Impact of Dairy Ingredients on Wheat Flour Dough Rheology and Bread Properties

Abstract

:1. Introduction

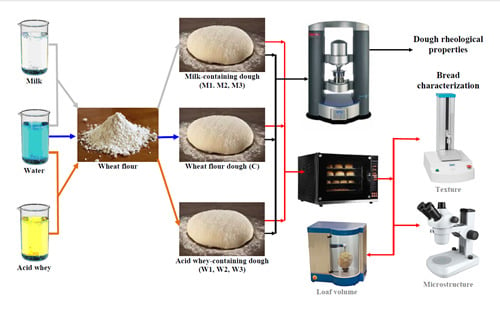

2. Materials and Methods

2.1. Materials

2.2. Bread Making

2.3. Dough Rheological Properties

2.3.1. Frequency Sweep Test

2.3.2. Creep and Recovery Test

2.3.3. Temperature Sweep Test

2.4. Bread Physical Properties

2.5. Texture Profile Analysis

2.6. Crumb Microstructure

2.7. Sensory Profile

2.8. Statistical Analysis

3. Results

3.1. Dough Rheological Properties

3.1.1. Frequency Sweep Test

3.1.2. Creep and Recovery

3.1.3. Temperature Sweep Test

3.2. Bread Physical Properties

3.3. Texture Profile Analysis

3.4. Crumb Microstructure

3.5. Sensory Profile

3.6. Correlations Analysis between Dough Rheology and Bread Characteristics

3.7. Multivariate Analysis of Bread Characteristics

4. Discussion

4.1. Dough Rheological Properties

4.2. Bread Characteristics

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Melachouris, N. Critical aspects in development of whey protein concentrate. J. Dairy Sci. 1984, 67, 2693–2700. [Google Scholar] [CrossRef]

- Sherwin, C. Use of whey and whey products in baked goods. AIB Tech. Bull. 1995, 17, 1–6. [Google Scholar]

- IDF. World Dairy Situation 2018. Bulletin of the International Dairy Ferderation 494/2018; International Dairy Ferderation: Brussels, Belgium, 2018. [Google Scholar]

- Bylund, G. Dairy Processing Handbook; Tetra Pak Processing Systems: Lund, Sweden, 2003. [Google Scholar]

- Paul, S.; Kulkarni, S.; Rao, K.J. Effect of indian cottage cheese (paneer) -whey on rheological and proofing characteristics of multigrain bread dough. J. Texture Stud. 2016, 47, 142–151. [Google Scholar] [CrossRef]

- Segal, R. Nutrition Principles; Academica: Galati, Romania, 2002. [Google Scholar]

- Gobbetti, M.; Minervini, F.; Rizzello, C.G. Bioactive Peptides in Dairy Products. In Handbook of Food Products Manufacturing; Hui, Y.H., Ed.; John Wiley & Sons: Oxford, UK, 2007; pp. 489–517. [Google Scholar]

- Smith, A.K.; Campbell, B.E. Microstructure of Milk Components. In Structure of Dairy Products; Tamine, A.Y., Ed.; Blackwell: Oxford, UK, 2007; pp. 59–71. [Google Scholar]

- US Department of Agriculture, Agricultural Research Service. USDA National Nutrient Database for Standard Reference, Release 24. Nutrient Data Laboratory Home Page. Available online: Fdc.nal.usda.gov (accessed on 5 May 2020).

- Moughan, P.J. Milk proteins: A rich source of bioactives for developing functional foods. In Milk Proteins; Boland, M., Singh, H., Eds.; Academic Press: Cambridge, UK, 2020; pp. 633–649. [Google Scholar]

- Kumar, R.; Sangwan, R.B.; Mann, B. Separation and Application of Bioactive Whey Proteins. Technological Advances in the Utilization of Dairy By-Products, 22nd Short Course. 2008. Available online: http://www.dairyprocessingcaft.com/wp-content/uploads/2012/05/Byproducts-2008.pdf (accessed on 25 May 2020).

- Wronkowska, M.; Jadacka, M.; Soral-Śmietana, M.; Zander, L.; Dajnowiec, F.; Banaszczyk, P.; Jeliński, T.; Szmatowicz, B. Acid whey concentrated by ultrafiltration a tool for modeling bread properties. LWT-Food Sci. Technol. 2015, 61, 172–176. [Google Scholar] [CrossRef]

- Roginski, H.; Fuquay, J.W.; Fox, P.F.; Jelen, P. Whey processing, utilization and products. Encycl. Dairy Sci. 2003, 2739–2745. [Google Scholar]

- Zadow, J.G. Whey and whey powders. In Encyclopedia of Food Science Food Technologies and Nutrition; Macrae, R., Robinson, R.K., Sadler, M.J., Eds.; Academic Press: San Diego, CA, USA, 1993; pp. 4888–4895. [Google Scholar]

- Lappa, I.K.; Papadaki, A.; Kachrimanidou, V.; Terpou, A.; Koulougliotis, D.; Eriotou, E.; Kopsahelis, N. Cheese Whey Processing: Integrated Biorefinery Concepts and Emerging Food Applications. Foods 2019, 8, 347. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ceglińska, A.; Pluta, A.; Skrzypek, J.; Krawczyk, P. Study on the application of nanofi ltrated whey-derived mineral components in the production of bread. Zywnosc. Nauka. Technologia. Jakosc. 2007, 6, 234–241. [Google Scholar]

- Munaza, B.; Prasad, S.G.M.; Gayas, B. Whey protein concentrate enriched biscuits. Int. J. Sci. Res. Publ. 2012, 2, 1–4. [Google Scholar]

- Tanner, R.I.; Dai, S.C.; Qi, F. Bread dough rheology in biaxial and step-shear deformations. Rheol. Acta 2008, 47, 739–749. [Google Scholar] [CrossRef]

- Song, Y.; Zheng, Q. Dynamic rheological properties of wheat flour dough and proteins. Trends Food Sci. Tech. 2007, 18, 132–138. [Google Scholar] [CrossRef]

- Dobraszczyk, B.J.; Morgenstern, M.P. Rheology and the breadmaking process. J. Cereal Sci. 2003, 38, 229–245. [Google Scholar] [CrossRef]

- Wang, F.C.; Sun, X.S. Creep-recovery of wheat flour doughs and relationship to other physical dough tests and breadmaking performance. Cereal Chem. 2002, 79, 567–571. [Google Scholar] [CrossRef]

- Van Bockstaele, F.; De Leyn, I.; Eeckhout, M.; Dewettinck, K. Non-linear creep-recovery measurements as a tool for evaluating the viscoelastic properties of wheat flour dough. J. Food Eng. 2011, 107, 50–59. [Google Scholar] [CrossRef]

- Berland, S.; Launay, B. Shear softening and thixotropic properties of wheat flour doughs in dynamic testing at high shear strain. Rheola Acta 1995, 34, 622–625. [Google Scholar] [CrossRef]

- Mayorga, B.O.; Gómez, M. Dairy Ingredients. In Bakery Products Science and Technology; Zhou, W., Ed.; Wiley Blackwell: West Sussex, UK, 2014; p. 259. [Google Scholar]

- Kenny, S.; Wehrle, K.; Stanton, C.; Arendt, E.K. Incorporation of dairy ingredients into wheat bread: Effects on dough rheology and bread quality. Eur. Food Res. Technol. 2000, 210, 391–396. [Google Scholar] [CrossRef]

- Kenny, S.; Wehrle, K.; Auty, M.; Arendt, E.K. Influence of Sodium Caseinate and Whey Protein on Baking Properties and Rheology of Frozen Dough. Cereal Chem. 2001, 78, 458–463. [Google Scholar] [CrossRef]

- Mannie, E.; Asp, E.H. Dairy ingredients for bread baking. Cereal Food World 1999, 44, 143–146. [Google Scholar]

- Zhou, W. (Ed.) Bakery Products Science and Technology; Wiley Blackwell: West Sussex, UK, 2014. [Google Scholar]

- Dubois, D.K.; Dreese, P. Functionality of nonfat dry milk in bakery products. In Dairy Products for the Cereal Processing Industry; Vetter, J.L., Ed.; American Association of Cereal: St Paul, MN, USA, 1984; pp. 91–105. [Google Scholar]

- Volpe, T.; Zabik, M.E. Whey protein contributing to loaf volume depression. Cereal Chem. 1975, 52, 188–197. [Google Scholar]

- Ammar, A.S.; Salem, S.A.; Badr, F.H. Rheological properties of wheat flour dough as affected by addition of whey and soy proteins. Pak. J. Nutr. 2011, 10, 302–306. [Google Scholar] [CrossRef]

- El-Assar, M.; Bekheet, M.; Hassanein, A.; Mayada, M. Effect of replacement of water by acid whey at different levels on quality characteristics of flat bread (balady) and fino bread. Bull. Natl. Nutr. Inst. Arab Repub. Egypt. 2017, 50, 196–218. [Google Scholar] [CrossRef]

- Secchi, N.; Fadda, C.; Piccinini, M.; Pinna, I.; Piga, A.; Catzeddu, P.; Fois, S. The effects of ovine whey powders on durum wheat-based doughs. J. Food Qual. 2018, 2018, 1789892. [Google Scholar] [CrossRef] [Green Version]

- Ji, T.; Penning, B.; Baik, B.K. Pre-harvest sprouting resistance of soft winter wheat varieties and associated grain characteristics. J. Cereal Sci. 2018, 83, 110–115. [Google Scholar] [CrossRef]

- Codină, G.G.; Mironeasa, S.; Mironeasa, C.; Popa, C.N.; Tamba-Berehoiu, R. Wheat flour dough Alveograph characteristics predicted by Mixolab regression models. J. Sci. Food Agric. 2012, 92, 638–644. [Google Scholar] [CrossRef]

- Mironeasa, S.; Codină, G.G. Effect of Composite Flour Made from Tomato Seed and Wheat of 650 Type of a Strong Quality for Bread Making on Bread Quality and Alveograph Rheological Properties. Int. J. Food Eng. 2018, 4, 22–26. [Google Scholar] [CrossRef]

- Mironeasa, S.; Zaharia, D.; Codină, G.G.; Ropciuc, S.; Iuga, M. Effects of Grape Peels Addition on Mixing, Pasting and Fermentation Characteristics of Dough from 480 Wheat Flour Type. Bull. UASVM Food Sci. Technol. 2018, 75, 27–35. [Google Scholar] [CrossRef]

- Mironeasa, S.; Iuga, M.; Zaharia, D.; Mironeasa, C. Rheological Analysis of Wheat Flour Dough as Influenced by Grape Peels of Different Particle Sizes and Addition Levels. Food Bioprocess Technol. 2019, 12, 228–245. [Google Scholar] [CrossRef]

- Lupi, F.R.; Puoci, F.; Bruno, E.; Baldino, N.; Marino, R.; Gabriele, D. The effects of process conditions on rheological properties of functional citrus fibre suspensions. Food Bioprod. Process. 2020, 121, 54–64. [Google Scholar] [CrossRef]

- Steffe, J.F. Rheological Methods in Food Process Engineering; Freeman Press: East Lansing, Michigan, 1996. [Google Scholar]

- Barnes, H.A. A Handbook of Elementary Rheology; Institute of Non-Newtonian Fluid Mechanics Wales, University of Wales: Aberystwyth, Wales, 2000. [Google Scholar]

- Bordei, D. Quality Control in Bakery Industry; Academica Publisher: Galati, Romania, 2007. [Google Scholar]

- Pongjaruvat, W.; Methacanon, P.; Seetapan, N.; Fuongfuchat, A.; Gamonpilas, C. Influence of pregelatinised tapioca starch and transglutaminase on dough rheology and quality of gluten-free jasmine rice breads. Food Hydrocoll. 2014, 36, 143–150. [Google Scholar] [CrossRef]

- Archunan, G. Microbiology; Sarup and Sons: New Delhi, India, 2004. [Google Scholar]

- Sikora, M.; Kowalski, S.; Tomasik, P.; Sady, M. Rheological and sensory properties of dessert sauces thickened by starch—Xanthan gum combinations. J. Food Eng. 2007, 79, 1144–1151. [Google Scholar] [CrossRef]

- Moreira, R.; Chenlo, F.; Torres, M.D.; Prieto, D.M. Influence of the particle size on the rheological behaviour of chestnut flour doughs. J. Food Eng. 2010, 100, 270–277. [Google Scholar] [CrossRef]

- Chinachoti, P.; Vodovotz, Y. Bread Staling; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Asghar, A.; Anjum, F.M.; Allen, J.C.; Daubert, C.R.; Rasool, G. Effect of modified whey protein concentrates on empirical and fundamental dynamic mechanical properties of frozen dough. Food Hydrocoll. 2009, 23, 1687–1692. [Google Scholar] [CrossRef]

- Nunes, M.H.B.; Ryan, L.A.M.; Arendt, E.K. Effect of low lactose dairy powder addition on the properties of gluten-free batters and bread quality. Eur. Food Res. Technol. 2009, 229, 31–41. [Google Scholar] [CrossRef]

- Upadhyay, R.; Ghosal, D.; Mehra, A. Characterization of bread dough: Rheological properties and microstructure. J. Food Eng. 2012, 109, 104–113. [Google Scholar] [CrossRef]

- Lelievre, J.; Husbands, J. Effects of sodium caseinate on the rheological properties of starch pastes. Starch/Stärke 1989, 41, 236–238. [Google Scholar] [CrossRef]

- Albano, K.M.; Franco, C.M.; Telis, V.R. Rheological behavior of Peruvian carrot starch gels as affected by temperature and concentration. Food Hydrocoll. 2014, 40, 30–43. [Google Scholar] [CrossRef]

- Mohammed, I.; Ahmed, A.R.; Senge, B. Dynamic rheological properties of chickpea and wheat flour dough’s. J. Appl. Sci. 2011, 11, 3405–3412. [Google Scholar] [CrossRef]

- Nammakuna, N.; Barringer, S.A.; Ratanatriwong, P. The effects of protein isolates and hydrocolloids complexes on dough rheology, physicochemical properties and qualities of gluten-free crackers. Food Sci. Nutr. 2016, 4, 143–155. [Google Scholar] [CrossRef]

- Weipert, D. The benefits of basic rheometry in studying dough rheology. Cereal Chem. 1990, 67, 311–317. [Google Scholar]

- Mirsaeedghazi, H.; Emam-Djomeh, Z.; Mousavi Ali, S.M. Rheometric Measurement of Dough Rheological Characteristics and Factors Affecting It. Int. J. Agric. Biol. 2008, 10, 112–119. [Google Scholar]

- Kumar, L.; Brennan, M.; Zheng, H.; Brennan, C. The effects of dairy ingredients on the pasting, textural, rheological, freeze-thaw properties and swelling behaviour of oat starch. Food Chem. 2018, 245, 518–524. [Google Scholar] [CrossRef]

- Considine, T.; Noisuwan, A.; Hemar, Y.; Wilkinson, B.; Bronlund, J.; Kasapis, S. Food Hydrocolloids Rheological investigations of the interactions between starch and milk proteins in model dairy systems: A review. Food Hydrocoll. 2017, 25, 2008–2017. [Google Scholar] [CrossRef]

- Tarancón, P.; Hernández, M.J.; Salvador, A.; Sanz, T. Relevance of creep and oscillatory tests for understanding how cellulose emulsions function as fat replacers in biscuits. LWT Food Sci. Technol. 2015, 62, 640–646. [Google Scholar] [CrossRef]

- Laguna, L.; Hernández, M.J.; Salvador, A.; Sanz, T. Study on Resistant Starch Functionality in Short Dough Biscuits by Oscillatory and Creep and Recovery Tests. Food Bioprocess Technol. 2013, 6, 1312–1320. [Google Scholar] [CrossRef]

- Chompoorat, P.; Ambardekar, A.; Mulvaney, S.; Rayas-Duarte, P. Rheological characteristics of gluten after modified by DATEM, ascorbic acid, urea and DTT using creep-recovery test. Int. J. Mod. 2013, 4, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Villanueva, M.; Pérez-quirce, S.; Collar, C.; Ronda, F. Impact of acidification and protein fortification on rheological and thermal properties of wheat, corn, potato and tapioca starch-based gluten-free bread doughs. LWT Food Sci. Technol. 2018, 96, 446–454. [Google Scholar] [CrossRef] [Green Version]

- Stathopoulos, C.; O’Kennedy, B. A rheological evaluation of concentrated casein systems as replacement for gluten: Calcium effects. Int. J. Dairy Technol. 2008, 61, 397–402. [Google Scholar] [CrossRef]

- Ronda, F.; Pérez-Quirce, S.; Angioloni, A.; Collar, C. Impact of viscous dietary fibres on the viscoelastic behaviour of gluten-free formulated rice doughs: A fundamental and empirical rheological approach. Food Hydrocoll. 2013, 32, 252–262. [Google Scholar] [CrossRef]

- Mastromatteo, M.; Guida, M.; Danza, A.; Laverse, J.; Frisullo, P.; Lampignano, V.; Del Nobile, M.A. Rheological, microstructural and sensorial properties of durum wheat bread as affected by dough water content. Food Res. Int. 2013, 51, 458–466. [Google Scholar] [CrossRef]

- Weegels, P.L.; Orsel, R.; van de Pijpekamp, A.M.; Lichtendonk, W.J.; Hamer, R.J.; Schofield, J.D. Fundamental properties of low Mr wheat proteins. II. Effects on dough properties. J. Cereal Sci. 1995, 21, 117–126. [Google Scholar] [CrossRef]

- Bloksma, A.J.; Bushuk, W. Rheology and chemistry of dough. In Wheat Chemistry and Technology; Pomeranz, Y., Ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 1988; Volume 2, pp. 131–200. [Google Scholar]

- Ronda, F.; Villanueva, M.; Collar, C. Influence of acidification on dough viscoelasticity of gluten-free rice starch-based dough matrices enriched with exogenous protein. LWT Food Sci. Technol. 2014, 59, 12–20. [Google Scholar] [CrossRef] [Green Version]

- Lazaridou, A.; Duta, D.; Papageorgiou, M.; Belc, N.; Biliaderis, C.G. Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J. Food Eng. 2007, 79, 1033–1047. [Google Scholar] [CrossRef]

- Iuga, M.; Mironeasa, C.; Mironeasa, S. Oscillatory Rheology and Creep-Recovery Behaviour of Grape Seed-Wheat Flour Dough: Effect of Grape Seed Particle Size, Variety and Addition Level. Bull. UASVM Food Sci. Technol. 2019, 76, 40–51. [Google Scholar] [CrossRef] [Green Version]

- Angioloni, A.; Dalla Rosa, M. Dough thermo-mechanical properties: Influence of sodium chloride, mixing time and equipment. J. Cereal Sci. 2005, 41, 327–331. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, J.; Tang, X. Effects of whey and soy protein addition on bread rheological property of wheat flour. J. Texture Stud. 2018, 49, 38–46. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Singh, N. Relationship of polymeric proteins and empirical dough rheology with dynamic rheology of dough and gluten from different wheat varieties. Food Hydrocoll. 2013, 33, 342–348. [Google Scholar] [CrossRef]

- He, H.; Hoseney, R.C. Differences in gas retention, protein solubility and rheological properties between flours of different baking quality. Cereal Chem. 1991, 68, 526–530. [Google Scholar]

- Rojas, J.A.; Rosell, C.M.; Benedito de Barber, C. Pasting properties of different wheat flour-hydrocolloid systems. Food Hydrocoll. 1999, 13, 27–33. [Google Scholar] [CrossRef]

- Tang, X.; Liu, J. A Comparative Study of Partial Replacement of Wheat Flour with Whey and Soy Protein on Rheological Properties of Dough and Cookie Quality. J. Food Qual. 2017, 2017, 2618020. [Google Scholar] [CrossRef]

- Ling, H.L. Effect of Heat Denaturation of Whey Proteins on the Rheological Properties of Cornstarch-Milk Systems. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 1983. [Google Scholar]

- Fessas, D.; Schiraldi, A. Water properties in wheat flour dough I: Classical thermogravimetry approach. Food Chem. 2001, 72, 237–244. [Google Scholar] [CrossRef]

- Erdogdu-Arnoczky, N.; Czuchajowska, Z.; Pomeranz, Y. Functionality of Whey and Casein in Fermentation and in Breadbaking by Fixed and Optimized Procedures. Cereal Chem. 1996, 73, 309–316. [Google Scholar]

- Sroan, B.; MacRitchie, F. Mechanism of gas cell stabilization in breadmaking. II. The secondary liquid lamellae. J. Cereal Sci. 2009, 49, 41–46. [Google Scholar] [CrossRef]

- Pareyt, B.; Finnie, S.M.; Putseys, J.A.; Delcour, J.A. Lipids in bread making: Sources, interactions, and impact on bread quality. J. Cereal Sci. 2011, 54, 266–279. [Google Scholar] [CrossRef]

- Schofield, R.K.; Scott Blair, G.W. The relationship between viscosity, elasticity and plastic strength of soft materials as illustrated by some mechanical properties of flour doughs. I. Proc. R. Soc. Lond. 1932, A138, 707–719. [Google Scholar]

- Walstra, P.; Geurts, T.J.; Noormen, A.; Jellema, A.; Van Boekel, M.A.J. Dairy Technology—Principles of Milk Properties and Processes; Marcel Dekker Inc.: New York, NY, USA, 1999. [Google Scholar]

- Codină, G.G.; Zaharia, D.; Stroe, S. Influence of calcium ions addition from gluconate and lactate salts on refined wheat flour dough rheological properties. CyTA J. Food 2018, 16, 884–891. [Google Scholar] [CrossRef]

- Scanlon, M.G.; Zghal, M.C. Bread properties and crumb structure. Food Res. Int. 2001, 34, 841–864. [Google Scholar] [CrossRef]

- Zghal, M.C.; Scanlon, M.G.; Sapirstein, H.D. Cellular Structure of Bread Crumb and its Influence on Mechanical Properties. J. Cereal Sci. 2002, 36, 167–176. [Google Scholar] [CrossRef]

- Demirkesen, I.; Mert, B.; Sumnu, G.; Sahin, S. Rheological properties of gluten-free bread formulations. J. Food Eng. 2010, 96, 295–303. [Google Scholar] [CrossRef]

- Liu, Z.; Scanlon, M.G. Predicting Mechanical Properties of Bread Crumb. Food Bioprod. Process. 2003, 81, 224–238. [Google Scholar] [CrossRef]

- Esteller, M.S.; Zancanaro, O.J.; Santos Palmeire, C.N.; da Silva Lannes, S.C. The effect of kefir addition on microstructure parameters and physical properties of porous white bread. Eur. Food Res. Technol. 2006, 222, 26–31. [Google Scholar] [CrossRef]

- Marklinder, I.; Haglund, Å.; Johansson, L. Influences of lactic acid bacteria on technological, nutritional, and sensory properties of barley sour dough bread. Food Qual. Pref. 1996, 7, 285–292. [Google Scholar] [CrossRef]

- Jekle, M.; Becker, T. Wheat dough microstructure: The relation between visual structure and mechanical behavior. Crit. Rev. Food Sci. Nutr. 2015, 55, 369–382. [Google Scholar] [CrossRef] [PubMed]

- Gaber, A.; Abd-El Satar, A.; Abdeen, I. Utilization of Ras Cheese Sweet Whey, Acidic Cheese Whey and Permeate to Improve of Baladi Bread Properties. J. Food Dairy Sci. 2017, 8, 449–453. [Google Scholar] [CrossRef]

- Kakan, A.; Changade, S.; Chopde, S. Effect of incorporation of Paneer whey on dough characteristics and organoleptic attributes of milk bread. Asian J. Dairy Food Res. 2016, 35, 143–148. [Google Scholar] [CrossRef]

| Sample | ||||||

|---|---|---|---|---|---|---|

| K′ (Pa·sn′) | n′ | K″ (Pa·sn″) | n″ | K* (Pa·sn″) | n* | |

| C | 67,170.67 ± 59.980 bw | 0.168 ± 0.002 ax | 18,873.054 ± 100.052 aw | 0.251 ± 0.020 ax | 69,705.540 ± 24.000 bw | 0.176 ± 0.009 ax |

| M1 | 60,297.61 ± 100.014 a | 0.197 ± 0.006 b | 18,996.005 ± 60.005 a | 0.266 ± 0.004 a | 63,073.670 ± 20.015 a | 0.206 ± 0.011 b |

| M2 | 81,740.20 ± 70.710 d | 0.209 ± 0.007 b | 28,679.779 ± 20.024 c | 0.262 ± 0.002 a | 86,570.750 ± 100.100 d | 0.216 ± 0.009 b |

| M3 | 72,493.27 ± 79.980 c | 0.206 ± 0.003 b | 25,774.818 ± 99.900 b | 0.255 ± 0.003 a | 76,866.193 ± 30.102 c | 0.213 ± 0.003 b |

| One-way ANOVA p values | ||||||

| p < 0.001 | p < 0.001 | p < 0.001 | ns | p < 0.001 | p < 0.001 | |

| W1 | 48,054.22 ± 29.793 z | 0.216 ± 0.005 y | 18,251.391 ± 39.918 z | 0.256 ± 0.001 x | 51,381.573 ± 9.239 z | 0.222 ± 0.019 y |

| W2 | 39,534.26 ± 50.029 x | 0.218 ± 0.000 y | 14,928.972 ± 70.016 x | 0.247 ± 0.003 x | 42,250.319 ± 100.170 x | 0.223 ± 0.009 y |

| W3 | 42,774.78 ± 100.129 y | 0.232 ± 0.001 z | 16,458.544 ± 159.740 y | 0.268 ± 0.006 x | 45,813.940 ± 98.494 y | 0.237 ± 0.003 y |

| One-way ANOVA p values | ||||||

| p < 0.001 | p < 0.001 | p < 0.001 | ns | p < 0.001 | ns | |

| Sample | Creep Phase | Recovery Phase | Temperature Sweep | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| JCo·105 (Pa−1) | JCm·105 (Pa−1) | λC (s) | μCo·10−6 (Pa s) | Jmax·105 (Pa−1) | JRo·105 (Pa−1) | JRm·105 (Pa−1) | λR (s) | Jr·105 (Pa−1) | Jr/Jmax (%) | Tmax (°C) | |

| C | 4.21 ± 0.03 cy | 10.01 ± 0.01 cx | 30.77 ± 0.07 ax | 1.03 ± 0.02 bz | 14.96 ± 0.16 by | 2.85 ± 0.02 bx | 6.70 ± 0.04 dz | 49.26 ± 0.02 cw | 9.55 ± 0.06 cy | 63.84 ± 0.28 ax | 84.70 ax |

| M1 | 5.17 ± 0.02 d | 10.00 ± 0.01 c | 32.57 ± 0.09 c | 0.88 ± 0.01 a | 17.63 ± 0.30 c | 5.86 ± 0.06 d | 6.10 ± 0.02 c | 40.48 ± 0.04 b | 11.96 ± 0.07 d | 67.84 ± 0.70 a | 87.70 b |

| M2 | 2.90 ± 0.06 b | 8.61 ± 0.02 b | 32.05 ± 0.03 b | 1.52 ± 0.01 c | 10.40 ± 0.09 a | 2.19 ± 0.07 a | 4.69 ± 0.06 b | 51.02 ± 0.07 d | 6.88 ± 0.13 b | 66.15 ± 4.51 a | 87.70 b |

| M3 | 2.51 ± 0.08 a | 8.10 ± 0.03 a | 33.67 ± 0.06 d | 1.51 ± 0.01 c | 9.45 ± 0.10 a | 3.19 ± 0.08 c | 3.40 ± 0.05 a | 34.48 ± 0.09 a | 6.59 ± 0.13 a | 69.74 ± 0.64 a | 87.70 b |

| One-way ANOVA p values | |||||||||||

| p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | ns | p < 0.001 | |

| W1 | 7.27 ± 0.02 w | 20.00 ± 0.02 y | 30.76 ± 0.06 x | 0.68 ± 0.02 x | 23.81 ± 0.09 w | 6.76 ± 0.03 y | 8.82 ± 0.02 w | 43.10 ± 0.05 y | 15.58 ± 0.05 w | 65.43 ± 0.04 y | 93.80 z |

| W2 | 4.80 ± 0.06 z | 20.01 ± 0.01 y | 37.03 ± 0.07 z | 0.75 ± 0.03 y | 18.39 ± 0.08 z | 8.66 ± 0.01 z | 4.94 ± 0.05 x | 28.08 ± 0.02 x | 13.60 ± 0.06 z | 73.95 ± 0.00 w | 90.80 y |

| W3 | 3.73 ± 0.05 x | 10.01 ± 0.01 x | 31.44 ± 0.05 y | 1.18 ± 0.01 w | 13.15 ± 0.06 x | 2.82 ± 0.02 x | 5.86 ± 0.04 y | 45.66 ± 0.07 z | 8.68 ± 0.06 x | 66.03 ± 0.12 z | 90.80 y |

| One-way ANOVA p values | |||||||||||

| p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | |

| Sample | Specific Volume (cm3/100 g) | Porosity (%) | Elasticity (%) |

|---|---|---|---|

| C | 356.41 ± 7.02 cz | 77.23 ± 0.13 cw | 90.63 ± 0.01 cx |

| M1 | 292.79 ± 5.63 b | 70.39 ± 0.10 a | 83.78 ± 0.03 a |

| M2 | 281.89 ± 3.31 ab | 71.76 ± 0.13 b | 94.12 ± 0.02 d |

| M3 | 273.77 ± 3.03 a | 70.31 ± 0.26 a | 88.57 ± 0.13 b |

| One-way ANOVA p values | |||

| p < 0.001 | p < 0.001 | p < 0.001 | |

| W1 | 333.73 ± 0.40 y | 73.30 ± 0.05 x | 96.97 ± 0.17 w |

| W2 | 306.87 ± 3.28 x | 73.70 ± 0.02 y | 94.30 ± 0.03 z |

| W3 | 326.6 ± 4.57 y | 75.79 ± 0.02 z | 91.43 ± 0.01 y |

| One-way ANOVA p values | |||

| p < 0.001 | p < 0.001 | p < 0.001 | |

| Sample | Firmness (N) | Cohesiveness (Adimensional) | Gumminess (N) | Chewiness (J) | Resilience (Adimensional) |

|---|---|---|---|---|---|

| C | 5.26 ± 0.45 ax | 0.73 ± 0.03 ay | 3.86 ± 0.47 ax | 3.86 ± 0.46 ax | 1.36 ± 0.14 ay |

| M1 | 7.93 ± 0.53 b | 0.80 ± 0.01 b | 6.38 ± 0.49 b | 6.37 ± 0.49 b | 1.89 ± 0.21 b |

| M2 | 11.07 ± 1.85 c | 0.74 ± 0.04 a | 8.19 ± 1.25 c | 8.19 ± 1.25 c | 1.53 ± 0.16 ab |

| M3 | 9.79 ± 0.59 bc | 0.77 ± 0.02 ab | 7.57 ± 0.29 bc | 7.56 ± 0.29 bc | 1.71 ± 0.22 ab |

| One-way ANOVA p values | |||||

| p < 0.001 | p < 0.05 | p < 0.001 | p < 0.001 | p < 0.05 | |

| W1 | 10.16 ± 1.28 y | 0.71 ± 0.07 y | 7.15 ± 0.44 y | 7.16 ± 0.43 y | 1.42 ± 0.31 y |

| W2 | 11.75 ± 2.95 y | 0.66 ± 0.02 y | 7.67 ± 1.82 y | 7.67 ± 1.82 y | 1.41 ± 0.06 y |

| W3 | 10.92 ± 1.34 y | 0.55 ± 0.04 x | 5.97 ± 0.54 y | 6.04 ± 0.66 y | 0.88 ± 0.13 x |

| One-way ANOVA p values | |||||

| p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.05 | |

| Sample | Pores Density (1/cm2) | Mean Cell Size (mm2) | Pore Circularity (Adimensional) | Cell Area Fraction (%) |

|---|---|---|---|---|

| C | 30.04 ± 1.77 by | 0.30 ± 0.05 abx | 0.26 ± 0.05 ax | 27.12 ± 2.02 ax |

| M1 | 20.42 ± 1.55 a | 0.20 ± 0.02 a | 0.17 ± 0.03 a | 30.46 ± 1.77 a |

| M2 | 35.60 ± 3.87 b | 0.35 ± 0.04 b | 0.16 ± 0.05 a | 38.21 ± 7.80 a |

| M3 | 32.35 ± 1.03 b | 0.32 ± 0.07 ab | 0.20 ± 0.06 a | 35.21 ± 4.54 a |

| One-way ANOVA p values | ||||

| p < 0.001 | p < 0.05 | ns | ns | |

| W1 | 30.00 ± 4.07 y | 0.30 ± 0.11 x | 0.19 ± 0.06 x | 35.13 ± 5.01 x |

| W2 | 19.06 ± 1.07 x | 0.19 ± 0.05 x | 0.29 ± 0.07 x | 28.75 ± 3.23 x |

| W3 | 21.45 ± 0.91 x | 0.22 ± 0.02 x | 0.19 ± 0.03 x | 30.42 ± 3.99 x |

| One-way ANOVA p values | ||||

| p < 0.001 | ns | ns | ns | |

| Volume | Firmness | K′ | n′ | K″ | n″ | K* | n* | JCo | JCm | λC | μCo | Jmax | JRo | JRm | λR | Jr | Jr/Jmax | Pores Density | Tmax | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Volume | 1.00 | ns | ns | ns | −0.63 ** | ns | −0.45 * | ns | 0.50 * | ns | −0.46 * | −0.54 * | 0.50 * | ns | 0.74 ** | ns | ns | −0.49 * | ns | ns |

| Firmness | 1.00 | ns | 0.75 ** | ns | ns | ns | 0.61 ** | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | 0.64 ** | |

| K′ | 1.00 | −0.52 * | 0.91 ** | ns | 0.99 ** | −0.46 * | −0.58 ** | −0.71 ** | ns | 0.74 ** | −0.64 ** | −0.68 ** | ns | 0.46 * | −0.70 ** | ns | 0.75 ** | −0.71 ** | ||

| n′ | 1.00 | ns | ns | −0.48 * | 0.91 ** | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | 0.81 ** | |||

| K″ | 1.00 | ns | 0.93 ** | ns | −0.60 ** | −0.61 ** | ns | 0.83 ** | −0.67 ** | −0.62 ** | −0.50 * | ns | −0.70 ** | ns | 0.79 ** | −0.42 * | ||||

| n″ | 1.00 | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | −0.10 | ns | |||||

| K* | 1.00 | ns | −0.59 ** | −0.71 ** | ns | 0.76 ** | −0.65 ** | −0.68 ** | ns | 0.45 * | −0.70 ** | ns | 0.76 ** | −0.69 ** | ||||||

| n* | 1.00 | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | 0.72 ** | |||||||

| JCo | 1.00 | 0.77 ** | ns | −0.90 ** | 0.99 ** | 0.70 ** | 0.88 ** | ns | 0.95 ** | ns | ns | 0.56 ** | ||||||||

| JCm | 1.00 | ns | −0.81 ** | 0.84 ** | 0.87 ** | 0.52 * | −0.47 * | 0.89 ** | ns | ns | 0.71 ** | |||||||||

| λC | 1.00 | ns | ns | 0.58 ** | −0.57 ** | −0.87 ** | ns | 0.89 ** | ns | ns | ||||||||||

| μCo | 1.00 | −0.95 ** | −0.83 ** | −0.72 ** | ns | −0.96 ** | ns | 0.56 ** | −0.46 ** | |||||||||||

| Jmax | 1.00 | 0.78 ** | 0.83 ** | ns | 0.98 ** | ns | ns | 0.57 ** | ||||||||||||

| JRo | 1.00 | ns | −0.71 ** | 0.88 ** | 0.55 ** | −0.57 ** | 0.56 ** | |||||||||||||

| JRm | 1.00 | ns | 0.72 ** | −0.51 * | ns | ns | ||||||||||||||

| λR | 1.00 | ns | −0.83 ** | 0.48 * | ns | |||||||||||||||

| Jr | 1.00 | ns | −0.46 * | 0.60 ** | ||||||||||||||||

| Jr/Jmax | 1.00 | ns | ns | |||||||||||||||||

| Pores density | 1.00 | ns | ||||||||||||||||||

| Tmax | 1.00 | |||||||||||||||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iuga, M.; Boestean, O.; Ghendov-Mosanu, A.; Mironeasa, S. Impact of Dairy Ingredients on Wheat Flour Dough Rheology and Bread Properties. Foods 2020, 9, 828. https://0-doi-org.brum.beds.ac.uk/10.3390/foods9060828

Iuga M, Boestean O, Ghendov-Mosanu A, Mironeasa S. Impact of Dairy Ingredients on Wheat Flour Dough Rheology and Bread Properties. Foods. 2020; 9(6):828. https://0-doi-org.brum.beds.ac.uk/10.3390/foods9060828

Chicago/Turabian StyleIuga, Mădălina, Olga Boestean, Aliona Ghendov-Mosanu, and Silvia Mironeasa. 2020. "Impact of Dairy Ingredients on Wheat Flour Dough Rheology and Bread Properties" Foods 9, no. 6: 828. https://0-doi-org.brum.beds.ac.uk/10.3390/foods9060828