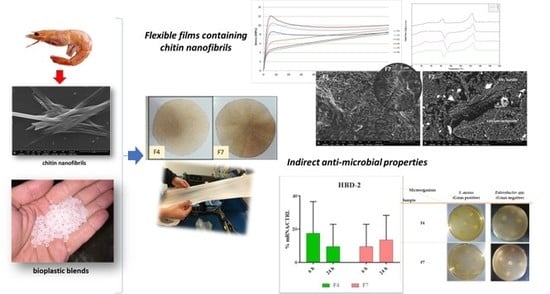

Properties and Skin Compatibility of Films Based on Poly(Lactic Acid) (PLA) Bionanocomposites Incorporating Chitin Nanofibrils (CN)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Brunauer–Emmett–Teller (BET) Characterization of Chitin Nano-Fibrils

2.2.2. Chitin Master-Batch Preparation

2.2.3. Blends Preparation

2.2.4. Melt Flow Rate

2.2.5. Mechanical Testing

2.2.6. Differential Scanning Calorimetry

2.2.7. Skin Compatibility Tests

2.2.8. Evaluation of Inflammatory and Indirect Antimicrobial Properties

2.2.9. Anti-Microbial Tests

3. Results

3.1. Comparison between Experimental and Theoretical Chitin BET Values

3.2. Melt Properties

3.3. Tensile Properties

3.4. DSC Characterization

3.5. Morphology of the Composites

3.6. Skin Compatibility Results

3.7. Evaluation of Antinflammatory and Indirect Antimicrobial Properties

3.8. Anti-Microbial Tests

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Moustafa, H.; El Kissi, N.; Abou-Kandil, A.I.; Abdel-Aziz, M.S.; Dufresne, A. PLA/PBAT Bionanocomposites with Antimicrobial Natural Rosin for Green Packaging. ACS Appl. Mater. Interf. 2017, 9, 20132–20141. [Google Scholar] [CrossRef] [PubMed]

- Sharma, R.; Jafari, S.M.; Sharma, S. Antimicrobial bio-nanocomposites and their potential applications in food packaging. Food Control 2020, 112, 107086. [Google Scholar] [CrossRef]

- Liao, C.; Li, Y.; Tjong, S.C. Antibacterial Activities of Aliphatic Polyester Nanocomposites with Silver Nanoparticles and/or Graphene Oxide Sheets. Nanomaterials 2019, 9, 1102. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Febo, P.; Gagliardini, A. Baby Diapers Past and Present: A Critical Review. In Bionanotechnology to Save the Environment: Plant and Fishery’s Biomass as Alternative to Petrol; Morganti, P., Ed.; MDPI: Basel, Switzerland, 2018; pp. 227–238. [Google Scholar]

- Huang, K.S.; Yang, C.H.; Huang, S.L.; Chen, C.Y.; Lu, Y.Y.; Lin, Y.S. Recent Advances in Antimicrobial Polymers: A Mini-Review. Int. J. Mol. Sci. 2016, 17, 1578. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Corsini, E.; Galli, C.L. Epidermal cytokines in experimental contact dermatitis. Toxicology 2000, 142, 203–211. [Google Scholar] [CrossRef]

- Panariello, L.; Coltelli, M.B.; Buchignani, M.; Lazzeri, A. Chitosan and nano-structured chitin for biobased anti-microbial treatments onto cellulose based materials. Eur. Polym. J. 2019, 113, 328–339. [Google Scholar] [CrossRef]

- Donnarumma, G.; Fusco, A.; Morganti, P.; Palombo, M.; Anniboletti, T.; Del Ciotto, P.; Baroni, A. Advanced medications made by green nanocomposites. Int. J. Res. Pharmaceut. Nano Sci. 2016, 5, 261–270. [Google Scholar]

- Danti, S.; Trombi, L.; Fusco, A.; Azimi, B.; Lazzeri, A.; Morganti, P.; Coltelli, M.-B.; Donnarumma, G. Chitin Nanofibrils and Nanolignin as Functional Agents in Skin Regeneration. Int. J. Mol. Sci. 2019, 20, 2669. [Google Scholar] [CrossRef] [Green Version]

- Morganti, P.; Danti, S.; Coltelli, M.B. Chitin and lignin to produce biocompatible tissues. Res. Clin. Dermatol. 2018, 1, 5–11. [Google Scholar] [CrossRef]

- Morganti, P.; Morganti, G.; Nunziata, M.L. Chitin Nanofibrils, a Natural Polymer from Fishery Waste: Nanoparticle and Nanocomposite Characteristics. In Bionanotechnology to Save the Environment: Plant and Fishery’s Biomass as Alternative to Petrol; MDPI: Basel, Switzerland, 2018; pp. 60–81. [Google Scholar]

- Pivsa-Art, W.; Fujii, K.; Nomura, K.; Aso, Y.; Ohara, H.; Yamane, H. The effect of poly(ethylene glycol) as plasticizer in blends of poly(lactic acid) and poly(butylene succinate). J. Appl. Polym. Sci. 2016, 133, 1–10. [Google Scholar] [CrossRef]

- Lim, S.T.; Hyun, Y.H.; Choi, H.J.; Jhon, M.S. Synthetic biodegradable aliphatic polyester/montmorillonite nanocomposites. Chem. Mater. 2002, 14, 1839–1844. [Google Scholar] [CrossRef]

- Bogaert, J.; Coszach, P. Poly(lactic acids): A potential solution to plastic waste dilemma. Macromol. Symp. 2000, 153, 287–303. [Google Scholar] [CrossRef]

- Helmes, R.J.K.; López-Contreras, A.M.; Benoit, M.; Abreu, H.; Maguire, J.; Moejes, F.; van den Burg, S.W.K. Environmental impacts of experimental production of lactic acid for bioplastics from Ulva spp. Sustainaiblity 2018, 10, 2462. [Google Scholar] [CrossRef] [Green Version]

- Aliotta, L.; Cinelli, P.; Coltelli, M.B.; Righetti, M.C.; Gazzano, M.; Lazzeri, A. Effect of nucleating agents on crystallinity and properties of poly (lactic acid) (PLA). Eur. Polym. J. 2017, 93, 822–832. [Google Scholar] [CrossRef]

- Raquez, J.M.; Habibi, Y.; Murariu, M.; Dubois, P. Polylactide (PLA)-based nanocomposites. Prog. Polym. Sci. 2013, 38, 1504–1542. [Google Scholar] [CrossRef]

- Martin, O.; Avérous, L. Poly(lactic acid): Plasticization and properties of biodegradable multiphase systems. Polymers 2001, 42, 6209–6219. [Google Scholar] [CrossRef]

- Ljungberg, N.; Wesslén, B. Preparation and properties of plasticized poly(lactic acid) films. Biomacromolecules 2005, 6, 1789–1796. [Google Scholar] [CrossRef]

- Fehri, S.; Cinelli, P.; Coltelli, M.-B.; Anguillesi, I.; Lazzeri, A. Thermal Properties of Plasticized Poly (Lactic Acid) (PLA) Containing Nucleating Agent. Int. J. Chem. Eng. Appl. 2016, 7, 85–88. [Google Scholar] [CrossRef] [Green Version]

- Gigante, V.; Canesi, I.; Cinelli, P.; Coltelli, M.B.; Lazzeri, A. Rubber Toughening of Polylactic Acid (PLA) with Poly(butylene adipate-co-terephthalate) (PBAT): Mechanical Properties, Fracture Mechanics and Analysis of Ductile-to-Brittle Behavior while Varying Temperature and Test Speed. Eur. Polym. J. 2019, 115, 125–137. [Google Scholar] [CrossRef]

- Al-Itry, R.; Lamnawar, K.; Maazouz, A. Improvement of thermal stability, rheological and mechanical properties of PLA, PBAT and their blends by reactive extrusion with functionalized epoxy. Polym. Degrad. Stab. 2012, 97, 1898–1914. [Google Scholar] [CrossRef]

- Teamsinsungvon, A.; Ruksakulpiwat, Y.; Jarukumjorn, K. Preparation and Characterization of Poly(lactic acid)/Poly(butylene adipate-co-terepthalate) Blends and Their Composite. Polym. Plast. Technol. Eng. 2013, 52, 1362–1367. [Google Scholar] [CrossRef]

- Liu, G.; Zheng, L.; Zhang, X.; Li, C.; Jiang, S.; Wang, D. Reversible lamellar thickening induced by crystal transition in poly(butylene succinate). Macromolecules 2012, 45, 5487–5493. [Google Scholar] [CrossRef]

- Gigante, V.; Coltelli, M.; Vannozzi, A.; Panariello, L.; Fusco, A.; Trombi, L.; Donnarumma, G.; Danti, S.; Lazzeri, A. Flat Die Extruded Biocompatible Poly(Lactic Acid). Polymers 2019, 11, 1857. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hassouna, F.; Raquez, J.M.; Addiego, F.; Dubois, P.; Toniazzo, V.; Ruch, D. New approach on the development of plasticized polylactide (PLA): Grafting of poly(ethylene glycol) (PEG) via reactive extrusion. Eur. Polym. J. 2011, 47, 2134–2144. [Google Scholar] [CrossRef]

- Dorez, G.; Taguet, A.; Ferry, L.; Lopez-Cuesta, J.M. Thermal and fire behavior of natural fibers/PBS biocomposites. Polym. Degrad. Stab. 2013, 98, 87–95. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Della Maggiore, I.; Bertoldo, M.; Signori, F.; Bronco, S.; Ciardelli, F. Poly(lcatic acid) Properties as a Consequnce of Poly(butylene adipate-co-terephtalate) Blending and Acetyl trybutyl Citrate Plasticization. J. Appl. Polym. Sci. 2008, 110, 1250–1262. [Google Scholar] [CrossRef]

- Fortunati, E.; Puglia, D.; Iannoni, A.; Terenzi, A.; Kenny, J.M.; Torre, L. Processing conditions, thermal and mechanical responses of stretchable poly (lactic acid)/poly (butylene succinate) films. Materials 2017, 10, 809. [Google Scholar] [CrossRef] [Green Version]

- Coltelli, M.B.; Bronco, S.; Chinea, C. The effect of free radical reactions on structure and properties of poly(lactic acid) (PLA) based blends. Polym. Degrad. Stab. 2010, 95, 332–341. [Google Scholar] [CrossRef]

- Coltelli, M.B.; Gigante, V.; Panariello, L.; Morganti, P.; Cinelli, P.; Danti, S.; Lazzeri, A. Chitin nanofibrils in renewable materials for packaging and personal care applications. Adv. Mater. Lett. 2018, 10, 425–430. [Google Scholar] [CrossRef]

- Coltelli, M.; Cinelli, P.; Gigante, V.; Aliotta, L.; Morganti, P.; Panariello, L.; Lazzeri, A. Chitin Nanofibrils in Poly(Lactic Acid)(PLA) Nanocomposites: Dispersion and Thermo-Mechanical Properties. Int. J. Mol. Sci. 2019, 20, 504. [Google Scholar] [CrossRef] [Green Version]

- Morganti, P. Chitin Nanofibrils in Skin Treatment. J. Appl. Cosmetol. 2014, 27, 251–270. [Google Scholar]

- Cinelli, P.; Coltelli, M.B.; Mallegni, N.; Morganti, P.; Lazzeri, A. Degradability and sustainability of nanocomposites based on polylactic acid and chitin nano fibrils. Chem. Eng. Trans. 2017, 60, 115–120. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, M.; Yang, S.; Luo, B.; Zhou, C. Liquid Crystalline Behaviors of Chitin Nanocrystals and Their Reinforcing Effect on Natural Rubber. ACS Sustain. Chem. Eng. 2018, 6, 325–336. [Google Scholar] [CrossRef]

- Liu, M.; Zheng, H.; Chen, J.; Li, S.; Huang, J.C.; Zhou, C. Chitosan-chitin nanocrystal composite scaffolds for tissue engineering. Carbohydr. Polym. 2016, 152, 832–840. [Google Scholar] [CrossRef]

- Rizvi, R.; Cochrane, B.; Naguib, H.; Lee, P.C. Fabrication and characterization of melt-blended polylactide-chitin composites and their foams. J. Cell. Plast. 2011, 47, 283–300. [Google Scholar] [CrossRef]

- Zhang, Q.; Wei, S.; Huang, J.; Feng, J.; Chang, P.R. Effect of surface acetylated-chitin nanocrystals on structure and mechanical properties of poly(lactic acid). J. Appl. Polym. Sci. 2014, 131, 2–9. [Google Scholar] [CrossRef]

- Araki, J.; Kurihara, M. Preparation of sterically stabilized chitin nanowhisker dispersions by grafting of poly(ethylene glycol) and evaluation of their dispersion stability. Biomacromolecules 2015, 16, 379–388. [Google Scholar] [CrossRef]

- Guan, Q.; Naguib, H.E. Fabrication and Characterization of PLA/PHBV-Chitin Nanocomposites and Their Foams. J. Polym. Environ. 2014, 22, 119–130. [Google Scholar] [CrossRef]

- Herrera, N.; Singh, A.A.; Salaberria, A.M.; Labidi, J.; Mathew, A.P.; Oksman, K. Triethyl citrate (TEC) as a dispersing aid in polylactic acid/chitin nanocomposites prepared via liquid-assisted extrusion. Polymers 2017, 9, 406. [Google Scholar] [CrossRef] [Green Version]

- Herrera, N.; Roch, H.; Salaberria, A.M.; Pino-Orellana, M.A.; Labidi, J.; Fernandes, S.C.M.; Radic, D.; Leiva, A.; Oksman, K. Functionalized blown films of plasticized polylactic acid/chitin nanocomposite: Preparation and characterization. Mater. Des. 2016, 92, 846–852. [Google Scholar] [CrossRef]

- Scatto, M.; Salmini, E.; Castiello, S.; Coltelli, M.B.; Conzatti, L.; Stagnaro, P.; Andreotti, L.; Bronco, S. Plasticized and nanofilled poly(lactic acid)-based cast films: Effect of plasticizer and organoclay on processability and final properties. J. Appl. Polym. Sci. 2013, 127, 4947–4956. [Google Scholar] [CrossRef]

- Li, J.; Gao, Y.; Zhao, J.; Sun, J.; Li, D. Homogeneous dispersion of chitin nanofibers in polylactic acid with different pretreatment methods. Cellulose 2017, 24, 1705–1715. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Cinelli, P.; Anguillesi, I.; Salvadori, S.; Lazzeri, A. Structure and properties of extruded composites based on bio-polyesters and nano-chitin. In Proceedings of the Symposium E-MRS Fall Meeting, Warsaw University of Technology, Warsaw, Poland, 15–18 September 2014; p. 192. [Google Scholar]

- Xiong, Z.; Yang, Y.; Feng, J.; Zhang, X.; Zhang, C.; Tang, Z.; Zhu, J. Preparation and characterization of poly(lactic acid)/starch composites toughened with epoxidized soybean oil. Carbohydr. Polym. 2013, 92, 810–816. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Sun, X.; Seib, P. Strengthening blends of poly(lactic acid) and starch with methylenediphenyl diisocyanate. J. Appl. Polym. Sci. 2001, 82, 1761–1767. [Google Scholar] [CrossRef]

- Teixeira, E.M.; Da Róz, A.L.; Carvalho, A.J.F.; Curvelo, A.A.S. The effect of glycerol/sugar/water and sugar/water mixtures on the plasticization of thermoplastic cassava starch. Carbohydr. Polym. 2007, 69, 619–624. [Google Scholar] [CrossRef]

- Ma, X.F.; Yu, J.G.; Wan, J.J. Urea and ethanolamine as a mixed plasticizer for thermoplastic starch. Carbohydr. Polym. 2006, 64, 267–273. [Google Scholar] [CrossRef]

- Shi, R.; Zhang, Z.; Liu, Q.; Han, Y.; Zhang, L.; Chen, D.; Tian, W. Characterization of citric acid/glycerol co-plasticized thermoplastic starch prepared by melt blending. Carbohydr. Polym. 2007, 69, 748–755. [Google Scholar] [CrossRef]

- Rodriguez-Gonzalez, F.J.; Ramsay, B.A.; Favis, B.D. Rheological and thermal properties of thermoplastic starch with high glycerol content. Carbohydr. Polym. 2004, 58, 139–147. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Danti, S.; Trombi, L.; Morganti, P.; Donnarumma, G.; Baroni, A.; Fusco, A.; Lazzeri, A. Preparation of Innovative Skin Compatible Films to Release Polysaccharides for Biobased Beauty Masks. Cosmetics 2018, 5, 70. [Google Scholar] [CrossRef] [Green Version]

- ARKEMA Technical Datasheet—Plastistrength® 550. 2019. Available online: https://www.additives-arkema.com/export/shared/.content/media/downloads/products-documentations/organic-peroxides/functional-additives-acrylic-modifiers/plastistrength/plastistrength-550-tds.pdf (accessed on 24 January 2020).

- Muzzarelli, C.; Morganti, P. Preparation of Chitin and Derivatives Thereof for Cosmetic and Therapeutic Use. U.S. Patent 8,552,164 B2, 8 October 2013. [Google Scholar]

- Morganti, P.; Carezzi, F.; Del Ciotto, P.; Morganti, G.; Nunziata, M.L.; Gao, X.; Tishenko, G.; Yudin, V. Chitin Nanofibrils: A Natural Multifunctional Polymer. In Nanobiotechnology; Phoenix, D.A., Ahmed, W., Eds.; One Central Press: Altrincham, UK, 2014; pp. 1–31. ISBN 978-1-910086-03-2. [Google Scholar]

- Signori, F.; Coltelli, M.B.; Bronco, S. Thermal degradation of poly(lactic acid) (PLA) and poly(butylene adipate-co-terephthalate) (PBAT) and their blends upon melt processing. Polym. Degr. Stab. 2009, 94, 74–82. [Google Scholar] [CrossRef]

- Bhatia, A.; Gupta, R.K.; Bhattacharya, S.; Choi, H.J. Effect of Clay on Thermal, Mechanical and Gas Barrier Properties of Biodegradable Poly(lactic acid)/Poly(butylene succinate) (PLA/PBS) Nanocomposites. Int. Polym. Process. 2010, 25, 5–14. [Google Scholar] [CrossRef]

- Fischer, E.W.; Sterzel, H.J.; Wegner, G. Investigation of the structure of solution grown crystals of lactide copolymers by means of chemical reactions. Colloid Polym. Sci. 1973, 251, 980–990. [Google Scholar] [CrossRef]

- Wilson, V.G. Growth and Differentiation of HaCaT Keratinocytes. In Epidermal Cells. Methods in Molecular Biology (Methods and Protocols); Turksen, K., Ed.; Springer: New York, NY, USA, 2013; Volume 1195, pp. 33–41. [Google Scholar] [CrossRef]

- Olaiya, N.G.; Surya, I.; Oke, P.K.; Rizal, S.; Sadiku, E.R.; Ray, S.; Farayibi, P.K.; Hossain, M.S.; Abdul Khalil, H.P.S. Properties and characterization of a PLA-Chitin-Starch Biodegradble Polymer Composite. Polymers 2019, 11, 1656. [Google Scholar] [CrossRef] [Green Version]

- Pereira, A.G.B.; Muniz, E.C.; Hsieh, Y.L. Chitosan-sheath and chitin-core nanowhiskers. Carbohydr. Polym. 2014, 107, 158–166. [Google Scholar] [CrossRef] [Green Version]

- Kaczmarek, H.; Nowicki, M.; Vuković-Kwiatkowska, I.; Nowakowska, S. Crosslinked blends of poly(lactic acid) and polyacrylates: AFM, DSC and XRD studies. J. Polym. Res. 2013, 20. [Google Scholar] [CrossRef] [Green Version]

- Mallegni, N.; Phuong, T.V.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A. Poly(lactic acid) (PLA) based tear resistant and biodegradable flexible films by blown film extrusion. Materials 2018, 11, 148. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Wu, Q.; Song, K.; Cheng, H.N.; Suzuki, S.; Lei, T. Chitin Nanofibers as Reinforcing and Antimicrobial Agents in Carboxymethyl Cellulose Films: Influence of Partial Deacetylation. ACS Sustain. Chem. Eng. 2016, 4, 4385–4395. [Google Scholar] [CrossRef]

- Min, B.; Lee, S.W.; Lim, J.N.; You, Y.; Lee, T.S.; Kang, P.H. Chitin and chitosan nanofibers: Electrospinning of chitin and deacetylation of chitin nanofibers. Polymer 2004, 45, 7137–7142. [Google Scholar] [CrossRef]

- Foster, L.J.R.; Butt, J. Chitosan films are NOT antimicrobial. Biotechnol. Lett. 2011, 33, 417–421. [Google Scholar] [CrossRef]

- Rai, S.; Dutta, P.K.; Mehrotra, G.K. Lignin Incorporated Antimicrobial Chitosan Film for Food Packaging Application. J. Polym. Mater. 2017, 34, 171. [Google Scholar]

| Gene | Primer Sequence | Conditions | Size (bp) |

|---|---|---|---|

| IL-1 α | 5′-CATGTCAAATTTCACTGCTTCATCC-3′ 5′-GTCTCTGAATCAGAAATCCTTCTATC-3′ | 5 s at 95 °C, 8 s at 55 °C, 17 s at 72 °C for 45 cycles | 421 |

| IL-1 β | 5′-GCATCCAGCTACGAATCTCC-3′ 5′-CCACATTCAGCACAGGACTC-3′ | 5 s at 95 °C, 14 s at 58 °C, 28 s at 72 °C for 40 cycles | 708 |

| TNF-α | 5′-CAGAGGGAAGAGTTCCCCAG-3′ 5′-CCTTGGTCTGGTAGGAGACG-3′ | 5 s at 95 °C, 6 s at 57 °C, 13 s at 72 °C for 40 cycles | 324 |

| IL-6 | 5′-ATGAACTCCTTCTCCACAAGCGC-3′ 5′-GAAGAGCCCTCAGGCTGGACTG-3′ | 5 s at 95 °C, 13 s at 56 °C, 25′ s at 72 °C for 40 cycles | 628 |

| IL-8 | 5-ATGACTTCCAAGCTGGCCGTG-3′ 5-TGAATTCTCAGCCCTCTTCAAAAACTTCTC-3′ | 5 s at 94 °C, 6 s at 55 °C, 12 s at 72 °C for 40 cycles | 297 |

| TGF-β | 5′-CCGACTACTACGCCAAGGAGGTCAC-3′ 5′-AGGCCGGTTCATGCCATGAATGGTG-3′ | 5 s at 94 °C, 9 s at 60 °C, 18 s at 72 °C for 40 cycles | 439 |

| HBD-2 | 5′-GGATCCATGGGTATAGGCGATCCTGTTA-3′ 5′-AAGCTTCTCTGATGAGGGAGCCCTTTCT-3′ | 5 s at 94 °C, 6 s at 63 °C, 10 s at 72 °C for 50 cycles 5 s at 94 °C, 6 s at 63 °C, 10 s at 72 °C for 50 cycles | 198 |

| Chitin Average Length (nm) | Chitin Average Width (nm) | Average Fibrils Volume (cm3) | Average Mass of Each Fibril (g) | Number of Chitin Fibrils per Gram | Experimental BET (m2/g) | Theoretical BET (m2/g) |

|---|---|---|---|---|---|---|

| 11,300 | 300 | 1.695 ×·10−14 | 2.4·×·10−14 | 4.15·×·1013 | 39.14 | 286.18 |

| Blends | PLA (wt.%) | PBS (wt.%) | ATBC (wt.%) | PS (wt.%) | PEG (%wt) | NC (wt.%) | Starch (wt.%) | Calcium Carbonate (wt.%) |

|---|---|---|---|---|---|---|---|---|

| F1 | 63 | 17 | 20 | - | - | - | - | - |

| F2 | 62 | 16 | 20 | 2 | - | - | - | - |

| F3 | 62 | 16 | 18 | - | 2 (PEG 6000) | 2 | - | - |

| F4 | 61 | 15 | 18 | 2 | 2 (PEG 6000) | 2 | - | - |

| F5 | 59 | 16 | 18 | - | 2 (PEG 400) | 2 | 3 | - |

| F6 | 58 | 15 | 18 | 2 | 2 (PEG 400) | 2 | 3 | - |

| F7 | 57.5 | 14.5 | 15 | 2 | 2 (PEG 6000) | 2 | - | 7 |

| Blends | Torque (N∙cm) | MVR (cm3/10 min) | MFR (g/10 min) |

|---|---|---|---|

| F1 | 67.8 ± 5.4 | 22.5 ± 2.0 | 23.6 ± 2.1 |

| F2 | 72.8 ± 6.0 | 11.8 ± 0.9 | 12.4 ± 0.9 |

| F3 | 60.0 ± 4.1 | 16.9 ± 1.5 | 18.4 ± 1.3 |

| F4 | 63.3 ± 3.6 | 11.8 ± 1.1 | 13.1 ± 1.3 |

| F5 | 42.0 ± 4.1 | 40.2 ± 10.5 | 43.5 ± 11.4 |

| F6 | 38.6 ± 2.2 | 50.7 ± 6.0 | 55.0 ± 6.5 |

| F7 | 73.5 ± 5.2 | 10.0 ± 1.3 | 11.4 ± 1.5 |

| Blends | Stress at Break σb (MPa) | Elongation at Break εb (%) | Stress at Yielding σy (MPa) |

|---|---|---|---|

| F1 | 31.8 ± 1.4 | 572.7 ± 20.7 | - |

| F2 | 33.0 ± 1.2 | 554.2 ± 12.3 | 10.2 ± 0.7 |

| F3 | 25.5 ± 1.2 | 455.2 ± 16.4 | 8.3 ± 1.5 |

| F4 | 25.5 ± 1.3 | 421.9 ± 25.1 | 11.6 ± 0.7 |

| F5 | 21.3 ± 3.1 | 398.7 ± 49.2 | - |

| F6 | 19.7 ± 1.5 | 381.2 ± 27.5 | - |

| F7 | 25.5 ± 1.0 | 400.1 ± 21.9 | 10.8 ± 1.8 |

| Blends | Tg (°C) | TC (°C) | ΔHC (J/g) | Tm (°C) | ΔHm (J/g) | XC % |

|---|---|---|---|---|---|---|

| F1 | 43.64 | ~96 | 3.05 | 143.74 | 18.84 | 27 |

| F2 | 36.29 | 86.71 | 12.97 | 145.58 | 19.94 | 12 |

| F4 | 43.90 | 87.52 | 19.31 | 145.91 | 20.57 | 2 |

| F7 | 43.55 | 85.72 | 11.97 | 145.46 | 18.82 | 13 |

| Blends | Tg (°C) | Tm,PBS (°C) | ΔHm,PBS (J/g) | TC,PLA (°C) | ΔHC,PLA (J/g) | Tm,PLA (°C) | ΔHm,PLA (J/g) | XC % |

|---|---|---|---|---|---|---|---|---|

| F1 | 26.96 | 79.63 | 3.74 | 88.21 | 11.49 | 144.27 | 22.62 | 19 |

| F2 | 33.54 | 83.40 | 6.83 | 96.72 | 16.90 | 145.40 | 20.54 | 6 |

| F4 | 34.75 | 84.87 | 5.81 | 96.53 | 20.06 | 147.24 | 22.87 | 5 |

| F7 | 30.24 | 83.72 | 6.68 | 94.87 | 15.00 | 146.01 | 20.07 | 9 |

| Sample | % ABRED |

|---|---|

| F4 | 150 |

| F14 | 137 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coltelli, M.-B.; Aliotta, L.; Vannozzi, A.; Morganti, P.; Panariello, L.; Danti, S.; Neri, S.; Fernandez-Avila, C.; Fusco, A.; Donnarumma, G.; et al. Properties and Skin Compatibility of Films Based on Poly(Lactic Acid) (PLA) Bionanocomposites Incorporating Chitin Nanofibrils (CN). J. Funct. Biomater. 2020, 11, 21. https://0-doi-org.brum.beds.ac.uk/10.3390/jfb11020021

Coltelli M-B, Aliotta L, Vannozzi A, Morganti P, Panariello L, Danti S, Neri S, Fernandez-Avila C, Fusco A, Donnarumma G, et al. Properties and Skin Compatibility of Films Based on Poly(Lactic Acid) (PLA) Bionanocomposites Incorporating Chitin Nanofibrils (CN). Journal of Functional Biomaterials. 2020; 11(2):21. https://0-doi-org.brum.beds.ac.uk/10.3390/jfb11020021

Chicago/Turabian StyleColtelli, Maria-Beatrice, Laura Aliotta, Alessandro Vannozzi, Pierfrancesco Morganti, Luca Panariello, Serena Danti, Simona Neri, Cristina Fernandez-Avila, Alessandra Fusco, Giovanna Donnarumma, and et al. 2020. "Properties and Skin Compatibility of Films Based on Poly(Lactic Acid) (PLA) Bionanocomposites Incorporating Chitin Nanofibrils (CN)" Journal of Functional Biomaterials 11, no. 2: 21. https://0-doi-org.brum.beds.ac.uk/10.3390/jfb11020021