Hydro-Thermo-Mechanical Analysis of an Existing Gravity Dam Undergoing Alkali–Silica Reaction

Abstract

:1. Introduction

2. Bi-Phase Damage Model

3. Model Validation

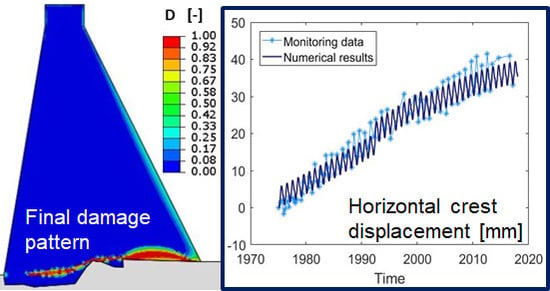

4. Results and Discussion. Structural Analysis of a Concrete Dam Affected by Alkali–Silica Reaction

4.1. Numerical Approach

4.2. Case Study: Gravity Dam in Canada

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ASR | Alkali–Silica Reaction |

References

- Stanton, T. Expansion of Concrete Through Reaction between Cement and Aggregate. Proc. Am. Soc. Civ. Eng. 1940, 66, 1781–1812. [Google Scholar]

- Sanjuán, M.Á.; Estévez, E.; Argiz, C. Alkali Ion Concentration Estimations in Cement Paste Pore Solutions. Appl. Sci. 2019, 9, 992. [Google Scholar] [CrossRef]

- Stanton, T. Studies of Use of Pozzolans for Counteracting Excessive Concrete Expansion Resulting from Reaction between Aggregates and the Alkalies in Cement. In Symposium on Use of Pozzolanic Materials in Mortars and Concretes; ASTM: West Conshohocken, PA, USA, 1950; p. 178. [Google Scholar]

- Thomas, M. The effect of supplementary cementing materials on alkali-silica reaction: A review. Cem. Concr. Res. 2011, 41, 1224–1231. [Google Scholar] [CrossRef]

- Sanjuán, M.A.; Argiz, C. Coal fly ash alkalis content characterization by means of a full factorial design. Mater. Lett. 2016, 164, 528–531. [Google Scholar] [CrossRef]

- Alnaggar, M.; Di Luzio, G.; Cusatis, G. Modeling Time-Dependent Behavior of Concrete Affected by Alkali Silica Reaction in Variable Environmental Conditions. Materials 2017, 10, 471. [Google Scholar] [CrossRef]

- Léger, P.; Coté, P.; Tinawi, R. Finite element analysis of concrete due to alkali-aggregate reactions. Comput. Struct. 1996, 60, 601–611. [Google Scholar] [CrossRef]

- Ingraffea, A. Case studies of simulation of fracture in concrete dams. Eng. Fract. Mech. 1990, 35, 553–564. [Google Scholar] [CrossRef]

- Józwiak-Niedzwiedzka, D.; Glinicki, M.A.; Gibas, K.; Baran, T. Alkali-Silica Reactivity of High Density Aggregates for Radiation Shielding Concrete. Materials 2018, 11, 2284. [Google Scholar] [CrossRef]

- Grymin, W.; Gawin, D.; Koniorczyk, M. Experimental and numerical investigation of the alkali-silica reaction in the cement-based materials. Arch. Civ. Mech. Eng. 2018, 18, 1698–1714. [Google Scholar] [CrossRef]

- Grymin, W.; Koniorczyk, M.; Pesavento, F. Macroscopic and mesoscopic approach to the alkali-silica reaction in concrete Macroscopic and Mesoscopic Approach to the Alkali-Silica Reaction in Concrete. AIP Conf. Proc. 1922. [Google Scholar] [CrossRef]

- Cuba Ramos, A. Multi-Scale Modeling of the Alkali-Silica Reaction in Concrete. Ph.D. Thesis, Ecole Polytechnique Federale de Lausanne, Lausanne, Switzerland, 2017. [Google Scholar]

- Esposito, R.; Hendriks, M.A.N. Literature review of modelling approaches for ASR in concrete: A new perspective. Eur. J. Environ. Civ. Eng. 2017, 8189, 1–21. [Google Scholar] [CrossRef]

- Fairbairn, E.M.R.; Ribeiro, F.L.B.; Lopes, L.E.; Toledo-filho, R.D.; Silvoso, M.M. Modelling the structural behaviour of a dam affected by alkali-silica reaction. Commun. Numer. Methods Eng. 2006, 22, 1–12. [Google Scholar] [CrossRef]

- Saouma, V.; Perotti, L.; Shimpo, T. Stress Analysis of Concrete Structures Subjected to Alkali-Aggregate Reactions. ACI Struct. J. 2007, 104, 532–541. [Google Scholar]

- Noret, C.; Molin, X.; Theme, A. Effect of concrete swelling on the equilibrium and displacements of an arch dam. In Proceedings of the XI ICOLD Benchmark Workshop on Numerical Analysis of Dams, Valencia, España, 20–21 October 2011. [Google Scholar]

- Carrazedo, R.; Sanches, R.A.K.; de Lacerda, L.A.; Divino, P.L. Concrete Expansion Induced by Alkali-Silica Reaction in a Small Arch Dam. Int. J. Civ. Eng. 2017. [Google Scholar] [CrossRef]

- Comi, C.; Kirchmayr, B.; Pignatelli, R. Two-phase damage modeling of concrete affected by alkali-silica reaction under variable temperature and humidity conditions. Int. J. Solids Struct. 2012, 49. [Google Scholar] [CrossRef]

- Gautam, B.P.; Panesar, D.K. A new method of applying long-term multiaxial stresses in concrete specimens undergoing ASR, and their triaxial expansions. Mater. Struct. Constr. 2016, 49, 3495–3508. [Google Scholar] [CrossRef]

- Ulm, F.J.; Coussy, O.; Kefei, L.; Larive, C. Thermo-chemo-mechanics of ASR expansion in concrete structures. J. Eng. Mech. 2000, 126, 233–242. [Google Scholar] [CrossRef]

- Multon, S.; Toutlemonde, F. Effect of moisture conditions and transfers on alkali silika reaction damaged structures. Cem. Concr. Res. 2010, 40, 924–934. [Google Scholar] [CrossRef]

- Mainguy, M.; Coussy, O.; Baroghel-Bouny, V. Role of air pressure in drying of weakly permeable materials. J. Eng. Mech. 2001, 127, 582–592. [Google Scholar] [CrossRef]

- Baroghel-bouny, V.; Mainguy, M.; Lassabatere, T.; Coussy, O. Characterization and identification of equilibrium and transfer moisture properties for ordinary and high-performance cementitious materials. Cem. Concr. Res. 1999, 29, 1225–1238. [Google Scholar] [CrossRef]

- Coussy, O. Poromechanics; John Wiley & Sons: New York, NY, USA, 2004. [Google Scholar]

- Comi, C.; Fedele, R.; Perego, U. A chemo-thermo-damage model for the analysis of concrete dams affected by alkali-silica reaction. Mech. Mater. 2009, 41, 210–230. [Google Scholar] [CrossRef]

- Comi, C.; Perego, U. Fracture energy based bi-dissipative damage model for concrete. Int. J. Solids Struct. 2001, 38, 6427–6454. [Google Scholar] [CrossRef]

- Multon, S.; Toutlemonde, F. Effect of applied stresses on alkali-silica reaction-induced expansions. Cem. Concr. Res. 2006, 36, 912–920. [Google Scholar] [CrossRef]

- Gautam, B.P.; Panesar, D.K.; Sheikh, S.A.; Vecchio, F.J. Multiaxial expansion-stress relationship for alkali silica reaction-affected concrete. ACI Mater. J. 2017, 114, 171–184. [Google Scholar] [CrossRef]

- Huang, M.; Pietruszczak, S. Modeling of thermomechanical effects of alkali-silica reaction. J. Eng. Mech. 1999, 125, 476–485. [Google Scholar] [CrossRef]

- Asadi, I.; Sha, P.; Fitri, Z.; Abu, B. Thermal conductivity of concrete—A review. J. Build. Eng. 2018, 20, 81–93. [Google Scholar] [CrossRef]

- Pomianowski, M.; Heiselberg, P.; Jensen, R.L.; Cheng, R.; Zhang, Y. A new experimental method to determine specific heat capacity of inhomogeneous concrete material with incorporated microencapsulated-PCM. Cem. Concr. Res. 2014, 55, 22–34. [Google Scholar] [CrossRef]

- Shin, J.H.; Struble, L.J.; Kirkpatrick, R.J. Microstructural Changes Due to Alkali-Silica Reaction during Standard Mortar Test. Materials 2015, 8, 8292–8303. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Parameter | Value | Unit |

|---|---|---|

| 26,000 | MPa | |

| 0.21 | - | |

| 2365 | kg/m | |

| 3 | MPa | |

| 1 | 1/C | |

| 30,000 | MPa | |

| 0.2 | - | |

| 1 | 1/C |

| Parameter | Value | Unit |

|---|---|---|

| 500 | days | |

| 1100 | days | |

| 350 | days | |

| 700 | days | |

| 0.01 | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colombo, M.; Comi, C. Hydro-Thermo-Mechanical Analysis of an Existing Gravity Dam Undergoing Alkali–Silica Reaction. Infrastructures 2019, 4, 55. https://0-doi-org.brum.beds.ac.uk/10.3390/infrastructures4030055

Colombo M, Comi C. Hydro-Thermo-Mechanical Analysis of an Existing Gravity Dam Undergoing Alkali–Silica Reaction. Infrastructures. 2019; 4(3):55. https://0-doi-org.brum.beds.ac.uk/10.3390/infrastructures4030055

Chicago/Turabian StyleColombo, Martina, and Claudia Comi. 2019. "Hydro-Thermo-Mechanical Analysis of an Existing Gravity Dam Undergoing Alkali–Silica Reaction" Infrastructures 4, no. 3: 55. https://0-doi-org.brum.beds.ac.uk/10.3390/infrastructures4030055