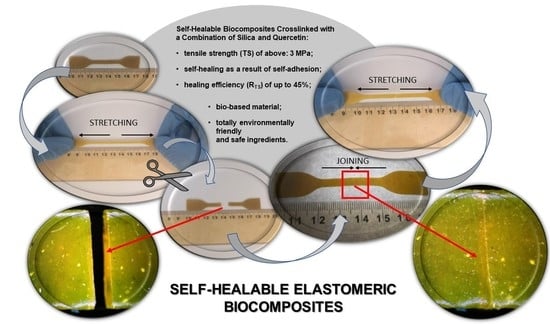

Self-Healable Biocomposites Crosslinked with a Combination of Silica and Quercetin

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Processing

2.2. Rheometric Study

2.3. Crosslink Density Analysis

2.4. Mechanical Properties and Self-Healing Ability Investigation

2.5. Fourier Transform Infrared Spectroscopy (FT-IR) Absorbance Spectra Analysis

2.6. Microscopic Observation of Healing Effect

3. Results and Discussion

3.1. Rheometric Study

3.2. Crosslink Density

3.3. Mechanical Properties and Self-Healing Ability Investigation

3.4. Fourier Transform Infrared Spectroscopy (FT-IR) Absorbance Spectra Analysis

3.5. Microscopic Observation of Healing Effect

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Martin, P.J.; Brown, P.; Chapman, A.V.; Cook, S. Silica-reinforced epoxidized natural rubber tire treads—Performance and durability. Rubber Chem. Technol. 2015, 88, 390–411. [Google Scholar] [CrossRef]

- Wan, N.Y.; Chin, K.P.; Saad, C.S.M. Comparison of epoxidised natural rubber (enr) 37.5 and enr 25/enr 50 physical blend: Specialty polymer for “green tyre” application. IOP Conf. Ser. Mater. Sci. Eng. 2010, 11, 012004. [Google Scholar] [CrossRef]

- Whba, R.; Su’ait, M.S.; Tian Khoon, L.; Ibrahim, S.; Mohamed, N.S.; Ahmad, A. Free-radical photopolymerization of acrylonitrile grafted onto epoxidized natural rubber. Polymers 2021, 13, 660. [Google Scholar] [CrossRef]

- Arrigo, R.; Mascia, L.; Clarke, J.; Malucelli, G. Structure evolution of epoxidized natural rubber (enr) in the melt state by time-resolved mechanical spectroscopy. Materials 2020, 13, 946. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hamzah, R.; Bakar, M.A.; Dahham, O.S.; Zulkepli, N.N.; Dahham, S.S. A structural study of epoxidized natural rubber (ENR-50) ring opening under mild acidic condition. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Algaily, B.; Kaewsakul, W.; Sarkawi, S.S.; Kalkornsurapranee, E. Enabling reprocessability of ENR-based vulcanisates by thermochemically exchangeable ester crosslinks. Plast. Rubber Compos. 2021, 1–14. [Google Scholar] [CrossRef]

- Jiang, C.; He, H.; Yao, X.; Yu, P.; Zhou, L.; Jia, D. Self-crosslinkable lignin/epoxidized natural rubber composites. J. Appl. Polym. Sci. 2014, 131, 1–9. [Google Scholar] [CrossRef]

- Pire, M.; Norvez, S.; Iliopoulos, I.; Le Rossignol, B.; Leibler, L. Imidazole-promoted acceleration of crosslinking in epoxidized natural rubber/dicarboxylic acid blends. Polymer 2011, 52, 5243–5249. [Google Scholar] [CrossRef]

- Srirachya, N.; Kobayashi, T.; Boonkerd, K. An alternative crosslinking of epoxidized natural rubber with maleic anhydride. Key Eng. Mater. 2017, 748, 84–90. [Google Scholar] [CrossRef]

- Xu, T.; Jia, Z.; Wang, S.; Chen, Y.; Luo, Y.; Jia, D.; Peng, Z. Self-crosslinkable epoxidized natural rubber–silica hybrids. J. Appl. Polym. Sci. 2017, 134, 1–10. [Google Scholar] [CrossRef]

- Iskandar, M.; Rahim, S.A.; Horoshenkov, K.V.; Rongong, J.; Ahmadi, H.; Picken, J. Epoxidized natural rubber for vibro-acoustic isolation. Polym. Test. 2018, 67, 92–98. [Google Scholar] [CrossRef]

- Ahmad, H.S.; Ismail, H.; Rashid, A.A. Tensile Properties and Morphology of Epoxidized Natural Rubber / Recycled Acrylonitrile-Butadiene Rubber (ENR 50/NBRr) Blends. Procedia Chem. 2016, 19, 359–365. [Google Scholar] [CrossRef] [Green Version]

- Tanjung, F.A.; Hassan, A.; Hasan, M. Use of epoxidized natural rubber as a toughening agent in plastics. J. Appl. Polym. Sci. 2015, 132, 42270–42279. [Google Scholar] [CrossRef] [Green Version]

- Rahman, A.; Sartore, L.; Bignotti, F.; Di Landro, L. Autonomic Self-Healing in Epoxidized Natural Rubber. ACS Appl. Mater. Interfaces 2013, 5, 1494–1502. [Google Scholar] [CrossRef]

- Cao, L.; Yuan, D.; Xu, C.; Chen, Y. Biobased, self-healable, high strength rubber with tunicate cellulose nanocrystals. Nanoscale 2017, 9, 15696–15706. [Google Scholar] [CrossRef]

- Rhaman, M.A.; Penco, M.; Spagnoli, G.; Grande, A.M.; Di Landro, L. Self-healing behavior of blends based on ionomers with ethylene/vinyl alcohol copolymer or epoxidized natural rubber. Macromol. Mater. Eng. 2011, 296, 1119–1127. [Google Scholar] [CrossRef]

- Rahman, M.A.; Penco, M.; Peroni, I.; Ramorino, G.; Grande, A.M.; Di Landro, L. Self-repairing systems based on ionomers and epoxidized natural rubber blends. ACS Appl. Mater. Interfaces 2011, 3, 4865–4874. [Google Scholar] [CrossRef]

- Utrera-Barrios, S.; Santana, M.H.; Verdejo, R.; López-Manchado, M.A. Design of Rubber Composites with Autonomous Self-Healing Capability. ACS Omega 2020, 5, 1902–1910. [Google Scholar] [CrossRef] [Green Version]

- Santana, H.M.; den Brabander, M.; García, S.; van der Zwaag, S. Routes to Make Natural Rubber Heal: A Review. Polym. Rev. 2018, 58, 585–609. [Google Scholar] [CrossRef]

- Chen, Y.; Tang, Z.; Liu, Y.; Wu, S.; Guo, B. Mechanically Robust, Self-Healable, and Reprocessable Elastomers Enabled by Dynamic Dual Cross-Links. Macromolecules 2019. [Google Scholar] [CrossRef]

- Mandal, S.; Simon, F.; Banerjee, S.S.; Tunnicliffe, L.B.; Nakason, C.; Das, C.; Das, M.; Naskar, K.; Wiessner, S.; Heinrich, G.; et al. Controlled Release of Metal Ion Cross-Linkers and Development of Self-Healable Epoxidized Natural Rubber. ACS Appl. Polym. Mater. 2021. [Google Scholar] [CrossRef]

- Peng, T.; Huang, J.; Gong, Z.; Ding, J.; Chen, Y. Multiple cross-linked networks enhanced ENR-based composite with excellent self-healing properties. Polym. Adv. Technol. 2021, 1–10. [Google Scholar] [CrossRef]

- Utrera-Barrios, S.; Verdejo, R.; López-Manchado, M.A.; Santana, H.M. Evolution of self-healing elastomers, from extrinsic to combined intrinsic mechanisms: A review. Mater. Horiz. 2020, 7, 2882–2902. [Google Scholar] [CrossRef]

- Imbernon, L.; Oikonomou, E.K.; Norvez, S.; Leibler, L. Chemically crosslinked yet reprocessable epoxidized natural rubber via thermo-activated disulfide rearrangements. Polym. Chem. 2015, 6, 4271–4278. [Google Scholar] [CrossRef]

- Cheng, B.; Lu, X.; Zhou, J.; Qin, R.; Yang, Y. Dual Cross-Linked Self-Healing and Recyclable Epoxidized Natural Rubber Based on Multiple Reversible E ff ects. ACS Sustain. Chem. Eng. 2019, 7, 4443–4455. [Google Scholar] [CrossRef]

- Raut, S.K.; Mondal, P.; Parameswaran, B.; Sarkar, S.; Dey, P.; Gilbert, R.; Bhadra, S.; Naskar, K.; Nair, S.; Singha, N.K. Self-healable Ultrahydrophobic Modified Bio-based Elastomer Using Diels-Alder ‘click chemistry’. Eur. Polym. J. 2020, 110204. [Google Scholar] [CrossRef]

- Cao, L.; Fan, J.; Huang, J.; Chen, Y. A robust and stretchable cross-linked rubbernetwork with recyclable and self-healable capabilities based on dynamic covalent bonds. J. Mater. Chem. A Mater. Energy Sustain. 2019, 7, 4922–4933. [Google Scholar] [CrossRef]

- Nie, J.; Mou, W.; Ding, J.; Chen, Y. Bio-based epoxidized natural rubber/chitin nanocrystals composites: Self-healing and enhanced mechanical properties. Compos. Part B 2019, 172, 152–160. [Google Scholar] [CrossRef]

- Xu, C.; Cui, R.; Fu, L.; Lin, B. Recyclable and heat-healable epoxidized natural rubber/bentonite composites. Compos. Sci. Technol. 2018, 167, 421–430. [Google Scholar] [CrossRef]

- Xu, C.; Nie, J.; Wu, W.; Zheng, Z.; Chen, Y. Self-Healable, Recyclable, and Strengthened Epoxidized Natural Rubber/Carboxymethyl Chitosan Biobased Composites with Hydrogen Bonding Supramolecular Hybrid Networks. ACS Sustain. Chem. Eng. 2019, 7, 15778–15789. [Google Scholar] [CrossRef]

- Nie, J.; Huang, J.; Fan, J.; Cao, L.; Xu, C.; Chen, Y. Strengthened, Self-Healing, and Conductive ENR-Based Composites Based on Multiple Hydrogen Bonding Interactions. ACS Sustain. Chem. Eng. 2020, 8, 13724–13733. [Google Scholar] [CrossRef]

- Kharouf, N.; Haikel, Y.; Ball, V. Polyphenols in dental applications. Bioengineering 2020, 7, 72. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez-Venegas, G.; Gómez-Mora, J.A.; Meraz-Rodríguez, M.A.; Flores-Sánchez, M.A.; Ortiz-Miranda, L.F. Effect of flavonoids on antimicrobial activity of microorganisms present in dental plaque. Heliyon 2019, 5, e03013. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, N.W.; Hong, D.W.; Attin, T.; Cheng, H.; Yu, H. Quercetin reduces erosive dentin wear: Evidence from laboratory and clinical studies. Dent. Mater. 2020, 36, 1430–1436. [Google Scholar] [CrossRef] [PubMed]

- Chladek, G.; Zmudzki, J.; Kasperski, J. Long-term soft denture lining materials. Materials 2014, 7, 5816–5842. [Google Scholar] [CrossRef] [Green Version]

- Flory, P.J.; Rehner, J. Statistical mechanics of cross-linked polymer networks II. Swelling. J. Chem. Phys. 1943, 11, 521–526. [Google Scholar] [CrossRef]

- Bandzierz, K.; Reuvekamp, L.; Dryzek, J.; Dierkes, W.; Blume, A.; Bielinski, D. Influence of network structure on glass transition temperature of elastomers. Materials 2016, 9, 607. [Google Scholar] [CrossRef] [Green Version]

- PKN. PN-ISO 37:1998 Standard—Polish Standard Guma i Kauczuk Termoplastyczny—Oznaczanie Właściwości Wytrzymałościowych przy Rozciąganiu; PKN: Warsaw, Poland, 1998. [Google Scholar]

- Xu, T.; Jia, Z.; Luo, Y.; Jia, D.; Peng, Z. Interfacial interaction between the epoxidized natural rubber and silica in natural rubber/silica composites. Appl. Surf. Sci. 2015, 328, 306–313. [Google Scholar] [CrossRef]

- Catauro, M.; Papale, F.; Bollino, F.; Piccolella, S.; Marciano, S.; Nocera, P.; Pacifico, S. Silica/quercetin sol-gel hybrids as antioxidant dental implant materials. Sci. Technol. Adv. Mater. 2015, 16, 035001. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kannan, R.R.R.; Arumugam, R.; Anantharaman, P. Fourier Transform Infrared Spectroscopy Analysis of Seagrass Polyphenols. Curr. Bioact. Compd. 2011, 7, 118–125. [Google Scholar] [CrossRef]

- Woźniak, M.; Kwaśniewska-Sip, P.; Waśkiewicz, A.; Cofta, G.; Ratajczak, I. The possibility of propolis extract application in wood protection. Forests 2020, 11, 465. [Google Scholar] [CrossRef] [Green Version]

| Components | Mass Ratio (phr) | ||||||

|---|---|---|---|---|---|---|---|

| ENR | ENR/ DCP2 | ENR/ Silica15 | ENR/ Quercetin2 | ENR/ Quercetin4 | ENR/ Quercetin2/ Silica15 | ENR/ Quercetin4/ Silica15 | |

| ENR-50 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| DCP | - | 2 | - | - | - | - | - |

| quercetin | - | - | - | 2 | 4 | 2 | 4 |

| silica | - | - | 15 | - | - | 15 | 15 |

| Composite | Mmin (dNm) | M20 (dNm) | ΔM20 (dNm) |

|---|---|---|---|

| ENR | 0.38 | 0.42 | 0.04 |

| ENR/silica15 | 0.84 | 0.86 | 0.02 |

| ENR/quercetin2 | 0.41 | 0.8 | 0.39 |

| ENR/quercetin4 | 0.51 | 1.31 | 0.8 |

| ENR/quercetin2/silica15 | 1.15 | 1.98 | 0.83 |

| ENR/quercetin4/silica15 | 1.24 | 2.76 | 1.52 |

| ENR/DCP2 | 0.38 | 4.34 | 3.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olejnik, O.; Masek, A.; Szynkowska-Jóźwik, M.I. Self-Healable Biocomposites Crosslinked with a Combination of Silica and Quercetin. Materials 2021, 14, 4028. https://0-doi-org.brum.beds.ac.uk/10.3390/ma14144028

Olejnik O, Masek A, Szynkowska-Jóźwik MI. Self-Healable Biocomposites Crosslinked with a Combination of Silica and Quercetin. Materials. 2021; 14(14):4028. https://0-doi-org.brum.beds.ac.uk/10.3390/ma14144028

Chicago/Turabian StyleOlejnik, Olga, Anna Masek, and Małgorzata Iwona Szynkowska-Jóźwik. 2021. "Self-Healable Biocomposites Crosslinked with a Combination of Silica and Quercetin" Materials 14, no. 14: 4028. https://0-doi-org.brum.beds.ac.uk/10.3390/ma14144028