Water-Based Lubricants: Development, Properties, and Performances

Abstract

:1. Introduction

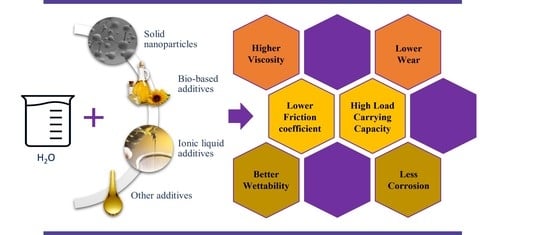

2. Development of Water-Based Lubricants with Different Additives

2.1. Water-Based Lubricants with Ionic Liquids Additives

2.2. Water-Based Lubricants with Bio-Derived Additives

2.3. Water-Based Lubricants with Solid Nanoparticles

2.4. Other Water-Based Lubricant Additives

3. Properties of Water-Based Lubricants

3.1. Viscosity

- Cavity formation

- Decreasing friction

- Film thickness

- Thermal behavior

3.2. Density

3.3. Wettability

3.4. Solubility and Other Properties

4. Performance of Water-Based Lubricants

4.1. Friction and Wear Reduction

4.2. Corrosion Reduction

5. Recent Advancement and Challenges of Water-Based Lubricants

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Scharf, T.; Prasad, S. Solid lubricants: A review. J. Mater. Sci. 2013, 48, 511–531. [Google Scholar] [CrossRef]

- Menezes, P.L.; Ingole, S.P.; Nosonovsky, M.; Kailas, S.V.; Lovell, M.R. Tribology for Scientists and Engineers; Springer: New York, NY, USA, 2013. [Google Scholar]

- Bart, J.; Gucciardi, E.; Cavallaro, S. Advanced lubricant fluids. In Biolubricants: Science and Technology; Woodhead Publishing Ltd.: Cambridge, UK, 2013; pp. 824–846. [Google Scholar]

- Panja, S.K. Tribological Properties of Ionic Liquids. In Tribology; IntechOpen: London, UK, 2020. [Google Scholar]

- Cai, M.; Yu, Q.; Liu, W.; Zhou, F. Ionic liquid lubricants: When chemistry meets tribology. Chem. Soc. Rev. 2020. [Google Scholar] [CrossRef]

- Fitch, J. The History of Lubrication. Available online: https://www.machinerylubrication.com/Read/579/lubrication-genesis (accessed on 7 April 2021).

- Ritchie, H. How Long before We Run Out of Fossil Fuels? Available online: https://ourworldindata.org/how-long-before-we-run-out-of-fossil-fuels (accessed on 7 April 2021).

- Wei, C.; Tobias, A.; Andreas, K.; Jurgen, R. Macroscopic Friction Studies of Alkylglucopyranosides as Additives for Water-Based Lubricants. Lubricants 2020, 8, 11. [Google Scholar] [CrossRef] [Green Version]

- Tomala, A.; Karpinska, A.; Werner, W.S.M.; Olver, A.; Stori, H. Tribological Properties of Additives for Water-Based Lubricants. Wear 2010, 296, 804–810. [Google Scholar] [CrossRef]

- Sagraloff, N.; Dobler, A.; Tobie, T.; Stahl, K.; Ostrowski, J. Development of an Oil Free Water-Based Lubricant for Gear Applications. Lubricants 2019, 7, 33. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Guo, Y.; Wang, D. PEI-RGO Nanosheets as a Nano-Additive for Enhancing the Tribological Properties of Water-Based Lubricants. Tribol. Int. 2019, 140. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, J.; Xia, W.; Cheng, X.; He, A.; Yun, J.H.; Wang, L.; Huang, H.; Jiao, S.; Huang, L.; et al. A study of the tribological behaviour of TiO2 nano-additive water-based lubricants. Tribol. Int. 2017, 109, 398–408. [Google Scholar] [CrossRef] [Green Version]

- Wu, H.; Jia, F.; Li, Z.; Lin, F.; Huo, M.; Huang, S.; Sayyar, S.; Jiao, S.; Huang, H.; Jiang, Z. Novel water-based nanolubricant with superior tribological performance in hot steel rolling. Int. J. Extrem. Manuf. 2020, 2. [Google Scholar] [CrossRef]

- Del Sol, I.; Gámez, A.; Rivero, A.; Iglesias, P. Tribological performance of ionic liquids as additives of water-based cutting fluids. Wear 2019, 426, 845–852. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y.; Liu, W.; Liu, Y.; Wang, K.; Li, J.; Ma, T.; Eryilmaz, O.L.; Shi, Y.; Erdemir, A. Superlubricity of polyalkylene glycol aqueous solutions enabled by ultrathin layered double hydroxide nanosheets. ACS Appl. Mater. Interfaces 2019, 11, 20249–20256. [Google Scholar] [CrossRef]

- Kailer, A.; Amann, T. Development of Water-Based Lubricants. Available online: https://www.iwm.fraunhofer.de/en/services/tribology/wear-protection-advanced-ceramics/development-of-water-based-lubricants.html (accessed on 2 February 2021).

- Supekar, S.D.; Graziano, D.J.; Skerlos, S.J.; Cresko, J. Comparing energy and water use of aqueous and gas-based metalworking fluids. J. Ind. Ecol. 2020, 24, 1158–1170. [Google Scholar] [CrossRef]

- Rahman, M.H.; Bhoi, P.R.; Saha, A.; Patil, V.; Adhikari, S. Thermo-catalytic co-pyrolysis of biomass and high-density polyethylene for improving the yield and quality of pyrolysis liquid. Energy 2021, 225, 120231. [Google Scholar] [CrossRef]

- Rahman, M.H. Catalytic Co-pyrolysis of Pinewood and Waste Plastics for Improving the Selectivity of Hydrocarbons and the Quality of Pyrolysis Oil; Georgia Southern University: Statesboro, GA, USA, 2020. [Google Scholar]

- Wang, B.; Tang, W.; Liu, X.; Huang, Z. Synthesis of ionic liquid decorated muti-walled carbon nanotubes as the favorable water-based lubricant additives. Appl. Phys. A 2017, 123, 1–11. [Google Scholar] [CrossRef]

- Khanmohammadi, H.; Wijanarko, W.; Espallargas, N. Ionic Liquids as Additives in Water-based Lubricants: From Surface Adsorption to Tribofilm Formation. Tribol. Lett. 2020, 68. [Google Scholar] [CrossRef]

- Carrion, F.-J.; Sanes, J.; Bermudez, M.-D.; Jimenez, A.-E. Ionic Liquids as Advanced Lubricant Fluids. Molecules 2009, 14, 2888–2908. [Google Scholar] [CrossRef]

- Zhou, F.; Liang, Y.; Liu, W. Ionic Liquid Lubricant: Designed Chemistry for Engineering Applications. Chem. Soc. Rev. 2009. [Google Scholar] [CrossRef]

- Plechkova, N.V.; Seddon, K.R. Applications of ionic liquids in the chemical industry. Chem. Soc. Rev. 2008, 37, 123–150. [Google Scholar] [CrossRef]

- Reeves, C.J.; Siddaiah, A.; Menezes, P.L. Tribological study of imidazolium and phosphonium ionic liquid-based lubricants as additives in carboxylic acid-based natural oil: Advancements in environmentally friendly lubricants. J. Clean Prod. 2018, 176, 241–250. [Google Scholar] [CrossRef]

- Reeves, C.J.; Siddaiah, A.; Menezes, P.L. Friction and Wear Behavior of Environmentally Friendly Ionic Liquids for Sustainability of Biolubricants. J. Tribol. 2019, 141. [Google Scholar] [CrossRef]

- Reeves, C.J.; Kasar, A.K.; Menezes, P.L. Tribological performance of environmental friendly ionic liquids for high-temperature applications. J. Clean Prod. 2021, 279, 123666. [Google Scholar] [CrossRef]

- Van Rensselar, J. Unleashing the potential of ionic liquids. Tribol. Lubr. Technol. 2010, 66, 24–31. [Google Scholar]

- Ye, C.; Liu, W.; Chen, Y.; Yu, L. Room-temperature ionic liquids: A novel versatile lubricant. Chem. Commun. 2001, 2244–2245. [Google Scholar] [CrossRef]

- Wasserscheid, P.; Welton, T. Ionic Liquids in Synthesis; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Westerholt, A.; Weschta, M.; Bosmann, A.; Tremmel, S.; Korth, Y.; Wolf, M.; Schlücker, E.; Wehrum, N.; Lennert, A.; Uerdingen, M. Halide-free synthesis and tribological performance of oil-miscible ammonium and phosphonium-based ionic liquids. ACS Sustain. Chem. Eng. 2015, 3, 797–808. [Google Scholar] [CrossRef]

- Zhang, S.; Ma, L.; Dong, R.; Zhang, C.; Sun, W.; Fan, M.; Yang, D.; Zhou, F.; Liu, W. Study on the synthesis and tribological properties of anti-corrosion benzotriazole ionic liquid. RSC Adv. 2017, 7, 11030–11040. [Google Scholar] [CrossRef] [Green Version]

- Tang, W.; Wang, B.; Li, J.; Li, Y.; Zhang, Y.; Quan, H.; Huang, Z. Facile Pyrolysis Synthesis of Ionic Liquid Capped Carbon Dots and Subsequent Application as the water-Based Lubricant Additives. J. Mater. Sci. 2019, 54, 1171–1183. [Google Scholar] [CrossRef]

- Meng, Y.; Xu, J.; Jin, Z.; Prakash, B.; Hu, Y. A review of recent advances in tribology. Friction 2020, 8. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Qu, J. Ionic Liquids as Lubricant Additives: A Review. Appl. Mater. Interfaces 2017, 9, 3209–3222. [Google Scholar] [CrossRef]

- Bremmer, B.; Plonsker, L.; Martin, J. Bio-Based Lubricants; United Soybean Board: Chesterfield, MO, USA, 2013. [Google Scholar]

- Reeves, C.; Siddaiah, A.; Menezes, P. Ionic Liquids: A Plausible Future of Bio-lubricants. J. Bio Tribo Corros. 2017. [Google Scholar] [CrossRef]

- Gucciardi, E.; Bart, J.; Cavallaro, S. Biolubricants: Science and Technology; Woodhead Publishing Limites: Cambridge, UK, 2013. [Google Scholar]

- Bhoi, P.; Ouedraogo, A.; Soloiu, V.; Quirino, R. Recent advances on catalysts for improving hydrocarbon compounds in bio-oil of biomass catalytic pyrolysis. Renew. Sustain. Energy Rev. 2020, 121, 109676. [Google Scholar] [CrossRef]

- Lindfors, C.; Kuoppala, E.; Oasmaa, A.; Solantausta, Y.; Arpiainen, V. Fractionation of bio-oil. Energy Fuels 2014, 28, 5785–5791. [Google Scholar] [CrossRef]

- Ji, H.; Zhang, X.; Tan, T. Preparation of a Water-Based Lubricant from Lignocellulosic Biomass and Its Tribological Properties. Ind. Eng. Chem. Res. 1999. [Google Scholar] [CrossRef]

- Mobarak, H.; Mohamad, N.; Masjuki, H.; Kalam, M.; Mahmud, K.; Habibullah, M.; Ashraful, A. The prospects of biolubricants as alternatives in automotive applications. Renew. Sustain. Energy Rev. 2014, 33, 34–43. [Google Scholar] [CrossRef]

- Sharma, Y.; Singh, B. An ideal feedstock, kusum (Schleichera triguga) for preparation of biodiesel: Optimization of parameters. Fuel 2010, 89, 1470–1474. [Google Scholar] [CrossRef]

- Karaosmanoglu, F.; Tuter, M.; Gollu, E.; Yanmaz, S.; Altintig, E. Fuel properties of cottonseed oil. Energy Sources 1999, 21, 821–828. [Google Scholar] [CrossRef]

- Usta, N.; Aydoğan, B.; Çon, A.; Uğuzdoğan, E.; Özkal, S. Properties and quality verification of biodiesel produced from tobacco seed oil. Energy Convers. Manag. 2011, 52, 2031–2039. [Google Scholar] [CrossRef]

- Singh, D.; Singh, S. Low cost production of ester from non edible oil of Argemone mexicana. Biomass Bioenergy 2010, 34, 545–549. [Google Scholar] [CrossRef]

- Wang, R.; Hanna, M.A.; Zhou, W.-W.; Bhadury, P.S.; Chen, Q.; Song, B.-A.; Yang, S. Production and selected fuel properties of biodiesel from promising non-edible oils: Euphorbia lathyris L., Sapium sebiferum L. and Jatropha curcas L. Bioresour. Technol. 2011, 102, 1194–1199. [Google Scholar] [CrossRef]

- Li, X.; He, X.-Y.; Li, Z.-L.; Wang, Y.-D.; Wang, C.-Y.; Shi, H.; Wang, F. Enzymatic production of biodiesel from Pistacia chinensis bge seed oil using immobilized lipase. Fuel 2012, 92, 89–93. [Google Scholar] [CrossRef]

- Wang, R.; Zhou, W.-W.; Hanna, M.A.; Zhang, Y.-P.; Bhadury, P.S.; Wang, Y.; Song, B.-A.; Yang, S. Biodiesel preparation, optimization, and fuel properties from non-edible feedstock, Datura stramonium L. Fuel 2012, 91, 182–186. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.; Kalam, M.; Hazrat, M.; Liaquat, A.; Shahabuddin, M.; Varman, M. Prospects of biodiesel from Jatropha in Malaysia. Renew. Sustain. Energy Rev. 2012, 16, 5007–5020. [Google Scholar] [CrossRef]

- Reeves, C.J.; Menezes, P.L.; Jen, T.-C.; Lovell, M.R. The influence of fatty acids on tribological and thermal properties of natural oils as sustainable biolubricants. Tribol. Int. 2015, 90, 123–134. [Google Scholar] [CrossRef]

- Lovell, M.R.; Kabir, M.; Menezes, P.L.; Higgs III, C.F. Influence of boric acid additive size on green lubricant performance. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2010, 368, 4851–4868. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Reeves, C.J.; Menezes, P.L.; Lovell, M.R.; Jen, T.-C. The size effect of boron nitride particles on the tribological performance of biolubricants for energy conservation and sustainability. Tribol. Lett. 2013, 51, 437–452. [Google Scholar] [CrossRef]

- Omrani, E.; Siddaiah, A.; Moghadam, A.D.; Garg, U.; Rohatgi, P.; Menezes, P.L. Ball Milled Graphene Nano Additives for Enhancing Sliding Contact in Vegetable Oil. Nanomaterials 2021, 11, 610. [Google Scholar] [CrossRef] [PubMed]

- Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Effect of micro-and nano-sized carbonous solid lubricants as oil additives in nanofluid on tribological properties. Lubricants 2019, 7, 25. [Google Scholar] [CrossRef] [Green Version]

- Siddaiah, A.; Kasar, A.K.; Manoj, A.; Menezes, P.L. Influence of environmental friendly multiphase lubricants on the friction and transfer layer formation during sliding against textured surfaces. J. Clean Prod. 2019, 209, 1245–1251. [Google Scholar] [CrossRef]

- Gu, Y.; Zhao, X.; Liu, Y.; Lv, Y. Preparation and Tribological Properties of Dual-Coated TiO2 Nanoparticles as Water-Based Lubricant Additives. J. Nanomater. 2014, 2014, 785680. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, H.T.C.K.-H. Assessment of Tribological Properties of Ti3C2 as a Water-Based Lubricant Additive. Materials 2020, 13, 5545. [Google Scholar] [CrossRef]

- Liu, T.; Zhou, C.; Gao, C.; Zhang, Y.; Yang, G.; Zhang, P.; Zhang, S. Preparation of Cu@SiO2 composite nanoparticle and its tribological properties as water-based lubricant additive. Lubr. Sci. 2020, 32, 69–79. [Google Scholar] [CrossRef]

- Ding, H.; Wang, M.; Li, M.; Huang, K.; Li, S.; Xu, L.; Yang, X.; Xia, J. Synthesis of a water-soluble, rubber seed oil–based sulfonate and its tribological properties as a water-based lubricant additive. J. Appl. Polym. Sci. 2018, 135, 46119. [Google Scholar] [CrossRef]

- Qiang, R.; Hu, L.; Hou, K.; Wang, J.; Yang, S. Water-Soluble Graphene Quantum Dots as High-Performance Water-Based Lubricant Additive for Steel/Steel Contact. Tribol. Lett. 2019, 67, 1–9. [Google Scholar] [CrossRef]

- Saffari, H.R.M.; Soltani, R.; Alaei, M.; Soleymani, M. Tribological properties of water-based drilling fluids with borate nanoparticles as lubricant additives. J. Pet. Sci. Eng. 2018, 171, 253–259. [Google Scholar] [CrossRef]

- Dong, X.; Wang, L.; Yang, X.; Lin, Y.; Xue, Y. Effect of ester based lubricant SMJH-1 on the lubricity properties of water based drilling fluid. J. Pet. Sci. Eng. 2015, 135, 161–167. [Google Scholar] [CrossRef]

- Nouri, J.M.; Vasilakos, I.; Yan, Y.; Reyes-Aldasoro, C.-C. Effect of Viscosity and Speed on Oil Cavitation Development in a Single Piston-Ring Lubricant Assembly. Lubricants 2019, 7, 88. [Google Scholar] [CrossRef] [Green Version]

- Hamrock, B.J.; Dowson, D. Ball Bearing Lubrication: The Elastohydrodynamics of Elliptical Contacts; ASME: New York, NY, USA, 1981. [Google Scholar]

- Menezes, P.L.; Kailas, S.V. Effect of roughness parameter and grinding angle on coefficient of friction when sliding of Al–Mg alloy over EN8 steel. J. Tribol. 2006, 128, 697–704. [Google Scholar] [CrossRef]

- Marx, N.; Fernández, L.; Barceló, F.; Spikes, H. Shear Thinning and Hydrodynamic Friction of Viscosity Modifier-Containing Oils. Part II: Impact of Shear Thinning on Journal Bearing Friction. Tribol. Lett. 2018, 66, 91. [Google Scholar] [CrossRef] [Green Version]

- MacConochie, I.O.; Newman, W.H. The effect of lubricant viscosity on the lubrication of gear teeth. Wear 1961, 4, 10–21. [Google Scholar] [CrossRef]

- Larsson, R. EHL Film Thickness Behavior. In Encyclopedia of Tribology; Wang, Q.J., Chung, Y.-W., Eds.; Springer: Boston, MA, USA, 2013; pp. 817–827. [Google Scholar]

- Shen, M.; Luo, J.; Wen, S.; Yao, J. Nano-tribological properties and mechanisms of the liquid crystal as an additive. Chin. Sci. Bull. 2001, 46, 1227–1232. [Google Scholar] [CrossRef]

- Ramezanizadeh, M.; Ahmadi, M.H.; Nazari, M.A.; Sadeghzadeh, M.; Chen, L. A review on the utilized machine learning approaches for modeling the dynamic viscosity of nanofluids. Renew. Sustain. Energy Rev. 2019, 114, 109345. [Google Scholar] [CrossRef]

- Hajmohammadi, M.R. Assessment of a lubricant based nanofluid application in a rotary system. Energy Convers. Manag. 2017, 146, 78–86. [Google Scholar] [CrossRef]

- Corcione, M. Empirical correlating equations for predicting the effective thermal conductivity and dynamic viscosity of nanofluids. Energy Convers. Manag. 2011, 52, 789–793. [Google Scholar] [CrossRef]

- Najiha, M.S.; Rahman, M.M.; Kadirgama, K. Performance of water-based TiO2 nanofluid during the minimum quantity lubrication machining of aluminium alloy, AA6061-T6. J. Clean Prod. 2016, 135, 1623–1636. [Google Scholar] [CrossRef] [Green Version]

- Omotowa, B.A.; Phillips, B.S.; Zabinski, J.S.; Shreeve, J.n.M. Phosphazene-Based Ionic Liquids: Synthesis, Temperature-Dependent Viscosity, and Effect as Additives in Water Lubrication of Silicon Nitride Ceramics. Inorg. Chem. 2004, 43, 5466–5471. [Google Scholar] [CrossRef] [PubMed]

- Moldoveanu, S.C.; David, V. (Eds.) Chapter 7—RP-HPLC Analytical Columns. In Selection of the HPLC Method in Chemical Analysis; Elsevier: Boston, MA, USA, 2017; pp. 279–328. [Google Scholar]

- Cabezudo, N.; Sun, J.; Andi, B.; Ding, F.; Wang, D.; Chang, W.; Luo, X.; Xu, B.B. Enhancement of surface wettability via micro- and nanostructures by single point diamond turning. Nanotechnol. Precis. Eng. 2019, 2, 8–14. [Google Scholar] [CrossRef]

- Pawlak, Z.; Urbaniak, W.; Oloyede, A. The relationship between friction and wettability in aqueous environment. Wear 2011, 271, 1745–1749. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, Y.; Zeng, Z.; Zhao, H.; Ge, X.; Wang, K.; Wang, L.; Xue, Q. PEGlated graphene as nanoadditive for enhancing the tribological properties of water-based lubricants. Carbon 2018, 137, 41–48. [Google Scholar] [CrossRef]

- Wang, X.-J.; Zhu, D.-S. Investigation of pH and SDBS on enhancement of thermal conductivity in nanofluids. Chem. Phys. Lett. 2009, 470, 107–111. [Google Scholar] [CrossRef]

- Sułek, M.W.; Ogorzałek, M.; Wasilewski, T.; Klimaszewska, E. Alkyl Polyglucosides as Components of Water Based Lubricants. J. Surfactants Deterg. 2013, 16, 369–375. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bhattacharjee, S.; Chakraborty, D.; Khan, S. Wetting behavior of aqueous 1-alkyl-3-methylimidazolium tetrafluoroborate {[Cn MIM][BF4] (n = 2, 4, 6)} on graphite surface. Chem. Eng. Sci. 2021, 229, 116078. [Google Scholar] [CrossRef]

- Basu, S.; Hanh, B.M.; Isaiah Chua, J.Q.; Daniel, D.; Ismail, M.H.; Marchioro, M.; Amini, S.; Rice, S.A.; Miserez, A. Green biolubricant infused slippery surfaces to combat marine biofouling. J. Colloid Interface Sci. 2020, 568, 185–197. [Google Scholar] [CrossRef]

- Nunes, D.G.; da Silva, A.d.P.M.; Cajaiba, J.; Pérez-Gramatges, A.; Lachter, E.R.; Nascimento, R.S.V. Influence of glycerides–xanthan gum synergy on their performance as lubricants for water-based drilling fluids. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Lakshmi, R.V.; Bera, P.; Anandan, C.; Basu, B.J. Effect of the size of silica nanoparticles on wettability and surface chemistry of sol–gel superhydrophobic and oleophobic nanocomposite coatings. Appl. Surf. Sci. 2014, 320, 780–786. [Google Scholar] [CrossRef]

- Wen, P.; Lei, Y.; Li, W.; Fan, M. Synergy between Covalent Organic Frameworks and Surfactants to Promote Water-Based Lubrication and Corrosion Resistance. ACS Appl. Nano Mater. 2020, 3, 1400–1411. [Google Scholar] [CrossRef]

- Zhang, C. Preparation and Tribological Properties of Water-Soluble Copper/Silica Nanocomposite as a Water-Based Lubricant Additive. Appl. Surf. Sci. 2012. [Google Scholar] [CrossRef]

- Pei, X.; Hu, L.; Liu, W.; Hao, J. Synthesis of Water-Soluble Carbon Nanotubes via Surface Initiated Redox Polymerization and Their Tribological Properties as Water-Based Lubricant Additive. Eur. Polym. J. 2008. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Q.; Zhu, H.; Liu, H.; Chen, Y.; Yang, M. Dispersing multi-walled carbon nanotubes with water soluble block copolymers and their use as supports for metal nanoparticles. Carbon 2007, 45, 285–292. [Google Scholar] [CrossRef]

- Yao, Z.; Braidy, N.; Botton, G.A.; Adronov, A. Polymerization from the surface of single-walled carbon nanotubes-preparation and characterization of nanocomposites. J. Am. Chem. Soc. 2003. [Google Scholar] [CrossRef]

- Gao, M.; Huang, S.; Dai, L.; Wallace, G.; Gao, R.; Wang, Z. Aligned coaxial nanowires of carbon nanotubes sheathed with conducting polymers. Zuschriften 2000. [Google Scholar] [CrossRef]

- Kong, H.; Gao, C.; Yan, D. Functionalization of multiwalled carbon nanotubes by atom transfer radical polymerization and defunctionalization of the products. Macromolecules 2004. [Google Scholar] [CrossRef]

- Wu, H.X.; Tong, R.; Qiu, X.Q.; Yang, H.F.; Lin, Y.H.; Cai, R.F.; Qian, S.X. Functionalization of multiwalled carbon nanotubes with polystyrene under atom transfer radical polymerization conditions. Carbon 2007, 45, 152–159. [Google Scholar] [CrossRef]

- Cui, J.; Wang, W.; You, Y.; Liu, C.; Wang, P. Functionalization of multiwalled carbon nanotubes by reversible addition fragmentation chain-transfer polymerization. Polymer 2004, 45, 8717–8721. [Google Scholar] [CrossRef]

- Rahman, M.H.; Bhoi, P.R. An Overview of Non-biodegradable Bioplastics. J. Clean Prod. 2021, 126218. [Google Scholar] [CrossRef]

- Cui, Y.; Ding, M.; Sui, T.; Zheng, W.; Qiao, G.; Yan, S.; Liu, X. Role of Nanoparticle Materials as Water-Based Lubricant Additives for Ceramics. Tribol. Int. 2019. [Google Scholar] [CrossRef]

- Gresham, R.M. The Mysterious World of MWF Additives. Available online: https://www.stle.org/images/pdf/STLE_ORG/BOK/OM_OA/Friction_Tribology/The%20Mysterious%20World%20of%20MWF%20Additives_tlt%20article_Sept06.pdf (accessed on 7 April 2021).

- Ma, H.; Li, J.; Chen, H.; Zuo, G.; Yu, Y.; Ren, T.; Zhao, Y. XPS and XANES characteristics of tribofilms and thermal films generated by two P- and/or S-containing additives in water-based lubricant. Tribol. Int. 2009. [Google Scholar] [CrossRef]

- Yong, W.; Qunji, X.; Lili, C. Tribological properties of some water-based lubricants containing polyethylene glycol under boundary lubrication conditions. J. Synth. Lubr. 1997. [Google Scholar] [CrossRef]

- Dong, R.; Yu, Q.; Bai, Y.; Ma, Z.; Zhang, J.; Zhang, C.; Yu, B.; Zhou, F.; Liu, W.; Cai, M. Towards Superior Lubricity and Anticorrosion Performances of Proton-Type Ionic Liquids Additives for Water-Based Lubricating Fluids. Chem. Eng. J. 2019. [Google Scholar] [CrossRef]

- Espinosa, T.; Sanes, J.; Jiménez, A.E.; Bermúdez, M.D. Bermúdez. Protic ammonium carboxylate ionic liquid lubricants of OFHC copper Wear. Wear 2013, 303, 495–509. [Google Scholar] [CrossRef]

- Zheng, G.; Zhang, G.; Ding, T.; Xiang, X.; Li, F.; Ren, T.; Liu, S.; Zheng, L. Tribological properties and surface interaction of novel water-soluble ionic liquid in water-glycol. Tribol. Int. 2017. [Google Scholar] [CrossRef]

- Guo, M.L.T.; Tsao, C.-Y.A. Tribological Behavior of Self-Lubricating Aluminium/SiC/Graphite Hybrid Composites Synthesized by the Semi-Solid Powder-Densification Method. Compos. Sci. Technol. 1999. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, Q.; Cai, M.; Shi, L.; Zhou, F.; Liu, W. Ibuprofen-Based Ionic Liquids as Additives for Enhancing the Lubricity and Antiwear of Water–Ethylene Glycol Liquid. Tribol. Lett. 2017, 65, 1–13. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, Q.; Cai, M.; Shi, L.; Zhou, F.; Liu, W. Synergy of lithium salt and non-ionic surfactant for significantly improved tribological properties of water-based fluids. Tribol. Int. 2017, 113, 58–64. [Google Scholar] [CrossRef]

- Fan, M.; Du, X.; Ma, L.; Wen, P.; Zhang, S.; Dong, R.; Sun, W.; Yang, D.; Zhou, F.; Liu, W. In situ preparation of multifunctional additives in water. Tribol. Int. 2019, 130, 317–323. [Google Scholar] [CrossRef]

- Chu, J.H.; Tong, L.B.; Zhang, J.B.; Kamado, S.; Jiang, Z.H.; Zhang, H.J.; Sun, G.X. Bio-inspired graphene-based coatings on Mg alloy surfaces and their integrations of anti-corrosive/wearable performances. Carbon 2019, 141, 154–168. [Google Scholar] [CrossRef]

- Yang, Z.; Sun, C.; Zhang, C.; Zhao, S.; Cai, M.; Liu, Z.; Yu, Q. Amino acid ionic liquids as anticorrosive and lubricating additives for water and their environmental impact. Tribol. Int. 2021, 153, 106663. [Google Scholar] [CrossRef]

- Xie, H.; Dang, S.; Xiang, L.; Jiang, B.; Zhou, S.; Sheng, H.; Yang, T.; Pan, F. Tribological performances of SiO2/graphene combinations as water-based lubricant additives for magnesium alloy rolling. Appl. Surf. Sci. 2019, 475, Fusheng. [Google Scholar] [CrossRef]

- Rietsch, J.-C.; Brender, P.; Dentzer, J.; Gadiou, R.; Vidal, L.; Vix-Guterl, C. Evidence of water chemisorption during graphite friction under moist conditions. Carbon 2013, 55, 90–97. [Google Scholar] [CrossRef]

- Avilés, M.; Carrión, F.; Sanes, J.; Bermúdez, M. Bio-based ionic liquid crystal for stainless steel-sapphire high temperature ultralow friction. Wear 2021, 204020. [Google Scholar] [CrossRef]

- Phillips, B.; Zabinski, J. Ionic liquid lubrication effects on ceramics in a water environment. Tribol. Lett. 2004, 17, 533–541. [Google Scholar] [CrossRef]

- Perry, S.S.; Tysoe, W.T. Frontiers of fundamental tribological research. Tribol. Lett. 2005, 19. [Google Scholar] [CrossRef] [Green Version]

- Selvam, B.; Marimuthu, P.; Narayanasamy, R.; Senthilkumar, V.; Tun, K.S.; Gupta, M. Effect of temperature and strain rate on compressive response of extruded magnesium nano-composite. J. Magnes. Alloy. 2015, 3. [Google Scholar] [CrossRef] [Green Version]

- Berman, D.; Erdemir, A.; Sumant, A. Few layer graphene to reduce wear and friction on sliding steel surfaces. Carbon 2013, 54, 454–459. [Google Scholar] [CrossRef]

- Liang, S.; Yi, M.; Shen, Z.; Liu, L.; Ma, S.; Zhang, X. In-situ exfoliated graphene for high-performance water-based lubricants. Carbon 2016, 96, 1181–1190. [Google Scholar] [CrossRef]

- Wu, H.; Kamila, H.; Huo, M.; Lin, F.; Huang, S.; Huang, H.; Jiao, S.; Xing, Z.; JIang, Z. Eco-friendl water-based nanolubricants for industrial-scale hot steel rolling. Lubricants 2020, 8, 96. [Google Scholar] [CrossRef]

- Deng, M.; Li, J.; Zhang, C.; Ren, J.; Zhou, N.; Luo, J. Investigation of running-in process in water-based lubrication aimed at achieving super-low friction. Tribol. Int. 2016, 102, 257–264. [Google Scholar] [CrossRef]

| Fossil-Based Lubricants | Biomass-Based Lubricants |

|---|---|

|

|

| Plant Species | Oil Content (% of Volume) |

|---|---|

| Jatropha | 40–60% |

| Rapeseed | 38–46% |

| Palm | 30–60% |

| Peanut | 45–55% |

| Olive | 45–70% |

| Coconut | 63–65% |

| Neem | 30–50% |

| Karanja | 30–50% |

| Castor | 45–60% |

| Linseed | 35–45% |

| Moringa | 20–36% |

| Aqueous Solutions | Contact Angle in Degree | Xanthan Gum Suspensions | Contact Angle in Degree |

|---|---|---|---|

| Water | 77.0 | Xanthan Gum | 69.3 |

| Monoglyceride 6 | 64.5 | Monoglyceride 6 + XG | 63.7 |

| Monoglyceride 87 | 13.7 | Monoglyceride 8 + XG | 9.6 |

| Monoglyceride 10 | 12.9 | Monoglyceride 10 + XG | 7.4 |

| WBL Additives | Properties | Advantages | Remarks | Ref. |

|---|---|---|---|---|

| Solid nanoparticle additives | ||||

| TiO2 |

|

|

| [57,96] |

| Titanium Carbide (Ti3C2) |

|

|

| [58] |

| SiO2 |

|

|

| [96] |

| Graphene quantum dots (GQD) |

|

|

| [61] |

| ZnO |

|

|

| [96] |

| SiO2/graphene |

|

|

| [109,110] |

| Polyethylenimine-reduced graphene oxide (PEI-RGO) |

|

|

| [11,70] |

| Multi-walled carbon nanotubes (MWNT) |

|

|

| [88,89] |

| Ionic liquid-based additives | ||||

| Ionic liquid capped Carbon Dots (CD-IL) |

|

|

| [33] |

| [THTDP] [Deca] |

|

|

| [96] |

| Ibuprofen-based ionic liquids |

|

|

| [104] |

| Amino acid ionic liquids (AAILs): P4444 (Tetrabutylphosphonium)-Histidine, P4444-serine, P4444-tryptophan (Trp), P4444-lysine, P4444-phenylalanine, P4444-cysteine, and P4444-methionine |

|

|

| [108] |

| Benzotriazole: P4444BTA |

|

|

| [23,32] |

| Ammonium ionic liquids: bis(2-hydroxyethyl) ammonium palmitate (DPA) |

|

|

| [34,111] |

| [Phosphazene][NTf2] |

|

|

| [35,75] |

| [1-Butyl-3-methylimidazolium ][PF₆] |

|

|

| [35,112] |

| Biobased and other WBL additives | ||||

| Lithium salt and nonionic surfactant (Li-TW) |

|

|

| [105] |

| Water-based oleic acid (OA)/2-acryloylamino-2-methyl-1-propanesulfonic cid (AMPS) |

|

|

| [60] |

| SMJH-1 |

|

|

| [63] |

| Alkyl glucopyranosides (APGs) |

|

|

| [8] |

| Polyethylene glycol (PEG) |

|

|

| [98,99] |

| Glycerol ester of levulinic acid (LAGLE) |

|

|

| [41] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, M.H.; Warneke, H.; Webbert, H.; Rodriguez, J.; Austin, E.; Tokunaga, K.; Rajak, D.K.; Menezes, P.L. Water-Based Lubricants: Development, Properties, and Performances. Lubricants 2021, 9, 73. https://0-doi-org.brum.beds.ac.uk/10.3390/lubricants9080073

Rahman MH, Warneke H, Webbert H, Rodriguez J, Austin E, Tokunaga K, Rajak DK, Menezes PL. Water-Based Lubricants: Development, Properties, and Performances. Lubricants. 2021; 9(8):73. https://0-doi-org.brum.beds.ac.uk/10.3390/lubricants9080073

Chicago/Turabian StyleRahman, Md Hafizur, Haley Warneke, Haley Webbert, Joaquin Rodriguez, Ethan Austin, Keli Tokunaga, Dipen Kumar Rajak, and Pradeep L. Menezes. 2021. "Water-Based Lubricants: Development, Properties, and Performances" Lubricants 9, no. 8: 73. https://0-doi-org.brum.beds.ac.uk/10.3390/lubricants9080073