Tailored CNTs Buckypaper Membranes for the Removal of Humic Acid and Separation of Oil-In-Water Emulsions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of CNTs and Buckypapers

2.2. Morphological and Structural Characterizations of CNTs and Buckypapers

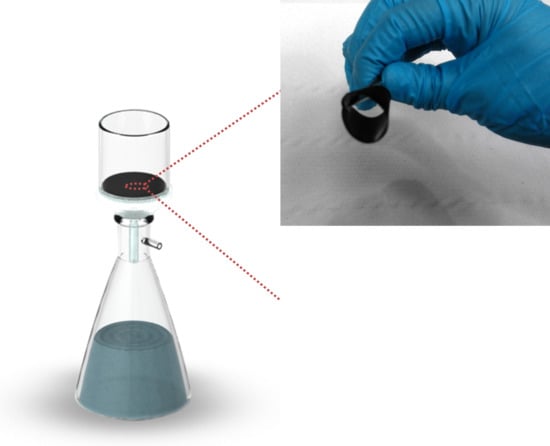

2.3. Buckypapers Filtration Performance

3. Results and Discussion

3.1. Characteristics of CNTs

3.2. Characteristics of Buckypapers

3.3. Filtration Performance of Buckypapers

3.3.1. Pure Water Permeability

3.3.2. Removal of Humic Acid (HA)

3.3.3. Separation of Oil-In-Water Emulsion

3.3.4. Sorption of Organic Liquids

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Ihsanullah. Carbon nanotube membranes for water purification: Developments, challenges, and prospects for the future. Sep. Purif. Technol. 2019, 209, 307–337. [Google Scholar] [CrossRef]

- Alsharief, A.; Mustafa, I.; AlNahyan, M.; Alnaqbi, W.; Almarzooqi, F. CNT–PVDF freestanding sheets for direct solar evaporation toward continuous desalination applications. J. Mater. Sci. 2020, 55, 2860–2869. [Google Scholar] [CrossRef]

- Tofighy, M.A.; Khanlari, S.; Mohammadi, T. Development of advanced nanocomposite membranes by carbon-based nanomaterials (CNTs and GO). In Nanocomposite Membranes for Water and Gas Separation; Elsevier: Amsterdam, The Netherlands, 2020; pp. 145–162. [Google Scholar]

- Teow, Y.H.; Mohammad, A.W. New generation nanomaterials for water desalination: A review. Desalination 2019, 451, 2–17. [Google Scholar] [CrossRef]

- Thamaraiselvan, C.; Wang, J.; James, D.K.; Narkhede, P.; Singh, S.P.; Jassby, D.; Tour, J.M.; Arnusch, C.J. Laser-induced graphene and carbon nanotubes as conductive carbon-based materials in environmental technology. Mater. Today 2019, 34, 115–131. [Google Scholar] [CrossRef]

- Cheng, B.; Yang, S.; Woldu, Y.T.; Shafique, S.; Wang, F. A study on the mechanical properties of a carbon nanotube probe with a high aspect ratio. Nanotechnology 2020, 31, 145707. [Google Scholar] [CrossRef] [PubMed]

- Abouelsayed, A.; Anis, B.; Hassaballa, S.; Khalil, A.S.; Rashed, U.M.; Eid, K.A.; Al-Ashkar, E. Preparation, characterization, Raman, and terahertz spectroscopy study on carbon nanotubes, graphene nano-sheets, and onion like carbon materials. Mater. Chem. Phys. 2017, 189, 127–135. [Google Scholar] [CrossRef]

- Peigney, A.; Laurent, C.; Flahaut, E.; Bacsa, R.R.; Rousset, A. Specific surface area of carbon nanotubes and bundles of carbon nanotubes. Carbon 2001, 39, 507–514. [Google Scholar] [CrossRef] [Green Version]

- Hirsch, A.; Vostrowsky, O. Functionalization of carbon nanotubes. In Functional Molecular Nanostructures; Springer: Berlin, Germany, 2005; pp. 193–237. [Google Scholar]

- Elnabawy, H.M.; Casanova-Chafer, J.; Anis, B.; Fedawy, M.; Scardamaglia, M.; Bittencourt, C. Wet chemistry route for the decoration of carbon nanotubes with iron oxide nanoparticles for gas sensing. Beilstein J. Nanotechnol. 2019, 10, 105–118. [Google Scholar] [CrossRef]

- Abouelsayed, A.; Anis, B.; Okasha, A.; Ali, A.M.; Elhotaby, W.; Khalil, A.S. Preparation, characterization, and spectroscopy study on CdSe quantum dots linked to multi-walled carbon nanotubes. Mater. Chem. Phys. 2018, 203, 1–8. [Google Scholar] [CrossRef]

- Gholami, S.; López, J.; Rezvani, A.; Vatanpour, V.; Cortina, J.L. Fabrication of thin-film nanocomposite nanofiltration membranes incorporated with aromatic amine-functionalized multiwalled carbon nanotubes. Rejection performance of inorganic pollutants from groundwater with improved acid and chlorine resistance. Chem. Eng. J. 2020, 384, 123348. [Google Scholar] [CrossRef]

- Ma, L.; Dong, X.; Chen, M.; Zhu, L.; Wang, C.; Yang, F.; Dong, Y. Fabrication and water treatment application of carbon nanotubes (CNTs)-based composite membranes: A review. Membranes 2017, 7, 16. [Google Scholar] [CrossRef] [Green Version]

- Sarkar, B.; Mandal, S.; Tsang, Y.F.; Kumar, P.; Kim, K.H.; Ok, Y.S. Designer carbon nanotubes for contaminant removal in water and wastewater: A critical review. Sci. Total Environ. 2018, 612, 561–581. [Google Scholar] [CrossRef] [PubMed]

- Rashid, M.H.O.; Pham, S.Q.; Sweetman, L.J.; Alcock, L.J.; Wise, A.; Nghiem, L.D. Synthesis, properties, water and solute permeability of MWNT buckypapers. J. Membr. Sci. 2014, 456, 175–184. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Fan, Q.; Qiao, Z.; Yang, Q.; Wang, Y.; Wang, X. Effects of water quality on the coagulation performances of humic acids irradiated with UV light. Front. Environ. Sci. Eng. 2015, 9, 147–154. [Google Scholar] [CrossRef]

- Kosobucki, P.; Buszewski, B. Natural organic matter in ecosystems—A review. Nova Biotechnol. Chim. 2014, 13, 109–129. [Google Scholar] [CrossRef]

- Sharma, S.; Bhattacharya, A. Drinking water contamination and treatment techniques. Appl. Water Sci. 2017, 7, 1043–1067. [Google Scholar] [CrossRef] [Green Version]

- Richardson, S.D. Disinfection by-products and other emerging contaminants in drinking water. TrAC Trends Anal. Chem. 2003, 22, 666–684. [Google Scholar] [CrossRef]

- Gopal, K.; Tripathy, S.S.; Bersillon, J.L.; Dubey, S.P. Chlorination byproducts, their toxicodynamics and removal from drinking water. J. Hazard. Mater. 2007, 140, 1–6. [Google Scholar] [CrossRef]

- Bhatnagar, A.; Sillanpää, M. Removal of natural organic matter (NOM) and its constituents from water by adsorption—A review. Chemosphere 2017, 166, 497–510. [Google Scholar] [CrossRef]

- Skandari, S.; Torabian, A.; Nabi Bidhendi, G.; Baghdadi, M.; Aminzadeh, B. Preparation of engineered carbon nanotube materials and its application in water treatment for removal of hydrophobic natural organic matter (NOM). Desalin. Water Treat. 2016, 57, 24855–24866. [Google Scholar] [CrossRef]

- Ndlangamandla, N.G.; Kuvarega, A.T.; Msagati, T.A.; Mamba, B.B.; Nkambule, T.T. A novel photodegradation approach for the efficient removal of natural organic matter (NOM) from water. Phys. Chem. Earthparts A B C 2018, 106, 97–106. [Google Scholar] [CrossRef]

- Jafari, A.; Mahvi, A.H.; Nasseri, S.; Rashidi, A.; Nabizadeh, R.; Rezaee, R. Ultrafiltration of natural organic matter from water by vertically aligned carbon nanotube membrane. J. Environ. Health Sci. Eng. 2015, 13, 51. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, Y.; Qiao, S.; Zheng, M.; Zhou, J.; Quan, X. Enhanced permeability, contaminants removal and antifouling ability of CNTs-based hollow fiber membranes under electrochemical assistance. J. Membr. Sci. 2019, 582, 335–341. [Google Scholar] [CrossRef]

- Sianipar, M.; Kim, S.H.; Iskandar, F.; Wenten, I.G. Functionalized carbon nanotube (CNT) membrane: Progress and challenges. RSC Adv. 2017, 7, 51175–51198. [Google Scholar] [CrossRef] [Green Version]

- Ali, S.; Rehman, S.A.U.; Luan, H.Y.; Farid, M.U.; Huang, H. Challenges and opportunities in functional carbon nanotubes for membrane-based water treatment and desalination. Sci. Total Environ. 2019, 646, 1126–1139. [Google Scholar] [CrossRef] [PubMed]

- Nikita, K.; Ray, D.; Aswal, V.K.; Murthy, C.N. Surface modification of functionalized multiwalled carbon nanotubes containing mixed matrix membrane using click chemistry. J. Membr. Sci. 2020, 596, 117710. [Google Scholar] [CrossRef]

- Intrchom, W.; Roy, S.; Mitra, S. Functionalized carbon nanotube immobilized membrane for low temperature ammonia removal via membrane distillation. Sep. Purif. Technol. 2020, 235, 116188. [Google Scholar] [CrossRef]

- Zhao, H.; Qiu, S.; Wu, L.; Zhang, L.; Chen, H.; Gao, C. Improving the performance of polyamide reverse osmosis membrane by incorporation of modified multi-walled carbon nanotubes. J. Membr. Sci. 2014, 450, 249–256. [Google Scholar] [CrossRef]

- Yang, X.; Lee, J.; Yuan, L.; Chae, S.R.; Peterson, V.K.; Minett, A.I.; Yin, Y.; Harris, A.T. Removal of natural organic matter in water using functionalised carbon nanotube buckypaper. Carbon 2013, 59, 160–166. [Google Scholar] [CrossRef]

- Gu, J.; Xiao, P.; Chen, J.; Zhang, J.; Huang, Y.; Chen, T. Janus polymer/carbon nanotube hybrid membranes for oil/water separation. Acs Appl. Mater. Interfaces 2014, 6, 16204–16209. [Google Scholar] [CrossRef]

- Gu, J.; Xiao, P.; Chen, J.; Liu, F.; Huang, Y.; Li, G. Robust preparation of superhydrophobic polymer/carbon nanotube hybrid membranes for highly effective removal of oils and separation of water-in-oil emulsions. J. Mater. Chem. A 2014, 2, 15268–15272. [Google Scholar] [CrossRef]

- Yan, L.; Zhang, G.; Zhang, L.; Zhang, W.; Gu, J.; Huang, Y.; Zhang, J.; Chen, T. Robust construction of underwater superoleophobic CNTs/nanoparticles multifunctional hybrid membranes via interception effect for oily wastewater purification. J. Membr. Sci. 2019, 569, 32–40. [Google Scholar] [CrossRef]

- Saththasivam, J.; Yiming, W.; Wang, K.; Jin, J.; Liu, Z. A novel architecture for carbon nanotube membranes towards fast and efficient oil/water separation. Sci. Rep. 2018, 8, 7418. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hu, J.; Li, X.; Dong, J. Development of Highly Efficient Oil–Water Separation Carbon Nanotube Membranes with Stimuli-Switchable Fluxes. ACS Omega 2018, 3, 6635–6641. [Google Scholar] [CrossRef]

- Wang, X.-D.; Vinodgopal, K.; Dai, G.-P. Synthesis of Carbon Nanotubes by Catalytic Chemical Vapor Deposition. In Perspective of Carbon Nanotubes; IntechOpen: London, UK, 2019. [Google Scholar]

- Turgunov, M.A.; Oh, J.O.; Yoon, S.H. Surface modification of multiwall carbon nanotubes by sulfuric acid and nitric acid. Materials 2014, 64, 22–25. [Google Scholar]

- Kharissova, O.V.; Kharisov, B.I.; de Casas Ortiz, E.G. Dispersion of carbon nanotubes in water and non-aqueous solvents. RSC Adv. 2013, 3, 24812–24852. [Google Scholar] [CrossRef]

- Malcolm, A.A.; Leong, H.Y.; Spowage, A.C.; Shacklock, A.P. Image segmentation and analysis for porosity measurement. J. Mater. Process. Technol. 2007, 192, 391–396. [Google Scholar] [CrossRef]

- Ajmani, G.S.; Cho, H.H.; Chalew, T.E.A.; Schwab, K.J.; Jacangelo, J.G.; Huang, H. Static and dynamic removal of aquatic natural organic matter by carbon nanotubes. Waterresearch 2014, 59, 262–270. [Google Scholar] [CrossRef]

- Branca, C.; Frusteri, F.; Magazu, V.; Mangione, A. Characterization of carbon nanotubes by TEM and infrared spectroscopy. J. Phys. Chem. B 2004, 108, 3469–3473. [Google Scholar] [CrossRef]

- Öncel, Ç.; Yürüm, Y. Carbon nanotube synthesis via the catalytic CVD method: A review on the effect of reaction parameters. Fullerenes, Nanotubes, and Carbon. Nonstructures 2006, 14, 17–37. [Google Scholar]

- Li, Q.; Yan, H.; Zhang, J.; Liu, Z. Effect of hydrocarbons precursors on the formation of carbon nanotubes in chemical vapor deposition. Carbon 2004, 42, 829–835. [Google Scholar] [CrossRef]

- Zhao, Z.; Yang, Z.; Hu, Y.; Li, J.; Fan, X. Multiple functionalization of multi-walled carbon nanotubes with carboxyl and amino groups. Appl. Surf. Sci. 2013, 276, 476–481. [Google Scholar] [CrossRef]

- Osswald, S.; Flahaut, E.; Gogotsi, Y. In situ Raman spectroscopy study of oxidation of double-and single-wall carbon nanotubes. Chem. Mater. 2006, 18, 1525–1533. [Google Scholar] [CrossRef]

- Pang, L.S.; Saxby, J.D.; Chatfield, S.P. Thermogravimetric analysis of carbon nanotubes and nanoparticles. J. Phys. Chem. 1993, 97, 6941–6942. [Google Scholar] [CrossRef]

- Kumanek, B.; Stando, G.; Wróbel, P.S.; Janas, D. Impact of Synthesis Parameters of Multi-Walled Carbon Nanotubes on their Thermoelectric Properties. Materials 2019, 12, 3567. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Le Hoa, T.M. Characterization of multi-walled carbon nanotubes functionalized by a mixture of HNO3/H2SO4. Diam. Relat. Mater. 2018, 89, 43–51. [Google Scholar]

- Ngo, C.L.; Le, Q.T.; Ngo, T.T.; Nguyen, D.N.; Vu, M.T. Surface modification and functionalization of carbon nanotube with some organic compounds. Adv. Nat. Sci. Nanosci. Nanotechnol. 2013, 4, 035017. [Google Scholar]

- Naseh, M.V.; Khodadadi, A.A.; Mortazavi, Y.; Sahraei, O.A.; Pourfayaz, F.; Sedghi, S.M. Functionalization of carbon nanotubes using nitric acid oxidation and DBD plasma. World Acad. Sci. Eng. Technol. 2009, 49, 177–179. [Google Scholar]

- Birch, M.E.; Ruda-Eberenz, T.A.; Chai, M.; Andrews, R.; Hatfield, R.L. Properties that influence the specific surface areas of carbon nanotubes and nanofibers. Ann. Occup. Hyg. 2013, 57, 1148–1166. [Google Scholar]

- Hu, Y.; Li, D.; Tang, P.; Bin, Y.; Wang, H. Comparative study of structure, mechanical and electromagnetic interference shielding properties of carbon nanotube buckypapers prepared by different dispersion media. Mater. Des. 2019, 184, 108175. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, D. Influence of geometries of multi-walled carbon nanotubes on the pore structures of Buckypaper. Compos. Part A Appl. Sci. Manuf. 2012, 43, 469–474. [Google Scholar] [CrossRef]

- Bai, L.; Liang, H.; Crittenden, J.; Qu, F.; Ding, A.; Ma, J.; Li, G. Surface modification of UF membranes with functionalized MWCNTs to control membrane fouling by NOM fractions. J. Membr. Sci. 2015, 492, 400–411. [Google Scholar] [CrossRef]

- Špitalský, Z.; Aggelopoulos, C.; Tsoukleri, G.; Tsakiroglou, C.; Parthenios, J.; Georga, S.; Krontiras, C.; Tasis, D.; Papagelis, K.; Galiotis, C. The effect of oxidation treatment on the properties of multi-walled carbon nanotube thin films. Mater. Sci. Eng. B 2009, 165, 135–138. [Google Scholar] [CrossRef]

- Whitby, R.L.; Fukuda, T.; Maekawa, T.; James, S.L.; Mikhalovsky, S.V. Geometric control and tuneable pore size distribution of buckypaper and buckydiscs. Carbon 2008, 46, 949–956. [Google Scholar] [CrossRef]

- Kobashi, K.; Yoon, H.; Ata, S.; Yamada, T.; Futaba, D.N.; Hata, K. Designing Neat and Composite Carbon Nanotube Materials by Porosimetric Characterization. Nanoscale Res. Lett. 2017, 12, 616. [Google Scholar] [CrossRef] [Green Version]

- Arif, M.F.; Kumar, S.; Shah, T. Tunable morphology and its influence on electrical, thermal and mechanical properties of carbon nanostructure-buckypaper. Mater. Des. 2016, 101, 236–244. [Google Scholar] [CrossRef]

- Farid, M.U.; Khanzada, N.K.; An, A.K. Understanding fouling dynamics on functionalized CNT-based membranes: Mechanisms and reversibility. Desalination 2019, 456, 74–84. [Google Scholar] [CrossRef]

- Huang, S.; Ras, R.H.; Tian, X. Antifouling membranes for oily wastewater treatment: Interplay between wetting and membrane fouling. Curr. Opin. Colloid Interface Sci. 2018, 36, 90–109. [Google Scholar] [CrossRef]

- Dong, X.; Chen, J.; Ma, Y.; Wang, J.; Chan-Park, M.B.; Liu, X.; Chen, P. Superhydrophobic and superoleophilic hybrid foam of graphene and carbon nanotube for selective removal of oils or organic solvents from the surface of water. Chem. Commun. 2012, 48, 10660–10662. [Google Scholar] [CrossRef]

| Parameter | CNT-I | CNT-II |

|---|---|---|

| Catalyst molar ratio | 6:0.1:18 | 1:0.1:13 |

| Active gas | Methane (CH4) | Acetylene (C2H2) |

| Reaction temperature | 1000 °C | 700 °C |

| Reaction time | 10 min | 30 min |

| Carrier gas flow rate | 300 mL/min | 900 mL/min |

| Active gas flow rate | 75 mL/min | 100 mL/min |

| Sample | SEM Pore Size (nm) | Mean Flow Pore, MFP (nm) |

|---|---|---|

| Pristine CNT-I | 57 ± 3 | 26 |

| Modified CNT-I | 27 ± 2 | 17 |

| Pristine CNT-II | 63 ± 5 | 31 |

| Modified CNT-II | 33 ± 5 | 22 |

| Property | Pristine CNT-I | Modified CNT-I | Pristine CNT-II | Modified CNT-II |

|---|---|---|---|---|

| Thickness (µm) | 153 ± 3 | 158 ± 5 | 150 ± 10 | 150 ± 4 |

| Contact angle (°) | 135 ± 7 | 45 ± 2 | 140 ± 5 | 42 ± 9 |

| PWP (L·m−2h−1·bar−1) | 80 ± 6 | 172 ± 4 | 88 ± 2 | 196 ± 8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elnabawy, E.; Elsherbiny, I.M.A.; Abdelsamad, A.M.A.; Anis, B.; Hassan, A.; Ulbricht, M.; Khalil, A.S.G. Tailored CNTs Buckypaper Membranes for the Removal of Humic Acid and Separation of Oil-In-Water Emulsions. Membranes 2020, 10, 97. https://0-doi-org.brum.beds.ac.uk/10.3390/membranes10050097

Elnabawy E, Elsherbiny IMA, Abdelsamad AMA, Anis B, Hassan A, Ulbricht M, Khalil ASG. Tailored CNTs Buckypaper Membranes for the Removal of Humic Acid and Separation of Oil-In-Water Emulsions. Membranes. 2020; 10(5):97. https://0-doi-org.brum.beds.ac.uk/10.3390/membranes10050097

Chicago/Turabian StyleElnabawy, Eman, Ibrahim M. A. Elsherbiny, Ahmed M. A. Abdelsamad, Badawi Anis, Abdelwahab Hassan, Mathias Ulbricht, and Ahmed S. G. Khalil. 2020. "Tailored CNTs Buckypaper Membranes for the Removal of Humic Acid and Separation of Oil-In-Water Emulsions" Membranes 10, no. 5: 97. https://0-doi-org.brum.beds.ac.uk/10.3390/membranes10050097