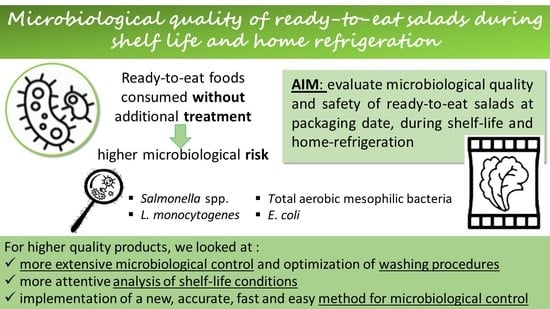

Microbiological Quality of Ready-to-Eat Leafy Green Salads during Shelf-Life and Home-Refrigeration

Abstract

:1. Introduction

2. Materials and Methods

2.1. Evaluation of RTES Microbiological Quality and Safety during Shelf-Life

- N = number of colonies per ml or gram of sample.

- ∑C = sum of all of the colonies in all plates counted.

- n1 = number of plates in the lower dilution counted.

- n2 = number of plates in the next higher dilution counted.

- d = dilution factor corresponding to the first dilution retained.

- N = number of colonies per ml or gram of sample.

- ∑a = sum of the CFU counted on all the dishes retained from two successive dilutions, at least one of which contains a minimum 15 blue CFU.

- n1 = number of plates in the lower dilution counted.

- n2 = number of plates in the next higher dilution counted.

- d = dilution factor corresponding to the first dilution retained.

2.2. Evaluation of RTES Microbiological Quality Simulating Home-Refrigeration after Package Opening

3. Results

3.1. Evaluation of RTES Microbiological Quality and Safety during Shelf-Life

3.2. Evaluation of RTES Microbiological Quality Simulating Home-Refrigeration after Package Opening

3.3. Accuracy of the MBS Method

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Betts, R. Microbial update: Fruit and salad. Int. Food Hyg. 2014, 25, 9–12. [Google Scholar]

- Little, C.L.; Gillespie, I.A. Prepared salads and public health. J. Appl. Microbiol. 2008, 105, 1729–1743. [Google Scholar] [CrossRef]

- Pilone, V.; Stasi, A.; Baselice, A. Quality preferences and pricing of fresh-cut salads in Italy: New evidence from market data. Brit. Food J. 2017, 119, 1473–1486. [Google Scholar] [CrossRef]

- Losio, M.N.; Pavoni, E.; Bilei, S.; Bertasi, B.; Bovec, D.; Capuano, F.; Farneti, S.; Blasi, G.; Comin, D.; Cardamone, C.; et al. Microbiological survey of raw and ready-to-eat leafy green vegetables marketed in Italy. Int. J. Food Microb. 2015, 2010, 88–91. [Google Scholar] [CrossRef] [PubMed]

- Olaimat, A.N.; Holley, R.A. Factors influencing the microbial safety of fresh produce: A review. Food Microb. 2012, 32, 1–19. [Google Scholar] [CrossRef] [PubMed]

- de Oliveira, M.A.; de Souza, V.M.; Morato Bergamini, A.M.; Pereira De Martinis, E.C. Microbiological quality of ready-to-eat minimally processed vegetables consumed in Brazil. Food Control 2011, 22, 1400–1403. [Google Scholar] [CrossRef]

- Abadias, M.; Usall, J.; Anguera, M.; Solsona, C.; Viñas, I. Microbiological quality of fresh, minimally-processed fruit and vegetables, and sprouts from retail establishments. Int. J. Food Microbiol. 2008, 123, 121–129. [Google Scholar] [CrossRef] [PubMed]

- Pinela, J.; Barreira, J.C.M.; Barros, L.; Antonio, A.L.; Carvalho, A.M.; Oliveira, M.B.P.P.; Ferreira, I.C.F.R. Postharvest quality changes in fresh-cut watercress stored under conventional and inert gas-enriched modified atmosphere packaging. Postharvest Biol. Technol. 2016, 112, 55–63. [Google Scholar] [CrossRef] [Green Version]

- Brandao, M.L.L.; Almeida, D.O.; Bispo, F.C.P.; Bricio, S.M.L.; Marin, V.A.; Miagostovich, M.P. Assessment of Microbiological Contamination of Fresh, Minimally Processed, and Ready-to-Eat Lettuces (Lactuca sativa), Rio de Janeiro State, Brazil. J. Food Sci. 2014, 79, M961–M966. [Google Scholar] [CrossRef]

- Oliveira, M.; Usall, J.; Solsona, C.; Alegre, I.; Vinas, I.; Abadias, M. Effects of packaging type and storage temperature on the growth of foodborne pathogens on shredded “Romaine” lettuce. Food Microbiol. 2010, 27, 375–380. [Google Scholar] [CrossRef]

- Erickson, M.C. Internalization of Fresh Produce by Foodborne Pathogens. Ann. Rev. Food Sci. Technol. 2012, 3, 283–310. [Google Scholar] [CrossRef] [PubMed]

- Meyer, K.M.; Leveau, J.H.J. Microbiology of the phyllosphere: A playground for testing ecological concepts. Oecologia 2012, 168, 621–629. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Erickson, M.C.; Webb, C.C.; Diaz-Perez, J.C.; Phatak, S.C.; Silvoy, J.J.; Davey, L.; Payton, A.S.; Liao, J.; Ma, L.; Doyle, M.P. Surface and internalized Escherichia coli O157: H7 on field-grown spinach and lettuce treated with spray-contaminated irrigation water. J. Food Prot. 2010, 73, 1023–1029. [Google Scholar] [CrossRef] [PubMed]

- Jay, J.M.; Loessner, M.J.; Golden, D.A. Modern Food Microbiology, 7th ed.; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Klerks, M.M.; Franz, E.; Van Gent-Pelzer, M.; Zijlstra, C.; van Bruggen, A.H.C. Differential interaction of Salmonella enterica serovars with lettuce cultivars and plant-microbe factors influencing the colonization efficiency. ISME J. 2007, 1, 620–631. [Google Scholar] [CrossRef] [Green Version]

- Klerks, M.M.; Van Gent-Pelzer, M.; Franz, E.; Zijlstra, C.; Van Bruggen, A.H.C. Physiological and molecular responses of Lactuca sativa to colonization by Salmonella enterica serovar Dublin. AEM 2007, 73, 4905–4914. [Google Scholar] [CrossRef] [Green Version]

- Callejon, R.M.; Rodríguez-Naranjo, M.I.; Úbeda, C.; Hornedo-Ortega, R.; García-Parrilla, M.C.; Troncoso, A.M. Reported foodborne outbreaks due to fresh produce in the United States and european union: Trends and causes. Foodborne Pathog. Dis. 2015, 12, 32–38. [Google Scholar] [CrossRef]

- Castro-rosas, J.; Cerna-Cortés, J.F.; Méndez-Reyes, E.; Lopez-Hernandez, D.; Gómez-Aldapa, C.A.; Estrada-Garcia, T. Presence of faecal coliforms, Escherichia coli and diarrheagenic E. coli pathotypes in ready-to-eat salads, from an area where crops are irrigated with untreated sewage water. Int. J. Food Microbiol. 2012, 156, 176–180. [Google Scholar] [CrossRef]

- Taban, M.B.; Halkman, K. Do leafy green vegetables and their ready-to-eat [RTE] salads carry a risk of foodborne pathogens? Anaerobe 2011, 17, 286–287. [Google Scholar] [CrossRef]

- Long, S.M.; Adak, G.K.; O’Brien, S.J.; Gillespie, I.A. General outbreaks of infectious intestinal disease linked with salad vegetables and fruit, England and Wales, 1992–2000. Comm. Dis. Public Health 2002, 5, 101–105. [Google Scholar]

- Vestrheim, D.F.; Lange, H.; Nygård, K.; Borgen, K.; Wester, A.L.; Kvarme, M.L.; Vold, L. Are ready-to-eat salads ready to eat? An outbreak of Salmonella Coeln linked to imported, mixed, pre-washed and bagged salad, Norway, November 2013. Epidemiol. Infect. 2016, 144, 1756–1760. [Google Scholar] [CrossRef] [Green Version]

- Centers for Disease Control and Prevention (CDC). Multistate Outbreak of Listeriosis Linked to Packaged Salads Produced at Springfield, Ohio Dole Processing Facility (Final Update). 2016. Available online: https://www.cdc.gov/listeria/outbreaks/bagged-salads-01-16/index.html (accessed on 8 April 2019).

- Stephan, R.; Althaus, D.; Kiefer, S.; Lehner, A.; Hatz, C.; Schmutz, C.; Jost, M.; Gerber, N.; Baumgartner, A.; Hachler, H.; et al. Foodborne transmission of Listeria monocytogenes via ready-to-eat salad: A nationwide outbreak in Switzerland, 2013-2014. Food Control 2015, 57, 14–17. [Google Scholar] [CrossRef]

- Centers for Disease Control and Prevention (CDC). Multistate Outbreak of Shiga toxin-producing Escherichia coli O157: H7 Infections Linked to Ready-to-Eat Salads (Final Update). 2013. Available online: http://www.cdc.gov/ecoli/2013/O157H7-11-13/index.html?s_cid=cs_002 (accessed on 8 April 2019).

- Campos, J.; Mourão, J.; Pestana, N.; Peixe, L.; Novais, C.; Antunes, P. Microbiological quality of ready-to-eat salads: An underestimated vehicle of bacteria and clinically relevant antibiotic resistance genes. Int. J. Food Microbiol. 2013, 16, 464–470. [Google Scholar] [CrossRef] [PubMed]

- Taban, B.M.; Aykut, S.A.; Akkoc, N.; Akcelik, M. Characterization of antibiotic resistance in Salmonella enterica isolates determined from ready-to-eat (RTE) salad vegetables. Braz. J. Microbiol. 2013, 44, 385–391. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Food Safety Authority of Ireland (FSAI). Guidance Note No. 3: Guidelines for the Interpretation of Results of Microbiological Testing of Ready-to-Eat Foods Placed on the Market (Revision 2); Food Safety Authority of Ireland (FSAI): Dublin, Ireland, 2016. [Google Scholar]

- Food Standards Australia New Zealand (FSANZ). Microbiological Quality Guide for Ready-to-Eat Foods. A Guide to Interpreting Microbiological Results. 2001. Available online: https://www.foodstandards.gov.au/code/microbiollimits/Documents/Guidelines%20for%20Micro%20exam.pdf (accessed on 6 October 2020).

- Santos, M.I.; Correira, C.; Cunha, M.I.C.; Saraiva, M.M.; Novais, M.R. Valores Guia para avaliação da qualidade microbiológica de alimentos prontos a comer preparados em estabelecimentos de restauração. Rev. Ordem Farm. 2005, 64, 66–68. [Google Scholar]

- Calonico, C.; Delfino, V.; Pesavento, G.; Mundo, M.; Lo Nostro, A. Microbiological Quality of Ready-to-eat Salads from Processing Plant to the Consumers. J. Food Nutr. Res. 2019, 7, 427–434. [Google Scholar]

- Becker, B.; Stoll, D.; Schulz, P.; Kulling, S.; Huch, M. Microbial Contamination of Organically and Conventionally Produced Fresh Vegetable Salads and Herbs from Retail Markets in Southwest Germany. Foodborne Pathog. Dis. 2019, 16, 269–275. [Google Scholar] [CrossRef]

- Bencardino, D.; Vitali, L.A.; Petrelli, D. Microbiological evaluation of ready-to-eat iceberg lettuce during shelf-life and effectiveness of household washing methods. IJFS 2018, 7, 6913. [Google Scholar] [CrossRef] [Green Version]

- Mogren, L.; Windstam, S.; Boqvist, S.; Vågsholm, I.; Söderqvist, K.; Rosberg, A.K.; Lindén, J.; Mulaosmanovic, E.; Karlsson, M.; Uhlig, E.; et al. The Hurdle Approach–A Holistic Concept for Controlling Food Safety Risks Associated With Pathogenic Bacterial Contamination of Leafy Green Vegetables. Front. Microbiol. 2018, 9, 1965. [Google Scholar] [CrossRef]

- Fiedler, G.; Kabisch, J.; Bohnlein, C.; Huch, M.; Becker, B.; Cho, G.S.; Franz, C.M.A.P. Presence of Human Pathogens in Produce from Retail Markets in Northern Germany. Foodborne Pathog. Dis. 2017, 14, 502–509. [Google Scholar] [CrossRef]

- Ilyas, S.; Qamar, M.U.; Rasool, M.H.; Abdulhaq, N.; Nawaz, Z. Multidrug-resistant pathogens isolated from ready-to-eat salads available at a local market in Pakistan. Brit. Food J. 2016, 118, 2068–2075. [Google Scholar] [CrossRef]

- Jeddi, M.Z.; Yunesian, M.; Gorji, M.E.; Noori, N.; Pourmand, M.R.; Khaniki, G.R. Microbial evaluation of fresh, minimally-processed vegetables and bagged sprouts from chain supermarkets. J. Health Popul. Nutr. 2014, 32, 391–399. [Google Scholar] [PubMed]

- Allen, K.J.; Kovacevic, J.; Cancarevic, A.; Wood, J.; Xu, J.; Gill, B.; Allen, J.K.; Mesak, L.R. Microbiological survey of imported produce available at retail across Canada. Int. J. Food Microbiol. 2013, 162, 135–142. [Google Scholar] [CrossRef] [PubMed]

- Althaus, D.; Hofer, E.; Corti, S.; Julmi, A.; Stephan, R. Bacteriological survey of ready-to-eat lettuce, fresh-cut fruit, and sprouts collected from the Swiss market. J. Food Prot. 2012, 75, 1338–1341. [Google Scholar] [CrossRef] [PubMed]

- Marinelli, L.; Maggi, O.; Aurigemma, C.; Tufi, D.; De Giusti, M. Fresh vegetables and ready-to eat salad: Phenotypic characterization of moulds and molecular characterization of yeasts. Ann. Ig. Med. Prev. Comunità 2012, 24, 301–309. [Google Scholar]

- de Giusti, M.; Aurigemma, C.; Marinelli, L.; Tufi, D.; de Medici, D.; di Pasquale, S.I.; de Vito, C.; Boccia, A. The evaluation of the microbial safety of fresh ready-to-eat vegetables produced by different technologies in Italy. J. Appl. Microbiol. 2010, 109, 996–1006. [Google Scholar] [CrossRef]

- Arienzo, A.; Sobze, M.S.; Wadoum, R.E.G.; Losito, F.; Colizzi, V.; Antonini, G. Field Application of the Micro Biological Survey Method for a Simple and Effective Assessment of Microbiological Quality of Water Sources in Developing Countries. Int. J. Environ. Res. Public Health 2015, 12, 10314–10328. [Google Scholar] [CrossRef] [Green Version]

- Losito, F.; Arienzo, A.; Bottini, G.; Priolisi, F.R.; Mari, A.; Antonini, A. Microbiological Safety and Quality of Mozzarella Cheese Assessed by the Microbiological Survey Method. J. Dairy Sci. 2014, 97, 46–55. [Google Scholar] [CrossRef] [Green Version]

- Losito, F.; Bottini, G.; De Ascentis, A.; Priolisi, F.R.; Mari, A.; Tarsitani, G.; Antonini, G. Qualitative and Quantitative Validation of the Micro Biological Survey Method for Listeria spp., Salmonella spp., Enterobactericeae and Staphylococcus aureus in Food Samples. Am. J. Food Technol. 2012, 7, 340–351. [Google Scholar]

- Bottini, G.; Losito, F.; De Ascentis, A.; Priolisi, F.R.; Mari, A.; Antonini, G. Validation of the Micro Biological Survey Method for Total Viable Count and Escherichia coli in Food Samples. Am. J. Food Technol. 2011, 6, 951–962. [Google Scholar]

- Arienzo, A.; Losito, F.; Stalio, O.; Antonini, G. Comparison of Uncertainty between Traditional and Alternative Methods for Food Microbiological Analysis. Am. J. Food Technol. 2016, 11, 29–36. [Google Scholar]

) for low-cost (LC) and high-cost (HC) samples: (a) baby romaine lettuce (BRL); (b) rocket salad (RS); (c) lamb’s lettuce (LL) samples (SD < 10%) evaluated using the plate count method * Significant difference (p < 0.05).

) for low-cost (LC) and high-cost (HC) samples: (a) baby romaine lettuce (BRL); (b) rocket salad (RS); (c) lamb’s lettuce (LL) samples (SD < 10%) evaluated using the plate count method * Significant difference (p < 0.05).

) for low-cost (LC) and high-cost (HC) samples: (a) baby romaine lettuce (BRL); (b) rocket salad (RS); (c) lamb’s lettuce (LL) samples (SD < 10%) evaluated using the plate count method * Significant difference (p < 0.05).

) for low-cost (LC) and high-cost (HC) samples: (a) baby romaine lettuce (BRL); (b) rocket salad (RS); (c) lamb’s lettuce (LL) samples (SD < 10%) evaluated using the plate count method * Significant difference (p < 0.05).

| Indicators | Contamination Levels (CFU/g) | ||

|---|---|---|---|

| Satisfactory | Acceptable | Not Acceptable | |

| TAMC | ≤104 | >104 ≤ 106 | >106 |

| E. coli | ≤10 | >10 ≤ 102 | >102 |

| Salmonella spp. | L. monocytogenes | |

|---|---|---|

| Compliant | 12 | 36 |

| Non-compliant | 24 | 0 |

| Total | 36 | 36 |

| LC | MC | HC | |

|---|---|---|---|

| BRL | +11% | +18% | +29% |

| RS | +10% | +5% | +20% |

| Overall | +10.5% | +11.5 | +24.5% |

| LC | HC | |

|---|---|---|

| Baby romaine lettuce | +11% | +8% |

| Rocket salad | +9% | +3% |

| Lamb’s lettuce | +7% | +5% |

| Overall | +9% | +5.3% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arienzo, A.; Murgia, L.; Fraudentali, I.; Gallo, V.; Angelini, R.; Antonini, G. Microbiological Quality of Ready-to-Eat Leafy Green Salads during Shelf-Life and Home-Refrigeration. Foods 2020, 9, 1421. https://0-doi-org.brum.beds.ac.uk/10.3390/foods9101421

Arienzo A, Murgia L, Fraudentali I, Gallo V, Angelini R, Antonini G. Microbiological Quality of Ready-to-Eat Leafy Green Salads during Shelf-Life and Home-Refrigeration. Foods. 2020; 9(10):1421. https://0-doi-org.brum.beds.ac.uk/10.3390/foods9101421

Chicago/Turabian StyleArienzo, Alyexandra, Lorenza Murgia, Ilaria Fraudentali, Valentina Gallo, Riccardo Angelini, and Giovanni Antonini. 2020. "Microbiological Quality of Ready-to-Eat Leafy Green Salads during Shelf-Life and Home-Refrigeration" Foods 9, no. 10: 1421. https://0-doi-org.brum.beds.ac.uk/10.3390/foods9101421