; Cladera-Olivera, F.; Ferreira Marczak, L.D. Extraction of pectin from passion fruit peel assisted by ultrasound. LWT Food Sci. Technol. 2016, 71, 110–115. [Google Scholar] [CrossRef]

- Seixas, F.L.; Fukuda, D.L.; Turbiani, F.R.B.; Garcia, P.S.; Petkowicz, C.L.D.O.; Jagadevan, S.; Gimenes, M.L. Extraction of pectin from passion fruit peel (Passiflora edulis f. flavicarpa) by microwave-induced heating. Food Hydrocoll. 2014, 38, 186–192. [Google Scholar] [CrossRef]

- Lin, Y.P.; An, F.P.; He, H.; Geng, F.; Song, H.B.; Huang, Q. Structural and rheological characterization of pectin from passion fruit (Passiflora edulis f. flavicarpa) peel extracted by high-speed shearing. Food Hydrocoll. 2021, 114, 106555. [Google Scholar] [CrossRef]

- Gavahian, M.; Mathad, G.N.; Pandiselvam, R.; Lin, J.; Sun, D.-W. Emerging technologies to obtain pectin from food processing by-products: A strategy for enhancing resource efficiency. Trends Food Sci. Technol. 2021, 115, 42–54. [Google Scholar] [CrossRef]

- Tran, T.T.B.; Saifullah, M.; Nguyen, N.H.; Nguyen, M.H.; Vuong, Q.V. Comparison of ultrasound-assisted and conventional extraction for recovery of pectin from Gac (Momordica cochinchinensis) pulp. Future Foods 2021, 4, 100074. [Google Scholar] [CrossRef]

- Maran, J.P.; Priya, B.; Al-Dhabi, N.A.; Ponmurugan, K.; Moorthy, I.G.; Sivarajasekar, N. Ultrasound assisted citric acid mediated pectin extraction from industrial waste of Musa balbisiana. Ultrason. Sonochem. 2017, 35, 204–209. [Google Scholar] [CrossRef]

- Chen, Y.; Shan, S.; Cao, D.; Tang, D. Steam flash explosion pretreatment enhances soybean seed coat phenolic profiles and antioxidant activity. Food Chem. 2020, 319, 126552. [Google Scholar] [CrossRef] [PubMed]

- Martin-Sampedro, R.; Capanema, E.A.; Hoeger, I.; Villar, J.C.; Rojas, O.J. Lignin changes after steam explosion and laccase-mediator treatment of eucalyptus wood chips. J. Agric. Food Chem. 2011, 59, 8761–8769. [Google Scholar] [CrossRef]

- Wan, F.C.; Feng, C.F.; Luo, K.Y.; Cui, W.Y.; Xia, Z.H.; Cheng, A.W. Effect of steam explosion on phenolics and antioxidant activity in plants: A review. Trends Food Sci. Technol. 2022, 124, 13–24. [Google Scholar] [CrossRef]

- Hong, Q.Y.; Chen, G.J.; Wang, Z.R.; Chen, X.H.; Shi, Y.; Chen, Q.L.; Kan, J.Q. Impact of processing parameters on physicochemical properties and biological activities of Qingke (highland hull-less barley) treated by steam explosion. J. Food Process. Preserv. 2020, 44, e14793. [Google Scholar] [CrossRef]

- Rojas-Pérez, L.C.; Narváez-Rincón, P.C.; Ballesteros, I. Improving sugar extraction from brewers’ spent grain using sequential deproteinization and acid-catalyzed steam explosion in a biorefinery context. Biomass Bioenergy 2022, 159, 106389. [Google Scholar] [CrossRef]

- Cui, J.; Zhao, C.; Feng, L.; Han, Y.; Du, H.; Xiao, H.; Zheng, J. Pectins from fruits: Relationships between extraction methods, structural characteristics, and functional properties. Trends Food Sci. Technol. 2021, 110, 39–54. [Google Scholar] [CrossRef]

- Schmidt, U.S.; Schütz, L.; Schuchmann, H.P. Interfacial and emulsifying properties of citrus pectin: Interaction of pH, ionic strength and degree of esterification. Food Hydrocoll. 2017, 62, 288–298. [Google Scholar] [CrossRef]

- Chen, H.; Liu, Y.; Zhang, J.; Jiang, Y.; Li, D. Pectin extracted from dragon fruit Peel: An exploration as a natural emulsifier. Int. J. Biol. Macromol. 2022, 221, 976–985. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Deng, L.; Dai, T.; Chen, J.; Liu, W.; Liu, C.; Chen, M.; Liang, R. Emulsifying and emulsion stabilization mechanism of pectin from Nicandra physaloides (Linn.) Gaertn seeds: Comparison with apple and citrus pectin. Food Hydrocoll. 2022, 130, 107674. [Google Scholar] [CrossRef]

- Ngouémazong, E.D.; Christiaens, S.; Shpigelman, A.; Van Loey, A.; Hendrickx, M. The Emulsifying and Emulsion-Stabilizing Properties of Pectin: A Review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 705–718. [Google Scholar] [CrossRef]

- Kulkarni, S.G.; Vijayanand, P. Effect of extraction conditions on the quality characteristics of pectin from passion fruit peel (Passiflora edulis f. flavicarpa L.). LWT Food Sci. Technol. 2010, 43, 1026–1031. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Zheng, L.L.; Zheng, X.Y.; Ai, B.L.; Yang, Y.; Pan, Y.G.; Sheng, Z.W. Effect of steam explosion treatments on the functional properties and structure of camellia (Camellia oleifera Abel.) seed cake protein. Food Hydrocoll. 2019, 93, 189–197. [Google Scholar] [CrossRef]

- Munoz-Almagro, N.; Valadez-Carmona, L.; Mendiola, J.A.; Ibanez, E.; Villamiel, M. Structural characterisation of pectin obtained from cacao pod husk. Comparison of conventional and subcritical water extraction. Carbohydr. Polym. 2019, 217, 69–78. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, Z.; Fischer, J.; Wicker, L. Intermolecular binding of blueberry pectin-rich fractions and anthocyanin. Food Chem. 2016, 194, 986–993. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hu, W.; Chen, S.; Wu, D.; Zhu, K.; Ye, X. Physicochemical and macromolecule properties of RG-I enriched pectin from citrus wastes by manosonication extraction. Int. J. Biol. Macromol. 2021, 176, 332–341. [Google Scholar] [CrossRef] [PubMed]

- Kazemi, M.; Khodaiyan, F.; Hosseini, S.S. Eggplant peel as a high potential source of high methylated pectin: Ultrasonic extraction optimization and characterization. LWT Food Sci. Technol. 2019, 105, 182–189. [Google Scholar] [CrossRef]

- Hosseini, S.S.; Khodaiyan, F.; Kazemi, M.; Najari, Z. Optimization and characterization of pectin extracted from sour orange peel by ultrasound assisted method. Int. J. Biol. Macromol. 2019, 125, 621–629. [Google Scholar] [CrossRef]

- Jiang, Y.; Xu, Y.H.; Li, F.; Li, D.P.; Huang, Q.R. Pectin extracted from persimmon peel: A physicochemical characterization and emulsifying properties evaluation. Food Hydrocoll. 2020, 101, 105561. [Google Scholar] [CrossRef]

- Tiwari, B.K. Ultrasound: A clean, green extraction technology. TrAC Trends Anal. Chem. 2015, 71, 100–109. [Google Scholar] [CrossRef]

- Miano, A.C.; Ibarz, A.; Augusto, P.E. Mechanisms for improving mass transfer in food with ultrasound technology: Describing the phenomena in two model cases. Ultrason. Sonochem. 2016, 29, 413–419. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.S.; Wang, Z.M.; Hu, D.; Xiao, K.J.; Wu, J.Y. Efficient extraction of pectin from sisal waste by combined enzymatic and ultrasonic process. Food Hydrocoll. 2018, 79, 189–196. [Google Scholar] [CrossRef]

- Basak, S.; Annapure, U.S. Trends in “green” and novel methods of pectin modification—A review. Carbohydr. Polym. 2022, 278, 118967. [Google Scholar] [CrossRef]

- Guo, X.B.; Guo, X.M.; Meng, H.C.; Zhang, B.B.; Yu, S.J. Using the high temperature resistant pH electrode to auxiliarily study the sugar beet pectin extraction under different extraction conditions. Food Hydrocoll. 2017, 70, 105–113. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.; Xiao, L.; Li, S.; Meng, T.; Wang, L.; Zhang, W. The effect of sonication-synergistic natural deep eutectic solvents on extraction yield, structural and physicochemical properties of pectins extracted from mango peels. Ultrason. Sonochem. 2022, 86, 106045. [Google Scholar] [CrossRef]

- Zhang, L.; Ye, X.; Xue, S.J.; Zhang, X.; Liu, D.; Meng, R.; Chen, S. Effect of high-intensity ultrasound on the physicochemical properties and nanostructure of citrus pectin. J. Sci. Food Agric. 2013, 93, 2028–2036. [Google Scholar] [CrossRef]

- Liu, C.Y.; Sun, Y.Y.; Jia, Y.Q.; Geng, X.Q.; Pan, L.C.; Jiang, W.; Xie, B.Y.; Zhu, Z.Y. Effect of steam explosion pretreatment on the structure and bioactivity of Ampelopsis grossedentata polysaccharides. Int. J. Biol. Macromol. 2021, 185, 194–205. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zhang, J.G.; Sun, H.J.; Wei, Z.J. Pectin from Abelmoschus esculentus: Optimization of extraction and rheological properties. Int. J. Biol. Macromol. 2014, 70, 498–505. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Zhang, S.; Waterhouse, G.I.N.; Zhou, T.; Du, Y.; Sun-Waterhouse, D.; Wu, P. Yeast fermentation of apple and grape pomaces affects subsequent aqueous pectin extraction: Composition, structure, functional and antioxidant properties of pectins. Food Hydrocoll. 2022, 133, 107945. [Google Scholar] [CrossRef]

- Ezzati, S.; Ayaseh, A.; Ghanbarzadeh, B.; Heshmati, M.K. Pectin from sunflower by-product: Optimization of ultrasound-assisted extraction, characterization, and functional analysis. Int. J. Biol. Macromol. 2020, 165, 776–786. [Google Scholar] [CrossRef] [PubMed]

- Rahmani, Z.; Khodaiyan, F.; Kazemi, M.; Sharifan, A. Optimization of microwave-assisted extraction and structural characterization of pectin from sweet lemon peel. Int. J. Biol. Macromol. 2020, 147, 1107–1115. [Google Scholar] [CrossRef] [PubMed]

- Qin, C.; Yang, G.; Zhu, C.; Wei, M. Characterization of edible film fabricated with HG-type hawthorn pectin gained using different extraction methods. Carbohydr. Polym. 2022, 285, 119270. [Google Scholar] [CrossRef] [PubMed]

- Muthukumaran, C.; Kanmani, B.; Sharmila, G.; Kumar, M.; Shanmugaprakash, M. Carboxymethylation of pectin: Optimization, characterization and in-vitro drug release studies. Carbohydr. Polym. 2018, 194, 311–318. [Google Scholar] [CrossRef]

- Sucheta; Misra, N.N.; Yadav, S.K. Extraction of pectin from black carrot pomace using intermittent microwave, ultrasound and conventional heating: Kinetics, characterization and process economics. Food Hydrocoll. 2020, 102, 105592. [Google Scholar] [CrossRef]

- Wang, W.J.; Ma, X.B.; Jiang, P.; Hu, L.L.; Zhi, Z.J.; Chen, J.L.; Ding, T.; Ye, X.Q.; Liu, D.H. Characterization of pectin from grapefruit peel: A comparison of ultrasound-assisted and conventional heating extractions. Food Hydrocoll. 2016, 61, 730–739. [Google Scholar] [CrossRef]

- Funami, T.; Nakauma, M.; Ishihara, S.; Tanaka, R.; Inoue, T.; Phillips, G.O. Structural modifications of sugar beet pectin and the relationship of structure to functionality. Food Hydrocoll. 2011, 25, 221–229. [Google Scholar] [CrossRef]

| Samples | Yield (%) | Protein Content (%) | TPC (mg GAE/g) |

|---|---|---|---|

| AE | 5.28 ± 1.57 b | 0.46 ± 0.08 d | 8.58 ± 0.47 b |

| UA | 6.52 ± 0.48 b | 0.51 ± 0.05 c | 9.15 ± 0.35 b |

| SEA | 9.93 ± 0.33 a | 0.68 ± 0.04 a | 17.55 ± 0.55 a |

| USEA | 10.72 ± 0.39 a | 0.62 ± 0.01 b | 18.85 ± 0.22 a |

| Samples | AE | UA | SEA | USEA |

|---|---|---|---|---|

| DE (%) | 74.50 ± 0.86 b | 83.40 ± 0.49 a | 59.31 ± 1.72 d | 68.49 ± 0.17 c |

| Mw (×105 Da) | 6.54 | 7.18 | 0.74 | 0.72 |

| Mw/Mn | 1.80 | 1.65 | 1.65 | 1.67 |

| Relative monosaccharide content (%, w/w) | ||||

| GalA | 78.41 | 82.90 | 74.66 | 81.26 |

| Ara | 15.74 | 12.20 | 14.35 | 12.04 |

| Gal | 3.10 | 2.76 | 5.61 | 3.80 |

| Rha | 1.39 | 0.98 | 1.43 | 1.30 |

| Xyl | 0 | 0 | 0 | 0 |

| Glc | 0.82 | 0.68 | 2.01 | 1.04 |

| Man | 0.54 | 0.48 | 1.94 | 0.56 |

| HG | 77.02 | 81.92 | 73.22 | 79.96 |

| RG–I | 21.62 | 16.92 | 22.83 | 18.44 |

| GalA/Rha | 56.43 | 84.62 | 52.07 | 62.61 |

| (Ara + Gal)/Rha | 13.56 | 15.27 | 13.92 | 12.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Y.; Yang, Y.; Zheng, L.; Zheng, X.; Xiao, D.; Wang, S.; Ai, B.; Sheng, Z. Extraction of Pectin from Passion Fruit Peel: Composition, Structural Characterization and Emulsion Stability. Foods 2022, 11, 3995. https://0-doi-org.brum.beds.ac.uk/10.3390/foods11243995

Liang Y, Yang Y, Zheng L, Zheng X, Xiao D, Wang S, Ai B, Sheng Z. Extraction of Pectin from Passion Fruit Peel: Composition, Structural Characterization and Emulsion Stability. Foods. 2022; 11(24):3995. https://0-doi-org.brum.beds.ac.uk/10.3390/foods11243995

Chicago/Turabian StyleLiang, Yonglun, Yang Yang, Lili Zheng, Xiaoyan Zheng, Dao Xiao, Shenwan Wang, Binling Ai, and Zhanwu Sheng. 2022. "Extraction of Pectin from Passion Fruit Peel: Composition, Structural Characterization and Emulsion Stability" Foods 11, no. 24: 3995. https://0-doi-org.brum.beds.ac.uk/10.3390/foods11243995