Characterization of Fatty Acid, Amino Acid and Volatile Compound Compositions and Bioactive Components of Seven Coffee (Coffea robusta) Cultivars Grown in Hainan Province, China

Abstract

:1. Introduction

2. Results and Discussion

2.1. Color Characteristics

| Cultivar | L* | a* | b* | C* | H* | |

|---|---|---|---|---|---|---|

| X1 | 53.35 ± 0.36 e | 3.23 ± 0.06 f | 24.77 ± 0.97 ab | 24.98 ± 0.97 ab | 83.05 ± 0.07 a | 0.97 ± 0.29 d |

| RY1 | 59.31 ± 0.72 a | 4.82 ± 0.23 b | 22.78 ± 0.30 d | 23.29 ± 0.29 d | 81.15 ± 0.24 d | 5.26 ± 0.48 a |

| RY2 | 56.57 ± 0.32 c | 4.55 ± 0.13 c | 25.36 ± 0.13 a | 25.77 ± 0.10 a | 81.82 ± 0.15 bc | 3.31 ± 0.22 c |

| X24-2 | 54.32 ± 0.19 de | 5.52 ± 0.08 a | 23.65 ± 0.19 cd | 24.30 ± 0.21 bc | 80.58 ± 0.06 e | 2.98 ± 0.06 c |

| X26 | 58.21 ± 1.05 b | 4.60 ± 0.11 bc | 24.12 ± 0.68 bc | 24.56 ± 0.68 bc | 81.59 ± 0.12 c | 4.89 ± 0.69 b |

| X28 | 55.36 ± 0.48 d | 4.22 ± 0.13 d | 23.34 ± 0.44 cd | 23.72 ± 0.46 cd | 81.86 ± 0.07 b | 2.63 ± 0.40 c |

| XCM | 54.54 ± 0.73 d | 3.70 ± 0.19 e | 20.90 ± 0.05 e | 21.23 ± 0.07 e | 82.02 ± 0.20 b | 4.20 ± 0.14 b |

2.2. Chlorogenic Acids, Trigonelline, and Caffeine Analysis

2.3. Total Lipid Content

2.4. Total Protein Content

2.5. Fatty Acid Composition

| Fatty Acids | Cultivars | ||||||

|---|---|---|---|---|---|---|---|

| X1 | RY1 | RY2 | X24-2 | X26 | X28 | XCM | |

| Saturated Fatty Acids (SFAs) | |||||||

| C14:0 | 5.6 ± 0.3 c | 10.7 ± 1.5 b | 9.5 ± 0.2 b | 14.9 ± 2.0 a | 9.7 ± 0.1 b | 10.5 ± 0.9 b | 10.6 ± 0.8 b |

| C16:0 | 1200.0 ± 13.0 b | 780.0 ± 10.0 e | 833.3 ± 25.2 de | 853.2 ± 70.9 d | 1300.0 ± 12.1 a | 953.4 ± 32.1 c | 913.3 ± 15.3 c |

| C18:0 | 260.0 ± 4.0 b | 150.0 ± 3.2 f | 163.3 ± 5.8 e | 186.7 ± 5.8 d | 273.4 ± 5.7 a | 196.5 ± 11.5 d | 213.3 ± 5.8 c |

| C20:0 | 150.0 ± 1.0 a | 95.4 ± 0.5 d | 98.0 ± 3.0 cd | 101.7 ± 7.6 cd | 130.0 ± 1.0 b | 100.0 ± 1.7 cd | 103.3 ± 5.8 c |

| C22:0 | 28.1 ± 1.1 a | 20.3 ± 0.6 c | 24.2 ± 0.6 b | 24.3 ± 2.5 b | 29.6 ± 0.5 a | 24.0 ± 1.1 b | 23.4 ± 0.7 b |

| C23:0 | 5.5 ± 0.5 c | 5.8 ± 0.2 c | 7.3 ± 0.2 b | 8.5 ± 1.0 a | 8.1 ± 0.2 ab | 6.4 ± 0.4 c | 8.7 ± 0.3 a |

| C24:0 | 18.0 ± 4.4 ab | 14.6 ± 2.8 bc | 19.3 ± 0.6 a | 12.4 ± 0.6 cd | 15.6 ± 1.2 abc | 13.3 ± 0.5 cd | 9.8 ± 0.3 d |

| Unsaturated Fatty Acids (UFAs) | |||||||

| C18:1 | 376.6 ± 5.7 a | 170.0 ± 1.0 f | 226.4 ± 5.7 e | 260.0 ± 20.1 d | 366.5 ± 11.5 a | 286.8 ± 15.3 c | 313.4 ± 15.2 b |

| C18:2 | 1600.0 ± 27.2 a | 920.0 ± 20.0 e | 1070.0 ± 60.8 d | 1013.2 ± 80.8 de | 1633.3 ± 57.7 a | 1266.5 ± 57.6 c | 1433.2 ± 57.5 b |

| C18:3 | 26.5 ± 0.6 b | 24.6 ± 1.5 c | 20.2 ± 0.6 d | 17.0 ± 1.0 e | 27.7 ± 0.5 b | 23.5 ± 1.1 c | 35.4 ± 0.6 a |

| C20:1 | 14.3 ± 0.6 a | 8.1 ± 0.1 e | 8.7 ± 0.4 de | 9.2 ± 0.3 d | 12.7 ± 0.6 b | 10.6 ± 0.5 c | 13.2 ± 0.6 b |

| ΣSFA | 1667.2 ± 24.3 | 1076.8 ± 18.8 | 1154.9 ± 35.6 | 1201.7 ± 90.4 | 1766.4 ± 20.8 | 1304.1 ± 48.2 | 1282.4 ± 29.0 |

| ΣUFA | 2017.4 ± 34.1 | 1122.7 ± 22.6 | 1325.3 ± 67.5 | 1299.4 ± 102.2 | 2040.2 ± 70.3 | 1587.4 ± 74.5 | 1795.2 ± 73.9 |

| TFA | 3684.6 ± 58.4 | 2199.5 ± 41.4 | 2480.2 ± 103.1 | 2501.1 ± 192.6 | 3806.6 ± 91.1 | 2891.5 ± 122.7 | 3077.6 ±102.9 |

| ΣUFA/ΣSFA | 1.21 ± 0.01 | 1.04 ± 0.01 | 1.15 ± 0.03 | 1.08 ± 0.02 | 1.15 ± 0.02 | 1.22 ± 0.04 | 1.40 ± 0.02 |

2.6. Amino Acid Composition

| Amino Acid | X1 | RY1 | RY2 | X24-2 | X26 | X28 | XCM |

|---|---|---|---|---|---|---|---|

| Essential Amino Acids (EAA) | |||||||

| Arginine | 0.62 ± 0.05 ab | 0.54 ± 0.05 b | 0.62 ± 0.05 ab | 0.61 ± 0.08 ab | 0.61 ± 0.04 ab | 0.58 ± 0.04 ab | 0.66 ± 0.05 a |

| Leucine | 0.85 ± 0.03 b | 0.74 ± 0.03 d | 0.84 ± 0.02 bc | 0.81 ± 0.03 c | 0.84 ± 0.02 bc | 0.81 ± 0.01 c | 0.96 ± 0.01 a |

| Phenylalanine | 0.58 ± 0.02 b | 0.50 ± 0.02 c | 0.58 ± 0.03 b | 0.56 ± 0.02 b | 0.58 ± 0.01 b | 0.57 ± 0.00 b | 0.67 ± 0.01 a |

| Threonine | 0.37 ± 0.02 ab | 0.32 ± 0.02 c | 0.36 ± 0.02 ab | 0.36 ± 0.01 ab | 0.35 ± 0.02 bc | 0.34 ± 0.01 bc | 0.39 ± 0.02 a |

| Methionine | 0.06 ± 0.01 ab | 0.06 ± 0.00 ab | 0.05 ± 0.01 ab | 0.05 ± 0.00 ab | 0.06 ± 0.01 b | 0.06 ± 0.00 ab | 0.07 ± 0.00 a |

| Lysine | 0.64 ± 0.02 b | 0.58 ± 0.03 d | 0.63 ± 0.02 bc | 0.61 ± 0.02 c | 0.63 ± 0.01 bc | 0.61 ± 0.01 c | 0.69 ± 0.01 a |

| Histidine | 0.22 ± 0.01 a | 0.20 ± 0.01 ab | 0.20 ± 0.02 ab | 0.20 ± 0.01 ab | 0.19 ± 0.01 b | 0.19 ± 0.01 b | 0.21 ± 0.02 a |

| Isoleucine | 0.40 ± 0.01 b | 0.34 ±0.01 d | 0.38 ± 0.01 bc | 0.37 ± 0.01 c | 0.39 ± 0.00 b | 0.37 ± 0.01 c | 0.44 ± 0.01 a |

| Non-Essential Amino Acids (NEA) | |||||||

| Aspartic acid | 1.04 ± 0.02 b | 0.94 ± 0.03 c | 1.04 ± 0.04 b | 1.04 ± 0.04 b | 1.00 ± 0.02 b | 1.02 ± 0.01 b | 1.16 ± 0.02 a |

| Valine | 0.57 ± 0.04 b | 0.49 ± 0.03 c | 0.55 ± 0.03 b | 0.54 ± 0.02 b | 0.56 ± 0.02 b | 0.54 ± 0.01 b | 0.62 ± 0.02 a |

| Alanine | 0.48 ± 0.01 b | 0.43 ± 0.01 c | 0.48 ± 0.02 b | 0.48 ± 0.02 b | 0.48 ± 0.01 b | 0.47 ± 0.00 b | 0.57 ± 0.01 a |

| Glycine | 0.64 ± 0.01 b | 0.58 ± 0.01 d | 0.65 ± 0.02 b | 0.63 ± 0.03 bc | 0.61 ± 0.01 cd | 0.61 ± 0.02 cd | 0.70 ± 0.02 a |

| Proline | 0.52 ± 0.01 b | 0.46 ± 0.01 d | 0.52 ± 0.02 b | 0.51 ± 0.02 b | 0.51 ± 0.01 b | 0.48 ± 0.01 c | 0.59 ± 0.01 a |

| Glutamic acid | 2.13 ± 0.08 b | 1.84 ± 0.06 d | 2.13 ± 0.11 b | 1.94 ± 0.07 cd | 2.05 ± 0.02 bc | 2.00 ± 0.01 c | 2.40 ± 0.03 a |

| Tyrosine | 0.24 ± 0.01 b | 0.22 ± 0.01 c | 0.26 ± 0.02 a | 0.26 ± 0.01 a | 0.24 ± 0.01 b | 0.24 ± 0.02 b | 0.27 ± 0.01 a |

| Serine | 0.50 ± 0.01 b | 0.45 ± 0.01 c | 0.52 ± 0.02 b | 0.52 ± 0.03 b | 0.49 ± 0.01 b | 0.49 ± 0.02 b | 0.55 ± 0.02 a |

| ΣEAA | 3.75 ± 0.10 | 3.28 ± 0.06 | 3.68 ± 0.11 | 3.59 ± 0.14 | 3.65 ± 0.03 | 3.53 ± 0.05 | 4.08 ± 0.06 |

| ΣNEA | 6.13 ± 0.16 | 5.42 ± 0.15 | 6.16 ± 0.23 | 5.90 ± 0.20 | 5.93 ± 0.06 | 5.85 ± 0.04 | 6.85 ± 0.08 |

| ΣEAA/ΣNEA | 0.61 ± 0.01 | 0.60 ± 0.01 | 0.60 ± 0.01 | 0.61 ± 0.01 | 0.62 ± 0.01 | 0.60 ± 0.00 | 0.59 ± 0.01 |

| TAA | 9.88 ± 0.25 | 8.70 ± 0.20 | 8.83 ± 0.33 | 9.49 ± 0.33 | 9.58 ± 0.07 | 9.38 ± 0.09 | 10.59 ± 0.13 |

2.7. Volatile Flavor Compounds Identified from Chinese Robusta Coffee

| No. | Rt (min) | Compounds | RI | Identification | Formula | Mol. Wt | |

|---|---|---|---|---|---|---|---|

| 1 | 3.080 | 3-Methylbutanal | 912 | MS, RI | C5H10O | 86 | |

| 2 | 3.483 | Ethanol | 944 | MS, RI | C2H6O | 46 | |

| 3 | 4.232 | Pentanal | 978 | MS, RI | C5H10O | 86 | |

| 4 | 5.744 | Toluene | 1008 | MS, RI | C7H8 | 92 | |

| 5 | 7.195 | Hexanal | 1053 | MS, RI | C6H12O | 94 | |

| 6 | 11.853 | Pyridine | 1159 | MS, RI | C5H5N | 79 | |

| 7 | 12.141 | Heptanal | 1165 | MS, RI | C7H14O | 114 | |

| 8 | 12.743 | d-Limonene | 1176 | MS, RI | C10H16 | 94 | |

| 9 | 13.833 | 2-Hexenal | 1197 | MS, RI | C6H10O | 98 | |

| 10 | 15.072 | 2-Pentylfuran | 1216 | MS, RI | C9H14O | 138 | |

| 11 | 16.752 | 1-Pentanol | 1240 | MS, RI | C5H12O | 88 | |

| 12 | 16.892 | Methylpyrazine | 1243 | MS, RI | C5H6N2 | 94 | |

| 13 | 18.769 | Octanal | 1270 | MS, RI | C8H16O | 128 | |

| 14 | 20.298 | Tridecane | 1294 | MS, RI | C13H28 | 184 | |

| 15 | 20.867 | (Z)-2-Heptenal | 1301 | MS, RI | C7H12O | 112 | |

| 16 | 21.307 | 2,6-Dimethylpyrazine | 1307 | MS, RI | C6H8N2 | 108 | |

| 17 | 21.644 | Ethylpyrazine | 1312 | MS, RI | C6H8N2 | 108 | |

| 18 | 22.213 | 6-Methyl-5-hepten-2-one | 1319 | MS, RI | C8H14O | 126 | |

| 19 | 24.737 | 2,6,10,14-Tetramethylhexadecane | 1353 | MS, RI | C20H42 | 282 | |

| 20 | 25.310 | 3,5-Dimethyldodecane | 1360 | MS, RI | C14H30 | 198 | |

| 21 | 26.465 | Nonanal | 1376 | MS, RI | C9H18O | 142 | |

| 22 | 27.177 | 4,8-Dimethyltridecane | 1385 | MS, RI | C15H32 | 212 | |

| 23 | 27.565 | (E)-3-Tetradecene | 1390 | MS, RI | C14H28 | 196 | |

| 24 | 28.071 | Tetradecane | 1397 | MS, RI | C14H30 | 198 | |

| 25 | 28.713 | 2-Dodecenal | 1405 | MS, RI | C12H22O | 182 | |

| 26 | 30.565 | Acetic acid | 1429 | MS, RI | C2H4O2 | 60 | |

| 27 | 31.336 | 7-Methylpentadecane | 1439 | MS, RI | C16H34 | 226 | |

| 28 | 31.679 | 1-Octen-3-ol | 1444 | MS, RI | C8H16O | 128 | |

| 29 | 32.052 | 4-Methyltetradecane | 1449 | MS, RI | C15H32 | 212 | |

| 30 | 32.421 | 10-Methyleicosane | 1453 | MS, RI | C21H44 | 296 | |

| 31 | 33.129 | 3-Methyltetradecane | 1463 | MS, RI | C15H32 | 212 | |

| 32 | 34.471 | 1,1′-(1,3-Propanediyl)bis-cyclohexane | 1480 | MS, RI | C15H28 | 208 | |

| 33 | 35.032 | Benzaldehyde | 1487 | MS, RI | C7H6O | 106 | |

| 34 | 36.022 | Pentadecane | 1500 | MS, RI | C15H32 | 212 | |

| 35 | 36.805 | 2-Methyl-(Z)-4-tetradecene | 1510 | MS, RI | C15H30 | 210 | |

| 36 | 39.743 | 4-Methyldodecane | 1549 | MS, RI | C13H28 | 184 | |

| 37 | 40.108 | 2-Methylpentadecane | 1554 | MS, RI | C16H34 | 226 | |

| 38 | 40.821 | Benzeneacetic acid-2-tetradecyl ester | 1563 | MS, RI | C22H36O2 | 332 | |

| 39 | 41.121 | 2-Tridecanol | 1567 | MS, RI | C13H28O | 200 | |

| 40 | 41.383 | (Z)-3-Hexadecene | 1570 | MS,RI | C16H32 | 224 | |

| 41 | 42.313 | Butyrolactone | 1583 | MS, RI | C4H6O2 | 86 | |

| 42 | 42.580 | n-Nonylcyclohexane | 1586 | MS, RI | C15H30 | 210 | |

| 43 | 43.565 | Hexadecane | 1599 | MS, RI | C16H34 | 226 | |

| 44 | 44.033 | Benzeneacetaldehyde | 1605 | MS, RI | C8H8O | 120 | |

| 45 | 44.672 | 1-Heptacosanol | 1614 | MS, RI | C27H56O | 396 | |

| 46 | 45.333 | 2,6,10-Trimethylpentadecane | 1623 | MS, RI | C18H38 | 254 | |

| 47 | 47.460 | Methoxyacetic acid-2-tetradecyl ester | 1652 | MS, RI | C17H30O3 | 286 | |

| 48 | 47.687 | 3-Methylbutanoic acid | 1655 | MS, RI | C5H10O2 | 102 | |

| 49 | 48.213 | 3-Methylhexadecane | 1662 | MS, RI | C17H36 | 240 | |

| 50 | 48.907 | 2,6,10,14-Tetramethylpentadecane | 1672 | MS, RI | C19H40 | 268 | |

| 51 | 50.221 | Naphthalene | 1690 | MS, RI | C10H8 | 128 | |

| 52 | 50.726 | Heptadecane | 1697 | MS, RI | C17H36 | 240 | |

| 53 | 52.640 | 2-Methyl-(E)-7-octadecene | 1724 | MS, RI | C19H38 | 266 | |

| 54 | 53.183 | Methyl salicylate | 1731 | MS, RI | C8H8O3 | 152 | |

| 55 | 56.140 | 2,6,10,14-Tetramethylhexadecane | 1773 | MS, RI | C20H42 | 282 | |

| 56 | 56.296 | 3-Methyl-2-butenoic acid | 1776 | MS, RI | C5H8O2 | 100 | |

| 57 | 57.592 | Octadecane | 1794 | MS, RI | C18H38 | 254 | |

| 58 | 57.812 | 2-Cyclohexyldecane | 1797 | MS, RI | C16H32 | 224 | |

| 59 | 60.186 | Hexanoic acid | 1833 | MS, RI | C6H12O2 | 116 | |

| 60 | 61.697 | 2,2,4-Trimethyl-3-carboxy isopropylpentanoic acid, isobutyl ester | 1857 | MS, RI | C6H30O4 | 286 | |

| 61 | 63.323 | Phenylethyl alcohol | 1882 | MS, RI | C8H10O | 122 | |

| 62 | 66.212 | 1-(1H-pyrrol-2-yl)-ethanone | 1940 | MS, RI | C6H7NO | 109 | |

| 63 | 67.180 | 1-Tetradecanol | 1962 | MS, RI | C14H30O | 214 | |

| 64 | 67.914 | Phenol | 1978 | MS, RI | C6H6O | 94 | |

| 65 | 68.217 | Dihydro-5-pentyl-2(3H)-furanone | 1985 | MS, RI | C9H16O2 | 156 | |

| 66 | 68.556 | 2-Pyrrolidinone | 1993 | MS, RI | C4H7NO | 85 | |

| 67 | 69.107 | Octadecanal | 2008 | MS, RI | C18H36O | 268 | |

| 68 | 69.481 | Eicosane | 2019 | MS, RI | C17H36 | 240 | |

| 69 | 73.400 | Caprolactam | 2142 | MS, RI | C6H11NO | 113 | |

| 70 | 73.992 | 2-Methoxy-4-vinyphenol | 2163 | MS, RI | C9H10O2 | 150 | |

| 71 | 75.083 | Hexadecanoic acid methyl ester | 2202 | MS, RI | C17H34O2 | 270 | |

| 72 | 75.954 | 2-Methyl-2-cyclopenten-1-one | 2237 | MS, RI | C6H8O | 96 | |

| 73 | 76.094 | Hexadecanoic acid ethyl ester | 2243 | MS, RI | C18H36O2 | 284 | |

| 74 | 76.746 | n-Decanoic acid | 2268 | MS, RI | C10H20O2 | 172 | |

| 75 | 77.221 | 5,6,7,7a-Tetrahydro-4,4,7a-trimethyl-2(4H)-benzofuranone | 2287 | MS, RI | C11H16O2 | 180 | |

| 76 | 82.546 | 3-Hydroxy-4-methoxybenzaldehyde | 2527 | MS, RI | C8H8O3 | 152 | |

| 77 | 85.466 | 1,2-Benzenedicarboxylic acid-butyl-2-methylpropyl ester | 2669 | MS, RI | C16H22O4 | 278 |

| Code | Relative Peak Areas of Samples (%) | ||||||

|---|---|---|---|---|---|---|---|

| X1 | RY1 | RY2 | X24-2 | X26 | X28 | XCM | |

| Alcohols | 2.72 ± 0.22 bc | 2.08 ± 0.24 c | 2.18 ± 0.11 c | 2.41 ± 0.12 bc | 2.24 ± 0.15 bc | 2.95 ± 0.29 b | 4.83 ± 0.65 a |

| Acids | 7.22 ± 0.69 ab | 6.79 ± 0.12 abc | 4.84 ± 1.91 c | 4.89 ± 0.40 c | 8.85 ± 0.13 a | 6.50 ± 0.68 bc | 6.87 ± 0.90 abc |

| Hydrocarbons | 61.07 ± 2.02 a | 63.20 ± 1.77 a | 61.87 ± 1.93 a | 62.70 ± 4.50 a | 54.90 ± 0.39 b | 60.33 ± 1.08 a | 44.60 ± 2.08 c |

| Aldehydes | 5.55 ± 0.57 ab | 5.03 ± 0.20 b | 5.45 ± 0.10 b | 5.27 ± 0.08 b | 5.17 ± 0.10 b | 5.28 ± 0.05 b | 6.05 ± 0.27 a |

| Esters | 3.13 ± 0.04 ab | 3.44 ± 0.26 a | 3.01 ± 0.18 ab | 3.12 ± 0.20 ab | 3.26 ± 0.30 a | 2.73 ± 0.19 b | 2.94 ± 0.25 ab |

| Furan | 0.12 ± 0.02 b | 0.12 ± 0.01 b | 0.11 ± 0.01 b | 0.11 ± 0.01 b | 0.17 ± 0.02 b | 0.15 ± 0.03 b | 0.27 ± 0.02 a |

| Pyrazines | 0.23 ± 0.04 a | 0.72 ± 0.09 b | 0.14 ± 0.04 a | 0.16 ± 0.02 a | 0.30 ± 0.02 a | 0.49 ± 0.11 c | 2.96 ± 0.13 a |

| Pyridine | 0.10 ± 0.02 c | 0.33 ± 0.02 b | 0.10 ± 0.03 c | 0.08 ± 0.01 c | 0.10 ± 0.01 c | 0.17 ± 0.04 c | 1.48 ± 0.10 a |

| Ketones | 1.31 ± 0.03 c | 1.01 ± 0.08 c | 1.17 ± 0.04 c | 1.08 ± 0.39 c | 3.55 ± 0.19 a | 1.30 ± 0.10 c | 2.92 ± 0.16 b |

| Phenols | 0.63 ± 0.06 bc | 0.80 ± 0.08 b | 0.76 ± 0.08 bc | 0.69 ± 0.07 bc | 0.50 ± 0.24 c | 0.78 ± 0.09 b | 1.06 ± 0.05 a |

| Others | 0.41 ± 0.15 a | 0.25 ± 0.06 ab | 0.23 ± 0.16 ab | 0.10 ± 0.05 b | 0.27 ± 0.17 ab | 0.29 ± 0.06 ab | 0.42 ± 0.03 a |

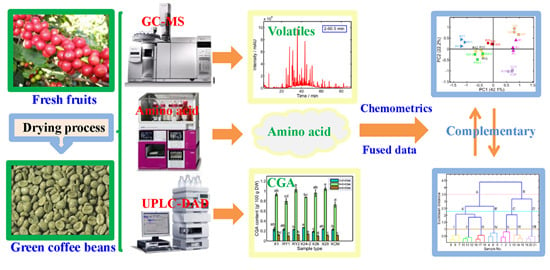

2.8. Principal Component Analysis

2.9. Hierarchical Cluster Analysis

3. Experimental Section

3.1. Chemicals and Reagents

3.2. Coffee Samples and Sample Preparation

3.3. Physicochemical Analyses.

3.3.1. Color Measurements

3.3.2. Preparation of Sample Solutions for Chlorogenic Acids, Trigonelline, and Caffeine Determination

3.3.3. UPLC-DAD Analysis

3.3.4. Determination of Total Protein Content

3.3.5. Determination of Total Lipid Content

3.3.6. Fatty Acid Analysis

3.3.7. Amino Acid Analysis

3.3.8. Extraction of Volatile Compounds from Ground Coffee by HS-SPME

3.3.9. GC-MS Analysis and Volatile Compounds Identification

3.4. Statistical Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Saura-Calixto, F.; Goñi, I. Antioxidant capacity of the Spanish Mediterranean diet. Food Chem. 2006, 94, 442–447. [Google Scholar] [CrossRef]

- Monente, C.; Ludwig, I.A.; Irigoyen, A.; de Peña, M.P.; Cid, C. Assessment of total (free and bound) phenolic compounds in spent coffee extracts. J. Agric. Food Chem. 2015, 63, 4327–4334. [Google Scholar] [CrossRef] [PubMed]

- Iwasa, K.; Setoyama, D.; Shimizu, H.; Seta, H.; Fujimura, Y.; Miura, D.; Miura, D.; Wariishi, H.; Nagai, C.; Nakahara, K. Identification of 3-methylbutanoyl glycosides in green Coffea arabica beans as causative determinants for the quality of coffee flavors. J. Agric. Food Chem. 2015, 63, 3742–3751. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, N.P.; de Jesus Garcia Salva, T.; Bragagnolo, N. Influence of coffee genotype on bioactive compounds and the in vitro capacity to scavenge reactive oxygen and nitrogen species. J. Agric. Food Chem. 2015, 63, 4815–4826. [Google Scholar] [CrossRef] [PubMed]

- International Coffee Organization. Coffee Market Report—September 2014. Available online: http://dev.ico.org/documents/cy2013-14/cmr-0914-e.pdf (accessed on 24 October 2014).

- Schievano, E.; Finotello, C.; de Angelis, E.; Mammi, S.; Navarini, L. Rapid authentication of coffee blends and quantification of 16-O-methylcafestol in roasted coffee beans by nuclear magnetic resonance. J. Agric. Food Chem. 2014, 62, 12309–12314. [Google Scholar] [CrossRef] [PubMed]

- Dziki, D.; Gawlik-Dziki, U.; Pecio, Ł.; Różyło, R.; Świeca, M.; Krzykowski, A.; Rudy, S. Ground green coffee beans as a functional food supplement—Preliminary study. LWT-Food Sci. Technol. 2015, 63, 691–699. [Google Scholar] [CrossRef]

- Chen, H.Z.; Zeng, X.P. Present status and development measures of coffee industry in Hainan. Trop. Agric. Eng. 2012, 36, 49–50. [Google Scholar]

- Ouyang, H.; Wang, Q.H.; Long, Y.Z.; Dong, Y.P.; Fu, H.M. Development strategy of Hainan coffee industry chain. Chin. J. Trop. Agric. 2012, 32, 58–63. [Google Scholar]

- Sunarharum, W.B.; Williams, D.J.; Smyth, H.E. Complexity of coffee flavor: A compositional and sensory perspective. Food Res. Int. 2014, 62, 315–325. [Google Scholar] [CrossRef]

- Bertrand, B.; Guyot, B.; Anthony, F.; Lashermes, P. Impact of the Coffea canephora gene introgression on beverage quality of C. arabica. Theor. Appl. Genet. 2003, 107, 387–394. [Google Scholar] [CrossRef] [PubMed]

- Esquivel, P.; Jiménez, V.M. Functional properties of coffee and coffee by-products. Food Res. Int. 2012, 46, 488–495. [Google Scholar] [CrossRef]

- Heck, C.I.; de Mejia, E.G. Yerba mate tea (Ilex paraguariensis): A comprehensive review on chemistry, health implications, and technological considerations. J. Food Sci. 2007, 72, 138–181. [Google Scholar] [CrossRef] [PubMed]

- Riedel, A.; Hochkogler, C.M.; Lang, R.; Bytof, G.; Lantz, I.; Hofmann, T.; Somoza, V. N-Methylpyridinium, a degradation product of trigonelline upon coffee roasting, stimulates respiratory activity and promotes glucose utilization in HepG2 cells. Food Funct. 2014, 5, 454–462. [Google Scholar] [CrossRef] [PubMed]

- Henry-Vitrac, C.; Ibarra, A.; Roller, M.; Mérillon, J.M.; Vitrac, X. Contribution of chlorogenic acids to the inhibition of human hepatic glucose-6-phosphatase activity in vitro by svetol, a standardized decaffeinated green coffee extract. J. Agric. Food Chem. 2010, 58, 4141–4144. [Google Scholar] [CrossRef] [PubMed]

- Lou, Z.X.; Wang, H.X.; Zhu, S.; Ma, C.Y.; Wang, Z.P. Antibacterial activity and mechanism of action of chlorogenic acid. J. Food Sci. 2011, 76, 398–403. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.G.; Hu, Q.P.; Liu, Y. Antioxidant and DNA-protective activities of chlorogenic acid isomers. J. Agric. Food Chem. 2012, 60, 11625–11630. [Google Scholar] [CrossRef] [PubMed]

- Mullen, W.; Nemzer, B.; Stalmach, A.; Ali, S.; Combet, E. Polyphenolic and hydroxycinnamate contents of whole coffee fruits from Chinese, India, and Mexico. J. Agric. Food Chem. 2013, 61, 5298–5309. [Google Scholar] [CrossRef] [PubMed]

- Jang, H.; Ahn, H.R.; Jo, H.; Kim, K.A.; Lee, E.H.; Lee, K.W.; Jung, S.H.; Lee, C.Y. Chlorogenic acid and coffee prevent hypoxia-induced retinal degeneration. J. Agric. Food Chem. 2014, 62, 182–191. [Google Scholar] [CrossRef] [PubMed]

- Speer, K.; Kölling-Speer, I. The lipid fraction of the coffee bean. Braz. J. Plant Physiol. 2006, 18, 201–216. [Google Scholar]

- Ferrari, M.; Ravera, F.; de Angelis, E.; Liverani, F.S.; Navarini, L. Interfacial properties of coffee oils. Colloid Surf. A 2010, 365, 79–82. [Google Scholar] [CrossRef]

- Mao, Z.X.; Fu, H.; Nan, Z.B.; Wan, C.G. Fatty acid, amino acids, and mineral composition of four common vetch seeds on Qinghai-Tibetan plateau. Food Chem. 2015, 171, 13–18. [Google Scholar] [CrossRef] [PubMed]

- Gressler, V.; Yokoya, N.S.; Fujii, M.T.; Colepicolo, P.; Filho, J.M.; Torres, R.P.; Pinto, E. Lipid, fatty acid, protein, amino acid and ash content in four Brazilian red algae species. Food Chem. 2010, 120, 585–590. [Google Scholar] [CrossRef]

- Toci, A.T.; Neto, V.J.M.F.; Torres, A.G.; Farah, A. Changes in triacylglycerols and free fatty acids composition during storage of roasted coffee. LWT-Food Sci. Technol. 2013, 50, 581–590. [Google Scholar] [CrossRef]

- Romano, R.; Santini, A.; Grottaglie, L.L.; Manzo, N.; Visconti, A.; Ritieni, A. Identification markers based on fatty acid composition to differentiate between roasted Arabica and Canephora (Robusta) coffee varieties in mixtures. J. Food Compos. Anal. 2014, 35, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Murkovic, M.; Derler, K. Analysis of amino acids and carbohydrates in green coffee. J. Biochem. Biophys. Methods 2006, 69, 25–32. [Google Scholar] [CrossRef] [PubMed]

- Casal, S.; Alves, M.R.; Mendes, E.; Oliveira, M.B.P.P.; Ferreira, M.A. Discrimination between Arabica and Robusta coffee species on the basis of their amino acid enantiomers. J. Agric. Food Chem. 2003, 51, 6495–6501. [Google Scholar] [CrossRef] [PubMed]

- Bertrand, B.; Boulanger, R.; Dussert, S.; Ribeyre, F.; Berthiot, L.; Descroix, F.; Joët, T. Climatic factors directly impact the volatile organic compound fingerprint in green Arabica coffee bean as well as coffee beverage quality. Food Chem. 2012, 135, 2575–2583. [Google Scholar] [CrossRef] [PubMed]

- Toci, A.T.; Farah, A. Volatile fingerprint of Brazilian defective coffee seeds: Corroboration of potential marker compounds and identification of new low quality indicators. Food Chem. 2014, 153, 298–314. [Google Scholar] [CrossRef] [PubMed]

- Craig, A.P.; Franca, A.S.; Oliveira, L.S. Discrimination between immature and mature green coffees by attenuated total reflectance and diffuse reflectance fourier transform infrared spectroscopy. J. Food Sci. 2011, 76, 1162–1168. [Google Scholar] [CrossRef] [PubMed]

- Smrke, S.; Kroslakova, I.; Gloess, A.N.; Yeretzian, C. Differentiation of degrees of ripeness of Catuai and Tipica green coffee by chromatographical and statistical techniques. Food Chem. 2015, 174, 637–642. [Google Scholar] [CrossRef] [PubMed]

- Perrone, D.; Donangelo, C.M.; Farah, A. Fast simultaneous analysis of caffeine, trigonelline, nicotinic acid, and sucrose in coffee by liquid chromatography-mass spectrometry. Food Chem. 2008, 110, 1030–1035. [Google Scholar] [CrossRef] [PubMed]

- Campa, C.; Ballester, J.F.; Doulbeau, S.; Dussert, S.; Hamon, S.; Noirot, M. Trigonelline and sucrose diversity in wild Coffea species. Food Chem. 2004, 88, 39–43. [Google Scholar] [CrossRef]

- De Castro, R.D.; Marraccini, P. Cytology, biochemistry and molecular changes during coffee fruit development. Braz. J. Plant Physiol. 2006, 18, 175–199. [Google Scholar] [CrossRef]

- Joët, T.; Laffargue, A.; Descroix, F.; Doulbeau, S.; Bertrand, B.; de Kochko, A.; Dussert, S. Influence of environmental factors, wet processing and their interactions on the biochemical composition of green Arabica coffee beans. Food Chem. 2010, 118, 693–701. [Google Scholar] [CrossRef]

- Oliveira, L.S.; Franca, A.S.; Mendonca, J.C.F.; Barros-Junior, B. Proximate composition and fatty acid profile of green and roasted defective coffee beans. LWT-Food Sci. Technol. 2006, 39, 235–239. [Google Scholar] [CrossRef]

- Ramalakshmi, K.; Kubra, I.R.; Rao, L.J.M. Physicochemical characteristics of green coffee: Comparison of graded and defective beans. J. Food Sci. 2007, 72, 333–337. [Google Scholar] [CrossRef] [PubMed]

- Montavon, P.; Mauron, A.F.; Duruz, E. Changes in green coffee protein profiles during roasting. J. Agri. Food Chem. 2003, 51, 2335–2343. [Google Scholar] [CrossRef] [PubMed]

- Charles-bernard, M.; Kraehenbuehl, K.; Rytz, A.; Roberts, D.D. Interactions between volatile and nonvolatile coffee components. 1. Screening of nonvolatile components. J. Agric. Food Chem. 2005, 53, 4417–4425. [Google Scholar] [CrossRef] [PubMed]

- Vasconcelos, A.L.S.; Franca, A.S.; Glória, M.B.A.; Mendonca, J.C.F. A comparative study of chemical attributes and levels of amines in defective green and roasted coffee beans. Food Chem. 2007, 101, 26–32. [Google Scholar] [CrossRef]

- Romijin, D.; Wiseman, S.A.; Scheek, L.M.; de Fouw, N.J.; van Tol, A. A linoleic acid enriched diet increases serum cholesterol esterification by lecithin: Cholesterol acyltransferase in meat-fed rats. Ann. Nutr. Metab. 1998, 42, 244–250. [Google Scholar] [CrossRef]

- Yang, K.; Wu, D.; Ye, X.Q.; Liu, D.H.; Chen, J.C.; Sun, P.L. Characterization of chemical composition of bee pollen in China. J. Agric. Food Chem. 2013, 61, 708–718. [Google Scholar] [CrossRef] [PubMed]

- Martín, M.J.; Pablos, F.; González, A.G.; Valdenebro, M.S.; León-Camacho, M. Fatty acid profiles as discriminant parameters for coffee varieties differentiation. Talanta 2001, 54, 291–297. [Google Scholar] [CrossRef]

- Casal, S.; Mendes, E.; Oliveira, M.B.P.P.; Ferreira, M.A. Roast effects on coffee amino acid enantiomers. Food Chem. 2005, 89, 333–340. [Google Scholar] [CrossRef]

- Cheong, M.W.; Tong, K.H.; Ong, J.J.M.; Liu, S.Q.; Curran, P.; Yu, B. Volatile composition and antioxidant capacity of Arabica coffee. Food Res. Int. 2013, 51, 388–396. [Google Scholar] [CrossRef]

- Gao, B.; Lu, Y.J.; Chen, P.; Yu, L.L. Differentiating organic and conventional sage by chromatographic and mass spectrometry flow injection fingerprints combined with principal component analysis. J. Agric. Food Chem. 2013, 61, 2957–2963. [Google Scholar] [CrossRef] [PubMed]

- Dong, W.J.; Ni, Y.N.; Kokot, S. Differentiation of Mint (Mentha haplocalyx Briq.) from different regions in China using gas and liquid chromatography. J. Sep. Sci. 2015, 38, 402–409. [Google Scholar] [CrossRef] [PubMed]

- Mancha Agresti, P.D.C.; Franca, A.S.; Oliveira, L.S.; Augusti, R. Discrimination between defective and non-defective Brazilian coffee beans by their volatile profile. Food Chem. 2008, 106, 787–796. [Google Scholar] [CrossRef]

- Zielinski, A.A.F.; Haminiuk, C.W.I.; Alberti, A.; Nogueira, A.; Demiate, I.M.; Granato, D. A comparative study of the phenolic compounds and the in vitro antioxidant activity of different Brazilian teas using multivariate statistical techniques. Food Res. Int. 2014, 60, 246–254. [Google Scholar] [CrossRef]

- Mendonca, J.C.F.; Franca, A.S.; Oliveira, L.S.; Nunes, M. Chemical characterization of non-defective and defective green Arabica and Robusta coffees by electrospray ionization-mass spectrometry (ESI-MS). Food Chem. 2008, 111, 490–497. [Google Scholar] [CrossRef] [PubMed]

- Xiao, L.P.; Mjøs, S.A.; Haugsgjerd, B.O. Effieciencies of three common lipid extraction methods evaluated by calculating mass balances of the fatty acids. J. Food Compos. Anal. 2012, 25, 198–207. [Google Scholar] [CrossRef]

- ISO 12966-2. In Animal and Vegetable Fats and Oils—Gas Chromatography of Fatty acid Methyl Esters—Part 2: Preparation of Methyl Esters of Fatty Acids; European Committee for Standardization: Brussels, Belgium, 2011.

- Akiyama, M.; Murakami, K.; Ohtani, N.; Iwatsuki, K.; Sotoyama, K.; Wada, A.; Tokumo, K.; Iwabuchi, H.; Tanaka, K. Analysis of volatile compounds released during the grinding of roasted coffee beans using solid-phase microextraction. J. Agric. Food Chem. 2003, 51, 1961–1969. [Google Scholar] [CrossRef] [PubMed]

- Bicchi, C.; Iori, C.; Rubiolo, P.; Sandra, P. Headspace sorptive extraction (HSSE), stir bar sorptive extraction (SBSE), and solid phase microextraction (SPME) applied to the analysis of roasted Arabica coffee and coffee brew. J. Agric. Food Chem. 2002, 50, 449–459. [Google Scholar] [CrossRef] [PubMed]

- Sample Availability: Samples of the coffee beans are available from the authors.

© 2015 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, W.; Tan, L.; Zhao, J.; Hu, R.; Lu, M. Characterization of Fatty Acid, Amino Acid and Volatile Compound Compositions and Bioactive Components of Seven Coffee (Coffea robusta) Cultivars Grown in Hainan Province, China. Molecules 2015, 20, 16687-16708. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules200916687

Dong W, Tan L, Zhao J, Hu R, Lu M. Characterization of Fatty Acid, Amino Acid and Volatile Compound Compositions and Bioactive Components of Seven Coffee (Coffea robusta) Cultivars Grown in Hainan Province, China. Molecules. 2015; 20(9):16687-16708. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules200916687

Chicago/Turabian StyleDong, Wenjiang, Lehe Tan, Jianping Zhao, Rongsuo Hu, and Minquan Lu. 2015. "Characterization of Fatty Acid, Amino Acid and Volatile Compound Compositions and Bioactive Components of Seven Coffee (Coffea robusta) Cultivars Grown in Hainan Province, China" Molecules 20, no. 9: 16687-16708. https://0-doi-org.brum.beds.ac.uk/10.3390/molecules200916687