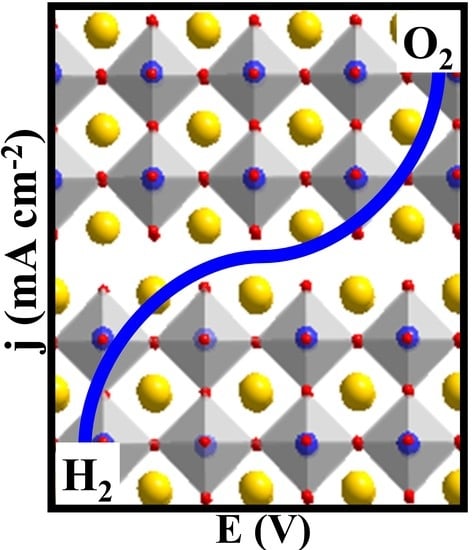

Isostructural Oxides Sr3Ti2−xMxO7−δ (M = Mn, Fe, Co; x = 0, 1) as Electrocatalysts for Water Splitting

Abstract

:1. Introduction

2. Results and Discussion

2.1. Crystal Structure and Oxygen Content

2.2. Electrical Conductivity

2.3. Electrocatalytic Properties for HER and OER

3. Materials and Methods

3.1. Synthesis

3.2. Characterization

3.3. Electrochemical OER/HER Measurements

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Karki, S.B.; Ramezanipour, F. Magnetic and electrical properties of BaSrMMoO6 (M = Mn, Fe, Co, and Ni). Mater. Today Chem. 2019, 13, 25–33. [Google Scholar] [CrossRef]

- Fanah, S.J.; Ramezanipour, F. Lithium-ion mobility in layered oxides Li2Ca1.5Nb3O10, Li2Ca1.5TaNb2O10 and Li2Ca1.5Ta2NbO10, enhanced by supercell formation. J. Energy Chem. 2021, 60, 75–84. [Google Scholar] [CrossRef]

- Fanah, S.J.; Yu, M.; Huq, A.; Ramezanipour, F. Insight into lithium-ion mobility in Li2La(TaTi)O7. J. Mater. Chem. A 2018, 6, 22152–22160. [Google Scholar] [CrossRef]

- Alom, M.S.; Ramezanipour, F. Layered Oxides SrLaFe1−xCoxO4-δ (x = 0 − 1) as Bifunctional Electrocatalysts for Water-Splitting. ChemCatChem 2021, 13, 3510–3516. [Google Scholar] [CrossRef]

- Fanah, S.J.; Yu, M.; Ramezanipour, F. Experimental and theoretical investigation of lithium-ion conductivity in Li2LaNbTiO7. Dalton Trans. 2019, 48, 17281–17290. [Google Scholar] [CrossRef] [PubMed]

- Fanah, S.J.; Ramezanipour, F. Strategies for Enhancing Lithium-Ion Conductivity of Triple-Layered Ruddlesden–Popper Oxides: Case Study of Li2−xLa2−yTi3−zNbzO10. Inorg. Chem. 2020, 59, 9718–9727. [Google Scholar] [CrossRef] [PubMed]

- Kananke-Gamage, C.C.W.; Ramezanipour, F. Variation of the electrocatalytic activity of isostructural oxides Sr2LaFeMnO7 and Sr2LaCoMnO7 for hydrogen and oxygen-evolution reactions. Dalton Trans. 2021, 50, 14196–14206. [Google Scholar] [CrossRef]

- Hona, R.K.; Huq, A.; Ramezanipour, F. Charge transport properties of Ca2FeGaO6−δ and CaSrFeGaO6−δ: The effect of defect-order. Mater. Chem. Phys. 2019, 238, 121924. [Google Scholar] [CrossRef]

- Hona, R.K.; Ramezanipour, F. Structure-dependence of electrical conductivity and electrocatalytic properties of Sr2Mn2O6 and CaSrMn2O6. J. Chem. Sci. 2019, 131, 109. [Google Scholar] [CrossRef]

- Alom, M.S.; Kananke-Gamage, C.C.W.; Ramezanipour, F. Perovskite Oxides as Electrocatalysts for Hydrogen Evolution Reaction. ACS Omega 2022, 7, 7444–7451. [Google Scholar] [CrossRef]

- Shafir, O.; Shopin, A.; Grinberg, I. Band-Gap Engineering of Mo- and W-Containing Perovskite Oxides Derived from Barium Titanate. Phys. Rev. Appl. 2020, 13, 034066. [Google Scholar] [CrossRef]

- Wang, Z.; Tan, S.; Xiong, Y.; Wei, J. Effect of B sites on the catalytic activities for perovskite oxides La.6Sr.4CoxFe1−xO3−δ as metal-air batteries catalysts. Prog. Nat. Sci. 2018, 28, 399–407. [Google Scholar] [CrossRef]

- Xu, X.; Pan, Y.; Zhong, Y.; Ran, R.; Shao, Z. Ruddlesden–Popper perovskites in electrocatalysis. Mater. Horiz. 2020, 7, 2519–2565. [Google Scholar] [CrossRef]

- Forslund, R.; Hardin, W.; Rong, X.; Abakumov, A.; Filimonov, D.; Alexander, C.; Mefford, J.; Iyer, H.; Kolpak, A.; Johnston, K.; et al. Exceptional electrocatalytic oxygen evolution via tunable charge transfer interactions in La0.5Sr1.5Ni1−xFexO4±δ Ruddlesden-Popper oxides. Nat. Commun. 2018, 9, 3150. [Google Scholar] [CrossRef] [PubMed]

- Yin, B.; Li, Y.; Sun, N.; Ji, X.; Huan, Y.; Dong, D.; Hu, X.; Wei, T. Activating ORR and OER in Ruddlesden-Popper based catalysts by enhancing interstitial oxygen and lattice oxygen redox reactions. Electrochim. Acta 2021, 370, 137747. [Google Scholar] [CrossRef]

- Reshak, A.H. Thermoelectric properties of Srn+1TinO3n+1 (n=1, 2, 3, ∞) Ruddlesden–Popper Homologous Series. Renew. Energy 2015, 76, 36–44. [Google Scholar] [CrossRef]

- Ge, W.; Zhu, C.; An, H.; Li, Z.; Tang, G.; Hou, D. Sol–gel synthesis and dielectric properties of Ruddlesden–Popper phase Srn+1TinO3n+1 (n = 1, 2, 3, ∞). Ceram. Int. 2014, 40, 1569–1574. [Google Scholar] [CrossRef]

- Navas, C.; Tuller, H.L.; Loye, H.-C.Z. Electrical conductivity and nonstoichiometry in doped Sr3Ti2O7. J. Eur. Ceram. Soc. 1999, 19, 737–740. [Google Scholar] [CrossRef]

- Nuansaeng, S.; Yashima, M.; Matsuka, M.; Ishihara, T. Mixed Conductivity, Nonstoichiometric Oxygen, and Oxygen Permeation Properties in Co-Doped Sr3Ti2O7−δ. Chem. Eur. J. 2011, 17, 11324–11331. [Google Scholar] [CrossRef]

- Sirikanda, N.; Matsumoto, H.; Ishihara, T. Effect of Co doping on oxygen permeation in Sr3Ti2O7 with Ruddlesden-Popper structure. Solid State Ion. 2011, 192, 599–601. [Google Scholar] [CrossRef]

- Chowki, S.; Sahu, B.; Singh, A.K.; Mohapatra, N. Dielectric response of double layered perovskite Sr3MnTiO7. AIP Conf Proc 2016, 1731, 090040. [Google Scholar]

- Sharma, I.B.; Singh, C.; Singh, D. Synthesis, structure, electric transport and magnetic properties of Sr3MnTiO7−δ. J. Alloys Compd. 2004, 375, 11–14. [Google Scholar] [CrossRef]

- Chowki, S.; Rayaprol, S.; Mukhopadhyay, A.; Mohapatra, N. Coexistence of spin glass type freezing and cooperative paramagnetic state in Sr3MnTiO7. Phys. Rev. B 2015, 92, 214416. [Google Scholar] [CrossRef]

- Ruddlesden, S.N.; Popper, P. The compound Sr3Ti2O7 and its structure. Acta Crystallogr. 1958, 11, 54–55. [Google Scholar] [CrossRef]

- Zvereva, I.; Pavlova, T.A.; Pantchuk, V.; Semenov, V.; Breard, Y.; Choisnet, J. The solid solution Sr3Ti2−xFexO7−δ (x 0.5): Characterization of Fe (III)–Fe (IV) mixed valences. Chim. Technol. Acta 2016, 3, 46–57. [Google Scholar] [CrossRef]

- Shannon, R.D. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallogr. Sect. A 1976, 32, 751–767. [Google Scholar] [CrossRef]

- Karki, S.B.; Ramezanipour, F. Pseudocapacitive Energy Storage and Electrocatalytic Hydrogen-Evolution Activity of Defect-Ordered Perovskites SrxCa3−xGaMn2O8 (x = 0 and 1). ACS Appl. Energy Mater. 2020, 3, 10983–10992. [Google Scholar] [CrossRef]

- Hona, R.K.; Huq, A.; Mulmi, S.; Ramezanipour, F. Transformation of Structure, Electrical Conductivity, and Magnetism in AA′Fe2O6−δ, A = Sr, Ca and A′ = Sr. Inorg. Chem. 2017, 56, 9716–9724. [Google Scholar] [CrossRef] [PubMed]

- Hona, R.K.; Karki, S.B.; Ramezanipour, F. Oxide Electrocatalysts Based on Earth-Abundant Metals for Both Hydrogen- and Oxygen-Evolution Reactions. ACS Sustain. Chem. Eng. 2020, 8, 11549–11557. [Google Scholar] [CrossRef]

- Hona, R.K.; Ramezanipour, F. Enhanced electrical properties in BaSrFe2O6−δ (δ = 0.5): A disordered defect-perovskite. Polyhedron 2019, 167, 69–74. [Google Scholar] [CrossRef]

- Karki, S.B.; Andriotis, A.N.; Menon, M.; Ramezanipour, F. Bifunctional Water-Splitting Electrocatalysis Achieved by Defect Order in LaA2Fe3O8 (A = Ca, Sr). ACS Appl. Energy Mater. 2021, 4, 12063–12066. [Google Scholar] [CrossRef]

- Feng, H.; Xu, Z.; Ren, L.; Liu, C.; Zhuang, J.; Hu, Z.; Xu, X.; Chen, J.; Wang, J.; Hao, W.; et al. Activating Titania for Efficient Electrocatalysis by Vacancy Engineering. ACS Catal. 2018, 8, 4288–4293. [Google Scholar] [CrossRef]

- Park, H.W.; Lee, D.U.; Park, M.G.; Ahmed, R.; Seo, M.H.; Nazar, L.F.; Chen, Z. Perovskite-nitrogen-doped carbon nanotube composite as bifunctional catalysts for rechargeable lithium-air batteries. ChemSusChem 2015, 8, 1058–1065. [Google Scholar] [CrossRef]

- Oh, M.Y.; Jeon, J.S.; Lee, J.J.; Kim, P.; Nahm, K.S. The bifunctional electrocatalytic activity of perovskite La0.6Sr0.4CoO3−δ for oxygen reduction and evolution reactions. RSC Adv. 2015, 5, 19190–19198. [Google Scholar] [CrossRef]

- Hona, R.K.; Ramezanipour, F. Effect of the Oxygen Vacancies and Structural Order on the Oxygen Evolution Activity: A Case Study of SrMnO3−δ Featuring Four Different Structure Types. Inorg. Chem. 2020, 59, 4685–4692. [Google Scholar] [CrossRef] [PubMed]

- Hona, R.K.; Karki, S.B.; Cao, T.; Mishra, R.; Sterbinsky, G.E.; Ramezanipour, F. Sustainable Oxide Electrocatalyst for Hydrogen- and Oxygen-Evolution Reactions. ACS Catal. 2021, 11, 14605–14614. [Google Scholar] [CrossRef]

- Hona, R.K.; Ramezanipour, F. Remarkable Oxygen-Evolution Activity of a Perovskite Oxide from the Ca2−xSrxFe2O6−δ Series. Angew. Chem. 2019, 131, 2082–2085. [Google Scholar] [CrossRef]

- Guan, D.; Zhou, J.; Huang, Y.-C.; Dong, C.-L.; Wang, J.-Q.; Zhou, W.; Shao, Z. Screening highly active perovskites for hydrogen-evolving reaction via unifying ionic electronegativity descriptor. Nat. Commun. 2019, 10, 3755. [Google Scholar] [CrossRef]

- Bockris, J.O.M.; Otagawa, T. Mechanism of oxygen evolution on perovskites. J. Phys. Chem. 1983, 87, 2960–2971. [Google Scholar] [CrossRef]

- Zhu, K.; Wu, T.; Li, M.; Lu, R.; Zhu, X.; Yang, W. Perovskites decorated with oxygen vacancies and Fe–Ni alloy nanoparticles as high-efficiency electrocatalysts for the oxygen evolution reaction. J. Mater. Chem. A 2017, 5, 19836–19845. [Google Scholar] [CrossRef]

- Bockris, J.O.M.; Otagawa, T. The Electrocatalysis of Oxygen Evolution on Perovskites. J. Electrochem. Soc. 1984, 131, 290–302. [Google Scholar] [CrossRef]

- Hong, W.T.; Risch, M.; Stoerzinger, K.A.; Grimaud, A.; Suntivich, J.; Shao-Horn, Y. Toward the rational design of non-precious transition metal oxides for oxygen electrocatalysis. Energy Environ. Sci. 2015, 8, 1404–1427. [Google Scholar] [CrossRef]

- Suntivich, J.; Hong, W.T.; Lee, Y.-L.; Rondinelli, J.M.; Yang, W.; Goodenough, J.B.; Dabrowski, B.; Freeland, J.W.; Shao-Horn, Y. Estimating Hybridization of Transition Metal and Oxygen States in Perovskites from O K-edge X-ray Absorption Spectroscopy. J. Phys. Chem. C 2014, 118, 1856–1863. [Google Scholar] [CrossRef]

- Suntivich, J.; May, K.J.; Gasteiger, H.A.; Goodenough, J.B.; Shao-Horn, Y. A Perovskite Oxide Optimized for Oxygen Evolution Catalysis from Molecular Orbital Principles. Science 2011, 334, 1383–1385. [Google Scholar] [CrossRef] [PubMed]

- Saitoh, T.; Bocquet, A.E.; Mizokawa, T.; Fujimori, A. Systematic variation of the electronic structure of 3d transition-metal compounds. Phys. Rev. B 1995, 52, 7934–7938. [Google Scholar] [CrossRef] [PubMed]

- Bocquet, A.E.; Mizokawa, T.; Saitoh, T.; Namatame, H.; Fujimori, A. Electronic structure of 3d-transition-metal compounds by analysis of the 2p core-level photoemission spectra. Phys. Rev. B 1992, 46, 3771–3784. [Google Scholar] [CrossRef] [PubMed]

- Kan, W.H.; Chen, M.; Bae, J.-S.; Kim, B.-H.; Thangadurai, V. Determination of Fe oxidation states in the B-site ordered perovskite-type Ba2Ca0.67Fe0.33NbO6−δ at the surface (nano-scale) and bulk by variable temperature XPS and TGA and their impact on electrochemical catalysis. J. Mater. Chem. A 2014, 2, 8736–8741. [Google Scholar] [CrossRef]

- Moritomo, Y.; Higashi, K.; Matsuda, K.; Nakamura, A. Spin-state transition in layered perovskite cobalt oxides: La2-xSrxCoO4(0.4 ≤ x ≤ 1.0). Phys. Rev. B 1997, 55, R14725–R14728. [Google Scholar] [CrossRef]

- Fan, L.; Rautama, E.L.; Lindén, J.; Sainio, J.; Jiang, H.; Sorsa, O.; Han, N.; Flox, C.; Zhao, Y.; Li, Y.; et al. Two orders of magnitude enhancement in oxygen evolution reactivity of La0.7Sr0.3Fe1−xNixO3−δ by improving the electrical conductivity. Nano Energy 2022, 93, 106794. [Google Scholar] [CrossRef]

- Larson, A.C.; Von Dreele, R.B. General Structure Analysis System (GSAS). In Los Alamos National Laboratory Report LAUR; NIST: Gaithersburg, MD, USA, 2004; pp. 86–748. [Google Scholar]

- Toby, B.H. EXPGUI, a graphical user interface for GSAS. J. Appl. Crystallogr. 2001, 34, 210–213. [Google Scholar] [CrossRef]

- Niu, S.; Li, S.; Du, Y.; Han, X.; Xu, P. How to Reliably Report the Overpotential of an Electrocatalyst. ACS Energy Lett. 2020, 5, 1083–1087. [Google Scholar] [CrossRef]

- Du, X.; Ma, G.; Zhang, X. Experimental and Theoretical Understanding on Electrochemical Activation Processes of Nickel Selenide for Excellent Water-Splitting Performance: Comparing the Electrochemical Performances with M–NiSe (M = Co, Cu, and V). ACS Sustain. Chem. Eng. 2019, 7, 19257–19267. [Google Scholar] [CrossRef]

- Du, X.; Su, H.; Zhang, X. Metal–Organic Framework-Derived Cu-Doped Co9S8 Nanorod Array with Less Low-Valence Co Sites as Highly Efficient Bifunctional Electrodes for Overall Water Splitting. ACS Sustain. Chem. Eng. 2019, 7, 16917–16926. [Google Scholar] [CrossRef]

- Atuchin, V.V.; Gavrilova, T.A.; Grivel, J.C.; Kesler, V.G. Electronic structure of layered ferroelectric high-k titanate La2Ti2O7. J. Phys. D Appl. Phys. 2009, 42, 035305. [Google Scholar] [CrossRef]

- Liu, J.; Ma, X.; Yang, L.; Liu, X.; Han, A.; Lv, H.; Zhang, C.; Xu, S. In situ green oxidation synthesis of Ti3+ and N self-doped SrTiOxNy nanoparticles with enhanced photocatalytic activity under visible light. RSC Adv. 2018, 8, 7142–7151. [Google Scholar] [CrossRef]

- Yang, H. The Structural and Morphology of (La0.6Sr0.4)MnO3 Thin Films Prepared by Pulsed Laser Deposition. MATEC Web Conf. 2016, 44, 02035. [Google Scholar] [CrossRef]

- Zhu, J.; Guo, S.; Chu, Z.; Jin, W. CO2-tolerant oxygen-permeable perovskite-type membranes with high permeability. J. Mater. Chem. A 2015, 3, 22564–22573. [Google Scholar] [CrossRef]

- Lim, Y.-G.; Kim, D.; Lim, J.-M.; Kim, J.-S.; Yu, J.-S.; Kim, Y.-J.; Byun, D.; Cho, M.; Cho, K.; Park, M.-S. Anti-fluorite Li6CoO4 as an alternative lithium source for lithium ion capacitors: An experimental and first principles study. J. Mater. Chem. A 2015, 3, 12377–12385. [Google Scholar] [CrossRef]

- Hona, R.K.; Huq, A.; Ramezanipour, F. Unraveling the Role of Structural Order in the Transformation of Electrical Conductivity in Ca2FeCoO6−δ, CaSrFeCoO6−δ, and Sr2FeCoO6−δ. Inorg. Chem. 2017, 56, 14494–14505. [Google Scholar] [CrossRef]

- Karmakar, A.; Kundu, S. A concise perspective on the effect of interpreting the double layer capacitance data over the intrinsic evaluation parameters in oxygen evolution reaction. Mater. Today Energy 2023, 33, 101259. [Google Scholar] [CrossRef]

- He, B.; Tan, K.; Gong, Y.; Wang, R.; Wang, H.; Zhao, L. Coupling amorphous cobalt hydroxide nanoflakes on Sr2Fe1.5Mo0.5O5+δ perovskite nanofibers to induce bifunctionality for water splitting. Nanoscale 2020, 12, 9048–9057. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Yu, J.; Yang, G.; Liu, H.; Zhou, W.; Shao, Z. Perovskite oxide/carbon nanotube hybrid bifunctional electrocatalysts for overall water splitting. Electrochim. Acta 2018, 286, 47–54. [Google Scholar] [CrossRef]

- Karki, S.B.; Hona, R.K.; Yu, M.; Ramezanipour, F. Enhancement of Electrocatalytic Activity as a Function of Structural Order in Perovskite Oxides. ACS Catal. 2022, 12, 10333–10337. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhou, W.; Zhong, Y.; Bu, Y.; Chen, X.; Zhong, Q.; Liu, M.; Shao, Z. A Perovskite Nanorod as Bifunctional Electrocatalyst for Overall Water Splitting. Adv. Energy Mater. 2017, 7, 1602122. [Google Scholar] [CrossRef]

- Kananke-Gamage, C.C.W.; Ramezanipour, F. Effect of structural symmetry on magnetic, electrical and electrocatalytic properties of isoelectronic oxides A2LaMn2O7 (A= Sr2+, Ca2+). J. Phys. Chem. Solids 2022, 171, 111013. [Google Scholar] [CrossRef]

- Alom, M.S.; Ramezanipour, F. Electrocatalytic activity of layered oxides SrLaAl1/2M1/2O4 (M = Mn, Fe, Co) for hydrogen- and oxygen-evolution reactions. Mater. Chem. Phys. 2023, 293, 126942. [Google Scholar] [CrossRef]

- Anantharaj, S.; Noda, S. How properly are we interpreting the Tafel lines in energy conversion electrocatalysis? Mater. Today Energy 2022, 29, 101123. [Google Scholar] [CrossRef]

- Shinagawa, T.; Garcia-Esparza, A.; Takanabe, K. Insight on Tafel slopes from a microkinetic analysis of aqueous electrocatalysis for energy conversion. Sci. Rep. 2015, 5, 13801. [Google Scholar] [CrossRef]

| Atom | x | y | z | Occupancy | Uiso (Å2) | Multiplicity |

|---|---|---|---|---|---|---|

| Sr1 | 0 | 0 | 0.5 | 1 | 0.0327(18) | 2 |

| Sr2 | 0 | 0 | 0.31421(16) | 1 | 0.0390(18) | 4 |

| Ti | 0 | 0 | 0.09932(27) | 1 | 0.0158(28) | 4 |

| O1 | 0 | 0 | 0 | 1 | 0.090(8) | 2 |

| O2 | 0 | 0 | 0.1882(12) | 1 | 0.090(8) | 4 |

| O3 | 0 | 0.5 | 0.0979(6) | 1 | 0.090(8) | 8 |

| Atom | x | y | z | Occupancy | Uiso (Å2) | Multiplicity |

|---|---|---|---|---|---|---|

| Sr1 | 0 | 0 | 0.5 | 1 | 0.021(4) | 2 |

| Sr2 | 0 | 0 | 0.30097(12) | 1 | 0.040(4) | 4 |

| Ti | 0 | 0 | 0.11764(17) | 0.5 | 0.034(4) | 4 |

| Mn | 0 | 0 | 0.11764(17) | 0.5 | 0.034(4) | 4 |

| O1 | 0 | 0 | 0 | 1 | 0.039(5) | 2 |

| O2 | 0 | 0 | 0.1897(7) | 1 | 0.039(5) | 4 |

| O3 | 0 | 0.5 | 0.0759(4) | 1 | 0.039(5) | 8 |

| Atom | x | y | z | Occupancy | Uiso (Å2) | Multiplicity |

|---|---|---|---|---|---|---|

| Sr1 | 0 | 0 | 0.5 | 1 | 0.0083(13) | 2 |

| Sr2 | 0 | 0 | 0.31585(9) | 1 | 0.0148(10) | 4 |

| Ti | 0 | 0 | 0.10014(20) | 0.5 | 0.0010(9) | 4 |

| Fe | 0 | 0 | 0.10014(20) | 0.5 | 0.0010(9) | 4 |

| O1 | 0 | 0 | 0 | 1 | 0.0542(17) | 2 |

| O2 | 0 | 0 | 0.1980(6) | 1 | 0.0542(17) | 4 |

| O3 | 0 | 0.5 | 0.0963(4) | 1 | 0.0542(17) | 8 |

| Atom | x | y | z | Occupancy | Uiso (Å2) | Multiplicity |

|---|---|---|---|---|---|---|

| Sr1 | 0 | 0 | 0 | 1 | 0.031(6) | 2 |

| Sr2 | 0 | 0 | 0.18493(21) | 1 | 0.052(6) | 4 |

| Ti | 0 | 0 | 0.4010(5) | 0.5 | 0.050(6) | 4 |

| Co | 0 | 0 | 0.4010(5) | 0.5 | 0.050(6) | 4 |

| O1 | 0 | 0 | 0.5 | 1 | 0.080(8) | 2 |

| O2 | 0 | 0 | 0.3126(13) | 1 | 0.080(8) | 4 |

| O3 | 0 | 0.5 | 0.0940(11) | 1 | 0.080(8) | 8 |

| Sr3Ti2O7 | Sr3TiMnO7 | ||

| Ti–O1 | 2.020(6) | Ti/Mn–O1 | 2.3766(35) |

| Ti–O2 | 1.808(23) | Ti/Mn–O2 | 1.456(12) |

| Ti–O3 × 4 | 1.95065(20) | Ti/Mn–O3 × 4 | 2.1006(31) |

| Average Ti–O | 1.9384(19) | Average Ti/Mn–O | 2.0391(29) |

| Ti–O1–Ti | 180.0(0) | Ti/Mn–O1–Ti/Mn | 180.0(0) |

| Ti–O3–Ti | 178.3 (8) | Ti/Mn–O3–Ti/Mn | 132.7(4) |

| Average Ti–O–Ti | 179.2(6) | Average Ti/Mn–O–Ti/Mn | 156.35(3) |

| Sr3TiFeO7−δ | Sr3TiCoO7−δ | ||

| Ti/Fe–O1 | 2.031(4) | Ti/Co–O1 | 2.003(11) |

| Ti/Fe–O2 | 1.984(13) | Ti/Co–O2 | 1.788(25) |

| Ti/Fe–O3 × 4 | 1.9468(4) | Ti/Co–O3 × 4 | 1.9367(13) |

| Average Ti/Fe–O | 1.9670(6) | Average Ti/Co–O | 1.9229(15) |

| Ti/Fe–O1–Ti/Fe | 180.0(0) | Ti/Co–O1–Ti/Co | 180.0(0) |

| Ti/Fe–O3–Ti/Fe | 175.4(6) | Ti/Co–O3–Ti/Co | 174.0(15) |

| Average Ti/Fe–O–Ti/Fe | 177.7(4) | Average Ti/Co–O–Ti/Co | 177.0(11) |

| Material | Conductivity at 25 °C (S/cm) | Activation Energy (eV) |

|---|---|---|

| Sr3Ti2O7 | 1.88719 × 10−10 | 0.1372 (298–573 K) 1.2327 (573–1073 K) |

| Sr3TiMnO7 | 1.2445 × 10−5 | 0.2966 (298–773 K) |

| Sr3TiFeO7−δ | 1.72 × 10−3 | 0.2714 (298–773 K) |

| Sr3TiCoO7−δ | 2.843 × 10−2 | 0.1883 (298–773 K) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kananke-Gamage, C.C.W.; Ramezanipour, F. Isostructural Oxides Sr3Ti2−xMxO7−δ (M = Mn, Fe, Co; x = 0, 1) as Electrocatalysts for Water Splitting. Inorganics 2023, 11, 172. https://0-doi-org.brum.beds.ac.uk/10.3390/inorganics11040172

Kananke-Gamage CCW, Ramezanipour F. Isostructural Oxides Sr3Ti2−xMxO7−δ (M = Mn, Fe, Co; x = 0, 1) as Electrocatalysts for Water Splitting. Inorganics. 2023; 11(4):172. https://0-doi-org.brum.beds.ac.uk/10.3390/inorganics11040172

Chicago/Turabian StyleKananke-Gamage, Chandana C. W., and Farshid Ramezanipour. 2023. "Isostructural Oxides Sr3Ti2−xMxO7−δ (M = Mn, Fe, Co; x = 0, 1) as Electrocatalysts for Water Splitting" Inorganics 11, no. 4: 172. https://0-doi-org.brum.beds.ac.uk/10.3390/inorganics11040172