Standardising Marine Renewable Energy Testing: Gap Analysis and Recommendations for Development of Standards

Abstract

:1. Introduction

1.1. Complexity of the MRE Sector

1.2. Structured Development Plans

2. Literature Review

2.1. Previous MRE Guidance Gap Identification Studies

- Modelling the power take-off (PTO) subsystem, including scaling, simulation at model scale, and performance prediction/assessment.

- Moorings and cable systems.

- Working towards a coherent set of guidelines/standards used by all test facilities.

- Testing in combined wave-current conditions.

- An understanding of failure mechanisms resulting from corrosion, and of the effect of wear, corrosion and fatigue combinations.

- 1.

- Limited knowledge transfer. It needs to be easier to find the wealth of experience, tools, and know-how that have been developed by the sector, in order for the industry to avoid repeating mistakes, minimise duplicate efforts, and leverage the experience of others to accelerate development.

- 2.

- High cost of measurement. This can lead to a trade-off between the breadth and duration of a test, and the number and quality of measurements.

- 3.

- Better measurement capabilities at low TRL. To facilitate scale model testing at 1:10 or smaller. Measurement capabilities are often inadequate and sensors either do not exist, are too expensive, or adversely impact device response.

- 4.

- Open-source tools for unified data processing and analysis. At present, data processing and analysis is conducted on a project-by-project basis using custom code. The sharing of vetted data reduction, processing, QA, and visualisation code, and adoption of standard methods would allow the industry to accelerate the analysis, and would increase the credibility of test results.

2.2. Types of Guidance Available for MRE Development

- General StandardsPublished by standards bodies such as the International Standards Organisation (ISO) or the International Electrotechnical Commission (IEC); these cover topics that are generally applicable to a wide range of established sectors. Examples include: ISO 9001 Quality management, or ISO/IEC 17025 General requirements for the competence of testing and calibration laboratories. These are beyond the scope of this paper.

- Technically focused and/or sector-specific Standards, Technical Specifications (TS), and Recommended Procedures (RP)Published by standards bodies or by certification organisations like DNV, these focus on technical aspects more relevant to the MRE and related sectors. Examples include: IEC 61400 Wind turbines, IEC TS 62600 wave, tidal and other water current converters, and DNV-OS-J103 Design of Floating Wind Turbine Structures.

- Sector-specific guidance documentsDeveloped by projects or organisations, these focus more specifically on aspects of MRE development and testing. Examples include: Protocols for the Equitable Assessment of Marine Energy Converters (EquiMar) [12] and supporting project deliverables, the MaRINET and MaRINET2 project deliverables, and the set of recommended procedures and guidelines published by the International Towing Tank Conference (ITTC) [13]. A tabular summary of the key topics covered by 78 of these documents is provided in Appendix A.

- Other SourcesIn addition, valuable information may be contained within internal guidance/reference documents, and specific details are often included in published academic papers and other reports. These may then be assimilated into the broader publications from the ITTC or IEC, etc.

2.3. Recent and Upcoming Guidance for MRE Development

- Part 1:2020 Vocabulary [21] gives an updated terminology for the series.

- Part 2:2019 Marine energy systems—design requirements [14] has also been updated with design conditions unique to marine energy converters.

- Part 3:2019 Measurement of mechanical loads [22] covers this for the purpose of load simulation, model validation, and certification. It also includes guidance on full-scale testing.

- Part 4:2020 Specification for establishing the qualification of new technology [23] has updated the qualification of development.

- Part 30:2018 Electrical power quality requirements [24] covers the definition and specification of the quantities to be determined to characterise the power quality of an MEC and measurement procedures to quantify the characteristics of an MEC.

- Part 103:2018 Guidelines for the early-stage development of wave energy converters—best practices and recommended procedures for the testing of pre-prototype devices [25] describes the minimum model test programmes that form the basis of structured technology development.

3. Materials and Methods

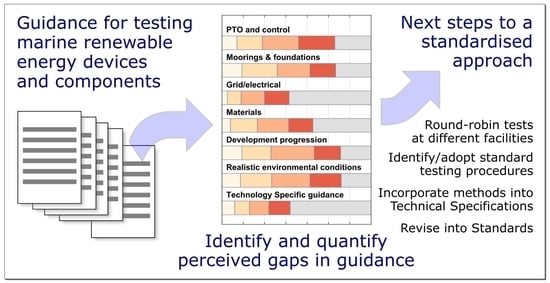

4. Analysis of Gaps in Published Guidance

4.1. Development Progression

4.2. More Realistic Environmental Conditions

4.2.1. Combination of Site Conditions

4.2.2. Impact of Marine Environment on MEC Integrity

4.3. PTO and Control

4.4. Grid/electrical

4.5. Moorings, Foundations, and Mounting Solutions

4.6. Other Gaps in Guidance

4.6.1. Impact of Blockage on Tidal Turbine Tests

4.6.2. Flow Characterisation Techniques

4.6.3. Testing of Floating Offshore Wind Turbines

4.7. Materials

4.7.1. Health and Safety

4.7.2. Uncertainties

5. Results of Survey to Prioritise Gaps Identified in Guidance

6. Pathway to Standardised Approach for MRE Testing

6.1. MaRINET2 Round Robin

6.1.1. Objectives

6.1.2. Testing Procedure and Preliminary Findings

6.2. Development and Adoption of Standards

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EMEC | European Marine Energy Centre |

| ENTSO-E | European Network of Transmission System Operators |

| FOWT | Floating Offshore Wind Turbine |

| IEC | International Electrotechnical Commission |

| ISO | International Standards Organisation |

| ITTC | International Towing Tank Conference |

| MaRINET | Marine Renewables Infrastructure Network |

| MEC | Marine Energy Converter |

| MRE | Marine Renewable Energy |

| ORE | Offshore Renewable Energy |

| O&M | Operation and Maintenance |

| PTO | Power Take-Off |

| QA | Quality Assurance |

| RETL | Renewable Energy Test Laboratories |

| RETB | Renewable Energy Certification Bodies |

| RR | Round Robin |

| TEC | Tidal Energy Converter |

| TNA | Transnational Access |

| TRL | Technology Readiness Level |

| TC | Technical Committee |

| TS | Technical Specification |

| WEC | Wave Energy Converter |

Appendix A

| Report Title | Date | WEC | TEC | OWT | Wind | Wave | Current | Resource | Lab Testing | Field Testing | Test Facilities | Development | Test Programme | Scaling | Scale Models | PTO/Control | Mooring/Support | Electrical/Grid | Component Test | Material Testing | Meas./Instrument. | Data Analysis | Num. Modelling | Environmental | Standards |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| International Electrotechnical Commission (IEC)—Standards and Technical Specifications (key documents only) | |||||||||||||||||||||||||

| IEC TS 62600-2 Design requirements for marine energy systems | 2016 | ∇ | ∇ | ∇ | ⧫ | ⧫ | ∇ | ⧫ | |||||||||||||||||

| IEC TS 62600-103: Guidelines for the early stage development of wave energy converters—Best practices and recommended procedures for the testing of pre-prototype devices | 2016 | ⧫ | ∇ | ⧫ | ⧫ | ∇ | ⧫ | ∇ | ⧫ | ∇ | ∇ | ∇ | ∇ | ∇ | |||||||||||

| IEC TS 62600-202: Scale testing of tidal stream energy systems † | 2022 † | ⧫ | ∇ | ∇ | ⧫ | ⧫ | ⧫ | ⧫ | ∇ | ⧫ | ∇ | ∇ | ∇ | ∇ | ∇ | ||||||||||

| International Towing Tank Conference (ITTC)—Recommended Procedures and Guidelines | |||||||||||||||||||||||||

| (key documents only, for a full list see https://ittc.info/downloads/quality-systems-manual/recommended-procedures-and-guidelines/, accessed on 7 June 2021) | |||||||||||||||||||||||||

| 7.5-02-01-01 Guide to the Expression of Uncertainty in Experimental Hydrodynamics | 2011 | ∇ | ∇ | ∇ | ∇ | ∇ | ⧫ | ★ | ∇ | ||||||||||||||||

| 7.5-02-07-01.1 Laboratory Modelling of Multidirectional Irregular Wave Spectra | 2017 | ⧫ | ∇ | ∇ | ★ | ⧫ | ∇ | ∇ | |||||||||||||||||

| 7.5-02-07-01.2 Laboratory Modelling of Waves: regular, irregular and extreme events | 2017 | ⧫ | ∇ | ∇ | ★ | ∇ | ⧫ | ∇ | |||||||||||||||||

| 7.5-02-07-03.7 Wave Energy Converter, Model Test Experiments | 2017 | ⧫ | ⧫ | ⧫ | ∇ | ∇ | ⧫ | ⧫ | ⧫ | ⧫ | ∇ | ∇ | ∇ | ∇ | |||||||||||

| 7.5-02-07-03.8 Model Tests for Offshore Wind Turbines | 2017 | ⧫ | ⧫ | ⧫ | ∇ | ∇ | ∇ | ⧫ | ∇ | ⧫ | ⧫ | ∇ | ⧫ | ||||||||||||

| 7.5-02-07-03.9 Model Tests for Current Turbines | 2017 | ⧫ | ∇ | ⧫ | ⧫ | ∇ | ∇ | ∇ | ⧫ | ∇ | ⧫ | ∇ | ∇ | ∇ | |||||||||||

| MaRINET2 Project Deliverables (Available at https://www.marinet2.eu/project-reports-2/, accessed on 7 June 2021) | |||||||||||||||||||||||||

| D2.1 Test recommendations and gap analysis report | 2018 | ⧫ | ⧫ | ⧫ | ∇ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ∇ | ∇ | ∇ | ∇ | ⧫ |

| D2.4 Test verification process | 2019 | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ||||||||||||||||

| D2.5 Round Robin findings and recommendations | 2021 † | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ∇ | ∇ | ⧫ | ∇ | ∇ | ∇ | ∇ | ⧫ | ⧫ | ⧫ | ⧫ | ∇ | ∇ | |||

| D2.6 Final guidelines for test applicants † | 2021 † | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ∇ | ∇ | ⧫ | ⧫ | ∇ | ⧫ | ∇ | ∇ | ⧫ | ∇ | ⧫ | ||||

| D2.7 Final guidelines for test facilities † | 2021 † | ⧫ | ⧫ | ⧫ | ∇ | ∇ | ∇ | ⧫ | ⧫ | ⧫ | ⧫ | ∇ | ⧫ | ∇ | ⧫ | ||||||||||

| D4.2 Report on remote access assessment and development | 2019 | ⧫ | ⧫ | ||||||||||||||||||||||

| D4.3 MaRINET2 Standard Testing Procedures manual † | 2021 † | ||||||||||||||||||||||||

| D4.4 Present and future grid connection testing | 2020 | ⧫ | ⧫ | ★ | |||||||||||||||||||||

| D6.4 MaRINET2 e-Infrastructure Pilot | 2019 | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ★ | |||||||||||||||||

| MaRINET 1 Project Deliverables (Available at http://www.marinet2.eu/archive-reports-2/research-reports/, accessed on 7 June 2021) | |||||||||||||||||||||||||

| D2.01 Wave Instrumentation Database | 2012 | ⧫ | ∇ | ∇ | ⧫ | ∇ | ∇ | ⧫ | ⧫ | ||||||||||||||||

| D2.02 Collation of Tidal Test Options | 2012 | ⧫ | ⧫ | ∇ | ⧫ | ∇ | ∇ | ⧫ | |||||||||||||||||

| D2.03 Review of Relevant PTO Systems | 2012 | ⧫ | ⧫ | ⧫ | ★ | ⧫ | |||||||||||||||||||

| D2.04 Collation of Offshore Wind-Wave Dynamics | 2012 | ⧫ | ⧫ | ⧫ | ⧫ | ∇ | |||||||||||||||||||

| D2.05 Report of Instrumentation Best Practice | 2013 | ⧫ | ∇ | ∇ | ⧫ | ∇ | ⧫ | ⧫ | |||||||||||||||||

| D2.06 Report on Offshore Wind System Monitoring Practice and Normalisation Procedures | 2013 | ⧫ | ⧫ | ∇ | ⧫ | ∇ | ⧫ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ||||||||||||

| D2.7 Tidal Measurement Best Practice Manual | 2013 | ⧫ | ∇ | ⧫ | ∇ | ⧫ | ⧫ | ∇ | ∇ | ∇ | ⧫ | ||||||||||||||

| D2.8 Best Practice Manual for Wave Simulation | 2015 | ∇ | ★ | ∇ | ⧫ | ∇ | ⧫ | ⧫ | ⧫ | ∇ | |||||||||||||||

| D2.09 Standards for Wave Data Analysis, Archival & Presentation | 2015 | ⧫ | ∇ | ⧫ | ⧫ | ∇ | |||||||||||||||||||

| D2.10 Best Practice Protocol for Offshore Wind System Fluid-Structure Interaction Testing | 2015 | ⧫ | ⧫ | ∇ | ⧫ | ⧫ | ∇ | ⧫ | ⧫ | ∇ | ⧫ | ⧫ | ∇ | ∇ | |||||||||||

| D2.11 Best Practice Manual for PTO Testing | 2015 | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ⧫ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | |||||||||||

| D2.12 Collation of Wave Simulation Methods | 2014 | ⧫ | ∇ | ★ | ∇ | ∇ | ★ | ∇ | ∇ | ||||||||||||||||

| D2.13 Collation of Model Construction Methods | 2012 | ⧫ | ∇ | ∇ | ⧫ | ∇ | ∇ | ⧫ | ⧫ | ⧫ | ∇ | ∇ | ∇ | ||||||||||||

| D2.14 Wave Data Presentation & Storage Review | 2012 | ⧫ | ∇ | ⧫ | ⧫ | ∇ | ⧫ | ∇ | |||||||||||||||||

| D2.16 Tidal Test Parameter Overview | 2013 | ∇ | ∇ | ∇ | ∇ | ||||||||||||||||||||

| D2.18 Tidal Data Analysis Best Practice | 2012 | ⧫ | ⧫ | ⧫ | ∇ | ∇ | ∇ | ∇ | ∇ | ||||||||||||||||

| D2.19 Generation of a set of typical dynamic load regimes for common conversion devices | 2012 | ∇ | ⧫ | ∇ | ∇ | ∇ | |||||||||||||||||||

| D2.20 Report on Physical Modelling Methods for Floating Wind Turbines | 2015 | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ⧫ | ∇ | |||||||||||||||||

| D2.21 Review of Mooring Testing Systems | 2014 | ∇ | ∇ | ∇ | ⧫ | ∇ | ∇ | ||||||||||||||||||

| D2.23 Review of Tow Tank Limitations | 2014 | ∇ | ∇ | ⧫ | ⧫ | ⧫ | |||||||||||||||||||

| D2.25 Review Best Practice Standard for Electrical PTO Systems | 2014 | ∇ | ∇ | ∇ | ⧫ | ⧫ | ∇ | ⧫ | ∇ | ∇ | ∇ | ∇ | ★ | ||||||||||||

| D2.26 Collation of European grid codes | 2013 | ∇ | ★ | ★ | |||||||||||||||||||||

| D2.28 Protocol for Model Construction | 2015 | ⧫ | ⧫ | ⧫ | ⧫ | ∇ | ∇ | ⧫ | ⧫ | ∇ | ⧫ | ||||||||||||||

| D2.29 Report on Comparative Testing of Tidal Devices | 2015 | ⧫ | ∇ | ∇ | ∇ | ∇ | |||||||||||||||||||

| D4.01 Tank test related instrumentation & best practice | 2014 | ⧫ | ⧫ | ⧫ | ∇ | ⧫ | ★ | ||||||||||||||||||

| D4.02 Report on dynamic test procedures | 2014 | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ⧫ | ⧫ | ∇ | ∇ | ⧫ | ⧫ | ∇ | ⧫ | ∇ | ⧫ | ★ | ||||||

| D4.03 Report on grid integration & power quality testing | 2014 | ∇ | ∇ | ∇ | ∇ | ∇ | |||||||||||||||||||

| D4.04 Report on low frequency response and moorings | 2014 | ∇ | ∇ | ∇ | ∇ | ★ | ∇ | ||||||||||||||||||

| D4.05 Report on non-intrusive wave field measurement | 2014 | ⧫ | ∇ | ∇ | ★ | ||||||||||||||||||||

| D4.06 Data reports and data bases on coastal & offshore wind measurements | 2014 | ∇ | ⧫ | ∇ | ∇ | ⧫ | |||||||||||||||||||

| D4.07 Best Practice Report on Environmental Monitoring & New Study Techniques | 2014 | ∇ | ∇ | ∇ | ⧫ | ★ | |||||||||||||||||||

| D4.08 Database for environmental monitoring techniques & equipment | 2013 | ∇ | ∇ | ⧫ | |||||||||||||||||||||

| D4.09 Report on remote underwater motion measurement | 2015 | ∇ | ⧫ | ⧫ | ⧫ | ∇ | |||||||||||||||||||

| D4.10 Report on Real Time Estimation of Incident Waves | 2015 | ∇ | ⧫ | ∇ | ⧫ | ||||||||||||||||||||

| D4.11 Report on new instrumentation and field measuring technology for tidal currents | 2015 | ∇ | ⧫ | ∇ | ⧫ | ∇ | ⧫ | ∇ | ∇ | ||||||||||||||||

| D4.12 Report on design and accuracy of the sensor and SHM-system | 2015 | ∇ | ⧫ | ∇ | ⧫ | ⧫ | ∇ | ⧫ | ∇ | ||||||||||||||||

| D4.13 Report on field test buoy research | 2015 | ∇ | ∇ | ∇ | ∇ | ⧫ | ⧫ | ∇ | |||||||||||||||||

| D4.14 Report on demand side grid compatibility | 2014 | ★ | ⧫ | ||||||||||||||||||||||

| D4.15 Report on numerical methods for PTO systems | 2014 | ∇ | ∇ | ∇ | ⧫ | ⧫ | ∇ | ∇ | ∇ | ★ | |||||||||||||||

| D4.16 Report on options for full-scale wind resource surveying | 2014 | ∇ | ∇ | ∇ | ∇ | ★ | |||||||||||||||||||

| D4.17 Report on environmental monitoring protocols | 2014 | ∇ | ∇ | ★ | ∇ | ||||||||||||||||||||

| Equimar Project Deliverables | |||||||||||||||||||||||||

| (deliverables relevant to testing only, for a full summary see http://www.equimar.org/equimar-project-deliverables.html, accessed on 7 June 2021) | |||||||||||||||||||||||||

| D1.1 Global analysis of pre-normative research activities for marine energy | 2009 | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ⧫ | ||||||||||||||

| D1.2 Recommendations from other sectors | 2009 | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ||||||||||||||||

| D2.2 Wave and Tidal Resource Characterisation | 2011 | ★ | ∇ | ⧫ | ⧫ | ∇ | |||||||||||||||||||

| D2.3 Application of Numerical Models | 2010 | ⧫ | ∇ | ⧫ | ★ | ||||||||||||||||||||

| D2.4 Wave Model Intercomparison | 2011 | ∇ | ⧫ | ⧫ | |||||||||||||||||||||

| D2.6 Extremes and Long Term Extrapolation | 2011 | ∇ | ⧫ | ∇ | |||||||||||||||||||||

| D2.7 Resource Assessment Protocol | 2010 | ∇ | ∇ | ⧫ | ∇ | ∇ | ∇ | ||||||||||||||||||

| D3.1 Identification of Limitations of the Current Practices Adopted for Early Stage Tidal and Wave Device Assessment | 2009 | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ||||||||||||||||

| D3.2 Concept Appraisal and Tank Testing Practices for 1st Stage Prototype Devices | 2009 | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ||||||||||||||||||

| D3.3 Assessment of current practice for tank testing of small marine energy devices | 2010 | ∇ | ∇ | ∇ | ∇ | ⧫ | ∇ | ∇ | ∇ | ⧫ | ∇ | ||||||||||||||

| D3.4 Best practice for tank testing of small marine energy devices | 2010 | ∇ | ∇ | ⧫ | ∇ | ⧫ | |||||||||||||||||||

| D4.2 Data Analysis and Presentation To Quantify Uncertainty | 2010 | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | |||||||||||||||

| D4.3 Test Sites Catalogue | 2011 | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ★ | |||||||||||||||||

| D5.1 Guidance protocols on choosing of electrical connection configurations | 2009 | ∇ | ∇ | ★ | ∇ | ||||||||||||||||||||

| D5.2 Device classification template | 2010 | ⧫ | ⧫ | ⧫ | ⧫ | ||||||||||||||||||||

| D5.3 Protocols and guidance for device specification and quantification of performance | 2010 | ∇ | ∇ | ∇ | ∇ | ∇ | |||||||||||||||||||

| European Marine Energy Centre (EMEC) draft standards and guides for wave and tidal energy. | |||||||||||||||||||||||||

| (see http://www.emec.org.uk/standards/, accessed on 7 June 2021) Six of these were submitted for IEC TC 114, marked *. | |||||||||||||||||||||||||

| 1. Assessment of Performance of Wave Energy Conversion Systems * | 2009 | ∇ | ⧫ | ∇ | ∇ | ⧫ | ⧫ | ⧫ | |||||||||||||||||

| 2. Assessment of Performance of Tidal Energy Conversion Systems * | 2009 | ∇ | ∇ | ⧫ | ∇ | ⧫ | ∇ | ⧫ | ⧫ | ||||||||||||||||

| 3. Assessment of Wave Energy Resource * | 2009 | ⧫ | ★ | ⧫ | ⧫ | ⧫ | |||||||||||||||||||

| 4. Assessment of Tidal Energy Resource * | 2009 | ⧫ | ★ | ⧫ | ⧫ | ⧫ | ∇ | ||||||||||||||||||

| 5. Guidelines for Health & Safety in the Marine Energy Industry | 2009 | ∇ | ∇ | ∇ | ∇ | ||||||||||||||||||||

| 6. Guidelines for Marine Energy Certification Schemes * | 2009 | ∇ | ∇ | ∇ | |||||||||||||||||||||

| 7. Guidelines for Design Basis of Marine Energy Conversion Systems * | 2009 | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ⧫ | |||||||||||||

| 8. Guidelines for Reliability, Maintainability and Survivability of Marine Energy Conversion Systems | 2009 | ∇ | ∇ | ||||||||||||||||||||||

| 9. Guidelines for Grid Connection of Marine Energy Conversion Systems | 2009 | ★ | ⧫ | ||||||||||||||||||||||

| 10. Tank Testing of Wave Energy Conversion Systems | 2009 | ∇ | ⧫ | ⧫ | ⧫ | ∇ | ∇ | ∇ | ∇ | ∇ | ∇ | ⧫ | ∇ | ||||||||||||

| 11. Guidelines for Project Development in the Marine Energy Industry | 2009 | ⧫ | ⧫ | ∇ | ∇ | ||||||||||||||||||||

| 12. Guidelines for Manufacturing, Assembly and Testing of Marine Energy Conversion Systems | 2009 | ∇ | |||||||||||||||||||||||

| Other guidance | |||||||||||||||||||||||||

| UEDIN Best Practice Guidelines for Tank Testing of Wave Energy Converters | 2010 | ∇ | ∇ | ⧫ | ∇ | ∇ | ∇ | ∇ | |||||||||||||||||

| OES–IA Guidelines for the development & testing of wave energy systems | 2010 | ⧫ | ⧫ | ⧫ | ⧫ | ∇ | ★ | ⧫ | ⧫ | ||||||||||||||||

| SuperGen Marine Guidance for Numerical Modelling in Wave and Tidal Energy | 2010 | ∇ | ∇ | ∇ | ⧫ | ||||||||||||||||||||

| 1 | Wave Energy Scotland programmes https://www.waveenergyscotland.co.uk/programmes/, accessed on 14 June 2021. |

| 2 | Testing Expertise and Access for Marine Energy Research https://teamer-us.org/, accessed on 4 March 2021. |

| 3 | Register of ITTC guidelines available at https://www.ittc.info/downloads/quality-systems-manual/recommended-procedures-and-guidelines/, accessed on 6 July 2021. |

References

- Noble, D.R.; Draycott, S.; Ordonez Sanchez, S.; Porter, K.; Johnstone, C.; Finch, S.; Judge, F.; Desmond, C.; Santos Varela, B.; Mendia, J.L.; et al. D2.1 Test Recommendations and Gap Analysis Report. Technical Report. MaRINET2 Consortium, 2018. Available online: https://www.marinet2.eu/project-reports-2/ (accessed on 7 June 2021).

- Hodges, J.; Henderson, J.; Ruedy, L.; Soede, M.; Weber, J.; Ruiz-Minguela, P.; Jeffrey, H.; Bannon, E.; Holland, M.; Maciver, R.; et al. An International Evaluation and Guidance Framework for Ocean Energy Technology; Technical Report; IEA-OES: Lisbon, Portugal, 2021; Available online: https://www.ocean-energy-systems.org/publications/oes-documents/ (accessed on 4 March 2021).

- ARENA. Commercial Readiness Index for Renewable Energy Sectors; Technical Report; Australian Renewable Energy Agency: Canberra, Australia, 2014. Available online: https://arena.gov.au/assets/2014/02/Commercial-Readiness-Index.pdf (accessed on 9 August 2021).

- Weber, J. WEC Technology Readiness and Performance Matrix—Finding the Best Research Technology Development Trajectory. In Proceedings of the International Conference on Ocean Energy, Dublin, Ireland, 17–19 October 2012. [Google Scholar]

- Noble, D.R.; Draycott, S.; Davey, T.A.D.; Bruce, T. Testing marine renewable energy devices in an advanced multi-directional combined wave-current environment. In Proceedings of the ASME 36th International Conference on Ocean, Offshore and Arctic Engineering (OMAE2017), Trondheim, Norway, 25–30 June 2017; ASME: Trondheim, Norway, 2017; Volume 7B, p. V07BT06A020. [Google Scholar] [CrossRef]

- Bahaj, A.S.; Blunden, L.; Anwar, A.A. Tidal-current Energy Device Development and Evaluation Protocol; Technical Report; University of Southampton: Southhampton, UK, 2008. [Google Scholar]

- Holmes, B. Tank Testing of Wave Energy Conversion Systems; Technical Report; BSI: London, UK, 2009. [Google Scholar]

- Holmes, B.; Nielsen, K. Guidelines for the Development and Testing of Wave Energy Systems; Technical Report; Hydraulics Maritime Research Centre, UCC: Cork, Ireland, 2010. [Google Scholar]

- Driscoll, F.; Mauer, E.; Rieks, J. 2017 Marine Hydrokinetic Instrumentation Workshop Report, Technical Report NREL/TP-5000-70591. Available online: https://www.osti.gov/biblio/1425575-marine-hydrokinetic-instrumentation-workshop-report (accessed on 4 March 2021).

- ORE Catapult; EMEC. Review of Standards/Guidelines for Marine Renewables (Wave & Tide); Technical Report July; ORE Catapult: Blyth, UK, 2014. Available online: https://tethys-engineering.pnnl.gov/sites/default/files/publications/ore2014.pdf (accessed on 22 May 2017).

- IEC. TC 114 Marine Energy—Wave, Tidal and Other Water Current Converters. Available online: https://www.iec.ch/dyn/www/f?p=103:7:710392897852646::::FSP_ORG_ID,FSP_LANG_ID:1316,25 (accessed on 7 June 2021).

- Ingram, D.M.; Smith, G.H.; Bittencourt-Ferreira, C.; Smith, H.C.M. Protocols for the Equitable Assessment of Marine Energy Converters; Technical Report; EquiMar Consortium: Edinburgh, UK, 2011. [Google Scholar]

- ITTC. Recommended Procedures and Guidelines: Analysis Procedure for Model Tests in Regular Waves 7.5-02-07-03.2; Procedure; ITTC: Zürich, Switzerland, 2017. [Google Scholar]

- IEC. Marine Energy—Wave, Tidal and Other Water Current Converters—Part 2: Design Requirements for Marine Energy Systems; Technical Specification IEC TS 62600-2; International Electrotechnical Commission: Geneva, Switzerland, 2016. [Google Scholar]

- Judge, F. D2.26 Final Guidelines for Test Applicants. Manuscript in Preparation. Technical Report. MaRINET2 Consortium, 2021. Available online: https://www.marinet2.eu/project-reports-2/ (accessed on 7 June 2021).

- Corlay, Y.; Vejayan, N.; le Boulluec, M.; Germain, G.; Martinez, R.; Ordonez, S.; Lopez, J.; Robles, E.; Candido, J.; Battensby, J.; et al. D2.7 Final Guidelines for Test Facilities. Technical Report. MaRINET2 Consortium, 2021. Available online: https://www.marinet2.eu/project-reports-2/ (accessed on 7 June 2021).

- Griffiths, J.; Brooker, R. D2.4 Test Verification Process. Technical Report. MaRINET2 Consortium, 2019. Available online: https://www.marinet2.eu/project-reports-2/ (accessed on 7 June 2021).

- Faÿ, F.X.; Robles, E.; Murray, D. D4.2 Report on Remote Access Assessment and Development. Technical Report. MaRINET2 Consortium, 2019. Available online: https://www.marinet2.eu/project-reports-2/ (accessed on 7 June 2021).

- Robles, E.; Nava, V.; Touzón, I.; Santos, M.; Murray, D.; Kelly, J.; Young, D.; Holdyk, A. D4.4: Present and Future Grid Connection Testing. Technical Report. MaRINET2 Consortium, 2020. Available online: https://www.marinet2.eu/project-reports-2/ (accessed on 7 June 2021).

- Martinez, R.; Khalid, F.; O’Hana, J.; Le Boullec, M.; Salcedo Fernandez, F.; Robles Sestafe, E. MaRINET2—D4.3: Standard Testing Procedures. Technical Report. MaRINET2 Consortium, 2021. Available online: https://www.marinet2.eu/project-reports-2/ (accessed on 7 June 2021).

- IEC. Marine Energy—Wave, Tidal and Other Water Current Converters—Part 1: Vocabulary; Technical Specification IEC TS 62600-1; International Electrotechnical Commission: Geneva, Switzerland, 2020. [Google Scholar]

- IEC. Marine Energy—Wave, Tidal and Other Water Current Converters—Part 3: Measurement of Mechanical Loads; Technical Specification IEC TS 62600-3; International Electrotechnical Commission: Geneva, Switzerland, 2020. [Google Scholar]

- IEC. Marine Energy—Wave, Tidal and Other Water Current Converters—Part 4: Specification for Establishing Qualification of New Technology; Technical Specification IEC TS 62600-4; International Electrotechnical Commission: Geneva, Switzerland, 2020. [Google Scholar]

- IEC. Marine energy—Wave, Tidal and Other Water Current Converters—Part 30: Electrical Power Quality Requirements; Technical Specification IEC TS 62600-30; International Electrotechnical Commission: Geneva, Switzerland, 2018. [Google Scholar]

- IEC. Marine Energy—Wave, Tidal and Other Water Current Converters—Part 103: Guidelines for the Early Stage Development of Wave Energy Converters: Best Practices and Recommended Procedures for the Testing of Pre-Prototype Scale Devices; Technical Specification IEC TS 62600-103; International Electrotechnical Commission: Geneva, Switzerland, 2018. [Google Scholar]

- MET-CERTIFIED Development of International Standards and Certification Schemes for Marine Energy Technologies. Available online: http://met-certified.eu/ (accessed on 9 June 2021).

- Gujer, P.; Matthias, K. D7.1 Review of FOWT Guidelines and Design Practice. Technical Report. 2015. Available online: https://lifes50plus.eu/results/ (accessed on 9 June 2021).

- IEC. Wind Energy Generation Systems—Part 3-2: Design Requirements for Floating Offshore Wind Turbines; Technical Specification IEC TS 61400-3-2; International Electrotechnical Commission: Geneva, Switzerland, 2019. [Google Scholar]

- Thys, M.; Fontanella, A.; Taruffi, F.; Manjock, A.; Belloli, M. D7.9 Guidance and Recommended Methods for Hybrid/HIL-Based FOWT Experimental Testing. Technical Report. 2019. Available online: https://lifes50plus.eu/results/ (accessed on 9 June 2021).

- ITTC. Specialist Committee on Modelling of Environmental Conditions. Final Report and Recommendations to the 29th ITTC. In Proceedings of the 29th International Towing Tank Conference, Virtual. 13–18 June 2021. [Google Scholar]

- ITTC. The Specialist Committee on Hydrodynamic Modelling of Marine Renewable Energy Devices. Final Report and Recommendations to the 29th ITTC. In Proceedings of the 29th International Towing Tank Conference, Virtual. 13–18 June 2021. [Google Scholar]

- Villate, J.; Ruiz-Minguela, P.; Berque, J.; Pirttimaa, L.; Cagney, D.; Cochrane, C.; Jeffrey, H. Strategic Research and Innovation Agenda for Ocean Energy; Technical Report; Ocean Energy Europe: Brussels, Belgium, 2020; Available online: https://oceanenergy-europe.eu/wp-content/uploads/2020/05/ETIP-Ocean-SRIA.pdf (accessed on 28 October 2020).

- IEC. Marine Energy—Wave, Tidal and Other Water Current Converters—Part 202: Scale Testing of Tidal Stream Energy Systems. Manuscript in Preparation; Draft Technical Specification; International Electrotechnical Commission: Geneva, Switzerland, 2020. [Google Scholar]

- Draycott, S.; Sellar, B.G.; Davey, T.A.D.; Noble, D.R.; Venugopal, V.; Ingram, D.M. Capture and simulation of the ocean environment for offshore renewable energy. Renew. Sustain. Energy Rev. 2019, 104, 15–29. [Google Scholar] [CrossRef]

- Draycott, S.; Davey, T.A.D.; Ingram, D.M.; Lawrence, J.; Day, A.H.; Johanning, L. Applying Site-Specific Resource Assessment: Emulation of Representative EMEC seas in the FloWave Facility. In Proceedings of the Twenty-Fifth International Ocean and Polar Engineering Conference (ISOPE2015), Big Island, HI, USA, 21–26 June 2015; pp. 815–821. [Google Scholar]

- Venugopal, V.; Davey, T.A.D.; Smith, H.C.M.; Smith, G.H.; Holmes, B.; Barret, S.; Prevosto, M.; Maisondieu, C.; Cavaleri, L.; Bertotti, L.; et al. D2.2 Wave and Tidal Resource Characterisation. Technical Report. 2011. Available online: https://www.equimar.org/equimar-project-deliverables.html (accessed on 25 April 2014).

- Venugopal, V.; Davey, T.A.D.; Smith, H.; Smith, G.; Cavaleri, L.; Bertotti, L.; Lawrence, J. D2.3 Application of Numerical Models. Technical Report. 2010. Available online: https://www.equimar.org/equimar-project-deliverables.html (accessed on 28 November 2016).

- Draycott, S.; Noble, D.; Davey, T.A.D.; Bruce, T.; Ingram, D.; Johanning, L.; Smith, H.; Day, A.H.; Kaklis, P. Re-creation of site-specific multi-directional waves with non-collinear current. Ocean. Eng. 2017, 152, 391–403. [Google Scholar] [CrossRef]

- Pillai, A.C.; Davey, T.; Draycott, S. A framework for processing wave buoy measurements in the presence of current. Appl. Ocean Res. 2021, 106, 102420. [Google Scholar] [CrossRef]

- IEC. Marine energy—Wave, Tidal and Other Water Current Converters—Part 101: Wave Energy Resource Assessment and Characterization; Technical Specification IEC TS 62600-101; International Electrotechnical Commission: Geneva, Switzerland, 2005. [Google Scholar]

- IEC. Marine energy—Wave, Tidal and Other Water Current Converters—Part 102: Wave Energy Converter Power Performance Assessment at a Second Location Using Measured Assessment Data; Technical Specification IEC TS 62600-102; International Electrotechnical Commission: Geneva, Switzerland, 2016. [Google Scholar]

- IEC. Marine Energy—Wave, Tidal and Other Water Current Converters—Part 201: Tidal Energy Resource Assessment and Characterization; Technical Specification IEC TS 62600-201; International Electrotechnical Commission: Geneva, Switzerland, 2015. [Google Scholar]

- IEC. Marine energy—Wave, Tidal and Other Water Current Converters—Part 10: The Assessment of Mooring System for Marine Energy Converters (MECs); Technical Specification IEC TS 62600-10; International Electrotechnical Commission: Geneva, Switzerland, 2015. [Google Scholar]

- Ekström, R.; Leijon, M. Control of offshore marine substation for grid-connection of a wave power farm. Int. J. Mar. Energy 2014, 5, 24–37. [Google Scholar] [CrossRef] [Green Version]

- Endegnanew, A.G.; D’Arco, S.; Torres-Olguin, R.E.; Marvik, J.I.; Tedeschi, E. D2.26 Collation of European Grid Codes. Technical Report. MaRINET, 2013. Available online: https://www.marinet2.eu/archive-reports-2/research-reports/ (accessed on 1 September 2021).

- Robles, E.; Haro-Larrode, M.; Santos-Mugica, M.; Etxegarai, A.; Tedeschi, E. Comparative analysis of European grid codes relevant to offshore renewable energy installations. Renew. Sustain. Energy Rev. 2019, 102, 171–185. [Google Scholar] [CrossRef]

- IEC. Wind Turbines—Part 21: Measurement and Assessment of Power Quality Characteristics of Grid Connected Wind Turbines; International Standard IEC 61400-21; International Electrotechnical Commission: Geneva, Switzerland, 2008. [Google Scholar]

- Harnois, V.; Weller, S.D.; Johanning, L.; Thies, P.R.; Le Boulluec, M.; Le Roux, D.; Soule, V.; Ohana, J. Numerical model validation for mooring systems: Method and application for wave energy converters. Renew. Energy 2015, 75, 869–887. [Google Scholar] [CrossRef] [Green Version]

- Spearman, D.K.; Strivens, S. Floating Wind Joint Industry Project: Phase 2 Summary Report. Technical Report. 2020. Available online: https://www.carbontrust.com/resources/floating-wind-joint-industry-project-phase-2-summary-report (accessed on 1 September 2021).

- Yang, S.H.; Ringsberg, J.W.; Johnson, E.; Hu, Z. Biofouling on mooring lines and power cables used in wave energy converter systems—Analysis of fatigue life and energy performance. Appl. Ocean Res. 2017, 65, 166–177. [Google Scholar] [CrossRef] [Green Version]

- Khalid, F.; Arini, N.R.; Johanning, L. Deliverable D2.4: Recommendations for WEC Mooring Guidelines and Standards. Technical Report. OPERA Consortium, 2019. Available online: http://opera-h2020.eu/ (accessed on 1 September 2021).

- Gaurier, B.; Germain, G.; Facq, J.V.; Johnstone, C.M.; Grant, A.D.; Day, A.H.; Nixon, E.; Di Felice, F.; Costanzo, M. Tidal Energy “Round Robin” Tests Comparisons between towing tank and circulating tank results. Int. J. Mar. Energy 2015, 12, 87–109. [Google Scholar] [CrossRef] [Green Version]

- Gaurier, B.; Ordonez-Sanchez, S.; Facq, J.V.; Germain, G.; Johnstone, C.; Martinez, R.; Salvatore, F.; Santic, I.; Davey, T.; Old, C.; et al. MaRINET2 Tidal Energy Round Robin Tests—Performance Comparison of a Horizontal Axis Turbine Subjected to Combined Wave and Current Conditions. J. Mar. Sci. Eng. 2020, 8, 463. [Google Scholar] [CrossRef]

- Bahaj, A.S.; Molland, A.F.; Chaplin, J.R.; Batten, W.M.J. Power and thrust measurements of marine current turbines under various hydrodynamic flow conditions in a cavitation tunnel and a towing tank. Renew. Energy 2007, 32, 407–426. [Google Scholar] [CrossRef]

- Martinez, R.; Payne, G.S.; Bruce, T. The effects of oblique waves and currents on the loadings and performance of tidal turbines. Ocean Eng. 2018, 164, 55–64. [Google Scholar] [CrossRef]

- Jourdain de Thieulloy, M.; Dorward, M.; Old, C.; Gabl, R.; Davey, T.; Ingram, D.M.; Sellar, B.G. On the Use of a Single Beam Acoustic Current Profiler for Multi-Point Velocity Measurement in a Wave and Current Basin. Sensors 2020, 20, 3881. [Google Scholar] [CrossRef] [PubMed]

- Blackmore, T.; Myers, L.E.; Bahaj, A.S. Effects of turbulence on tidal turbines: Implications to performance, blade loads, and condition monitoring. Int. J. Mar. Energy 2016, 14, 1–26. [Google Scholar] [CrossRef] [Green Version]

- Medici, D.; Ivanell, S.; Dahlberg, J.; Alfredsson, P.H. The upstream fl ow of a wind turbine: Blockage effect. Wind Energy 2011, 14, 691–697. [Google Scholar] [CrossRef]

- Simley, E.; Pao, L.Y.; Gebraad, P.; Churchfield, M. Investigation of the impact of the upstream induction zone on LIDAR measurement accuracy for wind turbine control applications using large-eddy simulation. J. Phys. Conf. Ser. 2014, 524, 012003. [Google Scholar] [CrossRef] [Green Version]

- Judge, F. D2.5 Round Robin Findings and Recommendations. Manuscript in Preparation. Technical Report. MaRINET2 Consortium, 2021. Available online: https://www.marinet2.eu/project-reports-2/ (accessed on 7 June 2021).

- Otter, A.; Murphy, J.; Desmond, C. Emulating aerodynamic forces and moments for hybrid testing of floating wind turbine models. J. Phys. Conf. Ser. 2020, 1618, 032022. [Google Scholar] [CrossRef]

- Lloyd’s Register. Rules for the Manufacture, Testing and Certification of Materials; Technical Report; Lloyd’s Register Group: London, UK, 2020; Available online: https://www.lr.org/en-gb/rules-for-the-manufacture-testing-and-certification-of-materials/ (accessed on 8 June 2021).

- ISO. ISO 45001 Occupational Health and Safety Management Systems—Requirements with Guidance for Use. International Standard. Available online: https://www.iso.org/standard/63787.html (accessed on 1 September 2021).

- RenewableUK. Offshore Wind and Marine Energy Health and Safety Guidelines. Technical Report. 2014. Available online: https://www.renewableuk.com/page/HealthSafety (accessed on 8 June 2021).

- RenewableUK. Wave and Tidal Health and Safety Guide: Principles and Practice. Technical Report. 2014. Available online: https://www.renewableuk.com/page/HealthSafety (accessed on 8 June 2021).

- IEC. Marine Energy—Wave, Tidal and Other Water Current Converters—Part 200: Electricity Producing Tidal Energy Converters—Power Performance Assessment; Technical Specification IEC TS 62600-200; International Electrotechnical Commission: Geneva, Switzerland, 2013. [Google Scholar]

- IEC. Marine Energy—Wave, Tidal and Other Water Current Converters—Part 100: Electricity Producing Wave Energy Converters—Power Performance Assessment; Technical Specification IEC TS 62600-100; International Electrotechnical Commission: Geneva, Switzerland, 2012. [Google Scholar]

- IEC. Wind Energy Generation Systems—Part 12-1: Power Performance Measurements of Electricity Producing Wind Turbines; International Standard IEC 61400-12-1; International Electrotechnical Commission: Geneva, Switzerland, 2017. [Google Scholar]

- Judge, F.M.; Lyden, E.; O’Shea, M.; Flannery, B.; Murphy, J. Uncertainty in Wave Basin Testing of a Fixed Oscillating Water Column Wave Energy Converter. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part B 2021. [Google Scholar] [CrossRef]

- Robertson, A.N.; Bachynski, E.E.; Gueydon, S.; Wendt, F.; Schünemann, P.; Jonkman, J. Assessment of experimental uncertainty for a floating wind semisubmersible under hydrodynamic loading. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Madrid, Spain, 17–22 June 2018; American Society of Mechanical Engineers: New York, NY, USA, 2018; Volume 51319, p. V010T09A076. [Google Scholar]

- Martinez, R.; Gaurier, B.; Ordonez-Sanchez, S.; Facq, J.V.; Germain, G.; Johnstone, C.; Salvatore, F.; Santic, I.; Davey, T.; Old, C.; et al. Tidal Energy Round Robin Tests: A comparison of flow measurements and turbine loading. J. Mar. Sci. Eng. 2021, 9, 425. [Google Scholar] [CrossRef]

- Ohana, J.; Gueydon, S.; Judge, F.; Haquin, S.; Weber, M.; Lyden, E.; Thiebaut, F.; O’Shea, M.; Murphy, J.; Davey, T.; et al. Round robin tests on a hinged raft wave energy converter. J. Mar. Sci. Eng. 2021, 9, 946. [Google Scholar]

- Khalid, F.; Davies, P.; Halswell, P.; Lacotte, N.; Thies, P.R.; Johanning, L. Evaluating Mooring Line Test Procedures through the Application of a Round Robin Test Approach. J. Mar. Sci. Eng. 2020, 8, 436. [Google Scholar] [CrossRef]

- ISO. Fibre Ropes for Offshore Stationkeeping—Part 2: Polyester; International Standard IEC 18692-2; International Organization for Standardization: Geneva, Switzerland, 2019. [Google Scholar]

| Stage | TRL | Nominal Test Scale * | Typical Infrastructure |

|---|---|---|---|

| 1. Concept development | 1–3 | Small scale (circa 1:50) | Small university laboratory |

| 2. Design optimisation | 3–5 | Larger scale (circa 1:25–1:10) | Industrial scale laboratory |

| 3. Scaled demonstration | 5–6 | Sub-prototype size (circa 1:4) | Benign test site |

| 4. Commercial-scale single device demonstration | 7–8 | Approaching full size (circa 1:1) | Exposed test site |

| 5. Commercial-scale array demonstration | 9 | Full size, small arrays | Commercial site |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noble, D.R.; O’Shea, M.; Judge, F.; Robles, E.; Martinez, R.; Khalid, F.; Thies, P.R.; Johanning, L.; Corlay, Y.; Gabl, R.; et al. Standardising Marine Renewable Energy Testing: Gap Analysis and Recommendations for Development of Standards. J. Mar. Sci. Eng. 2021, 9, 971. https://0-doi-org.brum.beds.ac.uk/10.3390/jmse9090971

Noble DR, O’Shea M, Judge F, Robles E, Martinez R, Khalid F, Thies PR, Johanning L, Corlay Y, Gabl R, et al. Standardising Marine Renewable Energy Testing: Gap Analysis and Recommendations for Development of Standards. Journal of Marine Science and Engineering. 2021; 9(9):971. https://0-doi-org.brum.beds.ac.uk/10.3390/jmse9090971

Chicago/Turabian StyleNoble, Donald R., Michael O’Shea, Frances Judge, Eider Robles, Rodrigo Martinez, Faryal Khalid, Philipp R. Thies, Lars Johanning, Yann Corlay, Roman Gabl, and et al. 2021. "Standardising Marine Renewable Energy Testing: Gap Analysis and Recommendations for Development of Standards" Journal of Marine Science and Engineering 9, no. 9: 971. https://0-doi-org.brum.beds.ac.uk/10.3390/jmse9090971