Figure 1.

Relationship between yield stress and temperature for different strain rates.

Figure 1.

Relationship between yield stress and temperature for different strain rates.

Figure 2.

Change in activation energy as a function of strain rate from linear regression equation.

Figure 2.

Change in activation energy as a function of strain rate from linear regression equation.

Figure 3.

Plastic flow curves of high-carbon bainitic steel at strain rate of 10 s−1 at a temperature of 900–1100 °C.

Figure 3.

Plastic flow curves of high-carbon bainitic steel at strain rate of 10 s−1 at a temperature of 900–1100 °C.

Figure 4.

Stress relaxation of high-carbon bainitic steel in temperature range 900–1100 °C and plastic deformation 0.28: (a) for strain rate 0.1 s−1, (b) strain rate 10 s−1.

Figure 4.

Stress relaxation of high-carbon bainitic steel in temperature range 900–1100 °C and plastic deformation 0.28: (a) for strain rate 0.1 s−1, (b) strain rate 10 s−1.

Figure 5.

Dependence of ln (ln (1/1 − X)) on ln t for T = 900 °C; ε = 0.28; = 0.1 s−1.

Figure 5.

Dependence of ln (ln (1/1 − X)) on ln t for T = 900 °C; ε = 0.28; = 0.1 s−1.

Figure 6.

Kinetics of meta-dynamic recrystallization in high-carbon bainite steel based on Avrami equation.

Figure 6.

Kinetics of meta-dynamic recrystallization in high-carbon bainite steel based on Avrami equation.

Figure 7.

Dependence of half time of meta-dynamic recrystallization (ln t0.5) on strain rate (ln ).

Figure 7.

Dependence of half time of meta-dynamic recrystallization (ln t0.5) on strain rate (ln ).

Figure 8.

Dependence of half time of meta-dynamic recrystallization (ln t0.5) on temperature (1/T).

Figure 8.

Dependence of half time of meta-dynamic recrystallization (ln t0.5) on temperature (1/T).

Figure 9.

Relationship ln (ln (1/1 − X)) to ln t in range T = 900–1100 °C; ε = 0.28; = 0.1–10 s−1.

Figure 9.

Relationship ln (ln (1/1 − X)) to ln t in range T = 900–1100 °C; ε = 0.28; = 0.1–10 s−1.

Figure 10.

Kinetics of meta-dynamic recrystallization of high-carbon bainitic steel for T = 900–1100 °C, = 0.1 s−1.

Figure 10.

Kinetics of meta-dynamic recrystallization of high-carbon bainitic steel for T = 900–1100 °C, = 0.1 s−1.

Figure 11.

Microstructure of sample after experimental tests for T = 900 °C; ε = 0.28; = 0.1 s−1 dγ = 23.7 μm; area 200×; etched with picric acid (C6H3N3O7).

Figure 11.

Microstructure of sample after experimental tests for T = 900 °C; ε = 0.28; = 0.1 s−1 dγ = 23.7 μm; area 200×; etched with picric acid (C6H3N3O7).

Figure 12.

Dependence of meta-dynamically recrystallized austenite grains (ln dMDRX) on Zener–Hollomon parameter (ln Z).

Figure 12.

Dependence of meta-dynamically recrystallized austenite grains (ln dMDRX) on Zener–Hollomon parameter (ln Z).

Figure 13.

Stress relaxation of high-carbon bainite steel for temperature 950 and 1050 °C: (a) ε = 0.05; = 0.1 s−1, (b) ε = 0.15; = 10 s−1.

Figure 13.

Stress relaxation of high-carbon bainite steel for temperature 950 and 1050 °C: (a) ε = 0.05; = 0.1 s−1, (b) ε = 0.15; = 10 s−1.

Figure 14.

Dependence of ln (ln (1/1 − X)) on ln t for T = 950 °C; ε = 0.05; = 0.1s−1.

Figure 14.

Dependence of ln (ln (1/1 − X)) on ln t for T = 950 °C; ε = 0.05; = 0.1s−1.

Figure 15.

Kinetics of static recrystallization in high-carbon bainitic steel based on Avrami equation.

Figure 15.

Kinetics of static recrystallization in high-carbon bainitic steel based on Avrami equation.

Figure 16.

Dependence of half time of static recrystallization (ln t0.5) on: (a) ln ε, (b) ln , (c) ln d0, (d) 1/T.

Figure 16.

Dependence of half time of static recrystallization (ln t0.5) on: (a) ln ε, (b) ln , (c) ln d0, (d) 1/T.

Figure 17.

Dependence of ln (ln1/1 − X)) on time (ln t) in range T = 950–1050 °C; ε = 0.05 and 0.1; = 0.1 and 10 s−1, according to which exponent in model describing kinetics of static recrystallization was determined.

Figure 17.

Dependence of ln (ln1/1 − X)) on time (ln t) in range T = 950–1050 °C; ε = 0.05 and 0.1; = 0.1 and 10 s−1, according to which exponent in model describing kinetics of static recrystallization was determined.

Figure 18.

Example of kinetics of static recrystallization in high-carbon bainitic steel based on the developed coefficients in mathematical model.

Figure 18.

Example of kinetics of static recrystallization in high-carbon bainitic steel based on the developed coefficients in mathematical model.

Figure 19.

Microstructure of samples after experimental testing for T = 950 °C; ε = 0.1; = 10 s−1; dγ = 27.2 μm; area 75×; etched with picric acid (C6H3N3O7).

Figure 19.

Microstructure of samples after experimental testing for T = 950 °C; ε = 0.1; = 10 s−1; dγ = 27.2 μm; area 75×; etched with picric acid (C6H3N3O7).

Figure 20.

Dependence of statically recrystallized austenite grains (ln dSRX) on: (a) ln d0; (b) ln ɛ; (c) ln ; (d) 1/T for different values of strain, (e) 1/T for different values of strain rate.

Figure 20.

Dependence of statically recrystallized austenite grains (ln dSRX) on: (a) ln d0; (b) ln ɛ; (c) ln ; (d) 1/T for different values of strain, (e) 1/T for different values of strain rate.

Figure 21.

Size of austenite grains after growing at T = 1100 °C: (a) after 0 s, d0 = 59.7 μm; (b) after 3600 s, d0 = 98.1 μm; area 100×; etched with picric acid (C6H3N3O7).

Figure 21.

Size of austenite grains after growing at T = 1100 °C: (a) after 0 s, d0 = 59.7 μm; (b) after 3600 s, d0 = 98.1 μm; area 100×; etched with picric acid (C6H3N3O7).

Figure 22.

Average grain size: (a) variant A: T = 950 °C; dγ. = 26.3 μm, (b) variant B: T = 900 °C; dγ. = 28.2 μm; (c) variant C: T = 850 °C; dγ. = 29.8 μm. Area 200×; etched with picric acid (C6H3N3O7).

Figure 22.

Average grain size: (a) variant A: T = 950 °C; dγ. = 26.3 μm, (b) variant B: T = 900 °C; dγ. = 28.2 μm; (c) variant C: T = 850 °C; dγ. = 29.8 μm. Area 200×; etched with picric acid (C6H3N3O7).

Figure 23.

Course of changes in grain size of alloy austenite under conditions of two plastic strains: (a) finish rolling temperature of 950 °C, (b) finish rolling temperature of 900 °C, (c) finish rolling temperature of 850 °C.

Figure 23.

Course of changes in grain size of alloy austenite under conditions of two plastic strains: (a) finish rolling temperature of 950 °C, (b) finish rolling temperature of 900 °C, (c) finish rolling temperature of 850 °C.

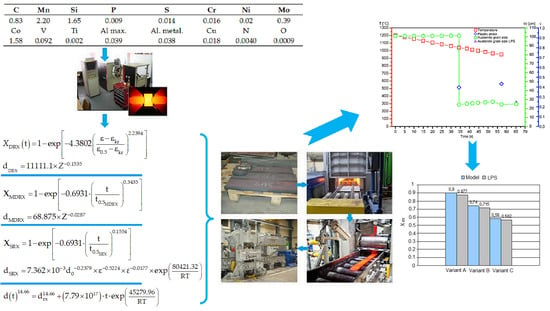

Figure 24.

Verification of developed model of microstructure evolution of high-carbon bainitic steel based on experimental tests carried out on semi-industrial LPS rolling line.

Figure 24.

Verification of developed model of microstructure evolution of high-carbon bainitic steel based on experimental tests carried out on semi-industrial LPS rolling line.

Figure 25.

Martensitic-bainitic structure after low-temperature heat treatment at 250 °C for 70 h, area 750×: (a) variant A, (b) variant B, (c) variant C.

Figure 25.

Martensitic-bainitic structure after low-temperature heat treatment at 250 °C for 70 h, area 750×: (a) variant A, (b) variant B, (c) variant C.

Table 1.

Chemical composition of high-carbon bainitic steel used in tests, mass%.

Table 1.

Chemical composition of high-carbon bainitic steel used in tests, mass%.

| C | Mn | Si | P | S | Cr | Ni | Mo |

|---|

| 0.83 | 2.20 | 1.65 | 0.009 | 0.014 | 0.016 | 0.02 | 0.39 |

| Co | V | Ti | Al max. | Al. metal. | Cu | N | O |

| 1.58 | 0.092 | 0.002 | 0.039 | 0.038 | 0.018 | 0.0040 | 0.0009 |

Table 2.

Preliminary austenite grain size.

Table 2.

Preliminary austenite grain size.

| Temperature (°C) | Grain Size (μm) |

|---|

| 900 | 29.1 |

| 950 | 31.7 |

| 1000 | 32.1 |

| 1050 | 89.4 |

| 1100 | 92.8 |

Table 3.

Values of softening coefficient under conditions of meta-dynamic recrystallization.

Table 3.

Values of softening coefficient under conditions of meta-dynamic recrystallization.

| T (°C) | ε (-) | (s−1) | t (s) | XmMDRX |

|---|

| 950 | 0.28 | 0.1 | 1 | 0.680 |

| 5 | 0.839 |

| 10 | 0.916 |

| 1000 | 0.28 | 0.1 | 1 | 0.686 |

| 5 | 0.951 |

| 10 | 0.986 |

| 1100 | 0.28 | 0.1 | 1 | 0.894 |

| 5 | 0.974 |

| 10 | 0.995 |

Table 4.

Kinetics of meta-dynamic recrystallization based on Avrami equation.

Table 4.

Kinetics of meta-dynamic recrystallization based on Avrami equation.

| T (°C) | ε (-) | (s−1) | Avrami Equation |

|---|

| 900 | 0.28 | 0.1 | X = 1 − exp(−0.2566t0.1753) |

| 1000 | 0.28 | 0.1 | X = 1 – exp(−0.6850t0.803) |

| 1100 | 0.28 | 0.1 | X = 1 – exp(−1.6706t0.4532) |

Table 5.

Obtained results of static recrystallization using the stress relaxation method.

Table 5.

Obtained results of static recrystallization using the stress relaxation method.

| T (°C) | ε (-) | (s−1) | t (s) | |

|---|

| 950 | 0.1 | 10 | 1 | 0.884 |

| 10 | 0.948 |

| 50 | 0.951 |

| 100 | 0.979 |

| 1050 | 0.1 | 10 | 1 | 0.912 |

| 10 | 0.966 |

| 50 | 0.979 |

| 100 | 0.994 |

Table 6.

Kinetics of static recrystallization based on Avrami equation.

Table 6.

Kinetics of static recrystallization based on Avrami equation.

| T (°C) | ε (-) | (s−1) | Avrami Equation |

|---|

| 950 | 0.1 | 10 | X = 1 − exp(−2.0456t0.1451) |

| 1050 | 0.1 | 10 | X = 1 − exp(−2.4133t0.2138) |

Table 7.

Average values of Vickers hardness.

Table 7.

Average values of Vickers hardness.

| Variant | Average Measurement Results | Standard Deviation |

|---|

| A | 681 HV10 | 27.6 |

| B | 680 HV10 | 17.2 |

| C | 706 HV10 | 16.8 |

Table 8.

The mean values of the tensile strength.

Table 8.

The mean values of the tensile strength.

| Variant | Average Measurement Results |

|---|

| TS (MPa) | A5 (%) |

|---|

| A | 1892 | 1.7 |

| B | 1752 | 2.6 |

| C | 1668 | 2.2 |