Safe Mining Assessment of Artisanal Barite Mining Activities in Nigeria

Abstract

:1. Introduction

2. A Review of Status of Artisanal and Small-Scale Mining (ASM) and Safe Mining Practices in Nigeria

2.1. Legal, Regulatory, and Institutional Frameworks of Artisanal and Small-Scale Mining

2.2. Mining Hazards in Nigeria

2.3. Safe Mining Methods for Local and Global Mining: Precautions and Control Measures

3. Materials and Methods

3.1. Survey of Miners

3.2. Chemical Analysis and Risk Assessment

4. Results

4.1. Characteristics of Survey Respondents

4.2. Health Hazards of Miners

5. Discussion

5.1. Major Inhibitors to Safe Mining Methods in Nigeria

5.2. Impact of COVID-19 on Health of Miners

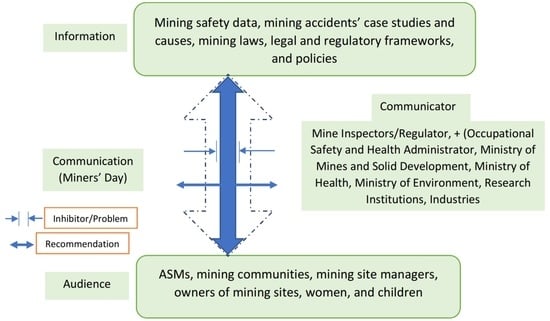

5.3. Policy Imperatives and Strategies for Fostering Safe Mining

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amponsah-Tawiah, K.; Ntow, M.A.O.; Mensah, J. Occupational Health and Safety Management and Turnover Intention in the Ghanaian Mining Sector. Saf. Health Work 2016, 7, 12–17. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- NIOSH. Injuries, Illnesses, and Hazardous Exposures in the Mining Industry, 1986–1995: A Survelliance Report; NIOSH: Washington, DC, USA, 2000; pp. 1–141.

- Donoghue, A.M. Occupational health hazards in mining: An overview. Occup. Med. 2004, 54, 283–289. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bringemeier, D. Inrush and mine inundation—A real threat to Australian coal mines. In Proceedings of the International Mine Water Association, Annual Conference, Bunbury, Australia, 30 September–4 October 2012; Volume 30. [Google Scholar]

- Walters, D.; Wadsworth, E.J.K.; Johnstone, R.; Quinlan, M. A Study of the Role of Workers Representatives in Health and Safety Arrangements in Coal Mines in Queensland; Cardiff University Press: Cardiff, UK, 2014; pp. 1–115. [Google Scholar]

- Geng, F.; Saleh, J.H. Challenging the emerging narrative: Critical examination of coalmining safety in China, and recommendations for tackling mining hazards. Saf. Sci. 2015, 75, 36–48. [Google Scholar] [CrossRef]

- Diwe, K.C.; Duru, C.B.; Iwu, A.C.; Merenu, I.A.; Uwakwe, K.A.; Oluoha, U.R.; Ogunniyan, T.B.; Madubueze, U.C.; Ohale, I. Occupational hazards, safety and hygienic practices among timber workers in a South Eastern State, Nigeria. Occup. Dis. Environ. Med. 2016, 4, 63–71. [Google Scholar] [CrossRef] [Green Version]

- Duarte, A.L.; DaBoit, K.; Oliveira, M.L.S.; Teixeira, E.C.; Schneider, I.L.; Silva, L.F.O. Hazardous elements and amorphous nanoparticles in historical estuary coal mining area. Geosci. Front. 2019, 10, 927–939. [Google Scholar] [CrossRef]

- Le Berre, S.; Bretesché, S. Having a high-risk job: Uranium miners’ perception of occupational risk in France. Extr. Ind. Soc. 2020, 7, 568–575. [Google Scholar] [CrossRef]

- De, B. Another Two Mine Fatalities Brings 2020 Total to 58 Deaths. 2021. Available online: https://www.miningweekly.com/ (accessed on 9 December 2020).

- Hopkins, A.; Maslen, S. Risky Rewards: How Company Bonuses Affect Safety; Ashgate Publishing, Ltd.: Surrey, UK, 2015. [Google Scholar]

- Quinlan, M. Ten Pathways to Death and Disaster: Learning from Fatal Incidents in Mines and Other High Hazard Workplaces; Federation Press: Alexandria, Australia, 2014. [Google Scholar]

- Mahdevari, S.; Shahriar, K.; Esfahanipour, A. Human health and safety risks management in underground coal mines using fuzzy TOPSIS. Sci. Total Environ. 2014, 488, 85–99. [Google Scholar] [CrossRef]

- Younger, P.L. Environmental impacts of coal mining and associated wastes: A geochemical perspective. Geol. Soc. Lond. Spec. Publ. 2004, 236, 169–209. [Google Scholar] [CrossRef]

- Young, S.; Balluz, L.; Malilay, J. Natural and technologic hazardous material releases during and after natural disasters: A review. Sci. Total Environ. 2004, 322, 3–20. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Younger, P.L.; Cheng, Y.; Zhang, B.; Zhou, H.; Liu, Q.; Dai, T.; Kong, S.; Jin, K.; Yang, Q. Addressing the CO2 emissions of the world’s largest coal producer and consumer: Lessons from the Haishiwan Coalfield, China. Energy 2015, 80, 400–413. [Google Scholar] [CrossRef] [Green Version]

- Bansah, K.J.; Yalley, A.B.; Dumakor-Dupey, N. The hazardous nature of small scale underground mining in Ghana. J. Sustain. Min. 2016, 15, 8–25. [Google Scholar] [CrossRef] [Green Version]

- Khanzode, V.V.; Maiti, J.; Ray, P.K. A methodology for evaluation and monitoring of recurring hazards in underground coal mining. Saf. Sci. 2011, 49, 1172–1179. [Google Scholar] [CrossRef]

- Oramah, I.T.; Richards, J.P.; Summers, R.; Garvin, T.; McGee, T. Artisanal and small-scale mining in Nigeria: Experiences from Niger, Nasarawa and Plateau states. Extr. Ind. Soc. 2015, 2, 694–703. [Google Scholar] [CrossRef]

- Daburum, N.H.; Songden, S.D.; Mangset, E.W. Assessment of Radiation Dose with Excess Life Cancer Risk of Mining Dumpsites of Wase, Plateau State, Nigeria. Afr. J. Med. Phy. Biomed. Eng. Sci 2019, 6, 47–54. [Google Scholar]

- JohnPaul, A.A.; Ayodeji, L.T.; Tangfu, X.; Ning, Z.; Liu, Y. Toxicity, uptake, potential ecological and health risks of Thallium (Tl) in environmental media around selected artisanal mining sites in Nigeria. Int. J. Environ. Anal. Chem. 2020. [Google Scholar] [CrossRef]

- Orosun, M.M.; Usikalu, M.R.; Oyewumi, K.J.; Achuka, J.A. Radioactivity levels and transfer factor for granite mining field in Asa, North-central Nigeria. Heliyon 2020, 6, e04240. [Google Scholar] [CrossRef]

- Gottesfeld, P.; Tirima, S.; Anka, S.M.; Fotso, A.; Nota, M.M. Reducing lead and silica dust exposures in small-scale mining in northern Nigeria. Ann. Work Expo. Health 2019, 63, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Anka, S.A.; Bello, T.S.; Waziri, A.F.; Muhammad, A.S.; Bello, I.; Nasiru, A.M. Environmental effect of lead combination of mining communities in Zamfara State, Nigeria: A review. J. Biol. Today World 2020, 9, 1–3. [Google Scholar]

- UNEP. Disaster Waste Management Guidelines; Joint UNEP/OCHA Environment Unit: Geneva, Switzerland, 2011. [Google Scholar]

- Aluko, T.; Njoku, K.; Adesuyi, A.; Akinola, M. Health risk assessment of heavy metals in soil from the iron mines of Itakpe and Agbaja, Kogi State, Nigeria. Pollution 2018, 4, 527–538. [Google Scholar]

- Adewumi, A.J.P.; Laniyan, T.A.; Xiao, T.; Liu, Y.; Ning, Z. Exposure of children to heavy metals from artisanal gold mining in Nigeria: Evidences from bio-monitoring of hairs and nails. Acta Geochim. 2020, 39, 451–470. [Google Scholar] [CrossRef]

- Adamu, C.I.; Nganje, T.N.; Edet, A. Heavy metal contamination and health risk assessment associated with abandoned barite mines in Cross River State, southeastern Nigeria. Environ. Nanotechnol. Monit. Manag. 2015, 3, 10–21. [Google Scholar] [CrossRef] [Green Version]

- Adamu, C.I.; Nganje, T.; Edet, A. Hydrochemical assessment of pond and stream water near abandoned barite mine sites in parts of Oban massif and Mamfe Embayment, Southeastern Nigeria. Environ. Earth Sci. 2014, 71, 3793–3811. [Google Scholar] [CrossRef]

- Laniyan, T.A.; Adewumi, A.J. Evaluation of contamination and ecological risk of heavy metals associated with cement production in Ewekoro, Southwest Nigeria. J. Health Pollut. 2020, 10, 200306. [Google Scholar] [CrossRef] [Green Version]

- Szeleg, E.; Janeczek, J.; Metelski, P. Native selenium as a byproduct of microbial oxidation of distorted pyrite crystals: The first occurrence in the Carpathians. Geol. Carpathica 2013, 64, 231. [Google Scholar] [CrossRef] [Green Version]

- Melekestseva, I.Y.; Tret’yakov, G.A.; Nimis, P.; Yuminov, A.M.; Maslennikov, V.V.; Maslennikova, S.P.; Kotlyarov, V.; Beltenev, V.; Danyushevsky, L.; Large, R. Barite-rich massive sulfides from the Semenov-1 hydrothermal field (Mid-Atlantic Ridge, 13 30.87′ N): Evidence for phase separation and magmatic input. Mar. Geol. 2014, 349, 37–54. [Google Scholar] [CrossRef]

- Dunjó, J.; Fthenakis, V.; Vílchez, J.A.; Arnaldos, J. Hazard and operability (HAZOP) analysis. A literature review. J. Hazard. Mater. 2010, 173, 19–32. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Wu, C.; Kang, L.; Reniers, G.; Huang, L. Work safety in China’s Thirteenth Five-Year plan period (2016–2020): Current status, new challenges and future tasks. Saf. Sci. 2018, 104, 164–178. [Google Scholar] [CrossRef]

- Wang, B.; Shen, Y.; Saravanan, V.; Luhach, A.K. Workplace safety and risk analysis using Additive Heterogeneous Hybridized Computational Model. Aggress Violent Behav. 2021, 101558. [Google Scholar] [CrossRef]

- Qin, Y.; Chen, Z.; Ding, B.; Li, Z. Impact of sand mining on the carbon sequestration and nitrogen removal ability of soil in the riparian area of Lijiang River, China. Environ. Pollut. 2020, 261, 114220. [Google Scholar] [CrossRef]

- Rezaie, B.; Anderson, A. Sustainable resolutions for environmental threat of the acid mine drainage. Sci. Total Environ. 2020, 717, 137211. [Google Scholar] [CrossRef]

- Rezaie, A.; Buresi, M.; Lembo, A.; Lin, H.; McCallum, R.; Rao, S.; Schmulson, M.; Valdovinos, M.; Zakko, S.; Pimentel, M. Hydrogen and methane-based breath testing in gastrointestinal disorders: The North American consensus. Am. J. Gastroenterol. 2017, 112, 775. [Google Scholar] [CrossRef] [Green Version]

- Warra, A.A.; Prasad, M.N.V. Artisanal and Small-Scale Gold Mining Waste Rehabilitation with Energy Crops and Native Flora-A Case Study from Nigeria; Elsevier Inc.: Philadelphia, PA, USA, 2018. [Google Scholar] [CrossRef]

- Ango, M.; Erdenebat, B.; Tang, K.Y. Creation of a Sustainable Mining Program through Formalization of Artisanal and Small Scale Miners; Columbia University Press: New York, NY, USA, 2019. [Google Scholar]

- Heffron, R.J. The role of justice in developing critical minerals. Extr. Ind. Soc. 2020, 7, 855–863. [Google Scholar] [CrossRef]

- Macdonald, K.; Lund, M.; Blanchette, M.; Mccullough, C. Regulation of artisanal small scale gold mining (ASGM) in Ghana and Indonesia as currently implemented fails to adequately protect aquatic ecosystems. In Proceedings of the International Mine Water Association Symposium, Xuzhou, China, 18–22 August 2014; pp. 401–405. [Google Scholar]

- Akper, P.T.; Ani, L. Legal and Policy Issues in the Development of Nigeria’s Mining Sector: Charting the Way Forward. SSRN 2020. [Google Scholar] [CrossRef]

- Wireko-Gyebi, R.S.; King, R.S.; Braimah, I.; Lykke, A.M. Local knowledge of risks associated with artisanal small-scale mining in Ghana. Int. J. Occup. Saf. Ergon. 2020, 1–8. [Google Scholar] [CrossRef]

- Nwibo, A.N.; Ugwuja, E.I.; Nwambeke, N.O.; Emelumadu, O.F.; Ogbonnaya, L.U. Pulmonary problems among quarry workers of stone crushing industrial site at Umuoghara, Ebonyi State, Nigeria. IJOEM 2012, 3, 178–185. [Google Scholar] [PubMed]

- Taiwo, A.M.; Awomeso, J.A. Assessment of trace metal concentration and health risk of artisanal gold mining activities in Ijeshaland, Osun State Nigeria—Part 1. J. Geochem. Explor. 2017, 177, 1–10. [Google Scholar] [CrossRef]

- Abdullahi, U.; Asuku, A.; Umar, A.; Ahmed, Y.A.; Adam, U.S.; Abdulmalik, N.F.; Yunusa, M.H.; Abubakar, A.R. Assessment of Radon Concentration And Associated Health Implications In Ground Water And Soil Around Riruwai Mine Site, Kano State, Nigeria And Its Environs. Fudma J. Sci. 2020, 4, 242–246. [Google Scholar] [CrossRef]

- Adewumi, A.J.; Laniyan, T.A. Ecological and human health risks associated with metals in water from Anka Artisanal Gold Mining Area, Nigeria. Hum. Ecol. Risk Assess. Int. J. 2021, 27, 307–326. [Google Scholar] [CrossRef]

- Järvholm, B.; Silverman, D. Lung cancer in heavy equipment operators and truck drivers with diesel exhaust exposure in the construction industry. Occup. Environ. Med. 2003, 60, 516–520. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Njinga, R.L.; Tshivhase, V.M. Major chemical carcinogens in drinking water sources: Health implications due to illegal gold mining activities in Zamfara State-Nigeria. Expo Health 2019, 11, 47–57. [Google Scholar] [CrossRef]

- Article, O. Prevalence of Cough among Adults in An Urban Community in Nigeria. West Afr. J. Med. 2011, 30, 5. [Google Scholar]

- Kyari, F.; Alhassan, M.B.; Abiose, A. Pattern and outcome of paediatric ocular trauma–A 3-year review at National Eye Centre, Kaduna. Niger. J. Ophthalmol. 2000, 8, 11–16. [Google Scholar] [CrossRef]

- Atakpa, A.; Argungu, G.M.; Muawiya, S.; Wase, M.M.; Shuaibu, L.M. Assessment of Mineral Resources in Federal Capital Territory (FCT) Abuja, Nigeria. Int. J. Res. Appl. Sci. Eng. Technol. 2019, 7, 819–823. [Google Scholar] [CrossRef]

- Merem, E.C.; Twumasi, Y.; Wesley, J.; Isokpehi, P.; Shenge, M.; Fageir, S.; Crisler, M.; Romorno, C.; Hines, A.; Hirse, G.; et al. Assessing the ecological effects of mining in West Africa: The case of Nigeria. Int. J. Min. Eng. Miner. Process. 2017, 6, 1–19. [Google Scholar] [CrossRef] [Green Version]

- UNEP/OCHA. Environment and Humanitarian Action: Increasing Effectiveness, Sustainability and Accountability; UNEP/OCHA Environment Unit: Geneva, Switzerland, 2014. [Google Scholar]

- Muhammad, S.; Tahir Shah, M.; Khan, S. Health risk assessment of heavy metals and their source apportionment in drinking water of Kohistan region, northern Pakistan. Microchem. J. 2011, 98, 334–343. [Google Scholar] [CrossRef]

- Dasgupta, A.K.; Harrison, J. Effects of vibration on the hand-arm system of miners in India. Occup. Med. 1996, 46, 71–78. [Google Scholar] [CrossRef] [Green Version]

- Denton, S.; Allsop, A.; Davies, M.; Al, E. The Prevention and Control of Fire and Explosion in Mines; Health & Safety Executive: Geneva, Switzerland, 2001.

- Frank, T.; Bise, C.J.; Michael, K. A hearing conservation program for coal miners. Occup. Health Saf. 2003, 72, 106. [Google Scholar] [PubMed]

- Manley, L. Should States Serve as Laboratories for Mine Safety Regulation. Ariz St. LJ 2009, 41, 379. [Google Scholar]

- Orogbu, L.O.; Onyeizugbe, C.U.; Chukwuma, E. Safety practice and employee productivity in selected mining firms in Ebonyi State, Nigeria. J. Res. Bus. Econ. Manag. 2018, 10, 1964–1970. [Google Scholar]

- Zhong, B.; Pan, X.; Love, P.E.D.; Sun, J.; Tao, C. Hazard analysis: A deep learning and text mining framework for accident prevention. Adv. Eng. Inform. 2020, 46, 101152. [Google Scholar] [CrossRef]

- Akpan, I.O. Effect of sample treatment on trace metal determination of Nigerian crude oils by Atomic Absorption Spectroscopy (AAS) Technique. Afr. J. Environ. Pollut. Health 2005, 4, 1–5. [Google Scholar]

- Ibe, K.A.; Ogeleka, D.F.; Ani, I.C.; Uyebi, G.O. Suitability of Nigerian barite as a weighting agent in drilling mud. Int. J. Min. Miner. Eng. 2016, 7, 51–63. [Google Scholar] [CrossRef]

- Muller, G. Index of geoaccumulation in sediments of the Rhine River. Geo. J. 1969, 2, 108–118. [Google Scholar]

- Hakanson, L. An ecological risk index for aquatic pollution control. A sedimentological approach. Water Res. 1980, 14, 975–1001. [Google Scholar] [CrossRef]

- EPA; ABD. Risk Assessment Guidance for Superfund; Volume I: Human health evaluation manual (Part A); EPA/540/1-89/002; Office of Emergency and Remedial Response, EPA: Washington, DC, USA, 1989.

- Camp Dresser & McKee, Inc. Guidelines for Water Reuse, US Environmental Protection Agency; EPA/625/R-04/108; USEPA: Washington, DC, USA, 2004.

- EPA, US. Fact Sheet PFOA & PFOS Drinking Water Health Advisories; EPA 800-F-16-003; US Environmental Protection Agency: Washington, DC, USA, 2016.

- Shah, I.; Khan, T.; Hanif, M.; Shah, A.; Siddiqui, S.; Khattak, S.A. Environmental aspects of selected heavy and trace elements of Cherat Coal deposits. J. Himal. Earth Sci. 2016, 49, 77–85. [Google Scholar]

- Adewumi, A.J.; Laniyan, T.A. Contamination, sources and risk assessments of metals in media from Anka artisanal gold mining area, Northwest Nigeria. Sci. Total Environ. 2020, 718, 137235. [Google Scholar] [CrossRef]

- Hessel, G.K.; Sluis-Cremer, P.A. Hearing loss in white South African goldminers. S. Afr. Med. J. 1987, 71, 354–367. [Google Scholar]

- Babatunde, O.; Ayodele, L.; Elegbede, O.; Babatunde, O.; Ojo, O.; Alawode, D.; Ademol, O.; Oluwasey, A. Practice of occupational safety among artisanal miners in a rural community in Southwest Nigeria. Int. J. Sci. Environ. Technol. 2013, 2, 622–633. [Google Scholar]

- WHO. Environmental and Occupational Health Hazards Associated with Artisanal and Small-Scale Gold Mining; World Health Organization HQ: Geneva, Switzerland, 2016. [Google Scholar]

- Tirima, S.; Bartrem, C.; von Lindern, I.; von Braun, M.; Lind, D.; Anka, S.M.; Abdullahi, A. Environmental remediation to address childhood lead poisoning epidemic due to artisanal gold mining in Zamfara, Nigeria. Environ. Health Perspect. 2016, 124, 1471–1478. [Google Scholar] [CrossRef] [Green Version]

- Nwagwu, W.E. Job Satisfaction of Information Technology Artisans in Nigeria. Mousaion 2018, 36, 24. [Google Scholar]

- Melodi, M.M.; Opafunso, Z.O. An Assessment of Existing Production and Revenue Capacities for Artisanal and Small-Scale Granite Mining in Southwest Nigeria. J. Min. World Express 2014, 3, 33–37. [Google Scholar] [CrossRef]

- Ahmed, Y.M.; Oruonye, E.D. Socioeconomic impact of artisanal and small scale mining on the Mambilla Plateau of Taraba State, Nigeria. World J. Soc. Sci. Res. 2016, 3, 1. [Google Scholar]

- Olley, B.O.; Abikoye, G.E. Predicting Intentions and Continuous Cannabis Use among Smokers. In Perspectives on Drugs, Alcohol and Society in Africa; Obot, I.S., Abikoye, G.E., Eds.; Centre for Research and Information on Substance Abuse (CRISA): Jos, Nigeria, 2016; Volume 3, pp. 116–122. [Google Scholar]

- Azodo, C.C.; Omuemu, V.O. Perception of spirituality, spiritual care, and barriers to the provision of spiritual care among undergraduate nurses in the University of Lagos, Nigeria. J. Clin. Sci. 2017, 14, 119–125. [Google Scholar] [CrossRef]

- Ralph, O.; Gilles, N.; Fon, N.; Luma, H.; Greg, N. Impact of Artisanal Gold Mining on Human Health and the Environment in the Batouri Gold District, East Cameroon. Acad. J. Interdiscip. Stud. 2018, 7, 25–44. [Google Scholar] [CrossRef] [Green Version]

- Esheya, S.E.; Okoye, P.C.U.; Nweze, P.N.J.; Okonkwo, N.A. Socio-Economic Effects of Chemical Pollution on Agricultural Production in Mineral Mining Communities of South-East Nigeria. Merit Res. J. Bus. Manag. 2017, 5, 63–68. [Google Scholar]

- Kalu, B. COVID-19 in Nigeria: A disease of hunger Respiratory health in athletes: Facing the COVID-19 challenge. Lancet Respir. 2020, 8, 556–557. [Google Scholar] [CrossRef]

- Adebowale, A.S.; Fagbamigbe, A.F.; Akinyemi, J.O.; Obisesan, O.K.; Awosanya, E.J.; Afolabi, R.F.; Alarape, S.A.; Obabiyi, S.O. The spread of COVID-19 outbreak in the first 120 days: A comparison between Nigeria and seven other countries. BMC Public Health 2021, 21, 129. [Google Scholar] [CrossRef] [PubMed]

- Laniyan, T.A.; Adewumi, A.J.P. Potential ecological and health risks of toxic metals associated with artisanal mining contamination in Ijero, southwest Nigeria. J. Environ. Sci. Health Part A 2020, 55, 858–877. [Google Scholar] [CrossRef]

- Amzat, J.; Aminu, K.; Kolo, V.I.; Akinyele, A.A. Coronavirus outbreak in Nigeria: Burden and socio-medical response during the first 100 days. Int. J. Infect Dis. 2020, 98, 218–224. [Google Scholar] [CrossRef]

- Nwagwu, W.E.; Igwe, E.G. Safety information-seeking behaviour of artisanal and small-scale miners in selected locations in Nigeria. Libri 2015, 65, 71–90. [Google Scholar] [CrossRef]

- Afolayan, D.O.; Adetunji, A.R.; Peter, A.; Oghenerume, O.; Amankwah, R.K. Characterization of barite reserves in Nigeria for use as weighting agent in drilling fluid. J. Pet. Explor. Prod. 2021, 1–22. [Google Scholar] [CrossRef]

- Mallo, S.J. Mitigating the Activities of Artisanal and Small-Scale Miners in Africa: Challenges for Engineering and Technological Institutions. IJMER 2012, 2, 4714–4725. [Google Scholar]

- Mensah, A.K.; Mahiri, I.O.; Owusu, O.; Mireku, O.D.; Wireko, I.; Kissi, E.A. Environmental Impacts of Mining: A Study of Mining Communities in Ghana. Appl. Ecol. Environ. Sci. 2015, 3, 81–94. [Google Scholar] [CrossRef]

- Saleh, J.H.; Cummings, A.M. Safety in the mining industry and the unfinished legacy of mining accidents: Safety levers and defense-in-depth for addressing mining hazards. Saf. Sci. 2011, 49, 764–777. [Google Scholar] [CrossRef]

| Case Study | Damages/Sources/Causes | Remedy | References |

|---|---|---|---|

| Concentration of 226Ra, 232Th, and 40K in mining dumps. | radiological hazards, high lifetime cancer risk index | No emerging medical health issues were observed. Regular medical Check-up of miners was recommended for early detection and treatment of potential health hazards | [20] |

| Concentration of Tl, K, Ca, Na and Mg in Au, Pb, and Zn mines’ tailings. | High contamination index of Thallium, high ecological and health risks. | Remediation method was recommended, awareness creation | [21] |

| Concentration of 40K, 238U, and 232Th in tailings from granite mine. | Radiological hazard is within the permissible limit based on UNSCAR | Bioaccumulation/transfer factor level to be monitored | [22] |

| Concentration of air-borne lead and respirable silica from dry lead ore grinding and processing | high risk of lead poisoning, silicosis and tuberculosis | Wet spray misting used to reduce the mean airborne Pb and respirable silica | [23,24,25] |

| Concentration of Cu, Cr, Pb, Cd and Zn in iron ore tailings | serious non-carcinogenic health risk in children, high carcinogenic risk in adults. | research-industry- miners nexus was advocated | [26] |

| Concentration of As, Sn, Nb, Ta and Cd in surface water and mine tailings (alluvial) soil | moderate arsenic and cadmium Contamination and Geo-accumulation index (CI & GAI) | enforcement of environmental and mining laws to control pollution |

| Mining Hazard/Accidents | Activities/Year | Locations | References |

|---|---|---|---|

| Air pollution (dusts, airborne Si, Ca), eyes damage asthma, damage to farm and cola-nut plantation | limestone quarry, cement production, lead mining (2013 till date) | Shagamu, Ewekoro (Ogun State), kalambana, Wumo, Kwakuti (Sokoto State), Ashaka (Gombe State), Jakura | [21] |

| Flooding, mysterious death, abandoned mines, contaminated lands, exposure to carcinogenic/radioactive substances. | Tin, columbite and clay mining (1960 till date) | Barkin-Ladi, Bukuru, Bossa, Riyom district (Plateau State). | [27] |

| Heavy metals water contamination, damaged ecosystem. airborne silica, land degradation | Coal, gold, and sand mining (2010–2013) | Enugu, Igun-Ijesha (Oguin State), Efikpo (Ebonyi State), Abeokuta, Owode, Ifo, Ado-Odo, Ofa, Ewekoro, Shagamu (Ogun State), Lagos State | [54] |

| Water and land degradation, pollutions | Marble mining (2010–2014) | Azara, Wuzue, Benu, Uywa, Lafia (Nassarawa) Luku, Minna (Niger State), Onyeama (Enugu State) | [54] |

| Death, mine collapse | Gold mining | Zawan (Plateau State) |

| Heavy Metals | Proportion | |

|---|---|---|

| Barite Mining Site (mg/L) | WHO Allowable Limit (mg/L) | |

| Zinc | 3.905 | 3.000 |

| Iron | 15.6094 | 0.300 |

| Copper | 0.3024 | 2.000 |

| Lead | 113.8127 | 0.010 |

| Cadmium | 0.0008 | 0.0030 |

| Elements | Ba | Pb | Zn | Cu | Fe |

|---|---|---|---|---|---|

| (Igeo) | |||||

| TB1 | 0.344 | 7.659 | –6.546 | 0 | 0.510 |

| TB2 | –1.985 | 2.821 | –8.118 | –10.966 | –7.243 |

| (CF) | |||||

| TB1 | 1.906 | 303.2 | 2.132 | ||

| TB2 | 0.379 | 10.600 | 0.010 | ||

| (CDI) Adult | |||||

| TB1 | |||||

| TB2 | |||||

| (CDI) Child | |||||

| TB1 | |||||

| TB2 |

| Elements | Health Quotient (HQ) | Health Index | ||||

|---|---|---|---|---|---|---|

| Ba | Pb | Zn | Cu | Fe | ||

| (HQ) Adult | ||||||

| TB1 | ||||||

| TB2 | ||||||

| (HQ) Child | ||||||

| TB1 | ||||||

| TB2 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Afolayan, D.O.; Onwualu, A.P.; Eggleston, C.M.; Adetunji, A.R.; Tao, M.; Amankwah, R.K. Safe Mining Assessment of Artisanal Barite Mining Activities in Nigeria. Mining 2021, 1, 224-240. https://0-doi-org.brum.beds.ac.uk/10.3390/mining1020015

Afolayan DO, Onwualu AP, Eggleston CM, Adetunji AR, Tao M, Amankwah RK. Safe Mining Assessment of Artisanal Barite Mining Activities in Nigeria. Mining. 2021; 1(2):224-240. https://0-doi-org.brum.beds.ac.uk/10.3390/mining1020015

Chicago/Turabian StyleAfolayan, David Oluwasegun, Azikiwe Peter Onwualu, Carrick McAfee Eggleston, Adelana Rasak Adetunji, Mingjiang Tao, and Richard Kwasi Amankwah. 2021. "Safe Mining Assessment of Artisanal Barite Mining Activities in Nigeria" Mining 1, no. 2: 224-240. https://0-doi-org.brum.beds.ac.uk/10.3390/mining1020015