Schedule Execution for Two-Machine Job-Shop to Minimize Makespan with Uncertain Processing Times

Abstract

:1. Introduction

1.1. Research Motivation

1.2. Contributions of This Research

2. Settings of Scheduling Problems and Main Notations

3. A Literature Review and Closed Results

3.1. Approaches to Scheduling Problems with Different Forms of Uncertainties

3.2. Closed Results for Uncertain (Interval) Flow-Shop Scheduling Problems

- (i)

- the set S is a set of pairs of the identical permutations of jobs from the set since the machine route for processing all jobs is the same ;

- (ii)

- the J-solution (see Definition 1) is a set of Johnson’s permutations of the jobs , i.e., for each scenario the set contains at least one optimal pair of identical Johnson’s permutations such that the inequality (2) holds for all indexes e and f.

4. The Off-Line Phase of Scheduling

4.1. Conditions for Existing a Single Optimal Pair of Job Permutations

4.2. Precedence Digraphs Determining a Minimal Dominant Set of Schedules

4.3. An Illustrative Example

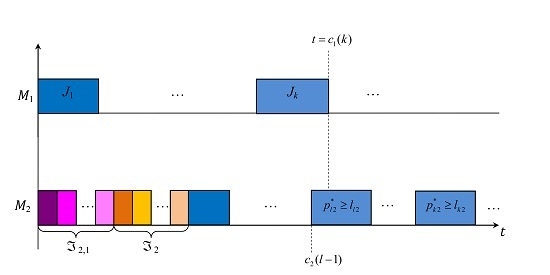

5. The On-line Phase of Scheduling

6. Scheduling Algorithms and Computational Results

6.1. Algorithms 3–5 for the On-Line Phase of Scheduling

- (a)

- the permutation of the jobs from set and the partial strict order of the jobs ;

- (b)

- the permutation of the jobs from set and the partial strict order of the jobs ;

- (c)

- the partial strict order of the jobs and the partial strict order of the jobs .

| Algorithm 3 for the on-line phase of scheduling | |

| Input: | Lower bounds and upper bounds on the durations of all operations processed on machines ; a permutation of the jobs and a permutation of the jobs ; an optimal permutation of the jobs from the set ; a partial strict order of the jobs from the set ; a number B of the conflict sets in the partial strict order . |

| Output: | Permutation of the jobs from the set . |

| Step 1: | Set . |

| Step 2: | UNTIL the completion time-point of the last job in the set , process the whole linear part of the jobs in the partial strict order on the machine till a conflict set of the jobs is met; let t denote a time-point of the completion of the linearly ordered set of jobs. |

| Step 3: | Process jobs of the permutation and then process the linear part in the partial strict order on the machine up to time-point t. |

| Step 4: | Check the conditions of Theorem 9 for the conflict set of the jobs. |

| Step 5: | IF the sufficient conditions of Theorem 9 hold THEN set and choose an arbitrary order of the conflict jobs GOTO step 11. |

| Step 6: | ELSE set for all conflict jobs and partition the conflict jobs into two subsets and , where if , and otherwise. |

| Step 7: | Construct the following order of the conflict jobs: First, arrange the jobs from the set in the non-decreasing order of the values of , then arrange the jobs from the set in the non-increasing order of the values of . |

| Step 8: | Check the conditions of Theorem 10 for the constructed permutation of the conflict jobs. |

| Step 9: | IF the sufficient conditions of Theorem 10 hold THEN set GOTO step 11. |

| Step 10: | Construct a Johnson’s permutation of the conflict jobs based on the inequalities (2) provided that . |

| Step 11: | Include the permutation of the conflict jobs in the strict order instead of the conflict set of these jobs. |

| Step 12: | RETURN |

| Step 13: | IFTHEN GOTO step 18. |

| Step 14: | Calculate makespan for the schedule s constructed at steps 1 – 12; calculate makespan for the optimal schedule polynomially calculated for the corresponding deterministic problem , where the factual processing times are randomly generated for all jobs . |

| Step 15: | IF = THEN GOTO step 17. |

| Step 16: | STOP 4: The constructed schedule s is not optimal for the factual processing times of the jobs . |

| Step 17: | STOP 3: The optimality of the constructed schedule s for the factual processing times of the jobs was established only after the execution of the schedule s. |

| Step 18: | STOP 2: The optimality of the constructed schedule s for the factual processing times of the jobs was proven before the end of the execution of this schedule. |

6.2. The Modified Example with Different Factual Scenarios

6.3. Computational Experiments

6.4. Computational Results

7. Concluding Remarks

Author Contributions

Acknowledgments

Conflicts of Interest

Appendix A

| Algorithm 1 | ||

| Input: | Segments for all jobs and machines , a partial strict order on the set in the form . | |

| Output: | EITHER an optimal job permutation for the problem with job set and any scenario , (see STOP 0). OR there no permutation of jobs from set , which is optimal for all scenarios , (see STOP 1). | |

| Step 1: | Set for all . construct a partition of the set of conflicting jobs into two subsets and , where if , and , otherwise. | |

| Step 2: | Construct a permutation , where the permutation contains jobs from the set in the non-decreasing order of the values and the permutation contains jobs from the set in the non-increasing order of the values , renumber jobs in the permutations and based on their orders. | |

| Step 3: | IF for the permutation conditions of Theorem 7 hold THEN GOTO step 8. | |

| Step 4: | Set for all . construct a partition of the set of conflicting jobs into two subsets and , where if 0, and , otherwise. | |

| Step 5: | Construct a permutation , where the permutation contains jobs from the set in the non-increasing order of the values , and the permutation contains jobs from the set in the non-decreasing order of the values , renumber jobs in the permutations and based on their orders. | |

| Step 6: | IF for the permutation conditions of Theorem 8 hold THEN GOTO step 9. | |

| Step 7: | ELSE there is no a single dominant permutation for problem with job set and any scenario STOP 1. | |

| Step 8: | RETURN permutation which is a single dominant permutation for the problem with job set STOP 0. | |

| Step 9: | RETURN permutation which is a single dominant permutation for the problem with job set STOP 0. | |

| Algorithm 2 | ||

| Input: | Lower bounds and upper bounds , , of the durations of all operations of jobs processed on machines . | |

| Output: | EITHER pair of permutations , where is a permutation of jobs from set on machine , is a permutation of jobs from set on machine , such that , (see STOP 0), OR permutation of jobs from set on machines and and a partial strict order of jobs from set , OR permutation of jobs from set on machines and and a partial strict order of jobs from set , OR a partial strict order of jobs from set and a partial strict order of jobs from set , (see STOP 1). | |

| Step 1: | Determine a partition of the job set , permutation of jobs from set and permutation of jobs from set , arrange the jobs in the increasing order of their indexes. | |

| Step 2: | IF the first inequality in condition (5) of Theorem 4 holds THEN BEGIN Construct a permutation of jobs from set , arrange them in the increasing order of their indexes; IF the second inequality in condition (5) of Theorem 4 holds THEN construct a permutation of jobs from set , arrange them in the increasing order of their indexes GOTO Step 10 END | |

| Step 3: | IF the first inequality in condition (6) of Theorem 4 holds THEN BEGIN Construct a permutation of jobs from set , arrange them in the increasing order of their indexes; IF the second inequality in condition (6) of Theorem 4 holds THEN construct a permutation of jobs from set , arrange the jobs in the increasing order of their indexes END | |

| Step 4: | IF both permutations and are constructed THEN GOTO Step 10. | |

| Step 5: | IF permutation is not constructed THEN fulfill Procedure 1. | |

| Step 6: | IF permutation is not constructed THEN fulfill Procedure 2. | |

| Step 7: | IF both permutations and are constructed THEN GOTO Step 10. | |

| Step 8: | IF permutation is constructed THEN GOTO Step 11. | |

| Step 9: | IF permutation is constructed THEN GOTO Step 12 ELSE GOTO Step 13. | |

| Step 10: | RETURN pair of permutations , where is the permutation of jobs from set processed on machine and is the permutation of jobs from set processed on machine such that STOP 0. | |

| Step 11: | RETURN the permutation of jobs from set processed on machines and , the partial strict order of jobs from set GOTO Step 14. | |

| Step 12: | RETURN the permutation of jobs from set processed on machines and , the partial strict order of jobs from set GOTO Step 14. | |

| Step 13: | RETURN the partial strict order of jobs from set and the partial strict order of jobs from set | |

| Step 14: | STOP 1. | |

Appendix B. Tables with Computational Results

| Uniform Distributions | Gamma Distributions | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

| 5 | Stop1 | 93.9 | 97.3 | 98.4 | 97.6 | 96.6 | 97.6 | 97.9 | 98.3 | 98 | 97.5 | 93.4 | 97 | 97.7 | 97.1 | 98.5 | 98.3 | 97.6 | 98.6 | 98.3 | 98.7 |

| Stop2 | 0.9 | 1 | 0.6 | 1.1 | 1.6 | 1.3 | 1.2 | 1.1 | 0.9 | 1.4 | 0.8 | 0.8 | 0.9 | 1.1 | 0.5 | 0.5 | 1.3 | 0.8 | 0.9 | 0.6 | |

| Stop3 | 5.1 | 1.7 | 1 | 1.3 | 1.8 | 1.1 | 0.9 | 0.6 | 1.1 | 1.1 | 5.3 | 2.2 | 1.4 | 1.8 | 1 | 1.2 | 1.1 | 0.6 | 0.8 | 0.7 | |

| Stop4 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 10 | Stop1 | 85.8 | 91.8 | 91.6 | 93 | 92.2 | 92.2 | 91.9 | 92.6 | 93.6 | 93.8 | 83.1 | 93.5 | 92.8 | 92.7 | 93.1 | 92.3 | 92.4 | 93.3 | 94.2 | 93.6 |

| Stop2 | 2.1 | 2.5 | 4.5 | 3.5 | 4.1 | 4 | 4.2 | 4.6 | 4.2 | 4.2 | 3.2 | 2.8 | 3.1 | 3.5 | 3.6 | 4.3 | 4.2 | 3.4 | 3.5 | 4.1 | |

| Stop3 | 11.7 | 5.7 | 3.9 | 3.5 | 3.7 | 3.8 | 3.9 | 2.8 | 2.2 | 2 | 12.8 | 3.7 | 4.1 | 3.8 | 3.3 | 3.4 | 3.4 | 3.3 | 2.3 | 2.3 | |

| Stop4 | 0.4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.9 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 20 | Stop1 | 70.6 | 73.2 | 73.3 | 71.9 | 69.6 | 63.4 | 63.6 | 57.7 | 56.3 | 53.4 | 70.2 | 73.7 | 74.1 | 71.5 | 67.2 | 64.2 | 63.4 | 61.5 | 56.1 | 57.5 |

| Stop2 | 4.3 | 6.8 | 9.4 | 8.6 | 8.8 | 11.1 | 9.4 | 10.1 | 9.2 | 9.2 | 4.3 | 8.1 | 8.7 | 10 | 10 | 11.3 | 9.1 | 9.1 | 8.9 | 7.5 | |

| Stop3 | 24.2 | 20 | 17.3 | 19.5 | 21.6 | 25.5 | 27 | 32.2 | 34.5 | 37.4 | 24.9 | 18.2 | 17.2 | 18.5 | 22.8 | 24.5 | 27.5 | 29.4 | 35 | 35 | |

| Stop4 | 0.9 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.6 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 30 | Stop1 | 53 | 55.1 | 47.5 | 41.1 | 31 | 30.7 | 23.4 | 20.3 | 18.5 | 13.4 | 52 | 52.2 | 44.9 | 34.9 | 33.6 | 26.3 | 27.3 | 18.3 | 18.9 | 14.2 |

| Stop2 | 4.8 | 8.8 | 9.1 | 9.7 | 9.8 | 7 | 6.7 | 5.2 | 4.2 | 4.4 | 6.2 | 8.9 | 10.1 | 10.4 | 11 | 7.9 | 6 | 4.6 | 5.9 | 4.5 | |

| Stop3 | 41.9 | 36.1 | 43.4 | 49.2 | 59.2 | 62.3 | 69.9 | 74.5 | 77.3 | 82.2 | 41 | 38.9 | 45 | 54.7 | 55.4 | 65.8 | 66.7 | 77.1 | 75.2 | 81.3 | |

| Stop4 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 40 | Stop1 | 41.6 | 32.5 | 24.7 | 16.4 | 10.9 | 8.9 | 5.9 | 3.9 | 2.1 | 2.3 | 37.8 | 31.8 | 22.2 | 18.6 | 10.6 | 8.5 | 6.1 | 4.3 | 3 | 1.9 |

| Stop2 | 4.9 | 7.6 | 7.7 | 6.6 | 4.2 | 2.9 | 2 | 1.1 | 0.7 | 0.3 | 5.2 | 8.5 | 9.1 | 4.8 | 2.9 | 3.5 | 2 | 1.6 | 1 | 0.6 | |

| Stop3 | 52.7 | 59.7 | 67.6 | 77 | 84.9 | 88.2 | 92.1 | 95 | 97.2 | 97.4 | 55.3 | 59.7 | 68.7 | 76.6 | 86.5 | 88 | 91.9 | 94.1 | 96 | 97.5 | |

| Stop4 | 0.8 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.7 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 50 | Stop1 | 29 | 16.1 | 9.3 | 5 | 2.4 | 1.4 | 1.6 | 0.8 | 0.5 | 0 | 26.2 | 19.4 | 10.4 | 5.6 | 3.9 | 1.6 | 0.6 | 0.5 | 0.3 | 0.1 |

| Stop2 | 4.7 | 5.4 | 5 | 2.6 | 1.2 | 0.8 | 0.2 | 0.3 | 0.3 | 0 | 3.7 | 5.6 | 3.8 | 2.2 | 0.7 | 0.7 | 0.7 | 0.1 | 0.2 | 0.1 | |

| Stop3 | 64.9 | 78.5 | 85.7 | 92.4 | 96.4 | 97.8 | 98.2 | 98.9 | 99.2 | 100 | 67.8 | 75 | 85.8 | 92.2 | 95.4 | 97.7 | 98.7 | 99.4 | 99.5 | 99.8 | |

| Stop4 | 1.4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 60 | Stop1 | 18.1 | 8.4 | 4.6 | 1.4 | 1 | 0.3 | 0.2 | 0.1 | 0 | 0 | 16.6 | 9.6 | 3.6 | 1.4 | 1 | 0.3 | 0 | 0.2 | 0 | 0 |

| Stop2 | 3.8 | 4 | 1.6 | 0.7 | 0.3 | 0.1 | 0 | 0 | 0 | 0 | 3.2 | 3.5 | 2.3 | 0.9 | 0.4 | 0 | 0.3 | 0 | 0.1 | 0 | |

| Stop3 | 76.4 | 87.5 | 93.8 | 97.9 | 98.7 | 99.6 | 99.8 | 99.9 | 100 | 100 | 77.7 | 86.9 | 94.1 | 97.7 | 98.6 | 99.7 | 99.7 | 99.8 | 99.9 | 100 | |

| Stop4 | 1.7 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2.5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 70 | Stop1 | 12.3 | 5.1 | 1.4 | 0.7 | 0.1 | 0 | 0 | 0 | 0 | 0 | 12.1 | 4.7 | 2.1 | 0.8 | 0.2 | 0 | 0.1 | 0 | 0 | 0 |

| Stop2 | 2.8 | 1.5 | 0.7 | 0.2 | 0.1 | 0 | 0 | 0 | 0 | 0 | 2 | 2.1 | 0.4 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 83.2 | 93.4 | 97.9 | 99.1 | 99.8 | 100 | 100 | 100 | 100 | 100 | 82.8 | 93.2 | 97.5 | 99 | 99.8 | 100 | 99.9 | 100 | 100 | 100 | |

| Stop4 | 1.7 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 80 | Stop1 | 8.9 | 1.9 | 0.4 | 0.3 | 0.2 | 0 | 0 | 0 | 0 | 0 | 10 | 2.3 | 0.6 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 |

| Stop2 | 1.8 | 0.8 | 0.5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2.2 | 1.1 | 0.2 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | |

| Stop3 | 87.1 | 97.1 | 99.1 | 99.7 | 99.8 | 100 | 100 | 100 | 100 | 100 | 84.2 | 96.5 | 99.2 | 99.8 | 100 | 99.9 | 100 | 100 | 100 | 100 | |

| Stop4 | 2.2 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3.6 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 90 | Stop1 | 6.9 | 0.8 | 0.2 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 5.7 | 0.9 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Stop2 | 1.2 | 0.7 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.5 | 0.5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 90.1 | 98.4 | 99.7 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 88 | 98.5 | 99.7 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| Stop4 | 1.8 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 4.8 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 100 | Stop1 | 4.4 | 0.3 | 0.1 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 4.1 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Stop2 | 1.1 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 92.1 | 99.4 | 99.9 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 90.2 | 99.4 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| Stop4 | 2.4 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 4.9 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Uniform Distributions | Gamma Distributions | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

| 5 | Stop1 | 96.7 | 98.9 | 98.6 | 99.5 | 99.7 | 99.7 | 99.9 | 99.9 | 99.9 | 99.9 | 96.7 | 98.9 | 99 | 99.3 | 99.6 | 99.4 | 99.7 | 99.8 | 99.9 | 99.8 |

| Stop2 | 0.8 | 0.3 | 0.7 | 0.1 | 0 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.3 | 0.4 | 0.1 | 0.3 | 0.1 | 0.4 | 0.2 | 0.1 | 0.1 | 0.2 | |

| Stop3 | 2.4 | 0.8 | 0.7 | 0.4 | 0.3 | 0.1 | 0 | 0 | 0 | 0 | 3 | 0.7 | 0.9 | 0.4 | 0.3 | 0.2 | 0.1 | 0.1 | 0 | 0 | |

| Stop4 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 10 | Stop1 | 93.4 | 96.2 | 97.6 | 97.7 | 98 | 98.4 | 98.4 | 98.7 | 98.5 | 99.6 | 93.5 | 96.1 | 97.5 | 97.6 | 97.8 | 98.1 | 98.4 | 98.2 | 99 | 98.7 |

| Stop2 | 1 | 1.4 | 1.4 | 1.4 | 1.4 | 1.3 | 1.1 | 1.2 | 1 | 0.4 | 1 | 1.8 | 1.1 | 1.3 | 1.5 | 1.6 | 1.3 | 1.5 | 0.9 | 1.1 | |

| Stop3 | 5.4 | 2.4 | 1 | 0.9 | 0.6 | 0.3 | 0.5 | 0.1 | 0.5 | 0 | 5.5 | 2.1 | 1.4 | 1.1 | 0.7 | 0.3 | 0.3 | 0.3 | 0.1 | 0.2 | |

| Stop4 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 20 | Stop1 | 85.4 | 86.9 | 89.5 | 90.2 | 90.8 | 90.5 | 89.1 | 90 | 90.3 | 90.1 | 83.5 | 87.5 | 88.8 | 88.4 | 90.6 | 89.9 | 91 | 89.4 | 90.9 | 90.1 |

| Stop2 | 2.6 | 4.8 | 5.3 | 5 | 5.8 | 5.8 | 5.7 | 5 | 5 | 5.4 | 3.1 | 5.7 | 5.8 | 7.4 | 4.7 | 5.8 | 4.9 | 6.5 | 6.2 | 4 | |

| Stop3 | 12 | 8.3 | 5.2 | 4.8 | 3.4 | 3.7 | 5.2 | 5 | 4.7 | 4.5 | 13.4 | 6.8 | 5.4 | 4.2 | 4.7 | 4.3 | 4.1 | 4.1 | 2.9 | 5.9 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 30 | Stop1 | 70.2 | 76.4 | 70.1 | 69.6 | 69.2 | 65.7 | 64.1 | 60.4 | 58 | 56 | 71.6 | 73.3 | 72.9 | 69 | 66 | 63.1 | 60.4 | 62.3 | 62.2 | 58.1 |

| Stop2 | 5.1 | 6.8 | 9.7 | 9.5 | 8.4 | 10.5 | 9.7 | 9.1 | 10.8 | 8.1 | 3.6 | 8.7 | 8.4 | 9.6 | 9.8 | 11.3 | 8.4 | 8.3 | 7.1 | 8.9 | |

| Stop3 | 24.6 | 16.8 | 20.2 | 20.9 | 22.4 | 23.8 | 26.2 | 30.5 | 31.2 | 35.9 | 24.8 | 18 | 18.7 | 21.4 | 24.2 | 25.6 | 31.2 | 29.4 | 30.7 | 33 | |

| Stop4 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 40 | Stop1 | 56.7 | 55.3 | 48.8 | 41.5 | 39.6 | 31.2 | 31.1 | 26.5 | 23.5 | 21.5 | 55.1 | 53.9 | 46.5 | 41.5 | 37.5 | 31.6 | 33.2 | 27.4 | 26.2 | 21 |

| Stop2 | 5.1 | 8.2 | 10.5 | 10.6 | 9.6 | 8.2 | 7.6 | 6.9 | 7.5 | 5 | 5.6 | 9.2 | 11.5 | 7.7 | 8.9 | 8.7 | 7.3 | 7.2 | 6 | 5.7 | |

| Stop3 | 38.2 | 36.5 | 40.7 | 47.9 | 50.8 | 60.6 | 61.3 | 66.6 | 69 | 73.5 | 39.3 | 36.9 | 42 | 50.8 | 53.6 | 59.7 | 59.5 | 65.4 | 67.8 | 73.3 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 50 | Stop1 | 42.6 | 35.2 | 27.2 | 22.9 | 14.3 | 11.4 | 9.9 | 6.9 | 6.6 | 5.9 | 43.9 | 37.3 | 29.2 | 22 | 16.3 | 13.2 | 10.8 | 10.5 | 5.5 | 5.7 |

| Stop2 | 4.4 | 9.5 | 9.8 | 6.5 | 6 | 5.2 | 3.8 | 3.4 | 2.2 | 2.4 | 6 | 10 | 7.3 | 6.9 | 6.5 | 4.8 | 4.7 | 2.8 | 1.9 | 2.5 | |

| Stop3 | 52.8 | 55.3 | 63 | 70.6 | 79.7 | 83.4 | 86.3 | 89.7 | 91.2 | 91.7 | 49.9 | 52.7 | 63.5 | 71.1 | 77.2 | 82 | 84.5 | 86.7 | 92.6 | 91.8 | |

| Stop4 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 60 | Stop1 | 32.9 | 20.7 | 14.4 | 10.7 | 6.3 | 3.3 | 3.3 | 2.2 | 1.4 | 0.8 | 31.7 | 23.1 | 15.7 | 10.4 | 7.2 | 3.9 | 2.9 | 1.4 | 0.9 | 0.6 |

| Stop2 | 5.4 | 5.5 | 4.2 | 2.6 | 2.3 | 1.7 | 0.8 | 0.6 | 0.3 | 0.4 | 5.6 | 6 | 6.4 | 3.6 | 2.4 | 1.5 | 1.5 | 0.8 | 0.3 | 0.7 | |

| Stop3 | 61.7 | 73.8 | 81.4 | 86.7 | 91.4 | 95 | 95.9 | 97.2 | 98.3 | 98.8 | 62.3 | 70.9 | 77.9 | 86 | 90.4 | 94.6 | 95.6 | 97.8 | 98.8 | 98.7 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 70 | Stop1 | 22.1 | 13.7 | 7.6 | 2.9 | 1.6 | 1.1 | 0.6 | 0.2 | 0.3 | 0.1 | 23.9 | 13.1 | 6.7 | 3.4 | 1.6 | 0.7 | 0.9 | 0.3 | 0.2 | 0.1 |

| Stop2 | 4.9 | 3.7 | 2.9 | 1.7 | 0.9 | 0.6 | 0.4 | 0.1 | 0 | 0.1 | 4.4 | 4.5 | 2 | 1.5 | 1.2 | 0.4 | 0 | 0.4 | 0.1 | 0.1 | |

| Stop3 | 72.8 | 82.6 | 89.5 | 95.4 | 97.5 | 98.3 | 99 | 99.7 | 99.7 | 99.8 | 71.6 | 82.4 | 91.3 | 95.1 | 97.2 | 98.9 | 99.1 | 99.3 | 99.7 | 99.8 | |

| Stop4 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 80 | Stop1 | 17.3 | 8.3 | 3.5 | 1.3 | 0.5 | 0.3 | 0.2 | 0 | 0 | 0 | 16.4 | 7.9 | 3.1 | 1.9 | 0.9 | 0.2 | 0 | 0 | 0 | 0 |

| Stop2 | 2.8 | 1.7 | 1.8 | 0.8 | 0.6 | 0 | 0 | 0 | 0 | 0 | 3.4 | 2.4 | 0.8 | 0.9 | 0.1 | 0.2 | 0.1 | 0 | 0 | 0 | |

| Stop3 | 79.4 | 90 | 94.7 | 97.9 | 98.9 | 99.7 | 99.8 | 100 | 100 | 100 | 79.6 | 89.7 | 96.1 | 97.2 | 99 | 99.6 | 99.9 | 100 | 100 | 100 | |

| Stop4 | 0.5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.6 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 90 | Stop1 | 12.1 | 4.5 | 1.4 | 0.7 | 0 | 0.1 | 0 | 0 | 0 | 0 | 12.6 | 5 | 2.9 | 0.4 | 0.1 | 0.1 | 0 | 0 | 0 | 0 |

| Stop2 | 2.5 | 2.3 | 1.3 | 0.3 | 0 | 0.1 | 0 | 0 | 0 | 0 | 3.2 | 1.8 | 0.2 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 85.2 | 93.2 | 97.3 | 99 | 100 | 99.8 | 100 | 100 | 100 | 100 | 83.7 | 93.2 | 96.9 | 99.4 | 99.9 | 99.9 | 100 | 100 | 100 | 100 | |

| Stop4 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 100 | Stop1 | 10.6 | 2.7 | 0.5 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | 9.1 | 2.8 | 0.5 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 |

| Stop2 | 1.9 | 1.2 | 0.3 | 0 | 0.2 | 0 | 0 | 0 | 0 | 0 | 2 | 0.6 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 87.4 | 96.1 | 99.2 | 99.7 | 99.8 | 100 | 100 | 100 | 100 | 100 | 88.2 | 96.6 | 99.3 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | |

| Stop4 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.7 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Uniform Distributions | Gamma Distributions | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

| 5 | Stop1 | 99.2 | 99.6 | 99.9 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 98.6 | 99.9 | 99.9 | 99.9 | 99.9 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 0.2 | 0.1 | 0.1 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 0.6 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.4 | 0.1 | 0.1 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 10 | Stop1 | 97.3 | 99 | 99.4 | 99.9 | 99.9 | 100 | 99.9 | 99.9 | 100 | 100 | 97.4 | 98.6 | 99.1 | 99.9 | 99.9 | 100 | 99.9 | 100 | 99.8 | 100 |

| Stop2 | 0.8 | 0.4 | 0.3 | 0.1 | 0.1 | 0 | 0.1 | 0.1 | 0 | 0 | 0.5 | 0.8 | 0.6 | 0.1 | 0.1 | 0 | 0.1 | 0 | 0.2 | 0 | |

| Stop3 | 1.9 | 0.6 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2.1 | 0.6 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 20 | Stop1 | 91.7 | 95.7 | 97.1 | 97.5 | 98.2 | 98.6 | 98.7 | 98.7 | 99.7 | 98.9 | 91.5 | 97 | 97.8 | 97.2 | 98.5 | 98.8 | 99.1 | 99.6 | 99.5 | 99.4 |

| Stop2 | 1.9 | 2.6 | 2 | 2.1 | 1.4 | 1.2 | 1.2 | 1.1 | 0.3 | 0.8 | 2.3 | 1.7 | 1.6 | 2.1 | 1.2 | 1 | 0.7 | 0.4 | 0.5 | 0.4 | |

| Stop3 | 6.4 | 1.7 | 0.9 | 0.4 | 0.4 | 0.2 | 0.1 | 0.2 | 0 | 0.3 | 6.2 | 1.3 | 0.6 | 0.7 | 0.3 | 0.2 | 0.2 | 0 | 0 | 0.2 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 30 | Stop1 | 81.9 | 87.1 | 89.1 | 91.9 | 91.7 | 92.2 | 92.2 | 93.8 | 93.7 | 93.9 | 83 | 87.2 | 91.7 | 91.7 | 92.4 | 91.6 | 92.2 | 92.8 | 92.9 | 93.4 |

| Stop2 | 4.6 | 6.2 | 5.9 | 4.5 | 5.5 | 4.3 | 4.3 | 3.9 | 2.8 | 2.5 | 3.1 | 5.1 | 4.1 | 4.4 | 3.7 | 4.4 | 4.8 | 4.2 | 3.5 | 3.5 | |

| Stop3 | 13.5 | 6.7 | 5 | 3.6 | 2.8 | 3.5 | 3.5 | 2.3 | 3.5 | 3.6 | 13.9 | 7.7 | 4.2 | 3.9 | 3.9 | 4 | 3 | 3 | 3.6 | 3.1 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 40 | Stop1 | 74.1 | 74.7 | 75.9 | 76 | 75.1 | 75.9 | 73.4 | 75.8 | 71.6 | 72.5 | 69.1 | 74.2 | 76.4 | 75.6 | 76.5 | 76.4 | 75 | 74 | 75.3 | 72.7 |

| Stop2 | 4.4 | 7.9 | 7.5 | 8.2 | 6.5 | 6.3 | 6.9 | 5.5 | 6.9 | 7 | 6 | 9.2 | 7.5 | 8 | 7.7 | 6.4 | 6.4 | 7.1 | 4.6 | 6.4 | |

| Stop3 | 21.5 | 17.4 | 16.6 | 15.8 | 18.4 | 17.8 | 19.7 | 18.7 | 21.5 | 20.5 | 24.8 | 16.6 | 16.1 | 16.4 | 15.8 | 17.2 | 18.6 | 18.9 | 20.1 | 20.9 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 50 | Stop1 | 61.4 | 60.7 | 56.9 | 53.7 | 50.4 | 49.7 | 47.3 | 47.3 | 44.7 | 39.1 | 58.2 | 60.6 | 57.7 | 51.7 | 49.1 | 50.9 | 48.3 | 48.2 | 43.9 | 44.3 |

| Stop2 | 5.3 | 9.2 | 9.7 | 10.4 | 10.2 | 7.7 | 8.4 | 7.1 | 6.7 | 6.3 | 5.8 | 8.7 | 8.5 | 12.4 | 10.2 | 9.1 | 7.8 | 7.1 | 6.6 | 5.3 | |

| Stop3 | 33.3 | 30.1 | 33.4 | 35.9 | 39.4 | 42.6 | 44.3 | 45.6 | 48.6 | 54.6 | 36 | 30.7 | 33.8 | 35.9 | 40.7 | 40 | 43.9 | 44.7 | 49.5 | 50.4 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 60 | Stop1 | 46.7 | 46.3 | 39.6 | 32.9 | 30.5 | 29.5 | 23.9 | 22.1 | 18.8 | 17.8 | 50.9 | 42.8 | 41.7 | 35.9 | 30.6 | 28 | 24 | 22.9 | 19 | 13.5 |

| Stop2 | 6.2 | 8.1 | 7.7 | 7.9 | 6.2 | 5.3 | 4.6 | 4.1 | 4.2 | 2.8 | 5 | 9.1 | 7.5 | 7.5 | 7.1 | 5.1 | 5.2 | 4.6 | 3.7 | 3.6 | |

| Stop3 | 47.1 | 45.6 | 52.7 | 59.2 | 63.3 | 65.2 | 71.5 | 73.8 | 77 | 79.4 | 44.1 | 48.1 | 50.8 | 56.6 | 62.3 | 66.9 | 70.8 | 72.5 | 77.3 | 82.9 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 70 | Stop1 | 39.9 | 34.5 | 24.5 | 20.2 | 17.6 | 12.2 | 8.7 | 8.6 | 7.6 | 5.5 | 38 | 34.8 | 23.5 | 19.1 | 15.7 | 13.7 | 9.5 | 9 | 6 | 4.7 |

| Stop2 | 5.7 | 7.4 | 6.7 | 5.5 | 4.1 | 2.8 | 2.7 | 1.9 | 1.4 | 0.9 | 6 | 6.8 | 6.3 | 5.6 | 3.9 | 4.8 | 3.4 | 1.4 | 1.4 | 1.3 | |

| Stop3 | 54.4 | 58.1 | 68.8 | 74.3 | 78.3 | 85 | 88.6 | 89.5 | 91 | 93.6 | 55.9 | 58.4 | 70.2 | 75.3 | 80.4 | 81.5 | 87.1 | 89.6 | 92.6 | 94 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 80 | Stop1 | 27.9 | 21.6 | 14.3 | 8.3 | 7.2 | 4.9 | 4.2 | 2.7 | 0.9 | 0.8 | 28.5 | 21.6 | 14 | 9.5 | 9.3 | 4.2 | 3.9 | 2.2 | 1.2 | 1.5 |

| Stop2 | 4.8 | 5 | 3.6 | 3 | 2.6 | 1.6 | 0.7 | 1 | 0.2 | 0.3 | 5.6 | 5.6 | 5.2 | 3.1 | 1.9 | 2.3 | 1.7 | 0.6 | 0.7 | 0.3 | |

| Stop3 | 67.2 | 73.4 | 82.1 | 88.7 | 90.2 | 93.5 | 95.1 | 96.3 | 98.9 | 98.9 | 65.9 | 72.8 | 80.8 | 87.4 | 88.8 | 93.5 | 94.4 | 97.2 | 98.1 | 98.2 | |

| Stop4 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 90 | Stop1 | 22.7 | 13.2 | 9.8 | 4.1 | 2.1 | 1.5 | 1.4 | 0.7 | 0.2 | 0 | 23 | 14.4 | 7.4 | 3.6 | 3.4 | 1.9 | 1.2 | 0.7 | 0.3 | 0.9 |

| Stop2 | 3.4 | 4.7 | 3.1 | 1.9 | 1.4 | 0.9 | 0.5 | 0.3 | 0.3 | 0.2 | 3.4 | 5.1 | 2.9 | 2 | 1 | 0.6 | 0.7 | 0.2 | 0.2 | 0.3 | |

| Stop3 | 73.9 | 82.1 | 87.1 | 94 | 96.5 | 97.6 | 98.1 | 99 | 99.5 | 99.8 | 73.4 | 80.5 | 89.7 | 94.4 | 95.6 | 97.5 | 98.1 | 99.1 | 99.5 | 98.8 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 100 | Stop1 | 17.1 | 8.9 | 3.8 | 2.1 | 1.2 | 0.6 | 0.2 | 0.2 | 0 | 0 | 14.7 | 8 | 4.7 | 2.5 | 1.4 | 0.3 | 0.3 | 0.2 | 0.1 | 0.1 |

| Stop2 | 2.6 | 4.3 | 1.6 | 1.5 | 0.4 | 0.2 | 0.2 | 0 | 0 | 0 | 4.6 | 2.4 | 1.7 | 0.6 | 0.5 | 0.3 | 0.3 | 0.1 | 0.1 | 0 | |

| Stop3 | 80.3 | 86.8 | 94.6 | 96.4 | 98.4 | 99.2 | 99.6 | 99.8 | 100 | 100 | 80.4 | 89.6 | 93.6 | 96.9 | 98.1 | 99.4 | 99.4 | 99.7 | 99.8 | 99.9 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Uniform Distributions | Gamma Distributions | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

| 5 | Stop1 | 99.8 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 99.5 | 99.8 | 99.9 | 100 | 99.9 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0.1 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.4 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 10 | Stop1 | 99.2 | 99.7 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 98.9 | 100 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 0.4 | 0.3 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.2 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 0.4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.9 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 20 | Stop1 | 96.8 | 98.9 | 99.4 | 99.5 | 99.9 | 99.8 | 100 | 100 | 100 | 99.9 | 96.4 | 98.6 | 99.6 | 99.7 | 99.9 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 1.1 | 0.6 | 0.4 | 0.5 | 0.1 | 0.2 | 0 | 0 | 0 | 0.1 | 1.6 | 0.8 | 0.4 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 2.1 | 0.5 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 0.6 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 30 | Stop1 | 91 | 95.7 | 97.8 | 98.7 | 99.2 | 99.5 | 99.4 | 99.8 | 99.9 | 100 | 91.8 | 94.9 | 97.3 | 98.6 | 99.1 | 99.6 | 99.9 | 99.9 | 99.7 | 100 |

| Stop2 | 3.5 | 1.7 | 1.2 | 0.9 | 0.7 | 0.2 | 0.4 | 0.1 | 0.1 | 0 | 2.3 | 3 | 1.8 | 1.1 | 0.7 | 0.3 | 0.1 | 0.1 | 0.3 | 0 | |

| Stop3 | 5.5 | 2.6 | 1 | 0.4 | 0.1 | 0.3 | 0.2 | 0.1 | 0 | 0 | 5.9 | 2.1 | 0.9 | 0.3 | 0.2 | 0.1 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 40 | Stop1 | 85.8 | 90.4 | 93.7 | 95.1 | 96.4 | 97.6 | 97.2 | 98.2 | 98.3 | 98.5 | 85.4 | 91.2 | 93 | 94.8 | 96.5 | 97.4 | 97.3 | 98 | 98.2 | 98 |

| Stop2 | 2.7 | 4.5 | 3.5 | 1.6 | 1.9 | 1.3 | 2.1 | 0.6 | 1 | 1 | 3.7 | 3.7 | 3.2 | 2.9 | 1.8 | 1.6 | 0.8 | 1.2 | 0.7 | 1.1 | |

| Stop3 | 11.5 | 5.1 | 2.8 | 3.3 | 1.7 | 1.1 | 0.7 | 1.2 | 0.7 | 0.5 | 10.9 | 5.1 | 3.8 | 2.3 | 1.7 | 1 | 1.9 | 0.8 | 1.1 | 0.9 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 50 | Stop1 | 75.3 | 82.5 | 84.8 | 87.4 | 87 | 88.2 | 89.7 | 90.7 | 90.5 | 92.3 | 76.3 | 82.5 | 82.4 | 85.4 | 87.5 | 89.7 | 89.6 | 90.4 | 90.7 | 91.3 |

| Stop2 | 5.1 | 5.5 | 6 | 4.4 | 5.1 | 3.8 | 3.7 | 3.3 | 3 | 3 | 4.1 | 5.9 | 6 | 5.9 | 3.9 | 3.5 | 3.3 | 2.4 | 2.7 | 2.4 | |

| Stop3 | 19.6 | 12 | 9.2 | 8.2 | 7.9 | 8 | 6.6 | 6 | 6.5 | 4.7 | 19.6 | 11.6 | 11.6 | 8.7 | 8.6 | 6.8 | 7.1 | 7.2 | 6.6 | 6.3 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 60 | Stop1 | 63.4 | 70.1 | 72.3 | 74.7 | 75.8 | 73.9 | 72.5 | 75.4 | 75.4 | 76.6 | 66.3 | 71 | 73.7 | 75.2 | 72.9 | 73.2 | 73.7 | 71.9 | 75.5 | 75.2 |

| Stop2 | 6.6 | 7 | 7.8 | 6.6 | 5.8 | 4.3 | 6.6 | 4.2 | 3.9 | 4.5 | 4.7 | 7.4 | 7 | 5.9 | 5.8 | 5.4 | 4.2 | 5.2 | 5.3 | 3.1 | |

| Stop3 | 30 | 22.9 | 19.9 | 18.7 | 18.4 | 21.8 | 20.9 | 20.4 | 20.7 | 18.9 | 29 | 21.6 | 19.3 | 18.9 | 21.3 | 21.4 | 22.1 | 22.9 | 19.2 | 21.7 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 70 | Stop1 | 51.6 | 60 | 57.2 | 55.7 | 56.5 | 52.9 | 50.5 | 50.9 | 50.8 | 50 | 49.5 | 57 | 54.6 | 55.1 | 54.8 | 53.2 | 52.8 | 49.9 | 50 | 51.5 |

| Stop2 | 6.3 | 7.5 | 8.3 | 7.3 | 6.1 | 5.8 | 7.2 | 6.2 | 5.7 | 4.2 | 6.3 | 8.6 | 8 | 7.2 | 6.5 | 5.6 | 7 | 5.9 | 5.2 | 5.7 | |

| Stop3 | 42.1 | 32.5 | 34.5 | 37 | 37.4 | 41.3 | 42.3 | 42.9 | 43.5 | 45.8 | 44.2 | 34.4 | 37.4 | 37.7 | 38.7 | 41.2 | 40.2 | 44.2 | 44.8 | 42.8 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 80 | Stop1 | 39.8 | 43.9 | 39.4 | 39 | 37.8 | 34.8 | 31.7 | 31.1 | 30 | 28.1 | 39 | 43.7 | 40.1 | 40.3 | 41.1 | 31.3 | 31.5 | 28.1 | 26 | 28.2 |

| Stop2 | 6.3 | 7.3 | 8.5 | 7.4 | 6.1 | 4.9 | 3.7 | 4.4 | 4.2 | 3.3 | 5.9 | 8.1 | 7.8 | 5.9 | 6.6 | 5.7 | 4.7 | 3.6 | 4.6 | 3 | |

| Stop3 | 53.9 | 48.8 | 52.1 | 53.6 | 56.1 | 60.3 | 64.6 | 64.5 | 65.8 | 68.6 | 55.1 | 48.2 | 52.1 | 53.8 | 52.3 | 63 | 63.8 | 68.3 | 69.4 | 68.8 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 90 | Stop1 | 33.7 | 28.9 | 27.6 | 24.1 | 20.7 | 18.2 | 16.8 | 13.5 | 14.1 | 12.4 | 31.7 | 32.1 | 28.8 | 23.8 | 23.8 | 20.1 | 17.1 | 15.9 | 14.2 | 12.3 |

| Stop2 | 6 | 7.7 | 6.9 | 5.3 | 4.5 | 3.3 | 3.6 | 2.8 | 2.6 | 1.7 | 5.7 | 7.1 | 5.9 | 6 | 4.7 | 3.5 | 3.8 | 3 | 3.1 | 1.6 | |

| Stop3 | 60.3 | 63.4 | 65.5 | 70.6 | 74.8 | 78.5 | 79.6 | 83.7 | 83.3 | 85.9 | 62.5 | 60.8 | 65.3 | 70.2 | 71.5 | 76.4 | 79.1 | 81.1 | 82.7 | 86.1 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 100 | Stop1 | 26.1 | 21.4 | 15.6 | 13.1 | 11.1 | 7.9 | 7.3 | 6 | 4.4 | 4.6 | 24.1 | 21.2 | 16.7 | 16.2 | 11 | 8.2 | 8.3 | 6.7 | 5.7 | 3.8 |

| Stop2 | 3.9 | 6.4 | 5.4 | 4.6 | 3.2 | 2.9 | 1.8 | 1.6 | 0.7 | 1.3 | 5 | 6.2 | 5 | 2.9 | 3.4 | 3.4 | 2.5 | 1.5 | 1.9 | 1 | |

| Stop3 | 70 | 72.2 | 79 | 82.3 | 85.7 | 89.2 | 90.9 | 92.4 | 94.9 | 94.1 | 70.9 | 72.6 | 78.3 | 80.9 | 85.6 | 88.4 | 89.2 | 91.8 | 92.4 | 95.2 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Uniform Distributions | Gamma Distributions | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

| 5 | Stop1 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 10 | Stop1 | 99.8 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 20 | Stop1 | 99.1 | 99.6 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 98.9 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 0.3 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.5 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 0.6 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.6 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 30 | Stop1 | 96.2 | 99.5 | 99.6 | 99.8 | 99.9 | 100 | 100 | 100 | 100 | 100 | 96.1 | 98.7 | 99.8 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 1.5 | 0.5 | 0.4 | 0.2 | 0.1 | 0 | 0 | 0 | 0 | 0 | 1.1 | 1.1 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 2.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2.8 | 0.2 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 40 | Stop1 | 91.3 | 97.4 | 99.2 | 99.2 | 99.6 | 99.9 | 100 | 100 | 100 | 100 | 91.4 | 96.7 | 98.9 | 99.1 | 99.7 | 99.6 | 99.9 | 100 | 100 | 100 |

| Stop2 | 3 | 1 | 0.2 | 0.5 | 0.1 | 0.1 | 0 | 0 | 0 | 0 | 2.1 | 1.7 | 0.6 | 0.7 | 0.3 | 0.2 | 0.1 | 0 | 0 | 0 | |

| Stop3 | 5.7 | 1.6 | 0.6 | 0.3 | 0.3 | 0 | 0 | 0 | 0 | 0 | 6.5 | 1.6 | 0.5 | 0.2 | 0 | 0.2 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 50 | Stop1 | 83.4 | 92.3 | 95.3 | 97.9 | 98.2 | 98.8 | 99.3 | 99.9 | 99.8 | 100 | 81.7 | 90 | 95.5 | 97.5 | 98.7 | 98.9 | 99.4 | 99.8 | 99.9 | 99.9 |

| Stop2 | 3.5 | 3.3 | 1.9 | 1.1 | 0.9 | 0.6 | 0.1 | 0.1 | 0.1 | 0 | 3.8 | 4.6 | 2.1 | 1.3 | 0.5 | 0.5 | 0.4 | 0 | 0 | 0 | |

| Stop3 | 13.1 | 4.4 | 2.8 | 1 | 0.9 | 0.6 | 0.6 | 0 | 0.1 | 0 | 14.5 | 5.4 | 2.4 | 1.2 | 0.8 | 0.6 | 0.2 | 0.2 | 0.1 | 0.1 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 60 | Stop1 | 69.4 | 83.1 | 87.1 | 93.8 | 94.5 | 96.1 | 96.4 | 97.8 | 98.6 | 98.3 | 71.2 | 81.5 | 89.2 | 92.6 | 93.5 | 95.1 | 98 | 98.2 | 98.5 | 98.9 |

| Stop2 | 5.7 | 6.7 | 5 | 2.5 | 2.2 | 1.3 | 0.8 | 0.7 | 0.4 | 0.6 | 6.5 | 6.8 | 3.3 | 3.3 | 2.3 | 2.1 | 0.5 | 0.8 | 0.7 | 0.1 | |

| Stop3 | 24.9 | 10.2 | 7.9 | 3.7 | 3.3 | 2.6 | 2.8 | 1.5 | 1 | 1.1 | 22.3 | 11.7 | 7.5 | 4.1 | 4.2 | 2.8 | 1.5 | 1 | 0.8 | 1 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 70 | Stop1 | 59.2 | 70.2 | 75.5 | 81.1 | 81.6 | 88.1 | 87.9 | 92.4 | 92.8 | 93.6 | 58.4 | 72.7 | 74.8 | 81.5 | 85.8 | 87.8 | 88 | 91 | 90.3 | 93.7 |

| Stop2 | 5.8 | 7.4 | 6.6 | 6 | 5.2 | 4.1 | 3.7 | 1.7 | 1.1 | 2.4 | 4.3 | 8.3 | 7.6 | 4.4 | 3.6 | 3.2 | 4.1 | 2.4 | 2.6 | 2 | |

| Stop3 | 35 | 22.4 | 17.9 | 12.9 | 13.2 | 7.8 | 8.4 | 5.9 | 6.1 | 4 | 37.3 | 19 | 17.6 | 14.1 | 10.6 | 9 | 7.9 | 6.6 | 7.1 | 4.3 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 80 | Stop1 | 45 | 57.2 | 61.8 | 62.7 | 67.8 | 68.7 | 71 | 74.9 | 75.5 | 77 | 46.8 | 54.8 | 61.1 | 64.1 | 69.4 | 71 | 71.4 | 73.8 | 75.8 | 76 |

| Stop2 | 7 | 8.5 | 7.2 | 7.4 | 7.5 | 6 | 6 | 5.2 | 4.2 | 3.9 | 5.5 | 7.5 | 7 | 7.7 | 6.4 | 5.3 | 6.4 | 4.5 | 4.4 | 3.5 | |

| Stop3 | 48 | 34.3 | 31 | 29.9 | 24.7 | 25.3 | 23 | 19.9 | 20.3 | 19.1 | 47.7 | 37.7 | 31.9 | 28.2 | 24.2 | 23.7 | 22.2 | 21.7 | 19.8 | 20.5 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 90 | Stop1 | 35.2 | 41.2 | 38.7 | 44.2 | 42.5 | 45.6 | 46.2 | 45.2 | 50.3 | 50 | 37.2 | 37.3 | 41.3 | 43.8 | 43.3 | 46.5 | 48 | 46.7 | 47.5 | 49.4 |

| Stop2 | 6 | 8.3 | 9.8 | 7.7 | 7.8 | 7.4 | 6.4 | 6.2 | 6.4 | 5.5 | 5.4 | 8.7 | 9.8 | 8.9 | 9.3 | 9.2 | 6.4 | 6.9 | 6.2 | 5.7 | |

| Stop3 | 58.8 | 50.5 | 51.5 | 48.1 | 49.7 | 47 | 47.4 | 48.6 | 43.3 | 44.5 | 57.4 | 54 | 48.9 | 47.3 | 47.4 | 44.3 | 45.6 | 46.4 | 46.3 | 44.9 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 100 | Stop1 | 25.7 | 28.8 | 25.2 | 22.6 | 21.4 | 21.4 | 20.2 | 20.5 | 19 | 22.1 | 26.5 | 26 | 25.2 | 25.5 | 25.1 | 22.1 | 22.8 | 19.9 | 23.8 | 20.7 |

| Stop2 | 4.1 | 8.6 | 8.1 | 6.9 | 7.9 | 5.9 | 6.6 | 5.4 | 5.5 | 4.3 | 3.7 | 9.2 | 7.8 | 6 | 7.2 | 7.1 | 5.4 | 5.1 | 4.8 | 4.9 | |

| Stop3 | 70.2 | 62.6 | 66.7 | 70.5 | 70.7 | 72.7 | 73.2 | 74.1 | 75.5 | 73.6 | 69.8 | 64.8 | 67 | 68.5 | 67.7 | 70.8 | 71.8 | 75 | 71.4 | 74.4 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Uniform Distributions | Gamma Distributions | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 40 | 60 | 80 | 100 | 20 | 40 | 60 | 80 | 100 | ||

| 5 | Stop1 | 99 | 99.5 | 99.7 | 99.3 | 99.4 | 98.1 | 99.7 | 99.8 | 99.2 | 99.7 |

| Stop2 | 0.3 | 0.3 | 0.2 | 0.4 | 0.6 | 0.4 | 0.2 | 0 | 0.6 | 0.3 | |

| Stop3 | 0.7 | 0.2 | 0.1 | 0.3 | 0 | 1.5 | 0.1 | 0.2 | 0.2 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 10 | Stop1 | 96.4 | 97.4 | 98.4 | 97.8 | 97.1 | 95.4 | 97.6 | 97.7 | 98 | 98.6 |

| Stop2 | 0.9 | 1.1 | 0.7 | 1.2 | 0.7 | 1.5 | 1.4 | 1 | 1.3 | 0.3 | |

| Stop3 | 2.7 | 1.5 | 0.9 | 1 | 2.2 | 3.1 | 1 | 1.3 | 0.7 | 1.1 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 20 | Stop1 | 84.3 | 81.4 | 76.5 | 71.7 | 67.9 | 86.5 | 80.5 | 73.8 | 71 | 66.5 |

| Stop2 | 3.1 | 3.5 | 3.7 | 2.5 | 2.1 | 2.9 | 3.5 | 2.9 | 3.7 | 1.7 | |

| Stop3 | 12.6 | 15.1 | 19.8 | 25.8 | 30 | 10.6 | 16 | 23.3 | 25.3 | 31.8 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 30 | Stop1 | 61.8 | 52.9 | 38.4 | 27.1 | 20.9 | 65.1 | 53 | 40 | 29.3 | 20.3 |

| Stop2 | 5.7 | 2.9 | 2.1 | 2.1 | 0.3 | 3.4 | 2.6 | 1.4 | 1.4 | 1.2 | |

| Stop3 | 32.5 | 44.2 | 59.5 | 70.8 | 78.8 | 31.4 | 44.4 | 58.6 | 69.3 | 78.5 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | |

| 40 | Stop1 | 38.6 | 25.5 | 14.1 | 7.3 | 3.1 | 40 | 24.4 | 13.6 | 6.5 | 3.2 |

| Stop2 | 5.4 | 1.2 | 1.2 | 0.4 | 0.3 | 4.5 | 2.4 | 0.4 | 0.4 | 0.1 | |

| Stop3 | 56 | 73.3 | 84.7 | 92.3 | 96.6 | 55.5 | 73.2 | 86 | 93.1 | 96.7 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 50 | Stop1 | 27.4 | 8.4 | 3.2 | 1.7 | 0.3 | 25.9 | 10.9 | 3.3 | 0.9 | 0.3 |

| Stop2 | 2.3 | 1.4 | 0.3 | 0 | 0 | 3.7 | 1.1 | 0 | 0 | 0 | |

| Stop3 | 70.2 | 90.2 | 96.5 | 98.3 | 99.7 | 70.4 | 88 | 96.7 | 99.1 | 99.7 | |

| Stop4 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 60 | Stop1 | 14.3 | 3.4 | 0.5 | 0.2 | 0 | 15.7 | 3.2 | 0.6 | 0.3 | 0 |

| Stop2 | 2.3 | 0.4 | 0 | 0 | 0 | 1.8 | 0.1 | 0.3 | 0 | 0 | |

| Stop3 | 83.4 | 96.2 | 99.5 | 99.8 | 100 | 82.4 | 96.7 | 99.1 | 99.7 | 100 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | |

| 70 | Stop1 | 8 | 1.1 | 0.3 | 0 | 0 | 6.5 | 1.7 | 0.1 | 0 | 0 |

| Stop2 | 0.9 | 0 | 0 | 0 | 0 | 1.5 | 0 | 0.1 | 0 | 0 | |

| Stop3 | 91.1 | 98.9 | 99.7 | 100 | 100 | 91.8 | 98.3 | 99.8 | 100 | 100 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0.2 | 0 | 0 | 0 | 0 | |

| 80 | Stop1 | 4 | 0.1 | 0 | 0.1 | 0 | 5.1 | 0.2 | 0 | 0 | 0 |

| Stop2 | 0.5 | 0.1 | 0 | 0 | 0 | 0.9 | 0 | 0 | 0 | 0 | |

| Stop3 | 95.5 | 99.8 | 100 | 99.9 | 100 | 93.8 | 99.8 | 100 | 100 | 100 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0.2 | 0 | 0 | 0 | 0 | |

| 90 | Stop1 | 2.6 | 0.3 | 0 | 0 | 0 | 2.2 | 0 | 0 | 0 | 0 |

| Stop2 | 0.3 | 0 | 0 | 0 | 0 | 0.4 | 0 | 0 | 0 | 0 | |

| Stop3 | 97.1 | 99.7 | 100 | 100 | 100 | 97 | 100 | 100 | 100 | 100 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0.4 | 0 | 0 | 0 | 0 | |

| 100 | Stop1 | 0.9 | 0 | 0 | 0 | 0 | 1.5 | 0 | 0 | 0 | 0 |

| Stop2 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 98.8 | 100 | 100 | 100 | 100 | 98.4 | 100 | 100 | 100 | 100 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | |

| Uniform Distributions | Gamma Distributions | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 40 | 60 | 80 | 100 | 20 | 40 | 60 | 80 | 100 | ||

| 5 | Stop1 | 98.9 | 99.4 | 99.3 | 99.7 | 99.5 | 98.4 | 99.7 | 99.4 | 99.7 | 99.7 |

| Stop2 | 0.2 | 0.3 | 0.4 | 0.3 | 0.3 | 0.4 | 0.2 | 0.2 | 0.2 | 0.2 | |

| Stop3 | 0.9 | 0.3 | 0.3 | 0 | 0.2 | 1.2 | 0.1 | 0.4 | 0.1 | 0.1 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 10 | Stop1 | 97 | 98.2 | 97.7 | 98.6 | 99.3 | 95.5 | 98.6 | 98.6 | 98.4 | 98.3 |

| Stop2 | 1 | 0.8 | 1.1 | 0.7 | 0.3 | 1.3 | 0.8 | 0.8 | 0.7 | 0.9 | |

| Stop3 | 2 | 1 | 1.2 | 0.7 | 0.4 | 3.2 | 0.6 | 0.6 | 0.9 | 0.8 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 20 | Stop1 | 86 | 86.7 | 83.3 | 76.9 | 75.4 | 88.3 | 86.1 | 83.3 | 77.4 | 74.6 |

| Stop2 | 2.6 | 2.8 | 2.5 | 3.1 | 2.5 | 2.5 | 2.3 | 3.1 | 2.7 | 2.3 | |

| Stop3 | 11.4 | 10.5 | 14.2 | 20 | 22.1 | 9.2 | 11.6 | 13.6 | 19.9 | 23.1 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 30 | Stop1 | 67.1 | 58.1 | 47.1 | 36.1 | 29.3 | 69 | 64.5 | 48.2 | 38.6 | 28.7 |

| Stop2 | 3.1 | 3.2 | 2.8 | 2.6 | 1.5 | 3.2 | 2.1 | 2.2 | 2 | 1.2 | |

| Stop3 | 29.8 | 38.7 | 50.1 | 61.3 | 69.2 | 27.8 | 33.4 | 49.6 | 59.4 | 70.1 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 40 | Stop1 | 48.2 | 30.1 | 18.9 | 11.1 | 8.3 | 45.6 | 31.8 | 17.6 | 10.5 | 6.6 |

| Stop2 | 2.7 | 3.7 | 1.2 | 0.3 | 0.1 | 4.3 | 2.6 | 1.9 | 0.7 | 0.3 | |

| Stop3 | 49.1 | 66.2 | 79.9 | 88.6 | 91.6 | 50.1 | 65.6 | 80.5 | 88.8 | 93.1 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 50 | Stop1 | 30.1 | 15.1 | 7.4 | 3 | 1.2 | 29.1 | 13.2 | 6 | 2.7 | 1.7 |

| Stop2 | 2.8 | 1.3 | 0.7 | 0.3 | 0 | 2.6 | 1.1 | 0.3 | 0.2 | 0 | |

| Stop3 | 67.1 | 83.6 | 91.9 | 96.7 | 98.8 | 68.3 | 85.7 | 93.7 | 97.1 | 98.3 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 60 | Stop1 | 19.2 | 7.6 | 1.9 | 0.5 | 0 | 21.1 | 5.9 | 2.6 | 0.5 | 0.3 |

| Stop2 | 1.5 | 0.4 | 0 | 0 | 0.1 | 2 | 0.5 | 0.2 | 0 | 0 | |

| Stop3 | 79.3 | 92 | 98.1 | 99.5 | 99.9 | 76.9 | 93.6 | 97.2 | 99.5 | 99.7 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 70 | Stop1 | 11.4 | 2.6 | 0.9 | 0 | 0 | 12 | 3.1 | 0.3 | 0 | 0.1 |

| Stop2 | 1.9 | 0.1 | 0 | 0 | 0 | 0.8 | 0.2 | 0 | 0 | 0 | |

| Stop3 | 86.7 | 97.3 | 99.1 | 100 | 100 | 87.2 | 96.7 | 99.7 | 100 | 99.9 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 80 | Stop1 | 7.6 | 1.2 | 0.1 | 0 | 0 | 7.9 | 0.6 | 0.2 | 0 | 0 |

| Stop2 | 0.7 | 0.1 | 0 | 0 | 0 | 1 | 0.1 | 0 | 0 | 0 | |

| Stop3 | 91.7 | 98.7 | 99.9 | 100 | 100 | 91.1 | 99.3 | 99.8 | 100 | 100 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 90 | Stop1 | 3.4 | 0.6 | 0.1 | 0 | 0 | 4.6 | 0.5 | 0.1 | 0 | 0 |

| Stop2 | 0.4 | 0 | 0 | 0 | 0 | 0.5 | 0 | 0 | 0 | 0 | |

| Stop3 | 96.2 | 99.4 | 99.9 | 100 | 100 | 94.9 | 99.5 | 99.9 | 100 | 100 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 100 | Stop1 | 2.7 | 0.2 | 0 | 0 | 0 | 2.9 | 0.2 | 0 | 0 | 0 |

| Stop2 | 0.5 | 0 | 0 | 0 | 0 | 0.3 | 0 | 0 | 0 | 0 | |

| Stop3 | 96.8 | 99.8 | 100 | 100 | 100 | 96.8 | 99.8 | 100 | 100 | 100 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Uniform Distributions | Gamma Distributions | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 40 | 60 | 80 | 100 | 20 | 40 | 60 | 80 | 100 | ||

| 5 | Stop1 | 98.6 | 99.2 | 99.6 | 99.4 | 99.5 | 98.3 | 99.2 | 99.7 | 99.8 | 99.6 |

| Stop2 | 0.1 | 0.4 | 0.3 | 0.4 | 0.5 | 0.5 | 0.1 | 0.1 | 0.1 | 0.3 | |

| Stop3 | 1.3 | 0.4 | 0.1 | 0.2 | 0 | 1.2 | 0.7 | 0.2 | 0.1 | 0.1 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 10 | Stop1 | 96.1 | 98.5 | 99.7 | 99.1 | 99.1 | 96.6 | 98.2 | 98.2 | 98.9 | 98.4 |

| Stop2 | 1.1 | 0.6 | 0.2 | 0.7 | 0.4 | 0.3 | 0.9 | 1.2 | 0.6 | 0.9 | |

| Stop3 | 2.8 | 0.9 | 0.1 | 0.2 | 0.5 | 3.1 | 0.9 | 0.6 | 0.5 | 0.7 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 20 | Stop1 | 88.8 | 87.6 | 84.6 | 80.1 | 77.6 | 89.5 | 89.8 | 84.6 | 83.5 | 79.3 |

| Stop2 | 1.9 | 2.4 | 2.6 | 2.2 | 2.8 | 3 | 1.9 | 2.7 | 1.9 | 2.4 | |

| Stop3 | 9.3 | 10 | 12.8 | 17.7 | 19.6 | 7.5 | 8.3 | 12.7 | 14.6 | 18.3 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 30 | Stop1 | 72 | 62.3 | 52.3 | 43.2 | 33.5 | 70.6 | 63.1 | 53 | 42.4 | 36.9 |

| Stop2 | 3.4 | 2.2 | 3.9 | 3 | 1.8 | 3.9 | 3.4 | 3.9 | 2.5 | 0.6 | |

| Stop3 | 24.6 | 35.5 | 43.8 | 53.8 | 64.7 | 25.5 | 33.5 | 43.1 | 55.1 | 62.5 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 40 | Stop1 | 50.6 | 37.1 | 25.9 | 15 | 9.9 | 50.7 | 36.4 | 25.9 | 16.5 | 10.3 |

| Stop2 | 3.7 | 2.1 | 1.8 | 0.7 | 0.4 | 3.5 | 2.7 | 1.3 | 1 | 0.4 | |

| Stop3 | 45.7 | 60.8 | 72.3 | 84.3 | 89.7 | 45.8 | 60.9 | 72.8 | 82.5 | 89.3 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 50 | Stop1 | 36.2 | 19.5 | 9.4 | 4.5 | 1.7 | 33.2 | 17.9 | 9.6 | 4.3 | 2.8 |

| Stop2 | 3.1 | 1.6 | 0 | 0.1 | 0.2 | 3.9 | 0.9 | 0.6 | 0.3 | 0 | |

| Stop3 | 60.7 | 78.9 | 90.6 | 95.4 | 98.1 | 62.9 | 81.2 | 89.8 | 95.4 | 97.2 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 60 | Stop1 | 25.2 | 7.7 | 3.1 | 1.2 | 0.3 | 24 | 7.6 | 3.5 | 0.6 | 0.5 |

| Stop2 | 2 | 0.7 | 0.3 | 0 | 0 | 1.6 | 1.2 | 0.2 | 0 | 0 | |

| Stop3 | 72.8 | 91.6 | 96.6 | 98.8 | 99.7 | 74.4 | 91.2 | 96.3 | 99.4 | 99.5 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 70 | Stop1 | 12 | 3.3 | 0.8 | 0.2 | 0.4 | 16.6 | 4.1 | 1.6 | 0.5 | 0.1 |

| Stop2 | 2.3 | 0.4 | 0.1 | 0 | 0 | 1.1 | 0.7 | 0 | 0 | 0 | |

| Stop3 | 85.7 | 96.3 | 99.1 | 99.8 | 99.6 | 82.3 | 95.2 | 98.4 | 99.5 | 99.9 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 80 | Stop1 | 9.4 | 1.8 | 0.3 | 0 | 0 | 9.9 | 1.8 | 0.1 | 0 | 0 |

| Stop2 | 1.4 | 0.1 | 0 | 0 | 0 | 1 | 0.1 | 0 | 0 | 0 | |

| Stop3 | 89.2 | 98.1 | 99.7 | 100 | 100 | 89 | 98.1 | 99.9 | 100 | 100 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | |

| 90 | Stop1 | 5.6 | 0.3 | 0.1 | 0.1 | 0 | 6.5 | 0.6 | 0.1 | 0 | 0 |

| Stop2 | 0.7 | 0.1 | 0 | 0 | 0 | 0.3 | 0.1 | 0 | 0 | 0 | |

| Stop3 | 93.7 | 99.6 | 99.9 | 99.9 | 100 | 93.2 | 99.3 | 99.9 | 100 | 100 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 100 | Stop1 | 4.5 | 0.5 | 0 | 0 | 0 | 4.5 | 0.2 | 0 | 0 | 0 |

| Stop2 | 0.2 | 0 | 0 | 0 | 0 | 0.2 | 0 | 0 | 0 | 0 | |

| Stop3 | 95.3 | 99.5 | 100 | 100 | 100 | 95.3 | 99.8 | 100 | 100 | 100 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Uniform Distributions | Gamma Distributions | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

| 5 | Stop1 | 98.9 | 99.5 | 100 | 99.8 | 100 | 99.9 | 100 | 100 | 100 | 99.9 | 98.4 | 99.4 | 99.9 | 100 | 99.9 | 99.9 | 100 | 100 | 100 | 100 |

| Stop2 | 0.4 | 0 | 0 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0.3 | 0.1 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | |

| Stop3 | 0.7 | 0.5 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 1.6 | 0.3 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 10 | Stop1 | 95.9 | 98.9 | 98.9 | 100 | 99.8 | 100 | 100 | 100 | 99.9 | 99.9 | 96.2 | 98.4 | 99.5 | 99.7 | 99.8 | 99.9 | 99.9 | 99.8 | 99.8 | 99.9 |

| Stop2 | 0.2 | 0.5 | 0.6 | 0 | 0.2 | 0 | 0 | 0 | 0.1 | 0 | 0.3 | 0.3 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.1 | |

| Stop3 | 3.8 | 0.6 | 0.5 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 3.4 | 1.3 | 0.3 | 0.2 | 0.1 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 20 | Stop1 | 88.8 | 97 | 97.1 | 97.8 | 97.8 | 97.5 | 98.2 | 98.7 | 97.5 | 97.9 | 88.5 | 95.3 | 96.5 | 97.2 | 97.6 | 97.3 | 97.9 | 98.3 | 98.2 | 97.5 |

| Stop2 | 1.6 | 1.2 | 1.1 | 0.5 | 0.6 | 1 | 0.6 | 0.4 | 0.2 | 0.2 | 1.6 | 1.6 | 1 | 1.3 | 0.5 | 0.7 | 0.8 | 0.7 | 0.6 | 0.4 | |

| Stop3 | 9.5 | 1.8 | 1.8 | 1.7 | 1.6 | 1.5 | 1.2 | 0.9 | 2.3 | 1.9 | 9.8 | 3.1 | 2.5 | 1.5 | 1.9 | 2 | 1.3 | 1 | 1.2 | 2.1 | |

| Stop4 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 30 | Stop1 | 79.3 | 85.8 | 86.6 | 85.1 | 81.4 | 83.3 | 82.6 | 79.2 | 77.4 | 75.9 | 80.4 | 86.3 | 86.5 | 85.1 | 81.2 | 81.6 | 80.8 | 80 | 79 | 76.1 |

| Stop2 | 3.7 | 2.2 | 2.5 | 1.7 | 2.9 | 1.8 | 1.5 | 1.2 | 1.5 | 1 | 2.4 | 2.8 | 2.8 | 1.7 | 1.9 | 1.4 | 1.4 | 1.3 | 1 | 0.6 | |

| Stop3 | 17 | 12 | 10.9 | 13.2 | 15.7 | 14.9 | 15.9 | 19.6 | 21.1 | 23.1 | 16.9 | 10.9 | 10.7 | 13.2 | 16.9 | 17 | 17.8 | 18.7 | 20 | 23.3 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 40 | Stop1 | 66.6 | 71.7 | 65.8 | 62.2 | 58.2 | 53.1 | 48.4 | 44 | 42 | 38.3 | 65.8 | 70.1 | 65.8 | 60.9 | 57.4 | 52.7 | 53.9 | 46.8 | 40.6 | 38.5 |

| Stop2 | 3 | 2.6 | 2.4 | 2.8 | 2.2 | 2.4 | 1.7 | 2 | 1.1 | 0.9 | 2.6 | 2.7 | 2.6 | 1.8 | 1.6 | 1.5 | 2.1 | 1 | 0.9 | 1.1 | |

| Stop3 | 30.2 | 25.7 | 31.8 | 35 | 39.6 | 44.5 | 49.9 | 54 | 56.9 | 60.8 | 31.1 | 27.2 | 31.6 | 37.3 | 41 | 45.8 | 44 | 52.2 | 58.5 | 60.4 | |

| Stop4 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 50 | Stop1 | 55.8 | 55.3 | 46.9 | 38.9 | 30.9 | 25.5 | 22.2 | 19.9 | 15.1 | 13.2 | 56 | 52.9 | 44.3 | 39.4 | 34.1 | 27.4 | 22.6 | 18.2 | 17.5 | 14.9 |

| Stop2 | 2.6 | 2.9 | 2.4 | 2.5 | 1.7 | 1 | 0.8 | 0.3 | 0.7 | 0.6 | 3.3 | 3.5 | 2.4 | 1.4 | 1.7 | 1.1 | 0.7 | 0.5 | 0.4 | 0.7 | |

| Stop3 | 41.6 | 41.8 | 50.7 | 58.6 | 67.4 | 73.5 | 77 | 79.8 | 84.2 | 86.2 | 40.5 | 43.6 | 53.3 | 59.2 | 64.2 | 71.5 | 76.7 | 81.3 | 82.1 | 84.4 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 60 | Stop1 | 44.4 | 35.9 | 27.8 | 20.1 | 15.6 | 12.7 | 8.6 | 7.1 | 7.8 | 3.3 | 43.6 | 36.5 | 26.2 | 20.7 | 14.6 | 9.9 | 8.8 | 6.4 | 4.2 | 3.2 |

| Stop2 | 3.2 | 2.7 | 1.6 | 0.9 | 0.8 | 0.7 | 0.2 | 0.1 | 0.2 | 0.1 | 3.3 | 2 | 1.4 | 1.8 | 1.7 | 0.2 | 0.2 | 0.3 | 0.1 | 0 | |

| Stop3 | 52.2 | 61.4 | 70.6 | 79 | 83.6 | 86.6 | 91.2 | 92.8 | 92 | 96.6 | 52.5 | 61.5 | 72.4 | 77.5 | 83.7 | 89.9 | 91 | 93.3 | 95.7 | 96.8 | |

| Stop4 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.6 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 70 | Stop1 | 33.5 | 25.4 | 17 | 11.2 | 6.6 | 2.8 | 2 | 1.2 | 1.1 | 0.7 | 36.7 | 24 | 17.3 | 11.6 | 5.7 | 5.2 | 3.5 | 1.5 | 0.7 | 1.1 |

| Stop2 | 2.5 | 2 | 1.5 | 0.4 | 0.5 | 0.1 | 0.3 | 0.2 | 0.1 | 0 | 2.4 | 1.9 | 1 | 0.5 | 0.2 | 0.2 | 0 | 0.1 | 0 | 0 | |

| Stop3 | 63.8 | 72.6 | 81.5 | 88.4 | 92.9 | 97.1 | 97.7 | 98.6 | 98.8 | 99.3 | 60.5 | 74.1 | 81.7 | 87.9 | 94.1 | 94.6 | 96.5 | 98.4 | 99.3 | 98.9 | |

| Stop4 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 80 | Stop1 | 29.8 | 13.5 | 10 | 5.1 | 2.9 | 1.2 | 0.3 | 0.4 | 0 | 0.1 | 27.9 | 18.6 | 8.4 | 4 | 2.5 | 1.4 | 0.9 | 0.4 | 0.2 | 0.1 |

| Stop2 | 1.9 | 1.4 | 0.3 | 0.4 | 0.1 | 0 | 0 | 0.1 | 0 | 0 | 2.5 | 0.8 | 0.5 | 0.2 | 0.1 | 0.2 | 0 | 0 | 0 | 0 | |

| Stop3 | 68.1 | 85.1 | 89.7 | 94.5 | 97 | 98.8 | 99.7 | 99.5 | 100 | 99.9 | 68.8 | 80.6 | 91.1 | 95.8 | 97.4 | 98.4 | 99.1 | 99.6 | 99.8 | 99.9 | |

| Stop4 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 90 | Stop1 | 22.4 | 10.5 | 3.9 | 1.7 | 0.7 | 0.1 | 0.3 | 0.2 | 0 | 0 | 20.8 | 10.2 | 4.5 | 3.1 | 0.7 | 0.2 | 0.3 | 0 | 0 | 0 |

| Stop2 | 1.9 | 0.6 | 0.6 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 1.6 | 0.9 | 0.5 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | |

| Stop3 | 75.3 | 88.9 | 95.5 | 98.2 | 99.3 | 99.9 | 99.7 | 99.8 | 100 | 100 | 76.8 | 88.9 | 95 | 96.9 | 99.3 | 99.7 | 99.7 | 100 | 100 | 100 | |

| Stop4 | 0.4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 100 | Stop1 | 15.6 | 5.9 | 1.5 | 0.9 | 0.6 | 0.1 | 0.1 | 0 | 0 | 0 | 15.9 | 6.7 | 2.6 | 0.9 | 0.2 | 0.1 | 0.2 | 0 | 0 | 0 |

| Stop2 | 1.6 | 0.7 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.7 | 0.2 | 0.2 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 82.3 | 93.4 | 98.3 | 99.1 | 99.4 | 99.9 | 99.9 | 100 | 100 | 100 | 81.4 | 93.1 | 97.2 | 99 | 99.8 | 99.9 | 99.8 | 100 | 100 | 100 | |

| Stop4 | 0.5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Uniform Distributions | Gamma Distributions | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

| 5 | Stop1 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 10 | Stop1 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 20 | Stop1 | 99.3 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 99.5 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 0.5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 30 | Stop1 | 98.4 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 99 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 0.5 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 1.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.9 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 40 | Stop1 | 97 | 99.8 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 96.4 | 99.8 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 0.1 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.5 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 2.9 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 50 | Stop1 | 93 | 99 | 99.9 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 92.8 | 99.6 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 1.2 | 0.5 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.9 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 5.8 | 0.5 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 6.3 | 0.3 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 60 | Stop1 | 86.6 | 97.9 | 99.6 | 99.5 | 99.8 | 99.8 | 99.8 | 99.9 | 100 | 100 | 85.8 | 97.1 | 99.3 | 99.6 | 99.8 | 99.7 | 99.9 | 100 | 100 | 100 |

| Stop2 | 1.4 | 0.5 | 0 | 0.2 | 0 | 0.1 | 0 | 0 | 0 | 0 | 1.5 | 0.4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 12 | 1.6 | 0.4 | 0.3 | 0.2 | 0.1 | 0.2 | 0.1 | 0 | 0 | 12.7 | 2.5 | 0.7 | 0.4 | 0.2 | 0.3 | 0.1 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 70 | Stop1 | 82.3 | 92.5 | 96.7 | 97.2 | 98.6 | 98.1 | 99 | 99.2 | 99.5 | 99.7 | 80 | 92.7 | 96.5 | 97.5 | 97.9 | 99.2 | 99.5 | 99.5 | 99.8 | 99.5 |

| Stop2 | 1.8 | 1.1 | 0.2 | 0.2 | 0 | 0 | 0.1 | 0 | 0 | 0.1 | 1.7 | 0.5 | 0 | 0.2 | 0.1 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 15.9 | 6.4 | 3.1 | 2.6 | 1.4 | 1.9 | 0.9 | 0.8 | 0.5 | 0.2 | 18.3 | 6.8 | 3.5 | 2.3 | 2 | 0.8 | 0.5 | 0.5 | 0.2 | 0.5 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 80 | Stop1 | 71.8 | 85.9 | 91.5 | 93.8 | 94.4 | 95.3 | 95.6 | 97.7 | 97.3 | 98.1 | 73.1 | 87.2 | 91 | 93.1 | 95.1 | 95.9 | 96.7 | 97.3 | 98.1 | 98.8 |

| Stop2 | 1.9 | 1.2 | 0.6 | 0.2 | 0.5 | 0 | 0 | 0.1 | 0 | 0.1 | 2 | 0.9 | 0.2 | 0.7 | 0.1 | 0.2 | 0 | 0.3 | 0 | 0 | |

| Stop3 | 26.3 | 12.9 | 7.9 | 6 | 5.1 | 4.7 | 4.4 | 2.2 | 2.7 | 1.8 | 24.9 | 11.9 | 8.8 | 6.2 | 4.8 | 3.9 | 3.3 | 2.4 | 1.9 | 1.2 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 90 | Stop1 | 63.2 | 77.8 | 81.6 | 84.2 | 85 | 88.7 | 89.9 | 91.5 | 93.6 | 93.6 | 61.7 | 77.2 | 83.3 | 85 | 86.4 | 88 | 90.4 | 91.4 | 92.7 | 94.4 |

| Stop2 | 2.6 | 1 | 0.8 | 1.1 | 0.2 | 0.2 | 0.6 | 0.2 | 0.1 | 0.2 | 2.6 | 1.9 | 0.9 | 0.2 | 0.5 | 0.2 | 0.1 | 0.1 | 0 | 0.1 | |

| Stop3 | 34.2 | 21.2 | 17.6 | 14.7 | 14.8 | 11.1 | 9.5 | 8.3 | 6.3 | 6.2 | 35.7 | 20.9 | 15.8 | 14.8 | 13.1 | 11.8 | 9.5 | 8.5 | 7.3 | 5.5 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 100 | Stop1 | 53.1 | 66.7 | 68.3 | 70.3 | 74.1 | 74.1 | 75.6 | 78.3 | 81 | 84.1 | 51.8 | 67 | 69.8 | 71 | 72.5 | 75.9 | 75.7 | 79.6 | 79.8 | 80.3 |

| Stop2 | 2.1 | 1.7 | 0.6 | 0.8 | 0.3 | 0.7 | 0.3 | 0.2 | 0.1 | 0.3 | 2.4 | 0.9 | 1 | 0.7 | 1.1 | 0.5 | 0.3 | 0.6 | 0.3 | 0.5 | |

| Stop3 | 44.8 | 31.6 | 31.1 | 28.9 | 25.6 | 25.2 | 24.1 | 21.5 | 18.9 | 15.6 | 45.8 | 32.1 | 29.2 | 28.3 | 26.4 | 23.6 | 24 | 19.8 | 19.9 | 19.2 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Uniform Distributions | Gamma Distributions | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

| 5 | Stop1 | 99.2 | 99.6 | 99.8 | 100 | 99.9 | 100 | 100 | 100 | 100 | 100 | 98.5 | 99.8 | 99.9 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 0 | 0.1 | 0.2 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0.2 | 0.1 | 0.1 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 0.8 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.3 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 10 | Stop1 | 98.1 | 99.2 | 99.4 | 99.9 | 99.9 | 99.8 | 100 | 100 | 100 | 100 | 96.4 | 99.2 | 99.8 | 99.7 | 99.8 | 99.9 | 99.9 | 100 | 100 | 100 |

| Stop2 | 0.1 | 0.5 | 0.4 | 0.1 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0.6 | 0.3 | 0.2 | 0.1 | 0 | 0.1 | 0.1 | 0 | 0 | 0 | |

| Stop3 | 1.8 | 0.3 | 0.2 | 0 | 0 | 0.2 | 0 | 0 | 0 | 0 | 3 | 0.5 | 0 | 0.2 | 0.2 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 20 | Stop1 | 91.3 | 97.7 | 97.7 | 97.8 | 99.1 | 98.7 | 98.8 | 98.7 | 99.1 | 99.6 | 90.3 | 96.5 | 97.6 | 98 | 98.4 | 99.1 | 99.4 | 99.4 | 99.2 | 99 |

| Stop2 | 1.4 | 0.8 | 0.8 | 0.7 | 0.4 | 0.7 | 0.4 | 0.4 | 0.1 | 0.1 | 0.3 | 1.3 | 1.4 | 0.9 | 0.7 | 0.6 | 0.1 | 0 | 0.6 | 0.3 | |

| Stop3 | 7.3 | 1.5 | 1.5 | 1.5 | 0.5 | 0.6 | 0.8 | 0.9 | 0.8 | 0.3 | 9.4 | 2.2 | 1 | 1.1 | 0.9 | 0.3 | 0.5 | 0.6 | 0.2 | 0.7 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 30 | Stop1 | 83.4 | 90.5 | 92 | 91.4 | 89.7 | 90.8 | 90.4 | 88.7 | 88.8 | 87 | 82.8 | 92.2 | 91.8 | 92.1 | 90.5 | 90.5 | 88.7 | 89.8 | 87.6 | 86.9 |

| Stop2 | 1.7 | 1.7 | 1.7 | 1.1 | 1.2 | 1.6 | 0.6 | 1.4 | 1.1 | 1 | 1.6 | 1.2 | 1.5 | 0.8 | 1.5 | 1.8 | 0.6 | 1.2 | 1.3 | 1.1 | |

| Stop3 | 14.8 | 7.8 | 6.3 | 7.5 | 9.1 | 7.6 | 9 | 9.9 | 10.1 | 12 | 15.6 | 6.6 | 6.7 | 7.1 | 8 | 7.7 | 10.7 | 9 | 11.1 | 12 | |

| Stop4 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 40 | Stop1 | 75.8 | 78.3 | 76.6 | 74 | 72 | 69.2 | 65.5 | 62.7 | 57.6 | 59.2 | 74.3 | 78.2 | 78.1 | 76.3 | 70.5 | 68.3 | 64 | 65.5 | 61.2 | 58.2 |

| Stop2 | 1.9 | 3 | 3 | 1.9 | 1.6 | 1.4 | 1.8 | 1 | 0.9 | 1.2 | 1.6 | 2.7 | 2.3 | 1.3 | 2.5 | 1.8 | 1.7 | 0.9 | 1.4 | 1.5 | |

| Stop3 | 22 | 18.7 | 20.4 | 24.1 | 26.4 | 29.4 | 32.7 | 36.3 | 41.5 | 39.6 | 24 | 19.1 | 19.6 | 22.4 | 27 | 29.9 | 34.3 | 33.6 | 37.4 | 40.3 | |

| Stop4 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 50 | Stop1 | 64.4 | 65 | 59.6 | 53.1 | 46.9 | 40.6 | 40.1 | 35 | 31.4 | 30.4 | 64.6 | 63.3 | 57.6 | 53.9 | 49.4 | 42.6 | 38.3 | 36.6 | 32.4 | 28 |

| Stop2 | 1.9 | 2.8 | 1.9 | 2.1 | 1.7 | 1.5 | 0.8 | 1.1 | 1.5 | 0.7 | 1.6 | 3.8 | 2.4 | 1.5 | 1.3 | 1.1 | 0.8 | 1.1 | 1.3 | 1.1 | |

| Stop3 | 33.7 | 32.2 | 38.5 | 44.8 | 51.4 | 57.9 | 59.1 | 63.9 | 67.1 | 68.9 | 33.6 | 32.9 | 40 | 44.6 | 49.3 | 56.3 | 60.9 | 62.3 | 66.3 | 70.9 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 60 | Stop1 | 54.4 | 52.2 | 42.3 | 33 | 28.1 | 21.7 | 19.9 | 15.8 | 13.7 | 11.3 | 54.4 | 49.2 | 43.4 | 33.6 | 26.7 | 22.2 | 20.2 | 14.9 | 13 | 11.1 |

| Stop2 | 1.4 | 2.9 | 1.8 | 1.6 | 1.4 | 0.7 | 0.4 | 0.3 | 0.2 | 0.3 | 2.4 | 2.4 | 2.3 | 2.8 | 0.9 | 0.9 | 0.7 | 0.4 | 0.3 | 0.3 | |

| Stop3 | 44.1 | 44.9 | 55.9 | 65.4 | 70.5 | 77.6 | 79.7 | 83.9 | 86.1 | 88.4 | 43 | 48.4 | 54.3 | 63.6 | 72.4 | 76.9 | 79.1 | 84.7 | 86.7 | 88.6 | |

| Stop4 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 70 | Stop1 | 47 | 37.9 | 25.3 | 21 | 14.1 | 11 | 7.5 | 6 | 4.4 | 3.1 | 44.2 | 34.1 | 28.5 | 19.4 | 14 | 11.3 | 7.5 | 4.4 | 4.1 | 3.1 |

| Stop2 | 1.5 | 1.4 | 1.3 | 1.5 | 0.7 | 0.5 | 0.3 | 0.2 | 0.1 | 0 | 2.1 | 2.9 | 1.4 | 0.7 | 0.9 | 0.4 | 0.1 | 0.2 | 0.1 | 0.1 | |

| Stop3 | 51.5 | 60.7 | 73.4 | 77.5 | 85.2 | 88.5 | 92.2 | 93.8 | 95.5 | 96.9 | 53.4 | 63 | 70.1 | 79.9 | 85.1 | 88.3 | 92.4 | 95.4 | 95.8 | 96.8 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 80 | Stop1 | 38 | 26.7 | 16 | 10.5 | 6.4 | 4.9 | 2.5 | 1.9 | 0.8 | 0.7 | 35 | 26.1 | 17.6 | 10.4 | 8.1 | 4.2 | 2.2 | 2.1 | 1.3 | 0.5 |

| Stop2 | 1.3 | 1.7 | 1.3 | 1 | 0.9 | 0.1 | 0 | 0.1 | 0 | 0 | 1.6 | 1.3 | 0.7 | 0.7 | 0.3 | 0.4 | 0 | 0 | 0 | 0 | |

| Stop3 | 60.6 | 71.6 | 82.7 | 88.5 | 92.7 | 95 | 97.5 | 98 | 99.2 | 99.3 | 63.1 | 72.6 | 81.7 | 88.9 | 91.6 | 95.4 | 97.8 | 97.9 | 98.7 | 99.5 | |

| Stop4 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 90 | Stop1 | 29 | 15.7 | 9.2 | 4.7 | 3.8 | 1.7 | 1.6 | 0 | 0.2 | 0.3 | 29.5 | 16.7 | 10.2 | 5.9 | 3.2 | 2.1 | 1.1 | 0.7 | 0.3 | 0.2 |

| Stop2 | 1.5 | 1.4 | 0.7 | 0.4 | 0.1 | 0.2 | 0.1 | 0 | 0 | 0.1 | 1.7 | 1.2 | 0.4 | 0.3 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 69.3 | 82.9 | 90.1 | 94.9 | 96.1 | 98.1 | 98.3 | 100 | 99.8 | 99.6 | 68.6 | 82.1 | 89.4 | 93.8 | 96.8 | 97.9 | 98.9 | 99.3 | 99.7 | 99.8 | |

| Stop4 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 100 | Stop1 | 21.6 | 12.2 | 6.7 | 2.4 | 1.6 | 0.6 | 0.2 | 0.1 | 0.1 | 0 | 23 | 11 | 5.8 | 3 | 1.7 | 0.5 | 0.2 | 0.3 | 0 | 0 |

| Stop2 | 1.2 | 0.8 | 0.1 | 0.1 | 0.1 | 0 | 0 | 0 | 0.1 | 0 | 1.1 | 0.6 | 0.5 | 0.2 | 0.1 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 77 | 87 | 93.2 | 97.5 | 98.3 | 99.4 | 99.8 | 99.9 | 99.8 | 100 | 75.3 | 88.4 | 93.7 | 96.8 | 98.2 | 99.5 | 99.8 | 99.7 | 100 | 100 | |

| Stop4 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.6 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Uniform Distributions | Gamma Distributions | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

| 5 | Stop1 | 98.6 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 99.3 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 1.2 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.7 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 10 | Stop1 | 97.8 | 99.4 | 99.8 | 99.8 | 100 | 99.8 | 100 | 100 | 100 | 100 | 97.3 | 99.7 | 99.7 | 100 | 100 | 99.9 | 100 | 100 | 99.9 | 100 |

| Stop2 | 0.2 | 0.1 | 0.1 | 0.2 | 0 | 0.2 | 0 | 0 | 0 | 0 | 0.2 | 0.1 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | |

| Stop3 | 2 | 0.5 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2.5 | 0.2 | 0.2 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 20 | Stop1 | 93.5 | 98.1 | 98.1 | 99.4 | 99.1 | 99.7 | 99.6 | 99.9 | 99.7 | 99.4 | 95 | 97.5 | 98.8 | 99 | 99.5 | 99.5 | 99.8 | 99.7 | 99.6 | 100 |

| Stop2 | 0.4 | 0.8 | 0.6 | 0.2 | 0.4 | 0.2 | 0.2 | 0.1 | 0.3 | 0.2 | 0.6 | 0.7 | 0.6 | 0.5 | 0.5 | 0.3 | 0.1 | 0.2 | 0.3 | 0 | |

| Stop3 | 6.1 | 1.1 | 1.3 | 0.4 | 0.5 | 0.1 | 0.2 | 0 | 0 | 0.4 | 4.4 | 1.8 | 0.6 | 0.5 | 0 | 0.2 | 0.1 | 0.1 | 0.1 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 30 | Stop1 | 85.9 | 94.2 | 96.1 | 95.2 | 94.3 | 95.3 | 96.1 | 95.8 | 95.8 | 95.2 | 89.9 | 94.2 | 94.2 | 95.3 | 95.4 | 95.9 | 95.2 | 95.2 | 92.8 | 96.3 |

| Stop2 | 0.6 | 1.4 | 1.1 | 1.1 | 1.2 | 0.5 | 0.7 | 1.1 | 0.3 | 0.4 | 0.9 | 0.8 | 1.4 | 1 | 1.5 | 1 | 1.2 | 0.6 | 1.1 | 0.3 | |

| Stop3 | 13.5 | 4.4 | 2.8 | 3.7 | 4.5 | 4.2 | 3.2 | 3.1 | 3.9 | 4.4 | 9.2 | 5 | 4.4 | 3.7 | 3.1 | 3.1 | 3.6 | 4.2 | 6.1 | 3.4 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 40 | Stop1 | 80.5 | 85.7 | 85.5 | 83.4 | 85.4 | 81.9 | 82.3 | 77.7 | 77.8 | 77.5 | 81.7 | 85.9 | 88.3 | 85.6 | 82.1 | 84.3 | 81.6 | 79.1 | 80.9 | 80.1 |

| Stop2 | 1.3 | 2.2 | 1.9 | 1.9 | 1.3 | 1.4 | 1.6 | 1.7 | 0.7 | 1.2 | 1.4 | 2.2 | 1.5 | 2.3 | 2 | 1.3 | 0.4 | 1.6 | 1 | 0.9 | |

| Stop3 | 18.2 | 12.1 | 12.6 | 14.7 | 13.3 | 16.7 | 16.1 | 20.6 | 21.5 | 21.3 | 16.9 | 11.9 | 10.2 | 12.1 | 15.9 | 14.4 | 18 | 19.3 | 18.1 | 19 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 50 | Stop1 | 74.1 | 74.8 | 72.6 | 70 | 67 | 62 | 59.2 | 58.5 | 54.9 | 52.7 | 73 | 75.9 | 73.6 | 69.7 | 67.6 | 60.9 | 62.6 | 59.1 | 56.6 | 52 |

| Stop2 | 1.2 | 2.6 | 2.5 | 1.8 | 1.3 | 1.5 | 1.5 | 0.9 | 0.9 | 0.6 | 0.9 | 2.1 | 2.1 | 1.3 | 1.2 | 1.1 | 0.8 | 1 | 0.6 | 0.4 | |

| Stop3 | 24.7 | 22.6 | 24.9 | 28.2 | 31.7 | 36.5 | 39.3 | 40.6 | 44.2 | 46.7 | 26.1 | 22 | 24.3 | 29 | 31.2 | 38 | 36.6 | 39.9 | 42.8 | 47.6 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 60 | Stop1 | 66.9 | 64.3 | 60.9 | 52.3 | 45 | 46.7 | 40 | 37.4 | 34.6 | 32.2 | 63.8 | 64.2 | 58.4 | 55.9 | 48.2 | 42.8 | 40.1 | 35.9 | 36.3 | 31.2 |

| Stop2 | 1.3 | 3.2 | 1.6 | 2.5 | 1.5 | 0.9 | 1.8 | 0.9 | 0.8 | 0.9 | 0.8 | 2 | 1.9 | 1.6 | 1.8 | 1.4 | 1.2 | 1.3 | 0.9 | 1.3 | |

| Stop3 | 31.8 | 32.5 | 37.5 | 45.2 | 53.5 | 52.4 | 58.2 | 61.7 | 64.6 | 66.9 | 35.4 | 33.8 | 39.7 | 42.5 | 50 | 55.8 | 58.7 | 62.8 | 62.8 | 67.5 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 70 | Stop1 | 58.4 | 52.6 | 42.7 | 38.7 | 34.6 | 29.4 | 21.1 | 21.5 | 17.6 | 16.3 | 57.7 | 50.8 | 45 | 37.9 | 31 | 27.6 | 26.2 | 21.6 | 20.5 | 15.1 |

| Stop2 | 1.4 | 2.2 | 1 | 2.3 | 0.8 | 0.7 | 0.5 | 0.3 | 0.2 | 0.1 | 0.9 | 3.5 | 2.4 | 1.1 | 1.3 | 0.6 | 0.6 | 0.4 | 0.3 | 0 | |

| Stop3 | 40.2 | 45.2 | 56.3 | 59 | 64.6 | 69.9 | 78.4 | 78.2 | 82.2 | 83.6 | 41.3 | 45.7 | 52.6 | 61 | 67.7 | 71.8 | 73.2 | 78 | 79.2 | 84.9 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 80 | Stop1 | 51.9 | 40.7 | 34.1 | 28.3 | 21.4 | 14.2 | 13.9 | 9.9 | 9.8 | 8 | 49.7 | 41.7 | 33.3 | 27.1 | 24.1 | 17.4 | 14.1 | 12.6 | 8.8 | 7.5 |

| Stop2 | 0.9 | 1.7 | 1.4 | 1.4 | 0.2 | 0.1 | 0.2 | 0.3 | 0.1 | 0 | 0.8 | 2.5 | 1.6 | 0.9 | 0.5 | 0.3 | 0.6 | 0.5 | 0 | 0 | |

| Stop3 | 47.2 | 57.6 | 64.5 | 70.3 | 78.4 | 85.7 | 85.9 | 89.8 | 90.1 | 92 | 49.4 | 55.8 | 65.1 | 72 | 75.4 | 82.3 | 85.3 | 86.9 | 91.2 | 92.5 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 90 | Stop1 | 44.2 | 31.3 | 24.6 | 17.3 | 12.3 | 11 | 7.1 | 4.7 | 3.6 | 4.2 | 44 | 32.7 | 24.8 | 16.3 | 12.7 | 10 | 7.9 | 6.5 | 4.2 | 3.8 |

| Stop2 | 1.3 | 1.3 | 0.4 | 0.8 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0 | 1 | 1.4 | 1.2 | 1 | 0.3 | 0 | 0.1 | 0 | 0.1 | 0.1 | |

| Stop3 | 54.5 | 67.4 | 75 | 81.9 | 87.5 | 88.9 | 92.8 | 95.2 | 96.3 | 95.8 | 54.6 | 65.9 | 74 | 82.7 | 87 | 90 | 92 | 93.5 | 95.7 | 96.1 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 100 | Stop1 | 36.1 | 24.3 | 17.8 | 12.4 | 7.5 | 6.2 | 3 | 2.9 | 2.3 | 1.1 | 35.5 | 25.9 | 15.3 | 10.6 | 6.9 | 5.1 | 3.1 | 2 | 1.8 | 1.7 |

| Stop2 | 0.8 | 1.6 | 0.8 | 0.6 | 0.2 | 0.1 | 0 | 0 | 0.1 | 0 | 1 | 1.1 | 0.3 | 0.3 | 0.2 | 0 | 0.1 | 0 | 0 | 0 | |

| Stop3 | 63.1 | 74.1 | 81.4 | 87 | 92.3 | 93.7 | 97 | 97.1 | 97.6 | 98.9 | 62.9 | 73 | 84.4 | 89.1 | 92.9 | 94.9 | 96.8 | 98 | 98.2 | 98.3 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.6 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Uniform Distributions | Gamma Distributions | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

| 5 | Stop1 | 98.9 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 99.6 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 1.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.4 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 10 | Stop1 | 97.6 | 99.6 | 99.9 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 98.2 | 99.5 | 99.9 | 99.9 | 100 | 100 | 100 | 99.9 | 100 | 100 |

| Stop2 | 0 | 0 | 0.1 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0.1 | 0 | 0 | 0 | 0.1 | 0 | 0 | |

| Stop3 | 2.4 | 0.4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1.8 | 0.5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 20 | Stop1 | 95.8 | 98.6 | 99 | 99.7 | 99.7 | 99.9 | 99.7 | 100 | 100 | 99.9 | 95.5 | 97.6 | 99.7 | 99.3 | 99.5 | 99.8 | 100 | 99.8 | 99.9 | 100 |

| Stop2 | 0 | 0.4 | 0.4 | 0.1 | 0.3 | 0.1 | 0.2 | 0 | 0 | 0.1 | 0.1 | 0.4 | 0 | 0.5 | 0.2 | 0.2 | 0 | 0.1 | 0.1 | 0 | |

| Stop3 | 4.2 | 1 | 0.6 | 0.2 | 0 | 0 | 0.1 | 0 | 0 | 0 | 4.4 | 2 | 0.3 | 0.2 | 0.3 | 0 | 0 | 0.1 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 30 | Stop1 | 93.2 | 94.8 | 97.1 | 97.8 | 98.1 | 98.9 | 99 | 99 | 98.5 | 99.3 | 93.4 | 94.9 | 96.8 | 98.3 | 98.5 | 97.4 | 98.8 | 99.4 | 99.1 | 99 |

| Stop2 | 0 | 0.8 | 0.5 | 0.9 | 0.2 | 0.1 | 0 | 0.4 | 0.5 | 0.1 | 0.5 | 1 | 0.7 | 0.3 | 0.4 | 0.9 | 0.2 | 0.1 | 0.5 | 0 | |

| Stop3 | 6.8 | 4.4 | 2.4 | 1.3 | 1.7 | 1 | 1 | 0.6 | 1 | 0.6 | 6.1 | 4.1 | 2.5 | 1.4 | 1.1 | 1.7 | 1 | 0.5 | 0.4 | 1 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 40 | Stop1 | 88.6 | 91.1 | 91 | 91.9 | 94.5 | 91.2 | 91.7 | 92 | 93.3 | 93 | 87.7 | 90.5 | 91.6 | 92 | 92.5 | 93 | 93.1 | 92.6 | 92 | 91.5 |

| Stop2 | 0.3 | 1.4 | 1.1 | 0.7 | 0.2 | 0.8 | 0.9 | 0.7 | 0.9 | 0.5 | 0.2 | 1.7 | 1 | 1.3 | 0.8 | 0.4 | 0.9 | 0.6 | 0.4 | 0.7 | |

| Stop3 | 11.1 | 7.5 | 7.9 | 7.4 | 5.3 | 8 | 7.4 | 7.3 | 5.8 | 6.5 | 12.1 | 7.8 | 7.4 | 6.7 | 6.7 | 6.6 | 6 | 6.8 | 7.6 | 7.8 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 50 | Stop1 | 84.6 | 86.9 | 84.6 | 84.8 | 81 | 82 | 79.3 | 79.7 | 77.8 | 77.8 | 85 | 84.9 | 82 | 81.6 | 82 | 83.1 | 77.2 | 79.7 | 78.5 | 78.1 |

| Stop2 | 0.6 | 0.9 | 1.2 | 1.6 | 1.6 | 1.1 | 1 | 0.8 | 1.1 | 0.9 | 0 | 2.2 | 1.8 | 2 | 1 | 1.2 | 1.3 | 0.9 | 1.1 | 1 | |

| Stop3 | 14.8 | 12.2 | 14.2 | 13.6 | 17.4 | 16.9 | 19.7 | 19.5 | 21.1 | 21.3 | 15 | 12.9 | 16.2 | 16.4 | 17 | 15.7 | 21.5 | 19.4 | 20.4 | 20.9 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 60 | Stop1 | 79.7 | 77.8 | 75.4 | 71.5 | 71.1 | 69.2 | 63.5 | 61.3 | 59 | 58.8 | 77.5 | 75.1 | 75.4 | 71.8 | 70.7 | 66.4 | 66.3 | 63.5 | 60.1 | 60.3 |

| Stop2 | 0.2 | 1.9 | 2 | 1.9 | 1.9 | 1.2 | 0.8 | 1.1 | 0.9 | 0.6 | 0.8 | 1.7 | 2.1 | 1.5 | 1.4 | 1.8 | 0.5 | 0.8 | 1.7 | 1 | |

| Stop3 | 20.1 | 20.3 | 22.6 | 26.6 | 27 | 29.6 | 35.7 | 37.6 | 40.1 | 40.6 | 21.7 | 23.2 | 22.5 | 26.7 | 27.9 | 31.8 | 33.2 | 35.7 | 38.2 | 38.7 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 70 | Stop1 | 73.5 | 68.5 | 65.8 | 65.9 | 57.7 | 54.2 | 49.6 | 47.9 | 44.8 | 45.3 | 75.4 | 71.4 | 65.7 | 62.8 | 59.4 | 55.9 | 50.7 | 49.5 | 44.6 | 43.2 |

| Stop2 | 0.6 | 1.7 | 1.6 | 1.4 | 1.5 | 0.7 | 0.9 | 0.7 | 0.7 | 0.8 | 0.2 | 1.5 | 1.2 | 1.2 | 1.4 | 0.7 | 1 | 0.7 | 1 | 0.7 | |

| Stop3 | 25.9 | 29.8 | 32.6 | 32.7 | 40.8 | 45.1 | 49.5 | 51.4 | 54.5 | 53.9 | 24.3 | 27.1 | 33.1 | 36 | 39.2 | 43.4 | 48.3 | 49.8 | 54.4 | 56.1 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 80 | Stop1 | 67.6 | 60.5 | 58.7 | 52.8 | 46.1 | 43.5 | 40.1 | 36.7 | 35.4 | 34.2 | 66.6 | 62.4 | 53.4 | 50.8 | 49 | 43 | 41.4 | 37.8 | 38.7 | 33.7 |

| Stop2 | 0.3 | 2.7 | 1.2 | 1.1 | 0.9 | 0.6 | 0.8 | 0.4 | 0.2 | 0.6 | 0.4 | 2.1 | 2 | 1.1 | 1.4 | 1 | 0.4 | 0.3 | 0.3 | 0.2 | |

| Stop3 | 32.1 | 36.8 | 40.1 | 46.1 | 53 | 55.9 | 59.1 | 62.9 | 64.4 | 65.2 | 32.9 | 35.5 | 44.6 | 48.1 | 49.6 | 56 | 58.2 | 61.9 | 61 | 66.1 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 90 | Stop1 | 63.3 | 50.9 | 49.5 | 42.8 | 36.3 | 36.2 | 33.7 | 28.7 | 28.2 | 28.9 | 58.2 | 54.1 | 51.9 | 44.1 | 37.3 | 33.8 | 31.6 | 30.8 | 27 | 27.5 |

| Stop2 | 0.8 | 1.5 | 1.7 | 0.9 | 0.5 | 0.1 | 0.3 | 0.2 | 0.2 | 0.3 | 0.3 | 1.4 | 1.2 | 1 | 0.7 | 0.5 | 0.4 | 0.1 | 0.3 | 0 | |

| Stop3 | 35.9 | 47.6 | 48.8 | 56.3 | 63.2 | 63.7 | 66 | 71.1 | 71.6 | 70.8 | 41.5 | 44.5 | 46.9 | 54.9 | 62 | 65.7 | 68 | 69.1 | 72.7 | 72.5 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 100 | Stop1 | 58.1 | 48.4 | 41.1 | 32.5 | 30.9 | 27.2 | 24.2 | 21.2 | 23.1 | 20.4 | 55.5 | 44.4 | 38.2 | 32.2 | 32.3 | 27.7 | 24.1 | 21.8 | 22.4 | 20.3 |

| Stop2 | 0.2 | 1 | 0.6 | 0.8 | 0.3 | 0.4 | 0.2 | 0.4 | 0 | 0 | 0.7 | 1.5 | 0.7 | 0.8 | 0.6 | 0.5 | 0.2 | 0.1 | 0.2 | 0 | |

| Stop3 | 41.6 | 50.6 | 58.3 | 66.7 | 68.8 | 72.4 | 75.6 | 78.4 | 76.9 | 79.6 | 43.8 | 54.1 | 61.1 | 67 | 67.1 | 71.8 | 75.7 | 78.1 | 77.4 | 79.7 | |

| Stop4 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Uniform Distributions | Gamma Distributions | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

| 5 | Stop1 | 100 | 99.8 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 0 | 0.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 10 | Stop1 | 100 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 99.8 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop3 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.2 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Stop4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 20 | Stop1 | 100 | 99.4 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 99.3 | 99.9 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Stop2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |