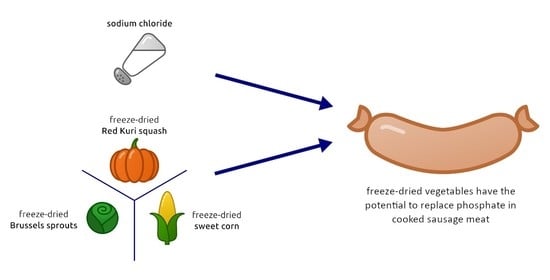

Dried Vegetables as Potential Clean-Label Phosphate Substitutes in Cooked Sausage Meat

Abstract

:1. Introduction

2. Materials and Methods

2.1. Overview over the Study and Selection Criteria

2.2. Meat, Plant Products, and Reagents

2.3. pH Screening of Vegetable Foods

2.4. Preparation of Minced Meat and Vegetable Additives

2.5. Preparation of Sausage Meat Samples

2.6. Determination of Water Holding Capacity

2.7. Sensory Tests

2.8. Color Assessment

2.9. Assessment of Textural Characteristics

2.10. Statistical Analysis

3. Results and Discussion

3.1. pH Screening in Vegetable Foods

3.2. Effect of Different Additives on the WHC of Sausage Meat Samples

3.3. Sensory Tests

3.4. Color and Texture of the Sausage Meat Samples

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EU. Regulation (EC) Nr. 1333/2008 of the European Parliament and of the Council of 16 December 2008 on food additives. Off. J. Eur. Union 2008, L354, 16–33. [Google Scholar]

- Ritz, E.; Hahn, K.; Ketteler, M.; Kuhlmann, M.K.; Mann, J. Phosphate additives in food--a health risk. Dtsch. Arztebl. Int. 2012, 109, 49–55. [Google Scholar] [CrossRef] [PubMed]

- Huang, M.S.; Sage, A.P.; Lu, J.; Demer, L.L.; Tintut, Y. Phosphate and pyrophosphate mediate PKA-induced vascular cell calcification. Biochem. Biophys. Res. Commun. 2008, 374, 553–558. [Google Scholar] [CrossRef] [PubMed]

- Giachelli, C.M. The emerging role of phosphate in vascular calcification. Kidney Int. 2009, 75, 890–897. [Google Scholar] [CrossRef]

- Onufrak, S.J.; Bellasi, A.; Shaw, L.J.; Herzog, C.A.; Cardarelli, F.; Wilson, P.W.; Vaccarino, V.; Raggi, P. Phosphorus levels are associated with subclinical atherosclerosis in the general population. Atherosclerosis 2008, 199, 424–431. [Google Scholar] [CrossRef]

- Cancela, A.L.; Santos, R.D.; Titan, S.M.; Goldenstein, P.T.; Rochitte, C.E.; Lemos, P.A.; dos Reis, L.M.; Graciolli, F.G.; Jorgetti, V.; Moyses, R.M. Phosphorus is associated with coronary artery disease in patients with preserved renal function. PLoS ONE 2012, 7, e36883. [Google Scholar] [CrossRef]

- Chambers, E.; Chambers, E.; Castro, M. What is “natural”? Consumer responses to selected ingredients. Foods 2018, 7, 65. [Google Scholar] [CrossRef]

- Asioli, D.; Aschemann-Witzel, J.; Caputo, V.; Vecchio, R.; Annunziata, A.; Naes, T.; Varela, P. Making sense of the “clean label” trends: A review of consumer food choice behavior and discussion of industry implications. Food Res. Int. 2017, 99, 58–71. [Google Scholar] [CrossRef]

- Bright, B.K. Understanding emerging trends, ingredients and nutrients in processed meats to tell your best brand story. In Proceedings of the Annual Meat Conference, Nashville, TN, USA, 25 February 2018. [Google Scholar]

- Cegiełka, A. “Clean label” as one of the leading trends in the meat industry in the world and in Poland—A review. Rocz. Państwowego Zakładu Hig. 2020, 71, 43–55. [Google Scholar] [CrossRef]

- Lawrie, R.A.; Ledward, D.A. Lawrie’s Meat Science, 7th ed.; Woodhead Publishing Limited: Cambridge, UK, 2006. [Google Scholar]

- Cheng, Q.; Sun, D.-W. Factors Affecting the Water Holding Capacity of Red Meat Products: A Review of Recent Research Advances. Crit. Rev. Food Sci. Nutr. 2008, 48, 137–159. [Google Scholar] [CrossRef]

- Offer, G.; Trinick, J. On the mechanism of water holding in meat: The swelling and shrinking of myofibrils. Meat Sci. 1983, 8, 245–281. [Google Scholar] [CrossRef] [PubMed]

- Seman, D.L.; Olson, D.G.; Mandigo, R.W. Effect of reduction and partial replacement of sodium on Bologna characteristics and acceptability. J. Food Sci. 1980, 45, 1116–1121. [Google Scholar] [CrossRef]

- Trout, G.R.; Schmidt, G.R. Effect of phosphate type and concentration, salt level and method of preparation on binding in restructured beef rolls. J. Food Sci. 1984, 49, 687–694. [Google Scholar] [CrossRef]

- Brewer, M.S. Chemical and physical characteristics of meat. Water holding capacity. In Encyclopedia of Meat Sciences, 2nd ed.; Dikeman, M., Devine, C., Eds.; Academic Press: Oxford, UK, 2014; pp. 274–282. [Google Scholar]

- Borch, E.; Kant-Muermans, M.-L.; Blixt, Y. Bacterial spoilage of meat and cured meat products. Int. J. Food Microbiol. 1996, 33, 103–120. [Google Scholar] [CrossRef] [PubMed]

- Delgado-Pando, G.; Ekonomou, S.I.; Stratakos, A.C.; Pintado, T. Clean label alternatives in meat products. Foods 2021, 10, 1615. [Google Scholar] [CrossRef] [PubMed]

- Thangavelu, K.P.; Kerry, J.P.; Tiwari, B.K.; McDonnell, C.K. Novel processing technologies and ingredient strategies for the reduction of phosphate additives in processed meat. Trends Food Sci. Technol. 2019, 94, 43–53. [Google Scholar] [CrossRef]

- Genccelep, H.; Saricaoglu, F.T.; Anil, M.; Agar, B.; Turhan, S. The effect of starch modification and concentration on steady-state and dynamic rheology of meat emulsions. Food Hydrocoll. 2015, 48, 135–148. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, W.; Wang, J. Recent advances in the study of modified cellulose in meat products: Modification method of cellulose, meat quality improvement and safety concern. Trends Food Sci. Technol. 2022, 122, 140–156. [Google Scholar] [CrossRef]

- Powell, M.J.; Sebranek, J.G.; Prusa, K.J.; Tarté, R. Evaluation of citrus fiber as a natural replacer of sodium phosphate in alternatively-cured all-pork Bologna sausage. Meat Sci. 2019, 157, 107883. [Google Scholar] [CrossRef]

- Magalhães, I.M.C.; Paglarini, C.D.S.; Vidal, V.A.S.; Pollonio, M.A.R. Bamboo fiber improves the functional properties of reduced salt and phosphate-free Bologna sausage. J. Food Process. Preserv. 2020, 44, e14929. [Google Scholar] [CrossRef]

- Petracci, M.; Laghi, L.; Rocculi, P.; Rimini, S.; Panarese, V.; Cremonini, M.A.; Cavani, C. The use of sodium bicarbonate for marination of broiler breast meat. Poult. Sci. 2012, 91, 526–534. [Google Scholar] [CrossRef] [PubMed]

- Choe, J.; Lee, J.; Jo, K.; Jo, C.; Song, M.; Jung, S. Application of winter mushroom powder as an alternative to phosphates in emulsion-type sausages. Meat Sci. 2018, 143, 114–118. [Google Scholar] [CrossRef] [PubMed]

- Nunez, S.M.; Cardenas, C.; Pinto, M.; Valencia, P.; Cataldo, P.; Guzman, F.; Almonacid, S. Bovine skin gelatin hydrolysates as potential substitutes for polyphosphates: The role of degree of hydrolysis and pH on water-holding capacity. J. Food Sci. 2020, 85, 1988–1996. [Google Scholar] [CrossRef] [PubMed]

- Parsons, A.N.; VanOverbeke, D.L.; Goad, C.L.; Mireles DeWitt, C.A. Retail display evaluation of steaks from select beef strip loins injected with a brine containing 1% ammonium hydroxide. Part 2: Cook yield, tenderness, and sensory attributes. J. Food Sci. 2011, 76, S84–S88. [Google Scholar] [CrossRef] [PubMed]

- Belitz, H.-D.; Grosch, W.; Schieberle, P. Food Chemistry, 4th ed.; Springer: Berlin/Heidelberg, Germany, 2009; p. 1070. [Google Scholar] [CrossRef]

- Souci, S.W.; Fachmann, W.; Kraut, H. Food Composition and Nutrition Tables, 8th ed.; Wissenschaftliche Verlagsgesellschaft: Stuttgart, Germany, 2016; p. 1263. [Google Scholar]

- Kemp, S.E.; Hollowood, T.; Hort, J. Sensory Evaluation: A Practical Handbook, 1st ed.; John Wiley & Sons Ltd.: Chichester, UK, 2009. [Google Scholar] [CrossRef]

- Schutz, H.G.; Cardello, A.V. A labeled affective magnitude (LAM) scale for assessing food liking/disliking. J. Sens. Stud. 2001, 16, 117–159. [Google Scholar] [CrossRef]

- Greene, J.L.; Bratka, K.J.; Drake, M.A.; Sanders, T.H. Effectiveness of category and line scales to characterize consumer perception of fruity fermented flavor in peanuts. J. Sens. Stud. 2006, 21, 146–154. [Google Scholar] [CrossRef]

- Lawless, H.T.; Popper, R.; Kroll, B.J. A comparison of the labeled magnitude (LAM) scale, an 11-point category scale and the traditional 9-point hedonic scale. Food Qual. Prefer. 2010, 21, 4–12. [Google Scholar] [CrossRef]

- Budday, S.; Nay, R.; de Rooij, R.; Steinmann, P.; Wyrobek, T.; Ovaert, T.C.; Kuhl, E. Mechanical properties of gray and white matter brain tissue by indentation. J. Mech. Behav. Biomed. Mater. 2015, 46, 318–330. [Google Scholar] [CrossRef]

- Uzlaşır, T.; Aktaş, N.i.; Gerçekaslan, K.E. Pumpkin seed oil as a partial animal fat replacer in Bologna-type sausages. Food Sci. Anim. Resour. 2020, 40, 551–562. [Google Scholar] [CrossRef]

- Han, M.; Bertram, H.C. Designing healthier comminuted meat products: Effect of dietary fibers on water distribution and texture of a fat-reduced meat model system. Meat Sci. 2017, 133, 159–165. [Google Scholar] [CrossRef]

- Verma, A.K.; Sharma, B.D.; Banerjee, R. Effect of sodium chloride replacement and apple pulp inclusion on the physico-chemical, textural and sensory properties of low fat chicken nuggets. LWT Food Sci. Technol. 2010, 43, 715–719. [Google Scholar] [CrossRef]

- Ahmad, S.S.; Khalid, M.; Younis, K. Interaction study of dietary fibers (pectin and cellulose) with meat proteins using bioinformatics analysis: An In-Silico study. LWT 2020, 119, 108889. [Google Scholar] [CrossRef]

- Fenwick, G.R.; Griffiths, N.M. The identification of the goitrogen (-)5-vinyloxazolidine-2-thione (goitrin), as a bitter principle of cooked brussels sprouts (Brassica oleracea L. var. gemmifera). Z. Lebensm. Unters. Forsch. 1981, 172, 90–92. [Google Scholar] [CrossRef] [PubMed]

- Beck, T.K.; Jensen, S.; Bjoern, G.K.; Kidmose, U. The masking effect of sucrose on perception of bitter compounds in Brassica vegetables. J. Sens. Stud. 2014, 29, 190–200. [Google Scholar] [CrossRef]

| Vegetable/Fruit | Plant Family | Fresh/Frozen/Dried | pH |

|---|---|---|---|

| Peas * | Fabaceae | frozen | 7.25 |

| Spinach * | Amaranthaceae | frozen | 6.99 |

| Red Kuri squash * | Cucurbitaceae | fresh | 6.92 |

| Sweet corn * | Poaceae | fresh | 6.81 |

| Avocado * | Lauraceae | fresh | 6.80 |

| Zucchini | Cucurbitaceae | fresh | 6.54 |

| Brussels sprouts * | Brassicaceae | frozen | 6.45 |

| Cassava | Euphorbiaceae | fresh | 6.39 |

| White cabbage | Brassicaceae | fresh | 6.39 |

| Broccoli | Brassicaceae | fresh | 6.38 |

| Cantaloupe | Cucurbitaceae | fresh | 6.36 |

| Beetroot | Amaranthaceae | fresh | 6.17 |

| Savoy cabbage | Brassicaceae | fresh | 6.02 |

| Celery root | Apiaceae | fresh | 5.91 |

| Sweet potato | Convolvulaceae | fresh | 5.87 |

| Date | Arecaceae | dried | 5.70 |

| Papaya (pulp/kernels) 1 | Caricaceae | fresh | 5.45/5.53 |

| Additive | Added Conc. 1 | Average LAM 2 Value | Minimum LAM 2 Value | Maximum LAM 2 Value | |||

|---|---|---|---|---|---|---|---|

| Brussels sprouts | 4.0% | 50.04 | ± | 13.52 | (*) | 22.25 | 78.06 |

| 1.6% | 49.96 | ± | 14.97 | (*) | 22.25 | 78.06 | |

| Red Kuri squash | 4.0% | 45.92 | ± | 15.63 | (**) | 12.25 | 87.11 |

| 1.6% | 52.17 | ± | 15.98 | (ns) | 22.25 | 78.06 | |

| Sweet corn | 4.0% | 57.53 | ± | 14.91 | (ns) | 34.06 | 87.11 |

| 1.6% | 55.61 | ± | 16.96 | (ns) | 22.25 | 87.11 | |

| Positive control | 59.78 | ± | 15.39 | 34.06 | 87.11 | ||

| Additive | Added Conc. 1 | L* (D65) | a* (D65) | b* (D65) |

|---|---|---|---|---|

| Brussels sprouts | 4.0% | 76.44 ± 0.88 (***) | 1.27 ± 0.15 (**) | 19.37 ± 0.36 (**) |

| 3.4% | 75.73 ± 1.53 (***) | 1.46 ± 0.35 (***) | 18.54 ± 0.79 (**) | |

| 2.8% | 75.95 ± 1.62 (***) | 1.56 ± 0.19 (***) | 18.48 ± 0.30 (**) | |

| 2.2% | 75.98 ± 1.83 (***) | 1.62 ± 0.28 (***) | 18.39 ± 0.83 (**) | |

| 1.6% | 76.29 ± 1.72 (***) | 1.48 ± 0.28 (***) | 17.68 ± 0.64 (ns) | |

| 1.0% | 76.80 ± 2.36 (**) | 1.68 ± 0.38 (***) | 17.01 ± 0.83 (ns) | |

| Red Kuri squash | 4.0% | 75.94 ± 0.85 (***) | 4.03 ± 0.71 (***) | 24.80 ± 2.49 (***) |

| 3.4% | 75.50 ± 1.35 (***) | 3.90 ± 0.47 (***) | 24.10 ± 1.77 (***) | |

| 2.8% | 75.60 ± 1.29 (***) | 3.52 ± 0.70 (***) | 22.80 ± 2.48 (***) | |

| 2.2% | 75.97 ± 1.34 (***) | 3.25 ± 0.78 (***) | 21.75 ± 1.66 (***) | |

| 1.6% | 76.58 ± 1.37 (**) | 2.84 ± 0.63 (***) | 19.98 ± 1.15 (***) | |

| 1.0% | 76.60 ± 1.49 (**) | 2.50 ± 0.46 (***) | 19.17 ± 1.04 (ns) | |

| Sweet corn | 4.0% | 75.86 ± 2.30 (**) | 2.71 ± 0.53 (***) | 21.12 ± 1.14 (***) |

| 3.4% | 77.06 ± 2.03 (*) | 2.42 ± 0.43 (***) | 20.59 ± 1.02 (***) | |

| 2.8% | 76.27 ± 1.61 (***) | 2.61 ± 0.28 (***) | 20.07 ± 0.91 (***) | |

| 2.2% | 76.75 ± 2.87 (*) | 2.29 ± 0.53 (***) | 19.07 ± 0.89 (*) | |

| 1.6% | 76.31 ± 2.13 (**) | 2.35 ± 0.55 (***) | 18.82 ± 1.06 (ns) | |

| 1.0% | 76.45 ± 2.23 (**) | 2.10 ± 0.47 (***) | 17.33 ± 0.56 (ns) | |

| Positive control | 78.91 ± 1.16 | 0.87 ± 0.39 | 17.29 ± 1.29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weigel, I.; Nistler, S.; Pichner, R.; Budday, S.; Gensberger-Reigl, S. Dried Vegetables as Potential Clean-Label Phosphate Substitutes in Cooked Sausage Meat. Foods 2023, 12, 1960. https://0-doi-org.brum.beds.ac.uk/10.3390/foods12101960

Weigel I, Nistler S, Pichner R, Budday S, Gensberger-Reigl S. Dried Vegetables as Potential Clean-Label Phosphate Substitutes in Cooked Sausage Meat. Foods. 2023; 12(10):1960. https://0-doi-org.brum.beds.ac.uk/10.3390/foods12101960

Chicago/Turabian StyleWeigel, Ingrid, Sarah Nistler, Rohtraud Pichner, Silvia Budday, and Sabrina Gensberger-Reigl. 2023. "Dried Vegetables as Potential Clean-Label Phosphate Substitutes in Cooked Sausage Meat" Foods 12, no. 10: 1960. https://0-doi-org.brum.beds.ac.uk/10.3390/foods12101960